Liquid Cooling Server Manifolds: Quick-Disconnects, Leak Risk And Serviceability

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Cooling Manifold Technology Evolution and Objectives

Liquid cooling technology for data centers has evolved significantly over the past decades, transitioning from niche applications in supercomputing to mainstream adoption in high-performance computing environments. The evolution began with simple air cooling systems, which proved inadequate as computing power densities increased exponentially. This limitation led to the development of direct-to-chip liquid cooling in the 1980s, primarily for mainframe computers, where coolant was circulated directly to heat-generating components.

By the early 2000s, the emergence of high-density server racks necessitated more efficient cooling solutions, catalyzing advancements in liquid cooling manifold systems. These early manifolds were characterized by permanent connections, limited flexibility, and rudimentary leak prevention mechanisms. The primary objective was simply to deliver coolant to the servers without significant consideration for serviceability or maintenance.

The mid-2010s marked a pivotal shift in manifold design philosophy, as data center operators began prioritizing operational efficiency alongside cooling performance. This period saw the introduction of the first generation of quick-disconnect couplings in manifold systems, allowing for server maintenance without draining the entire cooling loop. However, these early quick-disconnect solutions often suffered from reliability issues, including dripping during disconnection and mechanical failures after repeated use.

Current technological trajectories aim to address several critical objectives in liquid cooling manifold design. Foremost among these is the development of zero-leak quick-disconnect systems that maintain absolute fluid integrity during connection and disconnection cycles. This objective is driven by the increasing deployment of liquid cooling in mission-critical environments where even minor leaks can cause catastrophic system failures.

Another key objective is enhancing serviceability through modular manifold designs that allow for hot-swapping of servers without disrupting the cooling system's operation. This includes the development of standardized interfaces between cooling manifolds and server units, facilitating easier integration across different hardware platforms.

Reliability improvement represents a third critical objective, with emphasis on extending the operational lifespan of quick-disconnect components through advanced materials science and precision engineering. Current research focuses on materials that resist corrosion, minimize wear from repeated connections, and maintain seal integrity under varying temperature and pressure conditions.

The evolution of liquid cooling manifolds is further driven by sustainability goals, with objectives to reduce the environmental impact through more efficient coolant circulation, minimized pumping power requirements, and the use of environmentally friendly coolant formulations. These advancements collectively aim to establish liquid cooling as the standard for next-generation data centers, balancing performance, reliability, and operational efficiency.

By the early 2000s, the emergence of high-density server racks necessitated more efficient cooling solutions, catalyzing advancements in liquid cooling manifold systems. These early manifolds were characterized by permanent connections, limited flexibility, and rudimentary leak prevention mechanisms. The primary objective was simply to deliver coolant to the servers without significant consideration for serviceability or maintenance.

The mid-2010s marked a pivotal shift in manifold design philosophy, as data center operators began prioritizing operational efficiency alongside cooling performance. This period saw the introduction of the first generation of quick-disconnect couplings in manifold systems, allowing for server maintenance without draining the entire cooling loop. However, these early quick-disconnect solutions often suffered from reliability issues, including dripping during disconnection and mechanical failures after repeated use.

Current technological trajectories aim to address several critical objectives in liquid cooling manifold design. Foremost among these is the development of zero-leak quick-disconnect systems that maintain absolute fluid integrity during connection and disconnection cycles. This objective is driven by the increasing deployment of liquid cooling in mission-critical environments where even minor leaks can cause catastrophic system failures.

Another key objective is enhancing serviceability through modular manifold designs that allow for hot-swapping of servers without disrupting the cooling system's operation. This includes the development of standardized interfaces between cooling manifolds and server units, facilitating easier integration across different hardware platforms.

Reliability improvement represents a third critical objective, with emphasis on extending the operational lifespan of quick-disconnect components through advanced materials science and precision engineering. Current research focuses on materials that resist corrosion, minimize wear from repeated connections, and maintain seal integrity under varying temperature and pressure conditions.

The evolution of liquid cooling manifolds is further driven by sustainability goals, with objectives to reduce the environmental impact through more efficient coolant circulation, minimized pumping power requirements, and the use of environmentally friendly coolant formulations. These advancements collectively aim to establish liquid cooling as the standard for next-generation data centers, balancing performance, reliability, and operational efficiency.

