How Liquid Cooling Meets 1 kW+ Chip Heat Flux Without Flow Instability?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Power Chip Cooling Background and Objectives

The evolution of computing technology has consistently driven the need for more advanced thermal management solutions. Since the 1960s, chip power densities have steadily increased, following Moore's Law, with transistor counts doubling approximately every two years. This progression has led to today's high-performance computing systems that generate unprecedented heat fluxes exceeding 1 kW/cm². Traditional air cooling methods, which dominated the industry until the early 2000s, have reached their practical limits at approximately 150 W/cm².

Liquid cooling emerged as the next frontier in thermal management, offering significantly higher heat transfer coefficients and thermal capacities compared to air. The transition began with indirect liquid cooling systems using cold plates, followed by more advanced direct liquid cooling techniques such as single-phase and two-phase cooling. This evolution has been driven by demands from data centers, artificial intelligence accelerators, and high-performance computing applications where computational density continues to increase exponentially.

Current state-of-the-art electronic components, particularly in AI and supercomputing applications, generate heat fluxes approaching or exceeding 1 kW/cm². This represents a critical threshold where even advanced liquid cooling solutions face significant challenges, particularly regarding flow instability. Flow instability manifests as pressure fluctuations, uneven cooling, and potential system failure, becoming more pronounced as heat flux increases.

The primary objective of current research is to develop liquid cooling technologies capable of reliably managing 1 kW+ chip heat fluxes while maintaining flow stability across the entire cooling system. This requires innovations in multiple domains: coolant chemistry, microchannel design, surface engineering, and system-level integration. The goal extends beyond merely removing heat to doing so uniformly, efficiently, and reliably under varying operational conditions.

Secondary objectives include minimizing pumping power requirements, reducing system complexity, ensuring long-term reliability, and maintaining compatibility with existing manufacturing processes. Energy efficiency has become increasingly important as data centers now consume approximately 1-2% of global electricity, with cooling representing 30-40% of that energy usage.

The technological roadmap aims to achieve stable cooling solutions for 2 kW/cm² by 2025 and 5 kW/cm² by 2030, aligning with projected increases in computational density. Success in this domain will directly enable the next generation of high-performance computing systems, particularly those focused on artificial intelligence, scientific computing, and advanced graphics processing, where thermal limitations currently represent a primary constraint on performance scaling.

Liquid cooling emerged as the next frontier in thermal management, offering significantly higher heat transfer coefficients and thermal capacities compared to air. The transition began with indirect liquid cooling systems using cold plates, followed by more advanced direct liquid cooling techniques such as single-phase and two-phase cooling. This evolution has been driven by demands from data centers, artificial intelligence accelerators, and high-performance computing applications where computational density continues to increase exponentially.

Current state-of-the-art electronic components, particularly in AI and supercomputing applications, generate heat fluxes approaching or exceeding 1 kW/cm². This represents a critical threshold where even advanced liquid cooling solutions face significant challenges, particularly regarding flow instability. Flow instability manifests as pressure fluctuations, uneven cooling, and potential system failure, becoming more pronounced as heat flux increases.

The primary objective of current research is to develop liquid cooling technologies capable of reliably managing 1 kW+ chip heat fluxes while maintaining flow stability across the entire cooling system. This requires innovations in multiple domains: coolant chemistry, microchannel design, surface engineering, and system-level integration. The goal extends beyond merely removing heat to doing so uniformly, efficiently, and reliably under varying operational conditions.

Secondary objectives include minimizing pumping power requirements, reducing system complexity, ensuring long-term reliability, and maintaining compatibility with existing manufacturing processes. Energy efficiency has become increasingly important as data centers now consume approximately 1-2% of global electricity, with cooling representing 30-40% of that energy usage.

The technological roadmap aims to achieve stable cooling solutions for 2 kW/cm² by 2025 and 5 kW/cm² by 2030, aligning with projected increases in computational density. Success in this domain will directly enable the next generation of high-performance computing systems, particularly those focused on artificial intelligence, scientific computing, and advanced graphics processing, where thermal limitations currently represent a primary constraint on performance scaling.

