Liquid Cooling Two-Phase Loops: Boiling Stability, Dry-Out And Control

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Two-Phase Cooling Background and Objectives

Two-phase cooling technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical thermal management solutions. Initially developed for aerospace and defense applications in the 1960s, this technology leverages the high heat transfer coefficients associated with phase change processes, particularly the conversion of liquid to vapor. The fundamental principle exploits the latent heat of vaporization, which enables the absorption of substantially more thermal energy compared to single-phase cooling methods.

The evolution of two-phase cooling systems has been driven by increasing power densities in electronic components, particularly in high-performance computing, telecommunications, and power electronics sectors. Traditional air cooling and single-phase liquid cooling systems have reached their practical limits in many applications, necessitating more efficient thermal management solutions. Two-phase cooling offers theoretical heat transfer coefficients 10-100 times higher than single-phase liquid cooling, making it an attractive option for next-generation thermal management.

Recent technological advancements have focused on miniaturization and integration of two-phase cooling loops into compact electronic systems. The development of micro-channel evaporators, compact condensers, and specialized working fluids has enabled more efficient and reliable implementations. Additionally, the industry has witnessed significant progress in understanding and controlling the complex thermodynamic processes involved in two-phase flow, including nucleate boiling, flow boiling, and condensation phenomena.

The primary objectives of current research in two-phase cooling loops center around three critical challenges: boiling stability, dry-out prevention, and system control. Boiling stability refers to maintaining consistent and predictable phase change processes without destructive pressure fluctuations or flow instabilities. Dry-out prevention focuses on ensuring continuous wetting of heated surfaces to avoid catastrophic temperature excursions. System control encompasses the development of robust monitoring and regulation mechanisms to maintain optimal performance across varying heat loads and environmental conditions.

Future research aims to develop predictive models and control algorithms that can anticipate and mitigate instabilities before they occur. This includes advanced sensor integration, machine learning approaches for system optimization, and adaptive control strategies. Additionally, there is significant interest in developing novel working fluids with enhanced thermophysical properties and reduced environmental impact, as well as advanced surface treatments to promote efficient nucleation and delay dry-out conditions.

The ultimate goal is to create two-phase cooling systems that offer reliable operation under extreme thermal loads while maintaining compact form factors, energy efficiency, and cost-effectiveness for widespread commercial adoption across multiple industries.

The evolution of two-phase cooling systems has been driven by increasing power densities in electronic components, particularly in high-performance computing, telecommunications, and power electronics sectors. Traditional air cooling and single-phase liquid cooling systems have reached their practical limits in many applications, necessitating more efficient thermal management solutions. Two-phase cooling offers theoretical heat transfer coefficients 10-100 times higher than single-phase liquid cooling, making it an attractive option for next-generation thermal management.

Recent technological advancements have focused on miniaturization and integration of two-phase cooling loops into compact electronic systems. The development of micro-channel evaporators, compact condensers, and specialized working fluids has enabled more efficient and reliable implementations. Additionally, the industry has witnessed significant progress in understanding and controlling the complex thermodynamic processes involved in two-phase flow, including nucleate boiling, flow boiling, and condensation phenomena.

The primary objectives of current research in two-phase cooling loops center around three critical challenges: boiling stability, dry-out prevention, and system control. Boiling stability refers to maintaining consistent and predictable phase change processes without destructive pressure fluctuations or flow instabilities. Dry-out prevention focuses on ensuring continuous wetting of heated surfaces to avoid catastrophic temperature excursions. System control encompasses the development of robust monitoring and regulation mechanisms to maintain optimal performance across varying heat loads and environmental conditions.

Future research aims to develop predictive models and control algorithms that can anticipate and mitigate instabilities before they occur. This includes advanced sensor integration, machine learning approaches for system optimization, and adaptive control strategies. Additionally, there is significant interest in developing novel working fluids with enhanced thermophysical properties and reduced environmental impact, as well as advanced surface treatments to promote efficient nucleation and delay dry-out conditions.

