How KERS fosters the next generation of wearable tech

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Tech Background

Kinetic Energy Recovery Systems (KERS) have emerged as a groundbreaking technology in the realm of energy harvesting, with significant implications for the future of wearable devices. Originally developed for Formula One racing, KERS has evolved beyond its automotive roots to become a promising solution for sustainable energy generation in various applications, including wearable technology.

The concept of KERS is rooted in the principle of converting kinetic energy, typically lost during deceleration or braking, into usable electrical energy. This technology has undergone substantial refinement since its inception, with early systems focusing on mechanical flywheels and hydraulic accumulators. The progression towards more compact and efficient electrical systems has paved the way for its potential integration into wearable devices.

In the context of wearable technology, KERS represents a paradigm shift in how we approach power management and energy sustainability. Traditional wearables rely heavily on battery technology, which often limits device functionality and user experience due to frequent charging requirements. KERS offers a novel approach by harnessing the wearer's natural movements to generate supplementary power, potentially extending battery life or even enabling self-powered devices.

The evolution of KERS in wearable tech is closely tied to advancements in miniaturization and materials science. Early attempts to incorporate energy harvesting into wearables were hindered by bulky components and low efficiency. However, recent developments in nanotechnology and flexible electronics have opened new avenues for integrating KERS into sleek, comfortable wearable designs.

Key milestones in the adaptation of KERS for wearables include the development of piezoelectric materials capable of converting mechanical stress into electrical energy, the creation of triboelectric nanogenerators that generate electricity from friction, and the refinement of electromagnetic induction systems on a micro-scale. These innovations have collectively pushed the boundaries of what's possible in energy harvesting for wearable devices.

The potential applications of KERS in wearable tech span a wide spectrum, from fitness trackers and smartwatches to medical monitoring devices and augmented reality glasses. By reducing or eliminating the need for external charging, KERS-enabled wearables could offer unprecedented levels of convenience and functionality, particularly in scenarios where continuous operation is critical, such as in healthcare monitoring or in extreme environments.

As we look towards the future, the integration of KERS into wearable technology represents a convergence of sustainability, functionality, and user-centric design. This technology not only promises to address the persistent challenge of power management in wearables but also aligns with broader trends towards renewable energy and reduced environmental impact. The ongoing research and development in this field are setting the stage for a new generation of self-sustaining, energy-efficient wearable devices that could revolutionize how we interact with technology in our daily lives.

The concept of KERS is rooted in the principle of converting kinetic energy, typically lost during deceleration or braking, into usable electrical energy. This technology has undergone substantial refinement since its inception, with early systems focusing on mechanical flywheels and hydraulic accumulators. The progression towards more compact and efficient electrical systems has paved the way for its potential integration into wearable devices.

In the context of wearable technology, KERS represents a paradigm shift in how we approach power management and energy sustainability. Traditional wearables rely heavily on battery technology, which often limits device functionality and user experience due to frequent charging requirements. KERS offers a novel approach by harnessing the wearer's natural movements to generate supplementary power, potentially extending battery life or even enabling self-powered devices.

The evolution of KERS in wearable tech is closely tied to advancements in miniaturization and materials science. Early attempts to incorporate energy harvesting into wearables were hindered by bulky components and low efficiency. However, recent developments in nanotechnology and flexible electronics have opened new avenues for integrating KERS into sleek, comfortable wearable designs.

Key milestones in the adaptation of KERS for wearables include the development of piezoelectric materials capable of converting mechanical stress into electrical energy, the creation of triboelectric nanogenerators that generate electricity from friction, and the refinement of electromagnetic induction systems on a micro-scale. These innovations have collectively pushed the boundaries of what's possible in energy harvesting for wearable devices.

The potential applications of KERS in wearable tech span a wide spectrum, from fitness trackers and smartwatches to medical monitoring devices and augmented reality glasses. By reducing or eliminating the need for external charging, KERS-enabled wearables could offer unprecedented levels of convenience and functionality, particularly in scenarios where continuous operation is critical, such as in healthcare monitoring or in extreme environments.