Market Demand Analysis for 1kW+ Thermal Solutions

The demand for 1kW+ thermal solutions is experiencing unprecedented growth, primarily driven by the rapid advancement in high-performance computing systems. Data centers, which form the backbone of cloud computing, AI training, and scientific research, are witnessing a significant increase in power density as chip manufacturers continue to pack more transistors into smaller spaces. According to recent market analyses, the global data center cooling market is projected to reach $20 billion by 2025, with liquid cooling solutions accounting for approximately 30% of this market.

The emergence of AI accelerators and specialized computing hardware has dramatically altered the thermal management landscape. These chips, designed for intensive computational tasks, often operate at power densities exceeding 1kW per chip, creating thermal challenges that traditional air cooling systems cannot adequately address. Industry reports indicate that over 65% of hyperscale data center operators are actively exploring or implementing advanced liquid cooling technologies to manage these extreme heat loads.

Telecommunications and edge computing represent another significant market segment driving demand for high-performance cooling solutions. With the rollout of 5G networks and the increasing deployment of edge computing infrastructure, compact yet powerful computing systems are being installed in diverse environments, many of which lack traditional data center cooling infrastructure. This has created a $5 billion market opportunity for specialized thermal management solutions capable of handling high heat fluxes in constrained spaces.

The automotive and aerospace sectors are also emerging as important markets for advanced cooling technologies. Electric vehicle manufacturers are developing increasingly powerful onboard computing systems for autonomous driving capabilities, while aerospace companies require reliable cooling for mission-critical avionics. These applications demand cooling solutions that can handle high heat fluxes while maintaining exceptional reliability under varying environmental conditions.

From a geographical perspective, North America currently leads the market for advanced thermal solutions, accounting for approximately 40% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 18% annually, driven by rapid data center expansion in China, Japan, and Singapore. European demand is also substantial, particularly in countries with strong high-performance computing and research sectors.

The economic implications of effective thermal management extend beyond the immediate hardware costs. Data center operators estimate that cooling accounts for 35-40% of their operational expenses. Solutions that can efficiently manage 1kW+ heat fluxes while reducing energy consumption represent a compelling value proposition, with potential return on investment periods of less than two years in many applications.

The emergence of AI accelerators and specialized computing hardware has dramatically altered the thermal management landscape. These chips, designed for intensive computational tasks, often operate at power densities exceeding 1kW per chip, creating thermal challenges that traditional air cooling systems cannot adequately address. Industry reports indicate that over 65% of hyperscale data center operators are actively exploring or implementing advanced liquid cooling technologies to manage these extreme heat loads.

Telecommunications and edge computing represent another significant market segment driving demand for high-performance cooling solutions. With the rollout of 5G networks and the increasing deployment of edge computing infrastructure, compact yet powerful computing systems are being installed in diverse environments, many of which lack traditional data center cooling infrastructure. This has created a $5 billion market opportunity for specialized thermal management solutions capable of handling high heat fluxes in constrained spaces.

The automotive and aerospace sectors are also emerging as important markets for advanced cooling technologies. Electric vehicle manufacturers are developing increasingly powerful onboard computing systems for autonomous driving capabilities, while aerospace companies require reliable cooling for mission-critical avionics. These applications demand cooling solutions that can handle high heat fluxes while maintaining exceptional reliability under varying environmental conditions.

From a geographical perspective, North America currently leads the market for advanced thermal solutions, accounting for approximately 40% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 18% annually, driven by rapid data center expansion in China, Japan, and Singapore. European demand is also substantial, particularly in countries with strong high-performance computing and research sectors.

The economic implications of effective thermal management extend beyond the immediate hardware costs. Data center operators estimate that cooling accounts for 35-40% of their operational expenses. Solutions that can efficiently manage 1kW+ heat fluxes while reducing energy consumption represent a compelling value proposition, with potential return on investment periods of less than two years in many applications.

