How Liquid Cooling Minimizes Pump Power While Preserving Junction-To-Ambient ΔT?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Cooling Technology Evolution and Objectives

Liquid cooling technology has evolved significantly over the past several decades, transitioning from specialized applications in mainframe computers and supercomputers to becoming increasingly common in high-performance computing, data centers, and even consumer electronics. The fundamental principle behind liquid cooling—utilizing the superior thermal conductivity of liquids compared to air—has remained consistent, while implementation methods have grown increasingly sophisticated and efficient.

In the 1960s and 1970s, early liquid cooling systems were primarily direct immersion solutions used in large-scale computing environments. The 1980s saw the introduction of closed-loop systems with dedicated heat exchangers, marking a significant advancement in thermal management technology. By the 1990s and early 2000s, liquid cooling began appearing in high-end desktop computers, primarily targeting enthusiast markets.

The past decade has witnessed an acceleration in liquid cooling innovation driven by increasing power densities in electronic components. Modern CPUs and GPUs generate significantly more heat in smaller areas, creating thermal challenges that traditional air cooling struggles to address efficiently. This trend has been particularly pronounced in data centers, where rack densities continue to increase while operators simultaneously face pressure to reduce energy consumption.

Current liquid cooling technology encompasses several approaches, including cold plates with microchannels, direct-to-chip cooling, two-phase immersion cooling, and various hybrid solutions. Each approach offers different trade-offs between cooling efficiency, implementation complexity, and operational requirements. The specific challenge of minimizing pump power while maintaining effective junction-to-ambient temperature differentials represents a critical optimization problem in this field.

The primary objectives of modern liquid cooling research and development focus on several key areas: increasing cooling efficiency to handle higher heat fluxes, reducing energy consumption of pumping systems, minimizing system complexity and maintenance requirements, improving reliability and leak prevention, and developing environmentally friendly cooling fluids with optimal thermal properties.

Emerging trends include the development of smart liquid cooling systems with adaptive control mechanisms, integration of machine learning algorithms for predictive thermal management, exploration of novel cooling fluids including nanofluids, and innovations in microchannel design to optimize flow characteristics while minimizing pressure drops that necessitate higher pump power.

The ultimate goal in this technological evolution is to develop liquid cooling solutions that deliver superior thermal performance with minimal energy input, particularly from pumping systems, while maintaining reliability and cost-effectiveness across various application domains from high-performance computing to electric vehicle battery thermal management.

In the 1960s and 1970s, early liquid cooling systems were primarily direct immersion solutions used in large-scale computing environments. The 1980s saw the introduction of closed-loop systems with dedicated heat exchangers, marking a significant advancement in thermal management technology. By the 1990s and early 2000s, liquid cooling began appearing in high-end desktop computers, primarily targeting enthusiast markets.

The past decade has witnessed an acceleration in liquid cooling innovation driven by increasing power densities in electronic components. Modern CPUs and GPUs generate significantly more heat in smaller areas, creating thermal challenges that traditional air cooling struggles to address efficiently. This trend has been particularly pronounced in data centers, where rack densities continue to increase while operators simultaneously face pressure to reduce energy consumption.

Current liquid cooling technology encompasses several approaches, including cold plates with microchannels, direct-to-chip cooling, two-phase immersion cooling, and various hybrid solutions. Each approach offers different trade-offs between cooling efficiency, implementation complexity, and operational requirements. The specific challenge of minimizing pump power while maintaining effective junction-to-ambient temperature differentials represents a critical optimization problem in this field.

The primary objectives of modern liquid cooling research and development focus on several key areas: increasing cooling efficiency to handle higher heat fluxes, reducing energy consumption of pumping systems, minimizing system complexity and maintenance requirements, improving reliability and leak prevention, and developing environmentally friendly cooling fluids with optimal thermal properties.

Emerging trends include the development of smart liquid cooling systems with adaptive control mechanisms, integration of machine learning algorithms for predictive thermal management, exploration of novel cooling fluids including nanofluids, and innovations in microchannel design to optimize flow characteristics while minimizing pressure drops that necessitate higher pump power.