As we look towards the future, the integration of KERS into wearable technology represents a convergence of sustainability, functionality, and user-centric design. This technology not only promises to address the persistent challenge of power management in wearables but also aligns with broader trends towards renewable energy and reduced environmental impact. The ongoing research and development in this field are setting the stage for a new generation of self-sustaining, energy-efficient wearable devices that could revolutionize how we interact with technology in our daily lives.

Wearable Market Trends

The wearable technology market has been experiencing significant growth and transformation in recent years, driven by advancements in sensor technology, miniaturization, and increased consumer demand for health and fitness tracking devices. This trend is expected to continue, with the global wearable market projected to reach substantial growth in the coming years.

One of the key drivers of this market expansion is the increasing consumer awareness and adoption of health and fitness tracking devices. Smartwatches and fitness bands have become mainstream products, with major tech companies like Apple, Samsung, and Fitbit dominating the market. These devices offer features such as heart rate monitoring, sleep tracking, and activity tracking, catering to the growing health-conscious consumer base.

Another significant trend in the wearable market is the integration of advanced technologies such as artificial intelligence (AI) and machine learning (ML). These technologies enable more sophisticated data analysis and personalized insights, enhancing the value proposition of wearable devices. For instance, AI-powered wearables can provide more accurate health predictions and personalized fitness recommendations based on individual user data.

The healthcare sector is also playing a crucial role in driving the wearable market forward. Medical-grade wearables are gaining traction, with devices capable of monitoring vital signs, detecting early signs of diseases, and even administering medication. This trend is particularly relevant in the context of remote patient monitoring and telemedicine, which have seen accelerated adoption due to the global pandemic.

Emerging form factors and applications are expanding the wearable market beyond traditional wrist-worn devices. Smart clothing, hearables (smart earbuds), and even smart contact lenses are entering the market, offering new ways to integrate technology into daily life. These innovations are opening up new use cases and market segments, further driving the growth of the wearable industry.

The enterprise sector is also showing increased interest in wearable technology, particularly in areas such as workplace safety, productivity monitoring, and hands-free operations. This trend is expected to create new opportunities for wearable device manufacturers and software developers catering to business needs.

As the wearable market continues to evolve, interoperability and data integration are becoming increasingly important. Consumers expect their devices to work seamlessly across different platforms and applications, driving the need for standardization and improved connectivity solutions. This trend is likely to shape the development of future wearable technologies and ecosystems.

One of the key drivers of this market expansion is the increasing consumer awareness and adoption of health and fitness tracking devices. Smartwatches and fitness bands have become mainstream products, with major tech companies like Apple, Samsung, and Fitbit dominating the market. These devices offer features such as heart rate monitoring, sleep tracking, and activity tracking, catering to the growing health-conscious consumer base.

Another significant trend in the wearable market is the integration of advanced technologies such as artificial intelligence (AI) and machine learning (ML). These technologies enable more sophisticated data analysis and personalized insights, enhancing the value proposition of wearable devices. For instance, AI-powered wearables can provide more accurate health predictions and personalized fitness recommendations based on individual user data.

The healthcare sector is also playing a crucial role in driving the wearable market forward. Medical-grade wearables are gaining traction, with devices capable of monitoring vital signs, detecting early signs of diseases, and even administering medication. This trend is particularly relevant in the context of remote patient monitoring and telemedicine, which have seen accelerated adoption due to the global pandemic.

Emerging form factors and applications are expanding the wearable market beyond traditional wrist-worn devices. Smart clothing, hearables (smart earbuds), and even smart contact lenses are entering the market, offering new ways to integrate technology into daily life. These innovations are opening up new use cases and market segments, further driving the growth of the wearable industry.

The enterprise sector is also showing increased interest in wearable technology, particularly in areas such as workplace safety, productivity monitoring, and hands-free operations. This trend is expected to create new opportunities for wearable device manufacturers and software developers catering to business needs.

