Liquid Cooling Qualification: Burst/Pressure Cycling, HALT And Acceptance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Cooling Technology Background and Objectives

Liquid cooling technology has evolved significantly over the past decades, transitioning from specialized applications in mainframe computers and supercomputers to becoming increasingly prevalent in data centers, high-performance computing, and even consumer electronics. The fundamental principle of liquid cooling leverages the superior thermal conductivity of liquids compared to air, allowing for more efficient heat dissipation from electronic components. This efficiency becomes particularly critical as computing power densities continue to increase, with modern processors generating heat loads that traditional air cooling struggles to manage effectively.

The evolution of liquid cooling systems has seen several key developments, including the transition from open-loop to closed-loop systems, the introduction of dielectric fluids that eliminate electrical conductivity risks, and the development of direct-to-chip cooling technologies. Recent advancements have focused on improving reliability, reducing maintenance requirements, and enhancing overall system efficiency while minimizing environmental impact through the use of more sustainable coolants.

Current market trends indicate a growing adoption of liquid cooling solutions across various industries, driven by the need for higher computational performance, energy efficiency, and space optimization. As data centers face increasing pressure to reduce their carbon footprint while handling exponentially growing computational demands, liquid cooling presents a viable solution to address these seemingly contradictory requirements.

The primary objective of liquid cooling qualification processes, particularly those involving burst/pressure cycling, Highly Accelerated Life Testing (HALT), and acceptance testing, is to ensure the reliability, durability, and safety of these systems under various operational conditions. These qualification methodologies aim to identify potential failure modes before deployment, thereby preventing costly downtime and potential damage to critical computing infrastructure.

Pressure cycling tests specifically evaluate the system's ability to withstand repeated pressure fluctuations that occur during normal operation and potential fault conditions. HALT procedures accelerate the aging process by subjecting components to extreme conditions, identifying weaknesses that might only emerge after years of standard operation. Acceptance testing establishes standardized criteria to verify that manufactured systems meet design specifications and performance requirements.

The technological trajectory suggests continued refinement of these qualification methodologies, with increasing emphasis on standardization across the industry. As liquid cooling becomes more mainstream, establishing robust, universally accepted testing protocols becomes essential for ensuring interoperability, reliability, and safety across diverse implementation environments and use cases.

The evolution of liquid cooling systems has seen several key developments, including the transition from open-loop to closed-loop systems, the introduction of dielectric fluids that eliminate electrical conductivity risks, and the development of direct-to-chip cooling technologies. Recent advancements have focused on improving reliability, reducing maintenance requirements, and enhancing overall system efficiency while minimizing environmental impact through the use of more sustainable coolants.

Current market trends indicate a growing adoption of liquid cooling solutions across various industries, driven by the need for higher computational performance, energy efficiency, and space optimization. As data centers face increasing pressure to reduce their carbon footprint while handling exponentially growing computational demands, liquid cooling presents a viable solution to address these seemingly contradictory requirements.

The primary objective of liquid cooling qualification processes, particularly those involving burst/pressure cycling, Highly Accelerated Life Testing (HALT), and acceptance testing, is to ensure the reliability, durability, and safety of these systems under various operational conditions. These qualification methodologies aim to identify potential failure modes before deployment, thereby preventing costly downtime and potential damage to critical computing infrastructure.

Pressure cycling tests specifically evaluate the system's ability to withstand repeated pressure fluctuations that occur during normal operation and potential fault conditions. HALT procedures accelerate the aging process by subjecting components to extreme conditions, identifying weaknesses that might only emerge after years of standard operation. Acceptance testing establishes standardized criteria to verify that manufactured systems meet design specifications and performance requirements.

The technological trajectory suggests continued refinement of these qualification methodologies, with increasing emphasis on standardization across the industry. As liquid cooling becomes more mainstream, establishing robust, universally accepted testing protocols becomes essential for ensuring interoperability, reliability, and safety across diverse implementation environments and use cases.