The ultimate goal in this technological evolution is to develop liquid cooling solutions that deliver superior thermal performance with minimal energy input, particularly from pumping systems, while maintaining reliability and cost-effectiveness across various application domains from high-performance computing to electric vehicle battery thermal management.

Market Demand for Energy-Efficient Thermal Management

The global market for energy-efficient thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of data centers, high-performance computing systems, and advanced electronics. According to recent market analyses, the liquid cooling market is projected to grow at a CAGR of 14.2% through 2028, reaching a valuation of $7.2 billion, with energy efficiency being the primary driver.

The demand for efficient thermal management solutions that minimize pump power while maintaining optimal junction-to-ambient temperature differentials stems from several converging market factors. Data center operators face mounting pressure to reduce operational costs, with cooling accounting for approximately 40% of their energy consumption. This economic imperative is further intensified by regulatory frameworks and corporate sustainability commitments that mandate reduced carbon footprints across industries.

High-density computing environments, particularly those supporting AI and machine learning workloads, generate thermal loads exceeding 50 kW per rack, rendering traditional air cooling methods inadequate. These applications require thermal solutions that can efficiently dissipate heat while consuming minimal energy themselves, creating a significant market pull for advanced liquid cooling technologies that optimize the power-performance ratio.

The telecommunications sector's transition to 5G and eventually 6G infrastructure has created another substantial market segment demanding energy-efficient cooling solutions. Base stations and network equipment operating in varied environmental conditions require robust thermal management that minimizes operational costs while ensuring reliability.

Consumer electronics manufacturers are increasingly incorporating liquid cooling in premium devices, responding to user demands for higher performance without thermal throttling. This trend is particularly evident in the gaming hardware segment, where thermal management directly impacts product performance and user experience.

Industrial applications represent another growing market segment, with manufacturing automation systems, power electronics, and industrial computing platforms all requiring more sophisticated thermal management solutions. The industrial sector values solutions that minimize maintenance requirements while maximizing equipment lifespan through effective thermal control.

Market research indicates that customers across these segments are willing to pay a premium of 15-25% for cooling solutions that demonstrate measurable reductions in pump power consumption while maintaining or improving thermal performance. This price elasticity reflects the long-term operational savings these technologies enable, with payback periods typically ranging from 8 to 24 months depending on the application environment.

The demand for efficient thermal management solutions that minimize pump power while maintaining optimal junction-to-ambient temperature differentials stems from several converging market factors. Data center operators face mounting pressure to reduce operational costs, with cooling accounting for approximately 40% of their energy consumption. This economic imperative is further intensified by regulatory frameworks and corporate sustainability commitments that mandate reduced carbon footprints across industries.

High-density computing environments, particularly those supporting AI and machine learning workloads, generate thermal loads exceeding 50 kW per rack, rendering traditional air cooling methods inadequate. These applications require thermal solutions that can efficiently dissipate heat while consuming minimal energy themselves, creating a significant market pull for advanced liquid cooling technologies that optimize the power-performance ratio.

The telecommunications sector's transition to 5G and eventually 6G infrastructure has created another substantial market segment demanding energy-efficient cooling solutions. Base stations and network equipment operating in varied environmental conditions require robust thermal management that minimizes operational costs while ensuring reliability.

Consumer electronics manufacturers are increasingly incorporating liquid cooling in premium devices, responding to user demands for higher performance without thermal throttling. This trend is particularly evident in the gaming hardware segment, where thermal management directly impacts product performance and user experience.

Industrial applications represent another growing market segment, with manufacturing automation systems, power electronics, and industrial computing platforms all requiring more sophisticated thermal management solutions. The industrial sector values solutions that minimize maintenance requirements while maximizing equipment lifespan through effective thermal control.

Market research indicates that customers across these segments are willing to pay a premium of 15-25% for cooling solutions that demonstrate measurable reductions in pump power consumption while maintaining or improving thermal performance. This price elasticity reflects the long-term operational savings these technologies enable, with payback periods typically ranging from 8 to 24 months depending on the application environment.

Current Challenges in Pump Power Optimization

The optimization of pump power in liquid cooling systems represents a significant challenge in thermal management engineering. Current systems often struggle to balance the competing demands of minimizing power consumption while maintaining adequate thermal performance. The fundamental issue stems from the hydraulic resistance in cooling loops, which necessitates higher pump power to maintain sufficient flow rates for effective heat transfer. As electronic components continue to increase in power density, particularly in data centers, high-performance computing, and electric vehicles, this challenge becomes increasingly critical.