As the wearable market continues to evolve, interoperability and data integration are becoming increasingly important. Consumers expect their devices to work seamlessly across different platforms and applications, driving the need for standardization and improved connectivity solutions. This trend is likely to shape the development of future wearable technologies and ecosystems.

KERS Challenges

Kinetic Energy Recovery Systems (KERS) face several significant challenges in their integration with wearable technology. One of the primary obstacles is miniaturization. While KERS has been successfully implemented in larger applications such as Formula 1 racing cars, scaling down the technology to fit comfortably and unobtrusively in wearable devices presents a considerable engineering challenge. The components, including the flywheel, generator, and associated electronics, need to be drastically reduced in size without compromising efficiency or safety.

Power density is another critical issue. Wearable devices require high energy output in a compact form factor. Current KERS technologies struggle to achieve the necessary power-to-weight ratio that would make them viable for everyday wearable applications. This challenge is compounded by the need for the system to operate effectively under varying conditions of human movement, which are less predictable and consistent than those found in automotive applications.

Durability and reliability pose additional hurdles. Wearable devices are subjected to constant movement, impacts, and environmental stresses. KERS components, particularly the high-speed rotating parts, must be engineered to withstand these conditions while maintaining performance and safety. The system needs to be robust enough to function reliably over extended periods without frequent maintenance or replacement.

Heat management is a significant concern in KERS for wearables. The energy conversion process generates heat, which can be uncomfortable or even dangerous when in close proximity to the human body. Developing effective cooling mechanisms that don't add significant bulk or weight to the device is a complex engineering task.

User safety is paramount and presents its own set of challenges. The high-speed rotating components in KERS systems pose potential risks if not properly contained. Ensuring fail-safe mechanisms and protective enclosures that can withstand accidental impacts or drops without compromising the integrity of the system is crucial.

Integration with existing wearable ecosystems presents another layer of complexity. KERS must be designed to work seamlessly with other components of wearable devices, such as sensors, processors, and displays. This requires careful consideration of power management, data communication, and overall system architecture to ensure that the KERS enhances rather than hinders the functionality of the wearable device.

Lastly, cost-effectiveness remains a significant barrier to widespread adoption. The complex components and precision engineering required for KERS currently make it prohibitively expensive for mass-market wearable applications. Developing manufacturing processes and materials that can reduce costs while maintaining performance is essential for the technology to gain traction in the consumer wearables market.

Power density is another critical issue. Wearable devices require high energy output in a compact form factor. Current KERS technologies struggle to achieve the necessary power-to-weight ratio that would make them viable for everyday wearable applications. This challenge is compounded by the need for the system to operate effectively under varying conditions of human movement, which are less predictable and consistent than those found in automotive applications.

Durability and reliability pose additional hurdles. Wearable devices are subjected to constant movement, impacts, and environmental stresses. KERS components, particularly the high-speed rotating parts, must be engineered to withstand these conditions while maintaining performance and safety. The system needs to be robust enough to function reliably over extended periods without frequent maintenance or replacement.

Heat management is a significant concern in KERS for wearables. The energy conversion process generates heat, which can be uncomfortable or even dangerous when in close proximity to the human body. Developing effective cooling mechanisms that don't add significant bulk or weight to the device is a complex engineering task.

User safety is paramount and presents its own set of challenges. The high-speed rotating components in KERS systems pose potential risks if not properly contained. Ensuring fail-safe mechanisms and protective enclosures that can withstand accidental impacts or drops without compromising the integrity of the system is crucial.

Integration with existing wearable ecosystems presents another layer of complexity. KERS must be designed to work seamlessly with other components of wearable devices, such as sensors, processors, and displays. This requires careful consideration of power management, data communication, and overall system architecture to ensure that the KERS enhances rather than hinders the functionality of the wearable device.

Lastly, cost-effectiveness remains a significant barrier to widespread adoption. The complex components and precision engineering required for KERS currently make it prohibitively expensive for mass-market wearable applications. Developing manufacturing processes and materials that can reduce costs while maintaining performance is essential for the technology to gain traction in the consumer wearables market.