The ultimate goal is to create two-phase cooling systems that offer reliable operation under extreme thermal loads while maintaining compact form factors, energy efficiency, and cost-effectiveness for widespread commercial adoption across multiple industries.

Market Analysis for Liquid Cooling Solutions

The global liquid cooling solutions market is experiencing robust growth, driven primarily by the increasing power density of electronic components and the growing demand for efficient thermal management systems. The market was valued at approximately 2.8 billion USD in 2022 and is projected to reach 5.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 12.5% during the forecast period.

Data centers represent the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the escalating computational demands and the shift toward high-performance computing infrastructures. The adoption of liquid cooling solutions in data centers has been accelerated by the need to reduce operational costs associated with traditional air cooling methods, which can account for up to 40% of a data center's energy consumption.

The high-performance computing (HPC) sector follows as the second-largest market segment, with approximately 25% market share. The increasing complexity of computational tasks in scientific research, financial modeling, and artificial intelligence applications has necessitated more efficient cooling solutions to maintain optimal performance and prevent thermal throttling.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 30% and Europe at 25%. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to the rapid expansion of data center infrastructure in countries like China, India, and Singapore.

Two-phase liquid cooling systems, which leverage the phase change of the coolant to enhance heat transfer efficiency, are gaining significant traction in the market. These systems offer superior thermal performance compared to single-phase solutions, with the potential to handle heat fluxes exceeding 500 W/cm². However, challenges related to boiling stability, dry-out conditions, and control mechanisms have limited their widespread adoption.

The market is characterized by a mix of established players and innovative startups. Key market participants include Asetek, CoolIT Systems, Green Revolution Cooling, and Schneider Electric, among others. These companies are actively investing in research and development to address the technical challenges associated with two-phase cooling systems, particularly in the areas of boiling stability and dry-out prevention.

Customer demand is increasingly shifting toward integrated cooling solutions that offer not only superior thermal performance but also enhanced reliability, reduced maintenance requirements, and compatibility with existing infrastructure. This trend is driving manufacturers to develop more sophisticated control systems and predictive maintenance capabilities to ensure stable operation under varying load conditions.

Data centers represent the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the escalating computational demands and the shift toward high-performance computing infrastructures. The adoption of liquid cooling solutions in data centers has been accelerated by the need to reduce operational costs associated with traditional air cooling methods, which can account for up to 40% of a data center's energy consumption.

The high-performance computing (HPC) sector follows as the second-largest market segment, with approximately 25% market share. The increasing complexity of computational tasks in scientific research, financial modeling, and artificial intelligence applications has necessitated more efficient cooling solutions to maintain optimal performance and prevent thermal throttling.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 30% and Europe at 25%. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to the rapid expansion of data center infrastructure in countries like China, India, and Singapore.

Two-phase liquid cooling systems, which leverage the phase change of the coolant to enhance heat transfer efficiency, are gaining significant traction in the market. These systems offer superior thermal performance compared to single-phase solutions, with the potential to handle heat fluxes exceeding 500 W/cm². However, challenges related to boiling stability, dry-out conditions, and control mechanisms have limited their widespread adoption.

The market is characterized by a mix of established players and innovative startups. Key market participants include Asetek, CoolIT Systems, Green Revolution Cooling, and Schneider Electric, among others. These companies are actively investing in research and development to address the technical challenges associated with two-phase cooling systems, particularly in the areas of boiling stability and dry-out prevention.

Customer demand is increasingly shifting toward integrated cooling solutions that offer not only superior thermal performance but also enhanced reliability, reduced maintenance requirements, and compatibility with existing infrastructure. This trend is driving manufacturers to develop more sophisticated control systems and predictive maintenance capabilities to ensure stable operation under varying load conditions.

Technical Challenges in Two-Phase Cooling Systems

Two-phase cooling systems present significant technical challenges that must be addressed for reliable operation. The primary issue is boiling instability, which manifests as temperature and pressure fluctuations during the phase change process. These instabilities can lead to unpredictable thermal performance and potential system failure. The complex interplay between heat flux, flow rate, and channel geometry creates conditions where vapor bubbles may coalesce unpredictably, causing flow oscillations that disrupt the cooling efficiency.