Current Liquid Cooling Technologies and Challenges

Liquid cooling has emerged as a critical technology for managing the thermal challenges posed by high-performance computing systems. Current single-phase liquid cooling solutions typically employ water or dielectric fluids circulated through cold plates or microchannels to absorb and transport heat away from chips. These systems can handle heat fluxes ranging from 100-500 W/cm², significantly outperforming traditional air cooling methods which are limited to approximately 100 W/cm². However, as chip power densities approach and exceed 1 kW/cm², conventional single-phase liquid cooling faces substantial limitations.

Two-phase cooling technologies, including flow boiling and jet impingement, represent the current state-of-the-art approaches for ultra-high heat flux management. Flow boiling leverages the latent heat of vaporization, potentially handling heat fluxes up to 700-800 W/cm². Meanwhile, jet impingement cooling, which directs high-velocity fluid jets onto hot surfaces, has demonstrated capabilities approaching 1 kW/cm² in laboratory settings. These technologies benefit from the enhanced heat transfer coefficients associated with phase change phenomena.

Despite these advancements, significant challenges persist in scaling liquid cooling solutions to reliably manage 1 kW+ chip heat fluxes. Flow instability represents one of the most critical barriers, manifesting as pressure fluctuations, flow maldistribution, and premature critical heat flux (CHF) conditions. In two-phase systems, these instabilities are exacerbated by rapid bubble formation and expansion, creating unpredictable flow patterns that can lead to localized dryout and potential thermal runaway scenarios.

Material limitations further constrain current cooling solutions. Thermal interface materials (TIMs) often create bottlenecks in the heat transfer pathway, with thermal conductivities typically below 10 W/m·K. Additionally, corrosion and erosion concerns limit the selection of compatible materials for long-term reliability, particularly in systems using water as the working fluid.

Energy efficiency presents another significant challenge, as pumping power requirements increase non-linearly with heat flux. Current high-performance liquid cooling systems may consume 15-30% of the total system power budget, creating diminishing returns as cooling demands intensify. This power overhead directly impacts data center PUE (Power Usage Effectiveness) metrics and operational costs.

Manufacturing complexity and cost considerations also impede widespread adoption of advanced liquid cooling technologies. Microchannel cold plates with optimized geometries for 1 kW+ heat fluxes require precision manufacturing techniques with tight tolerances, driving up production costs. Integration challenges with existing chip packaging technologies further complicate implementation, particularly for heterogeneous computing architectures with varying thermal profiles across the chip surface.

Two-phase cooling technologies, including flow boiling and jet impingement, represent the current state-of-the-art approaches for ultra-high heat flux management. Flow boiling leverages the latent heat of vaporization, potentially handling heat fluxes up to 700-800 W/cm². Meanwhile, jet impingement cooling, which directs high-velocity fluid jets onto hot surfaces, has demonstrated capabilities approaching 1 kW/cm² in laboratory settings. These technologies benefit from the enhanced heat transfer coefficients associated with phase change phenomena.

Despite these advancements, significant challenges persist in scaling liquid cooling solutions to reliably manage 1 kW+ chip heat fluxes. Flow instability represents one of the most critical barriers, manifesting as pressure fluctuations, flow maldistribution, and premature critical heat flux (CHF) conditions. In two-phase systems, these instabilities are exacerbated by rapid bubble formation and expansion, creating unpredictable flow patterns that can lead to localized dryout and potential thermal runaway scenarios.

Material limitations further constrain current cooling solutions. Thermal interface materials (TIMs) often create bottlenecks in the heat transfer pathway, with thermal conductivities typically below 10 W/m·K. Additionally, corrosion and erosion concerns limit the selection of compatible materials for long-term reliability, particularly in systems using water as the working fluid.

Energy efficiency presents another significant challenge, as pumping power requirements increase non-linearly with heat flux. Current high-performance liquid cooling systems may consume 15-30% of the total system power budget, creating diminishing returns as cooling demands intensify. This power overhead directly impacts data center PUE (Power Usage Effectiveness) metrics and operational costs.