Current KERS Solutions

01 Energy recovery and storage systems in vehicles

KERS technology is implemented in vehicles to recover and store kinetic energy during braking or deceleration. This stored energy can then be used to provide additional power during acceleration, improving overall vehicle efficiency and performance. The system typically includes components for energy capture, storage, and release.- KERS integration in vehicles: Kinetic Energy Recovery Systems (KERS) are being integrated into various types of vehicles, including cars and motorcycles. These systems capture and store kinetic energy during braking, which can then be used to provide additional power during acceleration. This technology improves fuel efficiency and reduces emissions in both conventional and hybrid vehicles.

- Energy storage mechanisms in KERS: KERS utilizes different energy storage mechanisms to capture and reuse kinetic energy. Common storage methods include flywheels, hydraulic accumulators, and electric batteries. Each method has its advantages in terms of energy density, response time, and integration complexity. The choice of storage mechanism depends on the specific application and vehicle type.

- Control systems for KERS: Advanced control systems are crucial for optimizing KERS performance. These systems manage energy capture, storage, and release based on various factors such as vehicle speed, driver input, and road conditions. Intelligent control algorithms ensure seamless integration with the vehicle's powertrain and maximize energy efficiency gains.

- KERS applications in heavy vehicles: KERS technology is being adapted for use in heavy vehicles such as trucks and buses. In these applications, the system can recover significant amounts of energy during frequent stops and downhill operations. This recovered energy can then be used to assist in acceleration or power auxiliary systems, leading to substantial fuel savings in commercial fleets.

- Innovations in KERS efficiency: Ongoing research focuses on improving the overall efficiency of KERS. This includes developing more efficient energy conversion methods, reducing system weight, and minimizing energy losses during storage and retrieval. Advanced materials and manufacturing techniques are being explored to enhance the performance and durability of KERS components.

02 Hydraulic and pneumatic KERS

Some KERS designs utilize hydraulic or pneumatic systems for energy recovery and storage. These systems use fluid or compressed air to store and release energy, offering advantages in certain applications such as heavy-duty vehicles or industrial equipment. The technology can provide rapid energy storage and release capabilities.Expand Specific Solutions03 Electric and hybrid KERS

Electric and hybrid KERS systems use electric motors/generators and energy storage devices like batteries or supercapacitors. These systems are commonly used in electric and hybrid vehicles, as well as in motorsports. They offer high efficiency and the ability to integrate with existing electric powertrains.Expand Specific Solutions04 KERS integration with powertrain and control systems

Advanced KERS implementations focus on seamless integration with vehicle powertrains and control systems. This includes sophisticated control algorithms, power management strategies, and integration with other vehicle systems such as traction control and stability management to optimize energy recovery and utilization.Expand Specific Solutions05 Novel KERS applications and improvements

Ongoing research and development in KERS technology explores novel applications and improvements. This includes the use of KERS in non-automotive applications, such as industrial machinery or renewable energy systems, as well as enhancements to existing KERS designs to improve efficiency, reduce costs, or increase energy storage capacity.Expand Specific Solutions

Key KERS Players

The KERS (Kinetic Energy Recovery System) technology in wearable tech is in its early development stage, with a growing market potential as the wearable industry expands. The competitive landscape is characterized by a mix of established tech giants and innovative startups. Companies like Samsung, Apple, and Huawei are leveraging their expertise in consumer electronics to integrate KERS into wearables. Meanwhile, specialized firms such as HTC and Quasistatics are focusing on developing advanced KERS solutions. The technology's maturity varies, with some companies at the research stage, while others are closer to commercial applications. Academic institutions like the National University of Singapore and Huazhong University of Science & Technology are contributing to KERS advancements, indicating a collaborative ecosystem between industry and academia.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei's KERS implementation for wearables centers on their "Energy Harvesting" technology. They have developed a multi-source energy recovery system that combines kinetic energy with thermal and solar energy harvesting[2]. This system uses advanced microelectromechanical systems (MEMS) to capture energy from body movements, ambient heat, and light. Huawei's approach includes a flexible, thin-film energy harvesting layer that can be integrated into various wearable form factors, from smartwatches to smart clothing[4]. The company claims this technology can increase battery life by up to 50% in optimal conditions. Additionally, Huawei is exploring the use of AI algorithms to optimize energy harvesting and usage based on user activity patterns and environmental conditions[6].