Market Demand Analysis for Liquid Cooling Systems

The global liquid cooling market is experiencing unprecedented growth, driven primarily by the rapid expansion of data centers and high-performance computing facilities. Current market valuations place the liquid cooling systems sector at approximately 2.5 billion USD in 2023, with projections indicating a compound annual growth rate of 24.8% through 2028. This accelerated growth reflects the increasing demand for more efficient thermal management solutions capable of handling higher heat loads generated by advanced computing systems.

Data center operators represent the largest market segment, with over 60% of current demand. This is attributed to the escalating power densities in server racks, which have increased from an average of 5-10 kW per rack in 2015 to 15-30 kW per rack in 2023, with some high-performance applications exceeding 50 kW per rack. Traditional air cooling systems become inefficient and cost-prohibitive at these higher densities, creating a strong market pull for liquid cooling alternatives.

The automotive and electric vehicle sector constitutes the second-largest market segment, particularly for battery thermal management systems. As electric vehicle adoption accelerates globally, the need for reliable liquid cooling systems that can maintain optimal battery temperatures under various operating conditions has become critical. Industry reports indicate that over 85% of new electric vehicle designs incorporate some form of liquid cooling technology.

Reliability and qualification standards have emerged as key market differentiators. End-users increasingly demand comprehensive qualification testing, including burst/pressure cycling tests, Highly Accelerated Life Testing (HALT), and standardized acceptance criteria. A recent industry survey revealed that 78% of data center operators consider qualification testing results as "extremely important" in their procurement decisions, highlighting the growing emphasis on proven reliability.

Energy efficiency represents another significant market driver. With data centers consuming approximately 1-2% of global electricity and facing increasing regulatory pressure to reduce carbon footprints, liquid cooling systems that demonstrate superior energy efficiency gain substantial market advantage. Systems that can demonstrate a reduction in cooling energy consumption by 30% or more through proper qualification and testing protocols command premium pricing in the market.

Geographically, North America leads the market with approximately 40% share, followed by Asia-Pacific at 35% and Europe at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid data center expansion in China, Singapore, and India, along with government initiatives promoting energy-efficient technologies.

Data center operators represent the largest market segment, with over 60% of current demand. This is attributed to the escalating power densities in server racks, which have increased from an average of 5-10 kW per rack in 2015 to 15-30 kW per rack in 2023, with some high-performance applications exceeding 50 kW per rack. Traditional air cooling systems become inefficient and cost-prohibitive at these higher densities, creating a strong market pull for liquid cooling alternatives.

The automotive and electric vehicle sector constitutes the second-largest market segment, particularly for battery thermal management systems. As electric vehicle adoption accelerates globally, the need for reliable liquid cooling systems that can maintain optimal battery temperatures under various operating conditions has become critical. Industry reports indicate that over 85% of new electric vehicle designs incorporate some form of liquid cooling technology.

Reliability and qualification standards have emerged as key market differentiators. End-users increasingly demand comprehensive qualification testing, including burst/pressure cycling tests, Highly Accelerated Life Testing (HALT), and standardized acceptance criteria. A recent industry survey revealed that 78% of data center operators consider qualification testing results as "extremely important" in their procurement decisions, highlighting the growing emphasis on proven reliability.

Energy efficiency represents another significant market driver. With data centers consuming approximately 1-2% of global electricity and facing increasing regulatory pressure to reduce carbon footprints, liquid cooling systems that demonstrate superior energy efficiency gain substantial market advantage. Systems that can demonstrate a reduction in cooling energy consumption by 30% or more through proper qualification and testing protocols command premium pricing in the market.

Geographically, North America leads the market with approximately 40% share, followed by Asia-Pacific at 35% and Europe at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid data center expansion in China, Singapore, and India, along with government initiatives promoting energy-efficient technologies.

Current Challenges in Liquid Cooling Qualification Testing

The liquid cooling qualification testing landscape faces significant challenges as thermal management demands increase across industries. Current testing methodologies struggle to keep pace with evolving cooling system designs, particularly in high-performance computing, data centers, and electric vehicle applications. Traditional qualification standards developed for air cooling systems prove inadequate for the complex dynamics of liquid cooling solutions.