Traditional approaches to pump power optimization have relied heavily on increasing pump size or operating speeds, resulting in diminishing returns in terms of efficiency. The relationship between flow rate and pressure drop follows a quadratic curve, meaning that doubling the flow rate requires approximately four times the pump power. This non-linear relationship creates a significant barrier to efficiency improvements through conventional methods.

Microchannel designs, while offering improved thermal performance, often exacerbate pump power challenges due to increased pressure drops across these narrow passages. The industry has yet to develop standardized design methodologies that effectively balance the trade-offs between thermal performance and pumping requirements. This lack of standardization leads to overengineered systems that consume excessive energy or underperforming systems that fail to maintain optimal junction temperatures.

Material constraints further complicate optimization efforts. Current pump technologies face limitations in terms of reliability, efficiency, and compatibility with various coolants. The development of advanced materials that can withstand the corrosive effects of certain coolants while maintaining high efficiency remains an ongoing challenge. Additionally, the miniaturization of pumping systems for space-constrained applications introduces further complications in achieving optimal performance.

Control systems for variable flow rates represent another area of difficulty. Dynamic thermal loads require adaptive pumping solutions, but current control algorithms often lack the sophistication to optimize power consumption across varying operational conditions. The integration of sensors, controllers, and pumps into a cohesive system that can respond intelligently to changing thermal demands without excessive power consumption remains elusive in many applications.

Manufacturing considerations also impact pump power optimization. Complex cooling channel geometries that could theoretically improve efficiency are often difficult or prohibitively expensive to produce at scale. The industry continues to search for manufacturing techniques that can economically produce optimized cooling structures while maintaining tight tolerances necessary for predictable performance.

Traditional approaches to pump power optimization have relied heavily on increasing pump size or operating speeds, resulting in diminishing returns in terms of efficiency. The relationship between flow rate and pressure drop follows a quadratic curve, meaning that doubling the flow rate requires approximately four times the pump power. This non-linear relationship creates a significant barrier to efficiency improvements through conventional methods.

Microchannel designs, while offering improved thermal performance, often exacerbate pump power challenges due to increased pressure drops across these narrow passages. The industry has yet to develop standardized design methodologies that effectively balance the trade-offs between thermal performance and pumping requirements. This lack of standardization leads to overengineered systems that consume excessive energy or underperforming systems that fail to maintain optimal junction temperatures.

Material constraints further complicate optimization efforts. Current pump technologies face limitations in terms of reliability, efficiency, and compatibility with various coolants. The development of advanced materials that can withstand the corrosive effects of certain coolants while maintaining high efficiency remains an ongoing challenge. Additionally, the miniaturization of pumping systems for space-constrained applications introduces further complications in achieving optimal performance.

Control systems for variable flow rates represent another area of difficulty. Dynamic thermal loads require adaptive pumping solutions, but current control algorithms often lack the sophistication to optimize power consumption across varying operational conditions. The integration of sensors, controllers, and pumps into a cohesive system that can respond intelligently to changing thermal demands without excessive power consumption remains elusive in many applications.

Manufacturing considerations also impact pump power optimization. Complex cooling channel geometries that could theoretically improve efficiency are often difficult or prohibitively expensive to produce at scale. The industry continues to search for manufacturing techniques that can economically produce optimized cooling structures while maintaining tight tolerances necessary for predictable performance.

Contemporary Approaches to Pump Power Reduction

01 Pump design for thermal management in liquid cooling systems

Specialized pump designs are crucial for effective liquid cooling systems that reduce junction-to-ambient temperature differentials. These designs focus on optimizing flow rates, pressure capabilities, and energy efficiency to enhance heat transfer from electronic components. Advanced pump configurations incorporate features like variable speed control, redundant operation, and compact form factors to maintain optimal thermal conditions while minimizing power consumption.- Pump power optimization for liquid cooling systems: Liquid cooling systems require optimized pump power to efficiently transfer heat from the junction to the ambient environment. By carefully selecting pump power based on the cooling requirements, the junction-to-ambient temperature differential can be minimized. Various designs incorporate power management features that adjust pump speed according to thermal load, ensuring efficient operation while maintaining optimal temperature differentials.