Manufacturing complexity and cost considerations also impede widespread adoption of advanced liquid cooling technologies. Microchannel cold plates with optimized geometries for 1 kW+ heat fluxes require precision manufacturing techniques with tight tolerances, driving up production costs. Integration challenges with existing chip packaging technologies further complicate implementation, particularly for heterogeneous computing architectures with varying thermal profiles across the chip surface.

Current Flow Stability Solutions for High Heat Flux

01 High heat flux cooling solutions for electronics

Advanced liquid cooling systems designed specifically for high-performance electronics that generate significant heat flux. These systems employ specialized heat exchangers, microchannels, and coolant circulation techniques to efficiently remove heat from densely packed electronic components. The cooling solutions are optimized to handle extreme thermal loads while maintaining optimal operating temperatures for sensitive electronic devices.- High heat flux cooling solutions for electronics: Advanced liquid cooling systems designed specifically for high-performance electronic components that generate significant heat flux. These systems utilize specialized heat exchangers, microchannels, and optimized coolant flow to efficiently remove heat from densely packed electronic components such as processors, power modules, and data center equipment. The designs focus on maximizing thermal conductivity at the interface between the heat source and cooling medium to handle extreme heat flux conditions.

- Two-phase cooling systems for enhanced heat transfer: Cooling systems that leverage phase change phenomena (liquid to vapor) to significantly increase heat flux dissipation capabilities. These systems utilize the latent heat of vaporization to absorb large amounts of thermal energy at nearly constant temperatures. Implementations include various boiling and condensation mechanisms, specialized evaporator designs, and working fluid optimizations to manage high heat flux scenarios while maintaining stable operation across varying thermal loads.

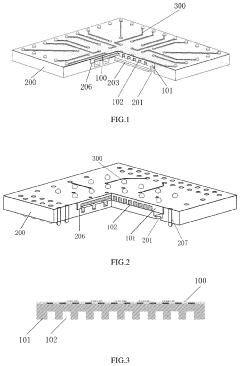

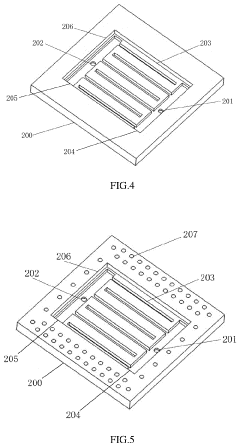

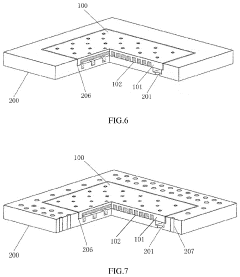

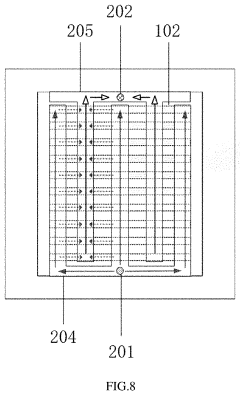

- Microchannel and microjet cooling technologies: Miniaturized liquid cooling architectures featuring microscale channels or jet impingement designs that significantly enhance heat transfer coefficients. These systems maximize surface area contact between coolant and heat source while optimizing fluid dynamics to target hotspots. The reduced hydraulic diameter of microchannels and the direct impingement of microjets allow for extremely efficient heat removal from concentrated heat flux sources while minimizing the required coolant volume and system footprint.

- Intelligent thermal management systems: Advanced cooling solutions incorporating sensors, controllers, and adaptive algorithms to dynamically respond to changing heat flux conditions. These systems monitor thermal parameters in real-time and automatically adjust coolant flow rates, distribution patterns, or cooling modes to optimize performance. The intelligent control enables more efficient operation by directing cooling capacity precisely where and when needed, preventing thermal throttling while minimizing energy consumption and acoustic noise.

- Novel coolant formulations and flow optimization: Specialized liquid coolants and flow management techniques designed to enhance heat flux handling capabilities. These innovations include nanofluids with suspended particles to improve thermal conductivity, dielectric coolants for direct contact with electronics, and engineered flow patterns to minimize boundary layer formation. Advanced manifold designs, flow distributors, and pumping systems ensure uniform coolant distribution across heat exchange surfaces, preventing localized hotspots even under extreme heat flux conditions.