Market Demand Analysis for Liquid-Cooled Server Solutions

The data center industry is experiencing a significant shift towards liquid cooling solutions, driven primarily by the increasing power density of modern computing systems. Traditional air cooling methods are becoming insufficient as server power consumption continues to rise, with high-performance computing (HPC) systems and AI accelerators now regularly exceeding 30-50kW per rack. This trend has created a robust and rapidly growing market for liquid cooling technologies, particularly for server manifolds with quick-disconnect capabilities.

Market research indicates that the global liquid cooling market for data centers was valued at approximately $2.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 24.8% through 2028. This growth is particularly pronounced in regions with high electricity costs or warm climates, where the efficiency benefits of liquid cooling provide substantial operational savings.

The demand for liquid-cooled server solutions is being driven by several key factors. First, the proliferation of AI and machine learning workloads has led to the deployment of specialized hardware that generates significantly more heat than traditional CPUs. These systems often require direct liquid cooling to maintain optimal operating temperatures and performance levels.

Energy efficiency has become a critical consideration for data center operators, with cooling typically accounting for 30-40% of a facility's total power consumption. Liquid cooling can reduce this overhead by up to 50%, offering substantial cost savings and supporting sustainability initiatives. Many large cloud service providers have committed to carbon-neutral or carbon-negative operations, further accelerating the adoption of more efficient cooling technologies.

Reliability concerns are also influencing market demand. As businesses become increasingly dependent on digital infrastructure, the cost of downtime has risen dramatically, often exceeding $5,000 per minute for enterprise operations. Liquid cooling systems with advanced features like leak-free quick-disconnects and redundant manifolds are seeing strong demand as they address these reliability requirements.

The market is segmented by solution type, with direct-to-chip cooling currently holding the largest market share at approximately 45%. However, immersion cooling is growing at the fastest rate due to its superior thermal performance for high-density applications. Hybrid solutions that combine multiple cooling approaches are emerging as a significant trend, particularly for facilities transitioning from traditional to liquid cooling infrastructures.

From a geographic perspective, North America leads the market with approximately 38% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid data center expansion in countries like China, Singapore, and India.

Market research indicates that the global liquid cooling market for data centers was valued at approximately $2.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 24.8% through 2028. This growth is particularly pronounced in regions with high electricity costs or warm climates, where the efficiency benefits of liquid cooling provide substantial operational savings.

The demand for liquid-cooled server solutions is being driven by several key factors. First, the proliferation of AI and machine learning workloads has led to the deployment of specialized hardware that generates significantly more heat than traditional CPUs. These systems often require direct liquid cooling to maintain optimal operating temperatures and performance levels.

Energy efficiency has become a critical consideration for data center operators, with cooling typically accounting for 30-40% of a facility's total power consumption. Liquid cooling can reduce this overhead by up to 50%, offering substantial cost savings and supporting sustainability initiatives. Many large cloud service providers have committed to carbon-neutral or carbon-negative operations, further accelerating the adoption of more efficient cooling technologies.

Reliability concerns are also influencing market demand. As businesses become increasingly dependent on digital infrastructure, the cost of downtime has risen dramatically, often exceeding $5,000 per minute for enterprise operations. Liquid cooling systems with advanced features like leak-free quick-disconnects and redundant manifolds are seeing strong demand as they address these reliability requirements.

The market is segmented by solution type, with direct-to-chip cooling currently holding the largest market share at approximately 45%. However, immersion cooling is growing at the fastest rate due to its superior thermal performance for high-density applications. Hybrid solutions that combine multiple cooling approaches are emerging as a significant trend, particularly for facilities transitioning from traditional to liquid cooling infrastructures.

From a geographic perspective, North America leads the market with approximately 38% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid data center expansion in countries like China, Singapore, and India.

Current Challenges in Liquid Cooling Manifold Implementation

Despite the growing adoption of liquid cooling solutions in data centers, the implementation of manifold systems faces several significant challenges that impede widespread deployment. The primary concern revolves around quick-disconnect couplings, which serve as critical connection points between cooling infrastructure and server hardware. These components must maintain perfect seals while allowing for frequent server maintenance operations, creating an inherent tension between serviceability and leak prevention.

Current quick-disconnect technologies exhibit reliability issues under the thermal cycling conditions typical in data center environments. The repeated expansion and contraction of materials can compromise seal integrity over time, leading to microscopic leaks that may not be immediately detectable but can cause catastrophic failures when accumulated. Industry testing reveals that even premium quick-disconnect solutions show degradation after 50-100 connection/disconnection cycles, falling short of the 500+ cycles expected during a server's operational lifetime.