Strengths: Multi-source energy harvesting for improved efficiency, adaptable to various wearable formats. Weaknesses: Complexity of integrating multiple energy sources, potential higher costs.

Google LLC

Technical Solution: Google's approach to KERS in wearable tech is centered around their Project Jacquard platform, which integrates smart textiles with energy harvesting capabilities. The company has developed conductive threads that can be woven into fabrics, creating a large surface area for kinetic energy capture[7]. This technology allows for energy harvesting from a wider range of body movements compared to traditional wearable devices. Google has also patented a "Gesture Recognition Using Ambient Light" system that could potentially be combined with KERS to create more energy-efficient gesture controls in wearables[8]. The company is exploring the use of machine learning algorithms to optimize energy harvesting based on user movement patterns and to predict energy needs, potentially leading to more efficient power management in wearable devices[9].

Strengths: Large-scale energy harvesting potential through smart textiles, innovative gesture recognition integration. Weaknesses: Challenges in mass production of smart textiles, potential durability issues with conductive threads.

KERS Core Innovations

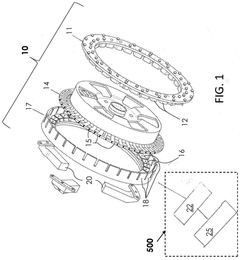

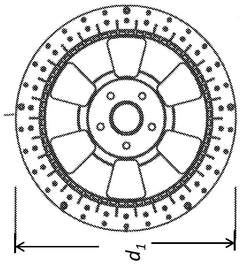

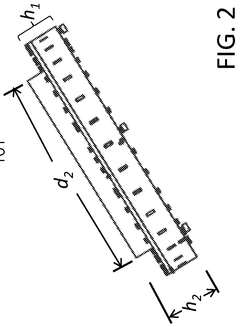

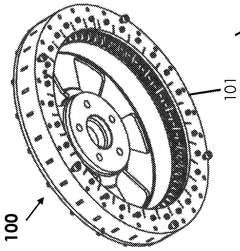

Powering and recharging long range electric vehicles

PatentWO2024263226A1

Innovation

- The Grayson Kinetic Recharger (GKR) system employs Advanced Kinetic Energy Recovery Systems (AKERS) with modular, scalable designs, including Center Hub, Rear Hub, and Hubless Tire kinetic rechargers, utilizing multiple redundant generators to convert kinetic energy into electricity, storing it in ultracapacitors for extended vehicle range without the need for large batteries.

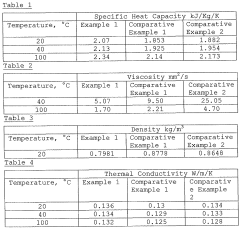

Lubricating composition

PatentWO2011113851A1

Innovation

- A lubricating composition comprising a base oil (such as mineral, synthetic, or vegetable oils) with specific heat capacity and kinematic viscosity properties, along with antioxidants and minimal water content, is used for cooling and insulating electric batteries or motors in KERS and hybrid vehicles.

KERS Energy Efficiency

Kinetic Energy Recovery Systems (KERS) have emerged as a promising technology for enhancing energy efficiency in wearable devices. By harnessing the kinetic energy generated through human movement, KERS offers a sustainable solution to power the next generation of wearable tech. This innovative approach addresses one of the most significant challenges in wearable technology: limited battery life.

KERS operates on the principle of converting mechanical energy into electrical energy. In the context of wearables, this translates to capturing the energy produced by the wearer's movements, such as walking, running, or even subtle gestures. This captured energy is then converted and stored for later use, effectively extending the device's operational time between charges.