02 Two-phase cooling systems for enhanced heat transfer

Cooling systems that utilize phase change phenomena to improve heat flux management. These systems leverage the latent heat of vaporization by allowing the coolant to transition between liquid and vapor phases, significantly increasing heat transfer efficiency. The designs incorporate specialized evaporators, condensers, and flow management components to control the phase change process and maintain stable operation under varying heat loads.Expand Specific Solutions03 Microchannel and microstructure cooling technologies

Liquid cooling systems featuring microscale channels and structures to maximize surface area for heat exchange. These designs incorporate precisely engineered microchannels, fins, and surface treatments to enhance coolant-surface interaction and boundary layer effects. The miniaturized cooling structures enable direct integration with heat-generating components, minimizing thermal resistance and improving overall system efficiency for high heat flux applications.Expand Specific Solutions04 Intelligent thermal management systems

Advanced cooling solutions incorporating sensors, controllers, and adaptive algorithms to dynamically manage heat flux. These systems monitor thermal conditions in real-time and automatically adjust coolant flow rates, distribution patterns, and other parameters to optimize cooling performance. The intelligent control enables preemptive thermal management, power optimization, and protection against thermal runaway in high-performance applications.Expand Specific Solutions05 Novel coolant formulations and flow enhancement techniques

Specialized liquid coolants and flow enhancement methods designed to improve heat flux handling capabilities. These innovations include nanofluid coolants with suspended particles, engineered surface wettability, and advanced flow distribution techniques. The formulations and methods work together to reduce thermal boundary resistance, enhance convective heat transfer, and improve the overall thermal conductivity of the cooling system for demanding applications.Expand Specific Solutions

Key Players in Advanced Thermal Management Industry

The liquid cooling market for high-power chips is transitioning from early adoption to growth phase, with increasing demand driven by AI and HPC applications requiring 1 kW+ heat flux solutions. Market size is expanding rapidly as data centers upgrade thermal management systems to handle next-generation processors. Technology maturity varies across players: IBM, Intel, and NVIDIA lead with advanced two-phase cooling solutions; Huawei and Dell are advancing with direct-to-chip liquid cooling; while specialized firms like Cooler Master and Strategic Thermal Labs focus on innovative approaches to flow stability. Academic-industry partnerships (Zhejiang University, ITRI) are accelerating development of novel microfluidic designs that prevent flow instabilities at extreme heat fluxes, positioning this technology for mainstream adoption within 2-3 years.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced two-phase liquid cooling solution specifically designed to address 1 kW+ chip heat flux challenges. Their system utilizes a combination of direct liquid cooling with engineered microchannels etched directly into silicon interposers that sit beneath high-performance chips. This approach creates a highly efficient thermal interface with minimal thermal resistance. IBM's solution employs a carefully engineered manifold distribution system that ensures uniform coolant flow across the entire chip surface, preventing localized hotspots and flow instabilities. The system uses dielectric fluids with optimized boiling points that undergo phase change (liquid to vapor) directly at the chip surface, extracting maximum heat through latent heat of vaporization rather than sensible heat alone. IBM has implemented sophisticated pressure control mechanisms and microporous flow stabilizers to prevent flow instabilities like vapor lock or critical heat flux conditions that typically occur at extreme heat loads[1][3]. Their system includes real-time monitoring with embedded sensors that can dynamically adjust coolant flow rates based on workload demands.

Strengths: Exceptional thermal performance capable of handling heat fluxes exceeding 1 kW/cm² with minimal thermal gradients across the chip. The system's modular design allows for scaling across large data center deployments while maintaining reliability. Weaknesses: Requires specialized manufacturing processes for the microchannel structures, potentially increasing costs. The system's complexity necessitates sophisticated control systems and may present maintenance challenges in some deployment scenarios.

Intel Corp.