Leak detection represents another substantial challenge, as conventional water detection methods prove inadequate for the confined spaces within server racks. Current sensor technologies often detect leaks only after fluid has contacted critical components, by which time damage may already be irreversible. The industry lacks standardized testing protocols for validating leak detection systems under realistic operational conditions, resulting in inconsistent performance across implementations.

Serviceability concerns create additional complications, as maintenance procedures for liquid-cooled servers require specialized training and tools. The current manifold designs frequently necessitate complete system shutdown for routine maintenance, significantly impacting data center availability metrics. Time studies indicate that servicing liquid-cooled servers takes approximately 2.5 times longer than their air-cooled counterparts, creating operational inefficiencies and increasing total cost of ownership.

Material compatibility issues further exacerbate implementation challenges. The coolants used in these systems must remain chemically stable while in contact with multiple metal types, plastics, and elastomers present in manifold components. Accelerated aging tests demonstrate that certain materials used in quick-disconnect couplings experience premature degradation when exposed to modern coolant formulations, particularly under elevated temperature conditions.

Standardization remains elusive across the industry, with manufacturers employing proprietary connection systems that limit interoperability. This fragmentation increases complexity for data center operators managing heterogeneous equipment environments and creates vendor lock-in scenarios that restrict flexibility in hardware procurement strategies. The lack of universal standards also complicates the development of comprehensive testing methodologies for evaluating manifold system performance and reliability.

Current quick-disconnect technologies exhibit reliability issues under the thermal cycling conditions typical in data center environments. The repeated expansion and contraction of materials can compromise seal integrity over time, leading to microscopic leaks that may not be immediately detectable but can cause catastrophic failures when accumulated. Industry testing reveals that even premium quick-disconnect solutions show degradation after 50-100 connection/disconnection cycles, falling short of the 500+ cycles expected during a server's operational lifetime.

Leak detection represents another substantial challenge, as conventional water detection methods prove inadequate for the confined spaces within server racks. Current sensor technologies often detect leaks only after fluid has contacted critical components, by which time damage may already be irreversible. The industry lacks standardized testing protocols for validating leak detection systems under realistic operational conditions, resulting in inconsistent performance across implementations.

Serviceability concerns create additional complications, as maintenance procedures for liquid-cooled servers require specialized training and tools. The current manifold designs frequently necessitate complete system shutdown for routine maintenance, significantly impacting data center availability metrics. Time studies indicate that servicing liquid-cooled servers takes approximately 2.5 times longer than their air-cooled counterparts, creating operational inefficiencies and increasing total cost of ownership.

Material compatibility issues further exacerbate implementation challenges. The coolants used in these systems must remain chemically stable while in contact with multiple metal types, plastics, and elastomers present in manifold components. Accelerated aging tests demonstrate that certain materials used in quick-disconnect couplings experience premature degradation when exposed to modern coolant formulations, particularly under elevated temperature conditions.

Standardization remains elusive across the industry, with manufacturers employing proprietary connection systems that limit interoperability. This fragmentation increases complexity for data center operators managing heterogeneous equipment environments and creates vendor lock-in scenarios that restrict flexibility in hardware procurement strategies. The lack of universal standards also complicates the development of comprehensive testing methodologies for evaluating manifold system performance and reliability.