The efficiency of KERS in wearable tech is particularly noteworthy. Studies have shown that KERS can recover up to 70% of the kinetic energy generated by human movement, depending on the specific design and implementation. This high recovery rate significantly reduces the reliance on traditional charging methods, making wearables more convenient and environmentally friendly.

One of the key advantages of KERS in wearables is its ability to provide continuous, low-level power generation. This is especially beneficial for devices that require constant, low-power operation, such as fitness trackers or health monitoring devices. By maintaining a steady trickle of power, KERS can keep these devices operational for extended periods without the need for frequent charging.

Moreover, KERS technology aligns well with the trend towards miniaturization in wearable tech. As devices become smaller and more integrated into everyday items, traditional battery solutions become less practical. KERS offers a compact, lightweight alternative that can be seamlessly incorporated into various wearable form factors without significantly increasing bulk or weight.

The energy efficiency of KERS also extends to its environmental impact. By reducing the frequency of charging and potentially decreasing the size of batteries required, KERS-enabled wearables can contribute to a reduction in electronic waste and energy consumption associated with device charging. This aligns with the growing demand for sustainable technology solutions in the consumer electronics market.

As KERS technology continues to evolve, its energy efficiency is expected to improve further. Ongoing research focuses on optimizing energy conversion rates, reducing energy losses in the system, and developing more sophisticated energy storage solutions. These advancements promise to push the boundaries of what's possible in wearable tech, potentially leading to devices that can operate indefinitely on harvested kinetic energy alone.

KERS operates on the principle of converting mechanical energy into electrical energy. In the context of wearables, this translates to capturing the energy produced by the wearer's movements, such as walking, running, or even subtle gestures. This captured energy is then converted and stored for later use, effectively extending the device's operational time between charges.

The efficiency of KERS in wearable tech is particularly noteworthy. Studies have shown that KERS can recover up to 70% of the kinetic energy generated by human movement, depending on the specific design and implementation. This high recovery rate significantly reduces the reliance on traditional charging methods, making wearables more convenient and environmentally friendly.

One of the key advantages of KERS in wearables is its ability to provide continuous, low-level power generation. This is especially beneficial for devices that require constant, low-power operation, such as fitness trackers or health monitoring devices. By maintaining a steady trickle of power, KERS can keep these devices operational for extended periods without the need for frequent charging.

Moreover, KERS technology aligns well with the trend towards miniaturization in wearable tech. As devices become smaller and more integrated into everyday items, traditional battery solutions become less practical. KERS offers a compact, lightweight alternative that can be seamlessly incorporated into various wearable form factors without significantly increasing bulk or weight.

The energy efficiency of KERS also extends to its environmental impact. By reducing the frequency of charging and potentially decreasing the size of batteries required, KERS-enabled wearables can contribute to a reduction in electronic waste and energy consumption associated with device charging. This aligns with the growing demand for sustainable technology solutions in the consumer electronics market.

As KERS technology continues to evolve, its energy efficiency is expected to improve further. Ongoing research focuses on optimizing energy conversion rates, reducing energy losses in the system, and developing more sophisticated energy storage solutions. These advancements promise to push the boundaries of what's possible in wearable tech, potentially leading to devices that can operate indefinitely on harvested kinetic energy alone.

KERS Safety Standards

As the adoption of Kinetic Energy Recovery Systems (KERS) in wearable technology continues to grow, the development and implementation of comprehensive safety standards become increasingly crucial. These standards are essential to ensure the safe operation of KERS-enabled devices and protect users from potential risks associated with energy harvesting and storage mechanisms.

One of the primary safety concerns for KERS in wearable tech is the management of thermal energy. The conversion of kinetic energy to electrical energy can generate heat, which must be effectively dissipated to prevent overheating and potential skin irritation or burns. Safety standards should specify maximum temperature thresholds for device surfaces in contact with the skin and require manufacturers to implement adequate thermal management systems.