One primary challenge is the lack of standardized testing protocols specifically designed for liquid cooling systems. While standards exist for individual components, comprehensive system-level qualification frameworks remain fragmented across different industries. This creates inconsistency in testing approaches and makes cross-industry comparisons difficult, ultimately slowing adoption and innovation.

Test duration presents another significant hurdle. Liquid cooling systems require extensive testing periods to accurately simulate real-world conditions and failure modes. Burst testing, pressure cycling, and Highly Accelerated Life Testing (HALT) procedures can span weeks or months, creating bottlenecks in product development cycles and increasing time-to-market. This extended timeline conflicts with accelerating product development schedules in competitive markets.

The complexity of simulating real-world operating conditions poses additional challenges. Liquid cooling systems encounter varied temperature profiles, pressure fluctuations, and chemical interactions that are difficult to replicate in laboratory settings. Current testing equipment often fails to accurately model these dynamic conditions, particularly the combined effects of thermal cycling, pressure variations, and mechanical stresses that occur simultaneously in operational environments.

Material compatibility testing represents another critical gap. The interaction between coolants and system materials over extended periods can lead to corrosion, degradation, or particulate formation. Current accelerated testing methods struggle to accurately predict these long-term effects, creating reliability uncertainties for systems expected to operate for 5-10 years in the field.

Data interpretation and correlation between test results and real-world performance remains problematic. The industry lacks robust models that translate accelerated test data into meaningful reliability predictions. This disconnect between qualification testing and actual field performance creates uncertainty in system design and warranty determinations.

Finally, emerging technologies like two-phase cooling and direct-to-chip liquid cooling introduce novel failure modes that existing qualification frameworks cannot adequately assess. As these advanced cooling technologies gain traction, the gap between testing capabilities and system requirements continues to widen, highlighting the urgent need for innovative qualification methodologies that can keep pace with rapid technological evolution.

One primary challenge is the lack of standardized testing protocols specifically designed for liquid cooling systems. While standards exist for individual components, comprehensive system-level qualification frameworks remain fragmented across different industries. This creates inconsistency in testing approaches and makes cross-industry comparisons difficult, ultimately slowing adoption and innovation.

Test duration presents another significant hurdle. Liquid cooling systems require extensive testing periods to accurately simulate real-world conditions and failure modes. Burst testing, pressure cycling, and Highly Accelerated Life Testing (HALT) procedures can span weeks or months, creating bottlenecks in product development cycles and increasing time-to-market. This extended timeline conflicts with accelerating product development schedules in competitive markets.

The complexity of simulating real-world operating conditions poses additional challenges. Liquid cooling systems encounter varied temperature profiles, pressure fluctuations, and chemical interactions that are difficult to replicate in laboratory settings. Current testing equipment often fails to accurately model these dynamic conditions, particularly the combined effects of thermal cycling, pressure variations, and mechanical stresses that occur simultaneously in operational environments.

Material compatibility testing represents another critical gap. The interaction between coolants and system materials over extended periods can lead to corrosion, degradation, or particulate formation. Current accelerated testing methods struggle to accurately predict these long-term effects, creating reliability uncertainties for systems expected to operate for 5-10 years in the field.

Data interpretation and correlation between test results and real-world performance remains problematic. The industry lacks robust models that translate accelerated test data into meaningful reliability predictions. This disconnect between qualification testing and actual field performance creates uncertainty in system design and warranty determinations.

Finally, emerging technologies like two-phase cooling and direct-to-chip liquid cooling introduce novel failure modes that existing qualification frameworks cannot adequately assess. As these advanced cooling technologies gain traction, the gap between testing capabilities and system requirements continues to widen, highlighting the urgent need for innovative qualification methodologies that can keep pace with rapid technological evolution.