Quick-Disconnect Coupling Solutions and Implementation Strategies

01 Quick-disconnect coupling designs for liquid cooling systems

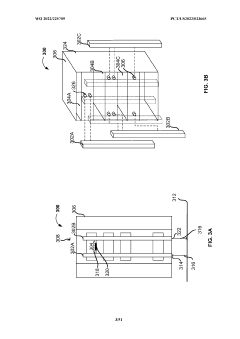

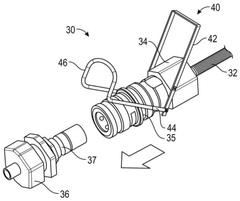

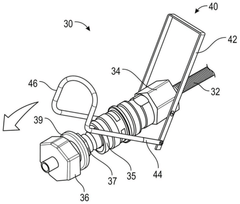

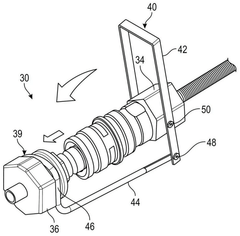

Quick-disconnect couplings are essential components in liquid cooling server systems that allow for safe and efficient connection and disconnection of cooling lines during maintenance. These couplings incorporate features such as automatic shutoff valves that prevent coolant leakage when disconnected, ensuring system integrity. Advanced designs include drip-free operation, minimal air inclusion during reconnection, and optimized flow characteristics to maintain cooling efficiency while reducing leak risks.- Quick-disconnect coupling designs for liquid cooling systems: Quick-disconnect couplings are essential components in liquid cooling server systems that allow for safe connection and disconnection of cooling lines during maintenance. These couplings incorporate features such as automatic shutoff valves that prevent coolant leakage when disconnected, ensuring system integrity. Advanced designs include drip-free disconnects that minimize fluid loss and contamination risks, while maintaining optimal flow characteristics to preserve cooling efficiency.

- Leak detection and prevention mechanisms: Liquid cooling systems incorporate sophisticated leak detection and prevention mechanisms to minimize the risk of coolant leakage that could damage server components. These include sensors that can detect moisture or pressure changes, automatic shutdown protocols that activate when leaks are detected, and containment systems designed to channel leaked fluid away from critical components. Some designs feature redundant sealing mechanisms and pressure monitoring systems that provide early warning of potential failures.

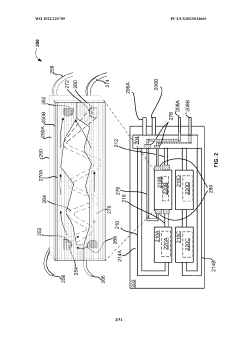

- Manifold design for improved serviceability: Server cooling manifolds are designed with serviceability in mind, featuring modular components that can be individually replaced without disrupting the entire cooling system. These designs include access points that allow for maintenance without complete system drainage, tool-less connection mechanisms for quick component replacement, and standardized interfaces that ensure compatibility across different server generations. Some manifolds incorporate bypass channels that maintain cooling to operational servers while individual units are serviced.

- Redundancy and fail-safe features: To ensure continuous operation even during component failures, liquid cooling systems implement redundancy and fail-safe features. These include parallel cooling paths that can maintain operation if one path fails, backup pumps that activate automatically when primary pumps malfunction, and isolation valves that can seal off compromised sections of the cooling system. Advanced systems incorporate predictive maintenance capabilities that identify potential failures before they occur, allowing for scheduled maintenance rather than emergency repairs.

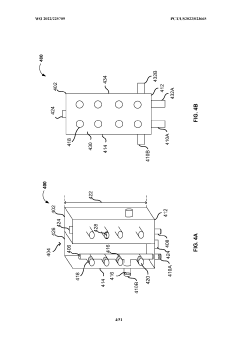

- Thermal interface optimization for cooling efficiency: The efficiency of liquid cooling systems depends significantly on the thermal interfaces between cooling components and server hardware. Designs focus on maximizing heat transfer through optimized contact surfaces, specialized thermal interface materials that reduce thermal resistance, and precision-engineered cold plates that conform to processor and component geometries. Some systems employ direct-to-chip cooling approaches that eliminate intermediate thermal interfaces, while others use micro-channel designs that increase surface area for heat exchange.

02 Leak detection and prevention mechanisms

Modern liquid cooling server manifolds incorporate sophisticated leak detection and prevention systems to minimize the risk of coolant leakage. These systems include sensors that can detect moisture or pressure changes, automatic shutdown protocols that activate when leaks are detected, and containment designs that channel any leaked coolant away from critical electronic components. Some designs also feature redundant sealing mechanisms and pressure monitoring to provide early warning of potential failures before catastrophic leaks occur.Expand Specific Solutions03 Serviceability enhancements for liquid cooling infrastructure

Serviceability is a critical consideration in liquid cooling server designs, with innovations focused on enabling maintenance without system downtime. Key features include modular manifold designs that allow for component replacement without draining the entire system, tool-less quick-disconnect mechanisms for rapid service operations, and accessibility improvements that provide clear service pathways to cooling components. These enhancements reduce maintenance time, minimize the risk of human error during servicing, and improve overall system reliability.Expand Specific Solutions04 Manifold design optimization for reliability