- Thermal junction design for enhanced heat transfer: The design of thermal junctions in liquid cooling systems significantly impacts the junction-to-ambient temperature differential. Advanced junction designs incorporate materials with high thermal conductivity and specialized geometries that maximize contact area with the cooling medium. These designs facilitate efficient heat transfer from heat-generating components to the cooling liquid, reducing the overall thermal resistance and improving the cooling performance.

- Flow rate control mechanisms for temperature management: Flow rate control mechanisms play a crucial role in managing the junction-to-ambient temperature differential in liquid cooling systems. By dynamically adjusting the flow rate based on thermal load, these mechanisms ensure optimal cooling performance while minimizing power consumption. Various implementations include variable speed pumps, flow restrictors, and intelligent control systems that monitor temperature differentials and adjust accordingly.

- Cooling system integration with electronic components: The integration of liquid cooling systems with electronic components affects the junction-to-ambient temperature differential. Direct contact cooling solutions, where the cooling medium directly interfaces with heat-generating components, minimize thermal resistance. Various mounting techniques and interface materials are employed to ensure efficient heat transfer from the junction to the cooling medium, reducing the temperature differential and improving overall system performance.

- Advanced coolant formulations for improved thermal performance: Specialized coolant formulations enhance the thermal performance of liquid cooling systems, affecting the junction-to-ambient temperature differential. These formulations incorporate additives that improve thermal conductivity, reduce viscosity, and prevent corrosion or biological growth. By optimizing the thermophysical properties of the coolant, heat transfer efficiency is improved, resulting in lower junction temperatures and more effective dissipation of heat to the ambient environment.

02 Power optimization techniques for liquid cooling pumps

Power consumption optimization in liquid cooling pumps is achieved through various techniques including intelligent control algorithms, energy-efficient motor designs, and adaptive pumping strategies. These approaches dynamically adjust pump performance based on thermal load requirements, maintaining optimal junction-to-ambient temperature differentials while minimizing energy usage. Implementation of power management circuits and low-power standby modes further enhances overall system efficiency.Expand Specific Solutions03 Thermal interface optimization between cooling fluid and heat source

Enhancing the thermal interface between the cooling fluid and heat source significantly impacts junction-to-ambient temperature differentials. This involves specialized cold plate designs, microchannel structures, and surface treatments that maximize contact area and heat transfer efficiency. Advanced interface materials and geometries facilitate improved thermal conductivity, reducing thermal resistance and enabling more effective heat dissipation from electronic components to the cooling medium.Expand Specific Solutions04 Integrated cooling system architectures for thermal management

Integrated cooling system architectures combine pumps, heat exchangers, and control systems in optimized configurations to effectively manage junction-to-ambient temperature differentials. These systems incorporate strategic component placement, fluid path optimization, and thermal zone management to enhance cooling efficiency. Advanced designs feature modular construction, redundant cooling paths, and adaptive control mechanisms that respond to changing thermal loads while maintaining optimal operating conditions.Expand Specific Solutions05 Cooling fluid properties and flow dynamics for enhanced thermal performance