Current Burst/Pressure Cycling and HALT Testing Methodologies

01 Thermal performance testing methods

Various methods for testing the thermal performance of liquid cooling systems, including temperature measurement techniques, heat load simulation, and thermal resistance calculations. These tests evaluate how effectively the cooling system dissipates heat under different operating conditions and help determine if the system meets design specifications for thermal management.- Thermal performance testing methods: Various methods for testing the thermal performance of liquid cooling systems, including temperature measurement techniques, heat load simulation, and thermal resistance calculations. These tests evaluate how effectively the cooling system dissipates heat under different operating conditions and help determine if the system meets thermal performance requirements.

- Reliability and durability testing: Testing procedures to evaluate the reliability and durability of liquid cooling systems over time, including accelerated life testing, stress testing, and failure mode analysis. These tests subject cooling systems to extreme conditions to identify potential failure points and verify system longevity under various operational scenarios.

- Leak detection and pressure testing: Methods for detecting leaks and testing pressure integrity in liquid cooling systems, including pressure decay tests, helium leak detection, and visual inspection techniques. These tests ensure the cooling system maintains proper fluid containment and pressure levels during operation, preventing coolant loss and system failure.

- Flow rate and hydraulic performance testing: Testing procedures to evaluate the flow characteristics and hydraulic performance of liquid cooling systems, including flow rate measurement, pressure drop analysis, and pump performance verification. These tests ensure proper coolant circulation throughout the system and verify that the cooling solution meets design specifications under various operating conditions.

- Automated testing systems and data analysis: Advanced automated systems for conducting comprehensive qualification testing of liquid cooling solutions, including data acquisition, real-time monitoring, and analytical software for test result interpretation. These systems enable efficient testing processes, consistent test conditions, and sophisticated analysis of cooling system performance across multiple parameters.

02 Reliability and durability testing

Testing procedures designed to evaluate the long-term reliability and durability of liquid cooling systems. These include accelerated life testing, stress testing under extreme conditions, and failure mode analysis. Such tests help identify potential weaknesses in the cooling system design and ensure the system can withstand operational demands over its expected lifetime.Expand Specific Solutions03 Leak detection and pressure testing

Methods for detecting leaks and testing pressure integrity in liquid cooling systems. These tests involve pressurizing the system and monitoring for pressure drops, using specialized detection fluids, or employing electronic leak detection equipment. Ensuring the system is leak-free is critical for preventing coolant loss and potential damage to electronic components.Expand Specific Solutions04 Flow rate and hydraulic performance testing

Testing procedures focused on measuring and validating the flow characteristics of liquid cooling systems. These tests evaluate parameters such as flow rate, pressure drop, pump performance, and fluid distribution across cooling channels. Proper hydraulic performance ensures efficient heat transfer and uniform cooling throughout the system.Expand Specific Solutions05 Automated testing systems and quality control

Advanced automated systems and methodologies for comprehensive qualification testing of liquid cooling solutions. These include integrated test platforms that can simultaneously evaluate multiple performance parameters, automated data collection and analysis tools, and quality control processes to ensure consistent manufacturing quality. Such systems help streamline the testing process and improve reliability of test results.Expand Specific Solutions

Key Industry Players in Liquid Cooling Technology

The liquid cooling qualification market is currently in a growth phase, with increasing demand driven by data center expansion, electric vehicle development, and high-performance computing needs. The market size is projected to expand significantly as thermal management becomes critical in advanced electronics. Technologically, the field shows varying maturity levels across different applications. Leading players like Intel, Huawei, and ABB Group are advancing pressure cycling and HALT testing methodologies, while specialized cooling technology providers such as DuPont and Resonac are developing innovative thermal interface materials. Academic institutions like Taiyuan University of Technology are contributing fundamental research, creating a competitive landscape balanced between established industrial giants and specialized cooling solution providers.

Hon Hai Precision Industry Co., Ltd.