Advanced manifold designs focus on enhancing reliability in liquid cooling server systems through structural and material innovations. These include the use of corrosion-resistant materials to prevent degradation over time, optimized flow path designs that reduce turbulence and pressure points, and integrated redundancy features that maintain cooling capability even if individual components fail. Some designs also incorporate vibration dampening elements to prevent connection loosening and employ specialized manufacturing techniques to eliminate potential leak points at joints and seams.Expand Specific Solutions05 Thermal management integration with leak mitigation

Modern liquid cooling systems balance effective thermal management with leak risk mitigation through integrated design approaches. These systems incorporate intelligent flow control that optimizes cooling performance while maintaining safe operating pressures, thermal sensors that provide real-time monitoring of system performance, and adaptive control systems that can adjust flow rates based on cooling demands. Some advanced designs also feature emergency isolation capabilities that can compartmentalize sections of the cooling system in the event of a detected leak, protecting critical server components.Expand Specific Solutions

Key Industry Players in Liquid Cooling Server Technology

The liquid cooling server manifold market is in a growth phase, driven by increasing data center power densities and efficiency demands. The market is expanding rapidly as companies seek to manage thermal challenges in high-performance computing environments. From a technological maturity perspective, the industry is evolving with key players focusing on balancing leak prevention with serviceability. NVIDIA and IBM lead with advanced enterprise solutions, while Supermicro, Inspur, and Lenovo are developing competitive offerings with improved quick-disconnect technologies. Chinese manufacturers like Baidu and xFusion are gaining market share with cost-effective solutions. Specialized cooling experts such as Strategic Thermal Labs and Envicool are advancing niche innovations to address reliability concerns, particularly around leak risks that remain a primary adoption barrier.

NVIDIA Corp.

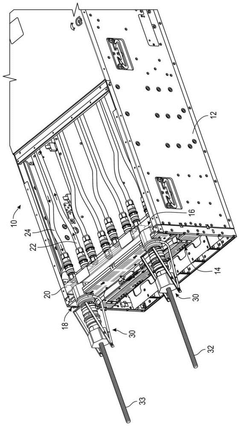

Technical Solution: NVIDIA has developed advanced liquid cooling solutions for their high-performance computing systems and data centers. Their direct-to-chip liquid cooling technology utilizes specialized quick-disconnect couplings that feature double shut-off valves to prevent leakage during connection and disconnection operations. The system employs a cold plate design that directly contacts the GPU and CPU components, with manifolds distributing coolant across multiple server racks. NVIDIA's solution incorporates leak detection sensors throughout the cooling loop that can trigger automatic shutdown protocols if moisture is detected. For serviceability, they've engineered their server racks with sliding rail systems that allow technicians to access components without fully disconnecting the cooling infrastructure. Their CDU (Cooling Distribution Unit) architecture separates the primary facility water loop from the server cooling loop using heat exchangers, reducing contamination risks and simplifying maintenance procedures.

Strengths: Superior thermal performance for high-density computing environments, reduced energy consumption compared to air cooling, and comprehensive leak detection systems. Weaknesses: Higher initial implementation costs, requires specialized training for maintenance personnel, and potential for system-wide disruption if a leak occurs in shared cooling infrastructure.

International Business Machines Corp.

Technical Solution: IBM has pioneered advanced liquid cooling solutions for data centers with their Rear Door Heat eXchanger and direct liquid cooling technologies. Their server manifold design features a modular approach with centralized distribution units that connect to individual server racks through flexible, reinforced tubing systems. IBM's quick-disconnect couplings utilize a dual-valve design that automatically seals both ends when disconnected, virtually eliminating drip potential during maintenance. The company has developed a proprietary leak detection system that combines moisture sensors with pressure monitoring to identify potential failures before they cause damage. For serviceability, IBM implements a "warm-swap" capability that allows individual server components to be replaced without shutting down the entire cooling system. Their manifold design incorporates isolation valves that enable sections of the cooling loop to be serviced independently, minimizing downtime. IBM's solution also features transparent sections in critical junctions to allow visual inspection of coolant flow and quality.

Strengths: Exceptional reliability with redundant safety systems, highly modular design allowing for incremental scaling, and comprehensive monitoring capabilities integrated with data center management systems. Weaknesses: Premium pricing compared to standard cooling solutions, proprietary components that may limit third-party service options, and complex installation requirements that increase deployment time.