The selection and management of cooling fluid properties significantly impact thermal performance in liquid cooling systems. Specialized coolants with enhanced thermal conductivity, optimized viscosity, and improved heat capacity enable more efficient heat transfer from junction to ambient. Flow dynamics considerations, including turbulence induction, flow distribution, and pressure drop management, further enhance cooling efficiency while balancing pump power requirements and system reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The liquid cooling technology market is currently in a growth phase, with increasing demand driven by data center thermal management needs and high-performance computing requirements. The market is projected to expand significantly as heat dissipation challenges intensify across industries. Companies like Cooler Master, Iceotope Group, and Fujitsu lead in commercial cooling solutions, while industrial players such as Continental Automotive, Raytheon, and Lockheed Martin focus on specialized applications requiring minimal pump power consumption. Academic institutions like Yangzhou University contribute research on optimizing junction-to-ambient temperature differentials. The technology is approaching maturity in certain sectors but continues to evolve with innovations from companies like Grundfos and NIDEC in pump efficiency and Energy Dome in thermal management systems.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has developed an innovative liquid cooling solution focused on minimizing pump power consumption while maintaining optimal thermal performance. Their approach centers on a low-pressure drop loop design that incorporates specially engineered cold plates with optimized microchannel structures. These cold plates feature gradually expanding channels that reduce local pressure drops while maintaining high heat transfer coefficients at critical junction points. The company's MasterLiquid series employs dual-chamber pump designs that separate the inlet and outlet flows, reducing turbulence and improving hydraulic efficiency. This configuration allows for effective cooling with lower pump speeds, directly reducing power consumption while maintaining the necessary junction-to-ambient temperature differential. Cooler Master has also implemented advanced impeller designs with computational fluid dynamics-optimized blade geometries that maximize flow rates at lower rotational speeds, further reducing power requirements[5]. Their systems incorporate flexible tubing with smooth internal surfaces and optimized bend radii to minimize flow resistance throughout the cooling loop. Testing has shown their solutions can maintain junction temperatures within 5-10°C of target while consuming up to 30% less pump power than conventional designs.

Strengths: Highly efficient pump designs reduce power consumption without sacrificing cooling performance; optimized cold plate geometries provide excellent thermal transfer with minimal pressure drop; consumer-friendly installation and maintenance. Weaknesses: Some premium solutions have higher initial costs; performance benefits may vary depending on specific system configurations; limited customization options for specialized industrial applications.

Grundfos Holding A/S

Technical Solution: Grundfos has developed advanced liquid cooling solutions specifically engineered to minimize pump power consumption while maintaining optimal thermal performance. Their approach centers on high-efficiency, variable-speed pumps with intelligent control systems that precisely match cooling capacity to thermal load requirements. The company's MAGNA3 and ALPHA series incorporate permanent magnet motor technology and advanced hydraulics that achieve significantly higher efficiency ratings compared to conventional pumps. These systems feature adaptive flow control that automatically identifies the optimal duty point, reducing unnecessary energy expenditure while ensuring adequate cooling. Grundfos has also developed specialized impeller designs with computational fluid dynamics-optimized geometries that minimize turbulence and pressure drops throughout the cooling circuit. Their cooling solutions incorporate pressure differential sensors and temperature monitoring systems that work in concert with proprietary algorithms to maintain ideal junction-to-ambient temperature differentials with minimal energy input. Testing has demonstrated that their systems can reduce pump energy consumption by up to 50% compared to fixed-speed alternatives while maintaining consistent thermal performance[6]. Additionally, Grundfos has pioneered flow distribution manifolds that ensure balanced coolant delivery across multiple cooling loops without requiring excessive pump pressure.

Strengths: Industry-leading pump efficiency reduces operational costs and energy consumption; intelligent control systems optimize performance based on real-time conditions; robust design ensures long-term reliability with minimal maintenance. Weaknesses: Higher initial investment compared to basic cooling solutions; optimal performance requires proper system integration and commissioning; some advanced features may be unnecessary for simpler cooling applications.

Key Innovations in Junction-To-Ambient ΔT Preservation

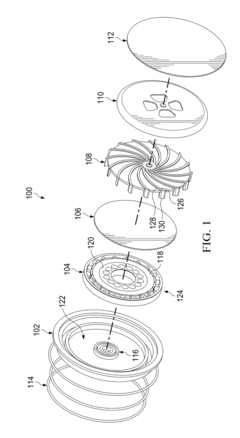

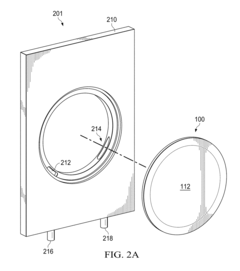

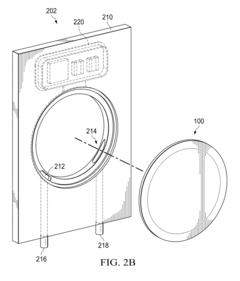

Adaptable thin section liquid pump for electronics cooling systems or other systems

PatentActiveUS20180199466A1

Innovation

- A thin-section centrifugal pump with a brushless open-frame motor and magnetic coupling, designed for closed-loop coolant flow, providing high flow rates and pressure heads, adaptable for integration into various structures to manage thermal energy transfer efficiently.