Technical Solution: Hon Hai (Foxconn) has established a comprehensive liquid cooling qualification system focused on consumer electronics and server manufacturing. Their burst/pressure cycling methodology tests components at 2x rated pressure for 100,000 cycles with particular attention to micro-channel cooling structures. Foxconn's HALT procedures incorporate rapid thermal cycling between -10°C and +70°C while simultaneously applying random vibration profiles that simulate transportation and handling stresses. Their acceptance criteria include strict leakage testing with helium mass spectrometry (sensitivity to 10^-9 cc/sec), thermal performance verification across multiple operating points, and accelerated life testing equivalent to 7 years of operation. Foxconn's qualification process also features specialized testing for manufacturing variability, with statistical process control methods applied to ensure consistent quality across high-volume production. Their approach includes compatibility testing with various coolants including water-glycol mixtures and dielectric fluids.

Strengths: Optimized for high-volume manufacturing environments; extensive experience with consumer electronics cooling requirements; efficient qualification processes suitable for rapid product development cycles. Weaknesses: May prioritize manufacturing efficiency over extreme durability requirements; some testing protocols less rigorous than those used in aerospace or military applications.

Battelle Memorial Institute

Technical Solution: Battelle has developed a sophisticated liquid cooling qualification framework focused on mission-critical applications in defense, aerospace, and energy sectors. Their burst/pressure cycling methodology incorporates both hydraulic and pneumatic testing up to 3x maximum operating pressure for 250,000 cycles, with specialized instrumentation to detect micro-leaks and material fatigue. Battelle's HALT procedures utilize combined environment testing chambers capable of temperature extremes from -65°C to +150°C while simultaneously applying vibration stresses up to 60G RMS across six axes. Their acceptance criteria include comprehensive materials analysis before and after testing, with electron microscopy examination of critical components to identify potential failure mechanisms at the microscopic level. Battelle's qualification process also features specialized testing for radiation resistance, electromagnetic interference, and chemical compatibility with exotic coolants used in specialized applications. Their approach incorporates physics-based modeling to predict long-term reliability beyond what can be directly tested.

Strengths: Extremely thorough testing methodologies suitable for mission-critical applications; multidisciplinary approach incorporating materials science and reliability engineering; extensive experience with military and aerospace standards. Weaknesses: Qualification process can be prohibitively expensive and time-consuming for commercial applications; testing protocols may exceed requirements for standard commercial products.

Critical Technical Analysis of Qualification Protocols

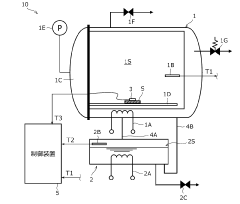

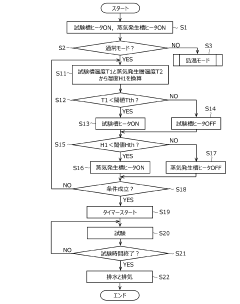

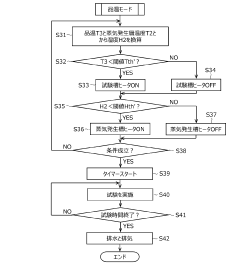

Accelerated life testing device and method

PatentActiveUS20160131571A1

Innovation

- An accelerated life testing method and device that uses a test chamber with an atmospheric controller to alternately change atmospheres, forming and removing a deposition layer to create an oxidation layer on a test piece, simulating oxidation conditions.

High acceleration life testing device and method for testing high acceleration life

PatentPendingJP2024089295A

Innovation

- A highly accelerated life testing device and method that includes a test space and a steam generation space, with temperature sensors directly attached to the sample and separate heaters for each space, allowing for precise temperature control through a control device that switches heaters based on direct sample temperature measurements.

Material Compatibility and Corrosion Prevention Strategies

Material compatibility is a critical consideration in liquid cooling systems, particularly when evaluating qualification methods such as burst/pressure cycling, HALT (Highly Accelerated Life Testing), and acceptance testing. The interaction between cooling fluids and system components can significantly impact system reliability and longevity.