Critical Patents and Innovations in Leak Prevention Technology

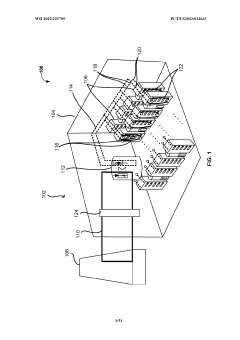

Quick disconnect blind-mate manifold

PatentWO2022225709A1

Innovation

- The implementation of a quick disconnect blind-mate manifold system that simplifies fluid connections between servers and cooling loops, reducing the need for intermediate tubing and enhancing airflow, with features like direct coupling and self-aligning connectors for rapid installation and removal.

Server comprising quick disconnect connector

PatentPendingCN116841355A

Innovation

- An improved fast-disconnect connector assembly is designed, using a manual pairing actuator, which reduces operating force through the mechanical structure of the handle and buckle, and achieves less force connection and disconnection.

Serviceability Enhancement Approaches for Liquid-Cooled Systems

Enhancing serviceability in liquid-cooled systems requires a comprehensive approach that addresses the unique challenges posed by coolant circulation components. Current industry practices focus on several key areas to improve maintenance efficiency while minimizing system downtime and leak risks.

The implementation of modular design principles represents a fundamental shift in liquid cooling architecture. By compartmentalizing cooling components into discrete, independently serviceable units, technicians can isolate specific sections for maintenance without disrupting the entire cooling infrastructure. This approach significantly reduces system downtime and simplifies the replacement of individual components such as pumps, heat exchangers, and manifold sections.

Quick-disconnect (QD) technology has evolved substantially to address historical concerns regarding reliability and leakage. Advanced QD couplings now incorporate dual-valve designs that automatically seal both the supply and return lines when disconnected, virtually eliminating coolant spillage during maintenance procedures. These mechanisms typically utilize specialized elastomeric seals and precision-machined components that maintain integrity over thousands of connection cycles.

Tool-less maintenance protocols have gained prominence in enterprise-grade liquid cooling solutions. These systems feature thumb-operated locking mechanisms, color-coded connection points, and standardized interface designs that enable rapid service without specialized equipment. Some manufacturers have introduced magnetic coupling systems that provide secure connections while allowing for quick separation during emergency maintenance scenarios.

Predictive maintenance capabilities represent the cutting edge of serviceability enhancement. Modern liquid cooling systems increasingly incorporate integrated sensor networks that monitor flow rates, pressure differentials, and coolant chemistry in real-time. These systems can detect early warning signs of potential failures, such as microbubble formation or pressure anomalies that might indicate developing leaks, allowing for preemptive maintenance before catastrophic failures occur.

Accessibility considerations have driven significant design innovations in manifold placement and orientation. Forward-thinking manufacturers now position manifolds and connection points at the front or top of server racks, eliminating the need to access rear compartments or remove adjacent equipment during service procedures. Some designs incorporate sliding rail systems that allow cooling components to extend outward from the rack for easier access during maintenance operations.

Standardization efforts across the industry are gradually addressing compatibility challenges that have historically complicated service procedures. Organizations like the Open Compute Project are developing reference designs for liquid cooling components that promote interchangeability between different vendors' products, potentially reducing spare parts inventories and simplifying maintenance training requirements for technical staff.

The implementation of modular design principles represents a fundamental shift in liquid cooling architecture. By compartmentalizing cooling components into discrete, independently serviceable units, technicians can isolate specific sections for maintenance without disrupting the entire cooling infrastructure. This approach significantly reduces system downtime and simplifies the replacement of individual components such as pumps, heat exchangers, and manifold sections.

Quick-disconnect (QD) technology has evolved substantially to address historical concerns regarding reliability and leakage. Advanced QD couplings now incorporate dual-valve designs that automatically seal both the supply and return lines when disconnected, virtually eliminating coolant spillage during maintenance procedures. These mechanisms typically utilize specialized elastomeric seals and precision-machined components that maintain integrity over thousands of connection cycles.

Tool-less maintenance protocols have gained prominence in enterprise-grade liquid cooling solutions. These systems feature thumb-operated locking mechanisms, color-coded connection points, and standardized interface designs that enable rapid service without specialized equipment. Some manufacturers have introduced magnetic coupling systems that provide secure connections while allowing for quick separation during emergency maintenance scenarios.

Predictive maintenance capabilities represent the cutting edge of serviceability enhancement. Modern liquid cooling systems increasingly incorporate integrated sensor networks that monitor flow rates, pressure differentials, and coolant chemistry in real-time. These systems can detect early warning signs of potential failures, such as microbubble formation or pressure anomalies that might indicate developing leaks, allowing for preemptive maintenance before catastrophic failures occur.