Electrical safety is another critical aspect that KERS safety standards must address. As these systems involve the generation and storage of electrical energy, proper insulation and protection against electrical shocks are paramount. Standards should define acceptable voltage and current limits for wearable devices, as well as requirements for electrical isolation and grounding to prevent accidental discharge or short circuits.

The mechanical components of KERS in wearables also require safety considerations. Moving parts involved in energy harvesting, such as oscillating weights or miniature turbines, must be securely contained to prevent injury. Safety standards should outline specifications for the durability and containment of these components, ensuring they can withstand the rigors of daily wear and potential impacts.

Energy storage is a key element of KERS technology, typically involving batteries or capacitors. Safety standards must address the potential risks associated with these storage devices, including guidelines for preventing overcharging, deep discharging, and thermal runaway. Additionally, standards should specify requirements for the safe disposal and recycling of energy storage components to minimize environmental impact.

Electromagnetic compatibility (EMC) is another crucial area for KERS safety standards. As these devices generate and store electrical energy, they must not interfere with other electronic devices, particularly medical implants like pacemakers. Standards should define acceptable levels of electromagnetic emissions and immunity requirements for KERS-enabled wearables.

Given the close proximity of KERS wearables to the human body, biocompatibility standards are essential. These should cover the materials used in device construction, ensuring they do not cause allergic reactions or long-term health effects from prolonged skin contact. Standards may also need to address potential interactions between KERS devices and medical treatments, such as MRI scans or defibrillators.

As KERS technology evolves, safety standards must remain dynamic and adaptable. Regular reviews and updates will be necessary to keep pace with technological advancements and emerging safety concerns. Collaboration between industry stakeholders, regulatory bodies, and research institutions will be crucial in developing and maintaining comprehensive safety standards that foster innovation while prioritizing user safety in the next generation of KERS-enabled wearable technology.

One of the primary safety concerns for KERS in wearable tech is the management of thermal energy. The conversion of kinetic energy to electrical energy can generate heat, which must be effectively dissipated to prevent overheating and potential skin irritation or burns. Safety standards should specify maximum temperature thresholds for device surfaces in contact with the skin and require manufacturers to implement adequate thermal management systems.

Electrical safety is another critical aspect that KERS safety standards must address. As these systems involve the generation and storage of electrical energy, proper insulation and protection against electrical shocks are paramount. Standards should define acceptable voltage and current limits for wearable devices, as well as requirements for electrical isolation and grounding to prevent accidental discharge or short circuits.

The mechanical components of KERS in wearables also require safety considerations. Moving parts involved in energy harvesting, such as oscillating weights or miniature turbines, must be securely contained to prevent injury. Safety standards should outline specifications for the durability and containment of these components, ensuring they can withstand the rigors of daily wear and potential impacts.

Energy storage is a key element of KERS technology, typically involving batteries or capacitors. Safety standards must address the potential risks associated with these storage devices, including guidelines for preventing overcharging, deep discharging, and thermal runaway. Additionally, standards should specify requirements for the safe disposal and recycling of energy storage components to minimize environmental impact.

Electromagnetic compatibility (EMC) is another crucial area for KERS safety standards. As these devices generate and store electrical energy, they must not interfere with other electronic devices, particularly medical implants like pacemakers. Standards should define acceptable levels of electromagnetic emissions and immunity requirements for KERS-enabled wearables.

Given the close proximity of KERS wearables to the human body, biocompatibility standards are essential. These should cover the materials used in device construction, ensuring they do not cause allergic reactions or long-term health effects from prolonged skin contact. Standards may also need to address potential interactions between KERS devices and medical treatments, such as MRI scans or defibrillators.

As KERS technology evolves, safety standards must remain dynamic and adaptable. Regular reviews and updates will be necessary to keep pace with technological advancements and emerging safety concerns. Collaboration between industry stakeholders, regulatory bodies, and research institutions will be crucial in developing and maintaining comprehensive safety standards that foster innovation while prioritizing user safety in the next generation of KERS-enabled wearable technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!