Coolant chemistry plays a fundamental role in material compatibility. Most liquid cooling systems utilize either water-based solutions with additives or dielectric fluids. Each coolant type presents unique compatibility challenges with common system materials including copper, aluminum, stainless steel, and various polymers. Galvanic corrosion becomes particularly problematic in systems combining dissimilar metals, such as copper and aluminum, necessitating proper inhibitor selection.

Prevention strategies must address both electrochemical and chemical corrosion mechanisms. Effective approaches include implementing sacrificial anodes in critical system locations, utilizing vapor phase corrosion inhibitors, and applying protective coatings to vulnerable components. These strategies must maintain their effectiveness under the extreme conditions present during qualification testing, particularly during HALT procedures where temperature and pressure fluctuations accelerate corrosion processes.

Qualification testing protocols should incorporate specific material compatibility evaluations. This includes extended exposure testing where system materials are subjected to coolant contact under elevated temperatures, simulating worst-case operating conditions. Weight loss analysis and surface examination techniques provide quantitative data on corrosion rates and mechanisms, informing material selection decisions.

Modern corrosion monitoring techniques enhance qualification procedures by providing real-time data. Electrical resistance probes, electrochemical impedance spectroscopy, and ultrasonic thickness measurements can be integrated into test setups to monitor corrosion progression during pressure cycling and HALT procedures. These techniques enable early detection of compatibility issues before catastrophic failures occur.

Fluid maintenance strategies represent another critical aspect of corrosion prevention. Regular monitoring of coolant pH, conductivity, and inhibitor concentration ensures continued protection throughout system life. Filtration systems that remove corrosion products and contaminants prevent secondary corrosion mechanisms and maintain heat transfer efficiency. These maintenance protocols should be validated during qualification testing to ensure their effectiveness under actual operating conditions.

Industry standards and best practices provide valuable frameworks for material compatibility evaluation. Standards from ASTM, NACE, and ASHRAE offer established methodologies for corrosion testing and material selection. Adherence to these standards during qualification testing ensures comprehensive evaluation of material compatibility and corrosion resistance, ultimately leading to more reliable liquid cooling systems.

Coolant chemistry plays a fundamental role in material compatibility. Most liquid cooling systems utilize either water-based solutions with additives or dielectric fluids. Each coolant type presents unique compatibility challenges with common system materials including copper, aluminum, stainless steel, and various polymers. Galvanic corrosion becomes particularly problematic in systems combining dissimilar metals, such as copper and aluminum, necessitating proper inhibitor selection.

Prevention strategies must address both electrochemical and chemical corrosion mechanisms. Effective approaches include implementing sacrificial anodes in critical system locations, utilizing vapor phase corrosion inhibitors, and applying protective coatings to vulnerable components. These strategies must maintain their effectiveness under the extreme conditions present during qualification testing, particularly during HALT procedures where temperature and pressure fluctuations accelerate corrosion processes.

Qualification testing protocols should incorporate specific material compatibility evaluations. This includes extended exposure testing where system materials are subjected to coolant contact under elevated temperatures, simulating worst-case operating conditions. Weight loss analysis and surface examination techniques provide quantitative data on corrosion rates and mechanisms, informing material selection decisions.

Modern corrosion monitoring techniques enhance qualification procedures by providing real-time data. Electrical resistance probes, electrochemical impedance spectroscopy, and ultrasonic thickness measurements can be integrated into test setups to monitor corrosion progression during pressure cycling and HALT procedures. These techniques enable early detection of compatibility issues before catastrophic failures occur.

Fluid maintenance strategies represent another critical aspect of corrosion prevention. Regular monitoring of coolant pH, conductivity, and inhibitor concentration ensures continued protection throughout system life. Filtration systems that remove corrosion products and contaminants prevent secondary corrosion mechanisms and maintain heat transfer efficiency. These maintenance protocols should be validated during qualification testing to ensure their effectiveness under actual operating conditions.

Industry standards and best practices provide valuable frameworks for material compatibility evaluation. Standards from ASTM, NACE, and ASHRAE offer established methodologies for corrosion testing and material selection. Adherence to these standards during qualification testing ensures comprehensive evaluation of material compatibility and corrosion resistance, ultimately leading to more reliable liquid cooling systems.