Dry-out phenomena represent another critical challenge, occurring when the liquid film on the heated surface becomes too thin or disappears entirely. This condition dramatically reduces heat transfer efficiency and can cause dangerous temperature spikes in the cooled components. Dry-out is particularly problematic in high-heat-flux applications where the evaporation rate exceeds the liquid replenishment rate, creating localized hot spots that can damage electronic components or other sensitive equipment.

Control systems for two-phase cooling loops face unique difficulties due to the non-linear behavior of the phase change process. Traditional PID controllers often struggle with the rapid dynamics and time delays inherent in two-phase systems. The transition between single-phase and two-phase flow regimes creates control discontinuities that are difficult to manage with conventional approaches. Additionally, sensor placement becomes critical, as temperature and pressure measurements must accurately capture the state of the system without introducing additional disturbances.

Material compatibility issues further complicate two-phase cooling implementation. Working fluids must maintain chemical stability while providing optimal thermophysical properties. Surface treatments and materials must resist corrosion and fouling over extended operation periods, as degradation can alter wetting characteristics and heat transfer performance. The development of specialized coatings and surface structures to enhance nucleation site density remains an active research area.

Scaling and manufacturability present practical challenges for commercial adoption. Microscale channels that enhance heat transfer also increase pressure drop and manufacturing complexity. Ensuring uniform flow distribution across parallel channels requires precise fabrication tolerances that may be difficult to achieve cost-effectively at scale. Furthermore, the integration of two-phase cooling systems into existing thermal management frameworks demands careful consideration of space constraints, orientation effects, and maintenance accessibility.

Modeling and simulation tools for two-phase systems remain limited in their predictive capabilities, particularly for transient conditions and complex geometries. The multiscale nature of the phenomena—from nanoscale nucleation to system-level flow dynamics—creates computational challenges that current models cannot fully address without significant simplifications.

Dry-out phenomena represent another critical challenge, occurring when the liquid film on the heated surface becomes too thin or disappears entirely. This condition dramatically reduces heat transfer efficiency and can cause dangerous temperature spikes in the cooled components. Dry-out is particularly problematic in high-heat-flux applications where the evaporation rate exceeds the liquid replenishment rate, creating localized hot spots that can damage electronic components or other sensitive equipment.

Control systems for two-phase cooling loops face unique difficulties due to the non-linear behavior of the phase change process. Traditional PID controllers often struggle with the rapid dynamics and time delays inherent in two-phase systems. The transition between single-phase and two-phase flow regimes creates control discontinuities that are difficult to manage with conventional approaches. Additionally, sensor placement becomes critical, as temperature and pressure measurements must accurately capture the state of the system without introducing additional disturbances.

Material compatibility issues further complicate two-phase cooling implementation. Working fluids must maintain chemical stability while providing optimal thermophysical properties. Surface treatments and materials must resist corrosion and fouling over extended operation periods, as degradation can alter wetting characteristics and heat transfer performance. The development of specialized coatings and surface structures to enhance nucleation site density remains an active research area.

Scaling and manufacturability present practical challenges for commercial adoption. Microscale channels that enhance heat transfer also increase pressure drop and manufacturing complexity. Ensuring uniform flow distribution across parallel channels requires precise fabrication tolerances that may be difficult to achieve cost-effectively at scale. Furthermore, the integration of two-phase cooling systems into existing thermal management frameworks demands careful consideration of space constraints, orientation effects, and maintenance accessibility.

Modeling and simulation tools for two-phase systems remain limited in their predictive capabilities, particularly for transient conditions and complex geometries. The multiscale nature of the phenomena—from nanoscale nucleation to system-level flow dynamics—creates computational challenges that current models cannot fully address without significant simplifications.