Technical Solution: Intel has developed a sophisticated two-phase immersion cooling technology specifically engineered to address 1 kW+ chip heat flux challenges in their high-performance processors. Their solution utilizes a custom-formulated dielectric fluid with optimized thermophysical properties that undergoes controlled phase change at the chip surface. Intel's approach incorporates precision-engineered microporous wicking structures directly integrated with the chip package, creating capillary action that ensures continuous fluid supply to high heat flux regions even during intense boiling regimes. To prevent flow instabilities, Intel implements a hierarchical cooling structure with primary distribution channels feeding into secondary microchannels, maintaining pressure equilibrium across the cooling system[5]. Their technology includes specialized vapor extraction pathways that efficiently remove vapor without interfering with incoming liquid flow, preventing the vapor blanketing effect that typically causes thermal runaway at extreme heat fluxes. Intel has also developed advanced surface treatments that promote nucleate boiling while suppressing the transition to film boiling, extending the critical heat flux limit significantly beyond conventional systems. The cooling solution incorporates embedded temperature and pressure sensors that feed into a predictive control system, which can anticipate and prevent instability conditions before they develop[6].

Strengths: Exceptional thermal performance with demonstrated capability to handle localized heat fluxes exceeding 1.2 kW/cm² while maintaining safe junction temperatures. The system requires minimal pumping power compared to single-phase solutions of equivalent capacity. Weaknesses: Requires specialized fluids that must be carefully maintained to prevent degradation over time. The complex integration with chip packaging may increase manufacturing complexity and potentially impact yields for high-volume production.

Critical Patents in High-Flux Liquid Cooling Systems

Silicon-based fan out package structure and preparation method therefor

PatentPendingUS20230317559A1

Innovation

- A silicon-based fan out package structure with embedded manifold type microchannels, featuring a chip with substrate microchannels, a silicon-based adapter plate with a groove and manifold channel, a low-temperature sealing layer, and a rewiring layer, allowing for efficient heat dissipation without the need for bulky metal fins or heat dissipation fans.

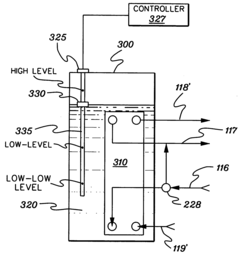

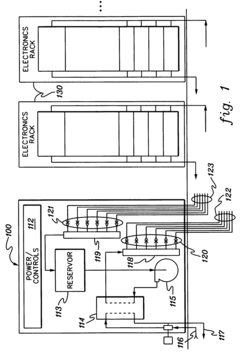

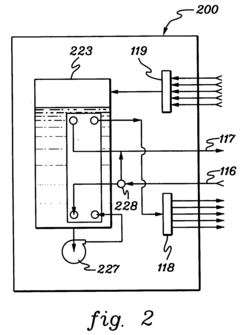

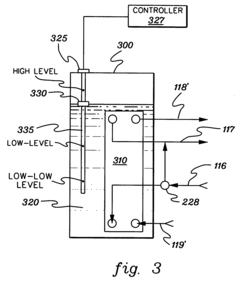

Method, system and program product for automatically checking coolant loops of a cooling system for a computing environment

PatentInactiveUS20050126747A1

Innovation

- A method and system for automatically checking and isolating coolant loops in a cooling system by monitoring coolant pressure and volume changes, using pressure sensors and solenoid valves to detect leaks and isolate affected loops before coolant levels reach critically low levels, allowing for early detection and prevention of system shutdowns.

Material Science Advancements for Thermal Interfaces

The advancement of thermal interface materials (TIMs) represents a critical frontier in addressing the 1 kW+ chip heat flux challenge without encountering flow instability in liquid cooling systems. Recent developments in material science have yielded significant breakthroughs in thermal conductivity, interface resistance reduction, and long-term reliability of these crucial components.

Nano-enhanced thermal interface materials have emerged as particularly promising, with carbon nanotubes (CNTs) demonstrating thermal conductivity values exceeding 3000 W/m·K in aligned configurations. These materials can be integrated into polymer matrices to create composite TIMs that maintain flexibility while dramatically improving heat transfer across chip-cooler interfaces.