Environmental Impact and Sustainability Considerations

Liquid cooling systems, while offering superior thermal management capabilities for high-performance computing environments, present significant environmental and sustainability considerations that must be addressed throughout their lifecycle. The coolants commonly used in these systems, particularly dielectric fluids, often contain compounds that may have substantial global warming potential (GWP) or ozone depletion potential (ODP). When evaluating liquid cooling qualification processes such as burst testing, pressure cycling, and HALT (Highly Accelerated Life Testing), it becomes essential to consider the environmental impact of potential leakage events and disposal protocols.

The manufacturing processes for liquid cooling components typically require energy-intensive operations and specialized materials, contributing to the overall carbon footprint of these systems. Qualification testing itself consumes additional resources and energy, particularly during accelerated life testing procedures that may require multiple test units and extended operation periods. However, these environmental costs must be balanced against the significant energy efficiency improvements that properly qualified liquid cooling systems can deliver during their operational lifetime.

Recycling and end-of-life considerations represent another critical environmental dimension. The mixed material composition of liquid cooling systems—combining metals, polymers, and specialized coolants—creates challenges for disassembly and material recovery. Qualification standards should increasingly incorporate design-for-recycling principles to facilitate more sustainable end-of-life management. This includes considerations for coolant recovery and purification processes that minimize waste and environmental contamination.

Water consumption represents a growing concern, particularly for systems that utilize water as a secondary cooling medium. Qualification testing should evaluate water efficiency metrics and encourage closed-loop designs that minimize consumption. In regions facing water scarcity, the sustainability of water-dependent cooling solutions requires particular scrutiny during qualification processes.

Energy efficiency improvements remain the primary environmental benefit of liquid cooling technologies. Properly qualified systems that maintain their integrity throughout their operational lifetime can significantly reduce data center power consumption, potentially offsetting their manufacturing and testing impacts. Qualification procedures should therefore include long-term efficiency metrics as key performance indicators.

Regulatory compliance with evolving environmental standards presents another dimension for consideration. As global regulations increasingly restrict certain chemical compounds and mandate improved energy efficiency, qualification processes must adapt to ensure systems meet current and anticipated future requirements. This forward-looking approach helps prevent premature obsolescence due to regulatory non-compliance.

The manufacturing processes for liquid cooling components typically require energy-intensive operations and specialized materials, contributing to the overall carbon footprint of these systems. Qualification testing itself consumes additional resources and energy, particularly during accelerated life testing procedures that may require multiple test units and extended operation periods. However, these environmental costs must be balanced against the significant energy efficiency improvements that properly qualified liquid cooling systems can deliver during their operational lifetime.

Recycling and end-of-life considerations represent another critical environmental dimension. The mixed material composition of liquid cooling systems—combining metals, polymers, and specialized coolants—creates challenges for disassembly and material recovery. Qualification standards should increasingly incorporate design-for-recycling principles to facilitate more sustainable end-of-life management. This includes considerations for coolant recovery and purification processes that minimize waste and environmental contamination.

Water consumption represents a growing concern, particularly for systems that utilize water as a secondary cooling medium. Qualification testing should evaluate water efficiency metrics and encourage closed-loop designs that minimize consumption. In regions facing water scarcity, the sustainability of water-dependent cooling solutions requires particular scrutiny during qualification processes.

Energy efficiency improvements remain the primary environmental benefit of liquid cooling technologies. Properly qualified systems that maintain their integrity throughout their operational lifetime can significantly reduce data center power consumption, potentially offsetting their manufacturing and testing impacts. Qualification procedures should therefore include long-term efficiency metrics as key performance indicators.

Regulatory compliance with evolving environmental standards presents another dimension for consideration. As global regulations increasingly restrict certain chemical compounds and mandate improved energy efficiency, qualification processes must adapt to ensure systems meet current and anticipated future requirements. This forward-looking approach helps prevent premature obsolescence due to regulatory non-compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!