Thermal Design Trade-offs and System Integration

The integration of liquid cooling systems into electronic devices presents complex thermal design challenges that require careful balancing of multiple factors. When optimizing liquid cooling to minimize pump power while maintaining effective junction-to-ambient temperature differentials, engineers must navigate several critical trade-offs that impact overall system performance.

Thermal resistance optimization represents the cornerstone of effective liquid cooling design. By strategically reducing thermal resistance at critical interfaces, designers can achieve the same junction-to-ambient temperature differential with significantly lower pump power requirements. This often involves selecting appropriate thermal interface materials, optimizing cold plate designs, and ensuring efficient heat exchanger configurations.

Flow path optimization emerges as another crucial consideration, where the arrangement of cooling channels directly impacts pressure drop and thermal performance. Parallel flow paths can reduce pressure requirements but may create uneven cooling, while serial configurations ensure consistent cooling but at higher pressure costs. Advanced designs increasingly incorporate mixed approaches with variable channel geometries to optimize both aspects simultaneously.

Component placement within the system significantly influences cooling efficiency. Positioning heat-generating components to minimize the thermal path to cooling elements reduces thermal resistance, while strategic grouping of components with similar thermal profiles enables more efficient cooling zone designs. This spatial optimization can reduce the required coolant flow rate, directly lowering pump power demands.

Material selection represents a fundamental trade-off between thermal performance, weight, cost, and reliability. While copper offers superior thermal conductivity, its weight and cost may be prohibitive for certain applications. Aluminum provides a balanced alternative, while emerging composite materials offer promising combinations of properties that may further optimize the power-performance equation.

System-level integration considerations extend beyond thermal performance to include factors such as noise, maintenance accessibility, and compatibility with existing infrastructure. The pump and cooling system must be designed not as isolated components but as integral parts of the overall device architecture, with careful attention to vibration isolation, acoustic dampening, and serviceability.

Reliability engineering plays a critical role in liquid cooling design, as the introduction of fluids into electronic systems creates potential failure modes not present in air-cooled designs. Redundancy in critical components, leak detection systems, and corrosion-resistant materials must be balanced against power and space constraints to ensure long-term system integrity without excessive energy consumption.

Thermal resistance optimization represents the cornerstone of effective liquid cooling design. By strategically reducing thermal resistance at critical interfaces, designers can achieve the same junction-to-ambient temperature differential with significantly lower pump power requirements. This often involves selecting appropriate thermal interface materials, optimizing cold plate designs, and ensuring efficient heat exchanger configurations.

Flow path optimization emerges as another crucial consideration, where the arrangement of cooling channels directly impacts pressure drop and thermal performance. Parallel flow paths can reduce pressure requirements but may create uneven cooling, while serial configurations ensure consistent cooling but at higher pressure costs. Advanced designs increasingly incorporate mixed approaches with variable channel geometries to optimize both aspects simultaneously.

Component placement within the system significantly influences cooling efficiency. Positioning heat-generating components to minimize the thermal path to cooling elements reduces thermal resistance, while strategic grouping of components with similar thermal profiles enables more efficient cooling zone designs. This spatial optimization can reduce the required coolant flow rate, directly lowering pump power demands.

Material selection represents a fundamental trade-off between thermal performance, weight, cost, and reliability. While copper offers superior thermal conductivity, its weight and cost may be prohibitive for certain applications. Aluminum provides a balanced alternative, while emerging composite materials offer promising combinations of properties that may further optimize the power-performance equation.

System-level integration considerations extend beyond thermal performance to include factors such as noise, maintenance accessibility, and compatibility with existing infrastructure. The pump and cooling system must be designed not as isolated components but as integral parts of the overall device architecture, with careful attention to vibration isolation, acoustic dampening, and serviceability.

Reliability engineering plays a critical role in liquid cooling design, as the introduction of fluids into electronic systems creates potential failure modes not present in air-cooled designs. Redundancy in critical components, leak detection systems, and corrosion-resistant materials must be balanced against power and space constraints to ensure long-term system integrity without excessive energy consumption.