Current Approaches to Boiling Stability Management

01 Two-phase cooling system stability mechanisms

Two-phase cooling systems employ various mechanisms to maintain stability during operation. These include specialized flow regulators, pressure control devices, and thermal management components that work together to prevent flow instabilities. The systems often incorporate feedback loops that monitor temperature and pressure conditions to adjust cooling parameters accordingly, ensuring consistent heat transfer and preventing oscillations that could lead to system failure.- Two-phase cooling system stability mechanisms: Two-phase cooling systems employ various stability mechanisms to maintain efficient operation. These systems utilize phase change phenomena where a working fluid alternates between liquid and vapor states to transfer heat. Stability is achieved through careful design of flow channels, pressure regulation components, and thermal interface materials. Advanced control algorithms monitor temperature and pressure parameters to prevent instabilities that could lead to system failure or reduced cooling efficiency.

- Dry-out prevention techniques in boiling systems: Preventing dry-out conditions is critical in two-phase cooling loops to maintain thermal performance. Techniques include implementing specialized wicking structures, engineered surface textures, and fluid distribution systems that ensure continuous liquid supply to heat transfer surfaces. Some systems incorporate capillary structures that use surface tension to maintain liquid film coverage even under high heat flux conditions. Monitoring systems can detect early signs of dry-out and adjust operating parameters accordingly.

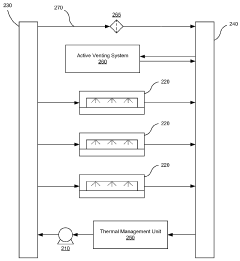

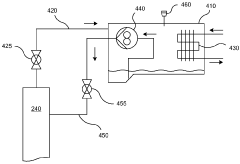

- Control systems for two-phase cooling loops: Advanced control systems are essential for maintaining optimal performance in two-phase cooling loops. These systems typically incorporate temperature sensors, pressure transducers, and flow meters to monitor operating conditions in real-time. Microcontroller-based systems process this data and adjust parameters such as pump speed, valve positions, and heat input to maintain stable operation. Predictive algorithms can anticipate instabilities before they occur, allowing for proactive adjustments to prevent system failure.

- Enhanced surface structures for boiling heat transfer: Specialized surface structures significantly improve boiling heat transfer efficiency in two-phase cooling systems. These include micro-structured surfaces, porous coatings, and engineered cavities that promote nucleation site formation. Such structures increase the effective heat transfer area and create favorable conditions for bubble formation and departure. By optimizing these surface characteristics, systems can achieve higher heat transfer coefficients while maintaining stability and preventing premature dry-out conditions.

- Working fluid selection and composition for phase-change cooling: The selection of appropriate working fluids is crucial for two-phase cooling system performance. Ideal fluids possess favorable thermophysical properties including high latent heat of vaporization, appropriate boiling point, good thermal conductivity, and suitable surface tension characteristics. Some systems utilize engineered fluid mixtures or additives to enhance performance characteristics. Environmental considerations and compatibility with system materials also influence fluid selection. The right working fluid can significantly improve system stability and prevent issues like dry-out.

02 Dry-out prevention techniques in boiling systems

Preventing dry-out conditions is critical in two-phase cooling loops to maintain efficient heat transfer. This is achieved through careful design of evaporator surfaces, implementation of capillary structures, and controlled fluid distribution systems. Advanced systems incorporate sensors to detect early signs of dry-out and trigger compensatory mechanisms such as flow rate adjustments or supplementary fluid delivery to vulnerable areas, ensuring continuous wetting of heat transfer surfaces.Expand Specific Solutions03 Control systems for two-phase cooling loops

Sophisticated control systems are essential for managing two-phase cooling loops effectively. These systems typically employ microprocessors that process data from multiple sensors monitoring temperature, pressure, flow rate, and vapor quality throughout the loop. Adaptive control algorithms adjust pump speeds, valve positions, and heat inputs to maintain optimal operating conditions across varying thermal loads. Some advanced systems incorporate predictive models to anticipate changes in cooling requirements and adjust parameters proactively.Expand Specific Solutions04 Enhanced surface designs for boiling heat transfer