Liquid metal TIMs, particularly gallium-based alloys, have shown exceptional performance with thermal conductivities approaching 86 W/m·K—nearly 40 times higher than conventional thermal greases. Their ability to conform perfectly to surface irregularities significantly reduces contact resistance, though challenges related to potential electrical conductivity and metal migration must be addressed through advanced encapsulation techniques.

Phase change materials (PCMs) have evolved to incorporate graphene and boron nitride nanostructures, creating hybrid TIMs that respond dynamically to temperature fluctuations. These materials transition from solid to semi-liquid states at specific temperatures, ensuring optimal interface contact during high-power operation while maintaining structural integrity during thermal cycling.

Diamond-based composite interfaces represent another frontier, with chemical vapor deposition (CVD) techniques enabling the creation of diamond films with thermal conductivity exceeding 2000 W/m·K. Recent innovations in diamond particle surface functionalization have improved their compatibility with polymer matrices, enhancing both thermal performance and mechanical stability.

Sintered metal interfaces, particularly copper and silver nanoparticle structures, have demonstrated the ability to form continuous thermal pathways with minimal porosity. Low-temperature sintering processes (below 250°C) have made these materials compatible with semiconductor manufacturing processes while achieving thermal conductivities above 200 W/m·K.

The integration of these advanced TIMs with microchannel liquid cooling systems has demonstrated the potential to manage heat fluxes exceeding 1.5 kW/cm² without triggering flow instabilities. This is achieved through the dramatic reduction in thermal resistance at the chip-cooler interface, allowing more uniform heat distribution into the cooling fluid and preventing localized boiling that often leads to flow instabilities.

Nano-enhanced thermal interface materials have emerged as particularly promising, with carbon nanotubes (CNTs) demonstrating thermal conductivity values exceeding 3000 W/m·K in aligned configurations. These materials can be integrated into polymer matrices to create composite TIMs that maintain flexibility while dramatically improving heat transfer across chip-cooler interfaces.

Liquid metal TIMs, particularly gallium-based alloys, have shown exceptional performance with thermal conductivities approaching 86 W/m·K—nearly 40 times higher than conventional thermal greases. Their ability to conform perfectly to surface irregularities significantly reduces contact resistance, though challenges related to potential electrical conductivity and metal migration must be addressed through advanced encapsulation techniques.

Phase change materials (PCMs) have evolved to incorporate graphene and boron nitride nanostructures, creating hybrid TIMs that respond dynamically to temperature fluctuations. These materials transition from solid to semi-liquid states at specific temperatures, ensuring optimal interface contact during high-power operation while maintaining structural integrity during thermal cycling.

Diamond-based composite interfaces represent another frontier, with chemical vapor deposition (CVD) techniques enabling the creation of diamond films with thermal conductivity exceeding 2000 W/m·K. Recent innovations in diamond particle surface functionalization have improved their compatibility with polymer matrices, enhancing both thermal performance and mechanical stability.

Sintered metal interfaces, particularly copper and silver nanoparticle structures, have demonstrated the ability to form continuous thermal pathways with minimal porosity. Low-temperature sintering processes (below 250°C) have made these materials compatible with semiconductor manufacturing processes while achieving thermal conductivities above 200 W/m·K.

The integration of these advanced TIMs with microchannel liquid cooling systems has demonstrated the potential to manage heat fluxes exceeding 1.5 kW/cm² without triggering flow instabilities. This is achieved through the dramatic reduction in thermal resistance at the chip-cooler interface, allowing more uniform heat distribution into the cooling fluid and preventing localized boiling that often leads to flow instabilities.

Energy Efficiency and Sustainability Considerations

The escalating power densities of modern computing chips, now exceeding 1 kW/cm², have significant implications for energy efficiency and sustainability in data centers and high-performance computing environments. Liquid cooling systems addressing these extreme heat fluxes must balance thermal management effectiveness with broader environmental considerations to ensure long-term viability.