Accessibility considerations have driven significant design innovations in manifold placement and orientation. Forward-thinking manufacturers now position manifolds and connection points at the front or top of server racks, eliminating the need to access rear compartments or remove adjacent equipment during service procedures. Some designs incorporate sliding rail systems that allow cooling components to extend outward from the rack for easier access during maintenance operations.

Standardization efforts across the industry are gradually addressing compatibility challenges that have historically complicated service procedures. Organizations like the Open Compute Project are developing reference designs for liquid cooling components that promote interchangeability between different vendors' products, potentially reducing spare parts inventories and simplifying maintenance training requirements for technical staff.

Environmental Impact and Energy Efficiency Considerations

Liquid cooling systems for servers represent a significant advancement in data center thermal management, offering substantial environmental benefits compared to traditional air cooling methods. The implementation of these systems, particularly through manifolds with quick-disconnect capabilities, contributes to meaningful reductions in energy consumption. Data centers utilizing liquid cooling typically achieve 20-40% lower Power Usage Effectiveness (PUE) ratios, directly translating to decreased carbon emissions and operational costs.

The environmental impact extends beyond energy efficiency to water conservation considerations. While liquid cooling systems require water resources, they demonstrate superior water usage effectiveness (WUE) compared to air cooling systems that rely on evaporative cooling towers. Advanced closed-loop liquid cooling designs can reduce water consumption by up to 30%, addressing growing concerns about data center water footprints in water-stressed regions.

Material selection for manifolds and quick-disconnect components presents another environmental dimension. The transition from copper to polymer-based components reduces embodied carbon and extraction impacts. However, this shift introduces end-of-life recycling challenges that must be addressed through comprehensive lifecycle assessments and circular economy approaches for cooling infrastructure.

Refrigerant selection in liquid cooling systems carries significant global warming potential implications. The industry trend toward low-GWP refrigerants and non-refrigerant coolants (such as mineral oil or engineered fluids) represents an important environmental advancement, though these alternatives must be evaluated for leak risk and long-term environmental persistence.

Serviceability features of quick-disconnect manifolds contribute to sustainability through extended equipment lifecycles. Systems designed for easy maintenance and component replacement can extend server operational life by 30-50%, reducing electronic waste generation. Additionally, modular designs facilitate targeted upgrades rather than wholesale replacements, further minimizing environmental impact.

The energy efficiency gains from liquid cooling enable higher computational density, allowing data centers to process more workloads within the same physical footprint. This space efficiency reduces construction material requirements and associated environmental impacts. Furthermore, the recovered waste heat from liquid cooling systems presents opportunities for beneficial reuse in district heating applications or conversion to other energy forms, creating potential for carbon-negative data center operations in certain implementations.

The environmental impact extends beyond energy efficiency to water conservation considerations. While liquid cooling systems require water resources, they demonstrate superior water usage effectiveness (WUE) compared to air cooling systems that rely on evaporative cooling towers. Advanced closed-loop liquid cooling designs can reduce water consumption by up to 30%, addressing growing concerns about data center water footprints in water-stressed regions.

Material selection for manifolds and quick-disconnect components presents another environmental dimension. The transition from copper to polymer-based components reduces embodied carbon and extraction impacts. However, this shift introduces end-of-life recycling challenges that must be addressed through comprehensive lifecycle assessments and circular economy approaches for cooling infrastructure.

Refrigerant selection in liquid cooling systems carries significant global warming potential implications. The industry trend toward low-GWP refrigerants and non-refrigerant coolants (such as mineral oil or engineered fluids) represents an important environmental advancement, though these alternatives must be evaluated for leak risk and long-term environmental persistence.

Serviceability features of quick-disconnect manifolds contribute to sustainability through extended equipment lifecycles. Systems designed for easy maintenance and component replacement can extend server operational life by 30-50%, reducing electronic waste generation. Additionally, modular designs facilitate targeted upgrades rather than wholesale replacements, further minimizing environmental impact.

The energy efficiency gains from liquid cooling enable higher computational density, allowing data centers to process more workloads within the same physical footprint. This space efficiency reduces construction material requirements and associated environmental impacts. Furthermore, the recovered waste heat from liquid cooling systems presents opportunities for beneficial reuse in district heating applications or conversion to other energy forms, creating potential for carbon-negative data center operations in certain implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!