Environmental Impact and Sustainability Considerations

Liquid cooling systems represent a significant advancement in thermal management technology with profound environmental implications. The optimization of pump power while maintaining effective junction-to-ambient thermal performance directly contributes to reduced energy consumption in cooling operations. Traditional air cooling systems typically require substantial energy input, particularly in high-performance computing environments, data centers, and advanced electronics applications. By contrast, efficiently designed liquid cooling solutions can achieve the same or better thermal performance with significantly lower power requirements.

The environmental benefits extend beyond direct energy savings. Lower pump power requirements translate to reduced carbon emissions throughout the operational lifecycle of electronic systems. Research indicates that optimized liquid cooling can reduce cooling-related energy consumption by 30-50% compared to conventional air cooling methods, representing a substantial decrease in carbon footprint for large-scale implementations such as data centers, which currently account for approximately 1-2% of global electricity consumption.

Material sustainability constitutes another critical environmental consideration. Advanced liquid cooling systems increasingly utilize environmentally friendly coolants with lower global warming potential (GWP) compared to traditional refrigerants. The transition from high-GWP hydrofluorocarbons to natural refrigerants or engineered fluids with minimal environmental impact represents a significant advancement in sustainable cooling technology. Additionally, the extended equipment lifespan resulting from more effective thermal management reduces electronic waste generation, addressing another pressing environmental concern.

Water usage efficiency emerges as a key sustainability metric for liquid cooling systems. While these systems require water resources, optimized designs that minimize pump power typically incorporate closed-loop configurations that substantially reduce water consumption compared to traditional cooling towers. The implementation of water recovery and recycling mechanisms further enhances sustainability by minimizing freshwater requirements in cooling operations.

Manufacturing processes for liquid cooling components also present environmental considerations. The production of specialized heat exchangers, pumps, and cooling plates involves resource extraction and energy-intensive manufacturing. However, lifecycle assessments indicate that the operational efficiency gains typically offset the initial environmental impact within relatively short timeframes, particularly in high-performance applications where cooling demands are substantial.

Regulatory frameworks increasingly recognize the environmental benefits of efficient cooling technologies. Energy efficiency standards and environmental certifications now frequently incorporate metrics related to cooling system performance, creating market incentives for the development and adoption of sustainable liquid cooling solutions that minimize pump power while maintaining thermal performance.

The environmental benefits extend beyond direct energy savings. Lower pump power requirements translate to reduced carbon emissions throughout the operational lifecycle of electronic systems. Research indicates that optimized liquid cooling can reduce cooling-related energy consumption by 30-50% compared to conventional air cooling methods, representing a substantial decrease in carbon footprint for large-scale implementations such as data centers, which currently account for approximately 1-2% of global electricity consumption.

Material sustainability constitutes another critical environmental consideration. Advanced liquid cooling systems increasingly utilize environmentally friendly coolants with lower global warming potential (GWP) compared to traditional refrigerants. The transition from high-GWP hydrofluorocarbons to natural refrigerants or engineered fluids with minimal environmental impact represents a significant advancement in sustainable cooling technology. Additionally, the extended equipment lifespan resulting from more effective thermal management reduces electronic waste generation, addressing another pressing environmental concern.

Water usage efficiency emerges as a key sustainability metric for liquid cooling systems. While these systems require water resources, optimized designs that minimize pump power typically incorporate closed-loop configurations that substantially reduce water consumption compared to traditional cooling towers. The implementation of water recovery and recycling mechanisms further enhances sustainability by minimizing freshwater requirements in cooling operations.

Manufacturing processes for liquid cooling components also present environmental considerations. The production of specialized heat exchangers, pumps, and cooling plates involves resource extraction and energy-intensive manufacturing. However, lifecycle assessments indicate that the operational efficiency gains typically offset the initial environmental impact within relatively short timeframes, particularly in high-performance applications where cooling demands are substantial.

Regulatory frameworks increasingly recognize the environmental benefits of efficient cooling technologies. Energy efficiency standards and environmental certifications now frequently incorporate metrics related to cooling system performance, creating market incentives for the development and adoption of sustainable liquid cooling solutions that minimize pump power while maintaining thermal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!