Energy consumption metrics reveal that cooling infrastructure typically accounts for 30-40% of a data center's total power usage. Advanced liquid cooling solutions capable of managing 1 kW+ heat fluxes can reduce this cooling overhead by 25-50% compared to traditional air cooling methods, substantially improving Power Usage Effectiveness (PUE) ratios from typical values of 1.6-2.0 down to 1.1-1.3.

Water usage represents another critical sustainability factor. While two-phase liquid cooling systems require working fluid, their closed-loop design minimizes consumption compared to evaporative cooling towers commonly used in conventional data centers. This reduction in water usage becomes increasingly important in regions facing water scarcity, where data centers' environmental impact extends beyond carbon footprint.

The chemical composition of cooling fluids presents both challenges and opportunities for sustainability. Dielectric fluids essential for direct-to-chip cooling must balance thermal performance with environmental considerations. Recent innovations have produced biodegradable alternatives to traditional fluorocarbon-based coolants, reducing potential environmental harm while maintaining thermal transfer capabilities necessary for ultra-high heat flux applications.

Life cycle assessment of liquid cooling infrastructure reveals additional sustainability benefits. The extended operational lifespan of electronic components under optimal thermal conditions—typically 30-40% longer than air-cooled equivalents—reduces electronic waste generation and resource consumption associated with hardware replacement cycles.

Heat recovery capabilities represent perhaps the most promising sustainability aspect of advanced liquid cooling systems. High-temperature liquid coolant exiting 1 kW+ chip cooling modules carries significant thermal energy that can be repurposed. Implementation of heat recovery systems can redirect this thermal energy to facility heating, domestic hot water production, or even district heating networks, transforming what was previously waste heat into a valuable resource and creating circular energy systems.

Carbon footprint analysis demonstrates that comprehensive liquid cooling solutions for extreme heat flux scenarios can reduce overall data center emissions by 30-45% when accounting for both direct energy savings and potential heat reuse applications, aligning computing infrastructure development with global decarbonization goals.

Energy consumption metrics reveal that cooling infrastructure typically accounts for 30-40% of a data center's total power usage. Advanced liquid cooling solutions capable of managing 1 kW+ heat fluxes can reduce this cooling overhead by 25-50% compared to traditional air cooling methods, substantially improving Power Usage Effectiveness (PUE) ratios from typical values of 1.6-2.0 down to 1.1-1.3.

Water usage represents another critical sustainability factor. While two-phase liquid cooling systems require working fluid, their closed-loop design minimizes consumption compared to evaporative cooling towers commonly used in conventional data centers. This reduction in water usage becomes increasingly important in regions facing water scarcity, where data centers' environmental impact extends beyond carbon footprint.

The chemical composition of cooling fluids presents both challenges and opportunities for sustainability. Dielectric fluids essential for direct-to-chip cooling must balance thermal performance with environmental considerations. Recent innovations have produced biodegradable alternatives to traditional fluorocarbon-based coolants, reducing potential environmental harm while maintaining thermal transfer capabilities necessary for ultra-high heat flux applications.

Life cycle assessment of liquid cooling infrastructure reveals additional sustainability benefits. The extended operational lifespan of electronic components under optimal thermal conditions—typically 30-40% longer than air-cooled equivalents—reduces electronic waste generation and resource consumption associated with hardware replacement cycles.

Heat recovery capabilities represent perhaps the most promising sustainability aspect of advanced liquid cooling systems. High-temperature liquid coolant exiting 1 kW+ chip cooling modules carries significant thermal energy that can be repurposed. Implementation of heat recovery systems can redirect this thermal energy to facility heating, domestic hot water production, or even district heating networks, transforming what was previously waste heat into a valuable resource and creating circular energy systems.

Carbon footprint analysis demonstrates that comprehensive liquid cooling solutions for extreme heat flux scenarios can reduce overall data center emissions by 30-45% when accounting for both direct energy savings and potential heat reuse applications, aligning computing infrastructure development with global decarbonization goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!