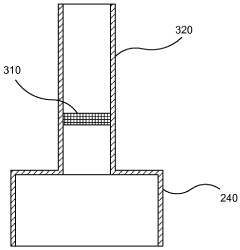

Specialized surface designs significantly improve boiling heat transfer efficiency and stability in two-phase cooling systems. These include micro-structured surfaces, porous coatings, and engineered nucleation sites that promote controlled bubble formation and departure. By optimizing surface characteristics, these designs reduce the superheat required for boiling initiation, enhance heat transfer coefficients, and expand the stable operating range before dry-out conditions occur, resulting in more efficient and reliable cooling performance.Expand Specific Solutions05 Working fluid composition and properties for phase-change cooling

The selection and formulation of working fluids play a crucial role in two-phase cooling system performance. Engineered fluids with specific thermophysical properties such as optimized surface tension, viscosity, and latent heat of vaporization can significantly enhance system stability and heat transfer efficiency. Some systems utilize fluid mixtures or additives that modify boiling behavior, reduce temperature glide, or improve wetting characteristics. Advanced working fluids also address environmental concerns while maintaining thermal performance across the operating temperature range.Expand Specific Solutions

Leading Companies in Two-Phase Cooling Industry

The liquid cooling two-phase loop technology market is currently in a growth phase, with increasing demand driven by thermal management challenges in high-performance computing, telecommunications, and aerospace applications. The global market is estimated at $1.2-1.5 billion, expanding at 8-10% CAGR as data centers and electronics require more efficient cooling solutions. Leading players demonstrate varying levels of technical maturity: CoolIT Systems and Vertiv have commercialized solutions for data centers; Intel, Microsoft, and HPE are advancing server-specific implementations; aerospace specialists like Euro Heat Pipes and Raytheon focus on reliability in extreme conditions; while ZTE, Ericsson, and Siemens are integrating this technology into telecommunications infrastructure. The primary technical challenges being addressed include boiling stability control mechanisms, prevention of dry-out conditions, and development of intelligent control systems for variable heat loads.

Intel Corp.

Technical Solution: Intel has pioneered two-phase immersion cooling technology for high-performance computing applications that addresses boiling stability through their Thermal Interface Material (TIM) optimization and microprocessor architecture design. Their approach integrates specially designed vapor chambers directly into chip packaging, creating a closed-loop two-phase cooling system that efficiently manages heat dissipation from high-density computing environments. Intel's solution incorporates microporous wicking structures with precisely engineered pore sizes and distributions to enhance capillary action and fluid circulation while preventing dry-out conditions. The system utilizes advanced phase-change materials with carefully selected boiling points matched to specific thermal profiles of different processor workloads. Intel's control systems employ machine learning algorithms that analyze thermal patterns across the processor die to predict potential hotspots and dynamically adjust workload distribution to prevent localized dry-out events.

Strengths: Seamless integration with Intel processor architecture ensures optimized performance; significant reduction in cooling energy consumption (40-45% compared to traditional air cooling). Weaknesses: Technology primarily optimized for Intel's own hardware ecosystem; requires specialized facility infrastructure for implementation.

Euro Heat Pipes SA

Technical Solution: Euro Heat Pipes has developed specialized two-phase cooling technology primarily for aerospace and satellite applications that has been adapted for high-performance computing environments. Their solution utilizes capillary-driven heat pipes and loop heat pipes that operate without mechanical pumps, relying instead on capillary pressure generated by advanced wick structures to circulate the working fluid. The company's proprietary wick manufacturing process creates precisely controlled pore sizes and permeability gradients that optimize fluid transport while preventing dry-out conditions. Their systems incorporate specially designed evaporator sections with multiple redundant fluid paths to maintain operation even if partial blockage occurs. Euro Heat Pipes' technology features passive control mechanisms that respond to temperature changes through thermophysical properties of the working fluid, automatically adjusting heat transfer capacity to match varying thermal loads without requiring active electronic controls.

Strengths: Extremely high reliability due to passive operation with no moving parts; capable of operating in any orientation including zero-gravity environments. Weaknesses: Limited heat transport capacity compared to actively pumped systems; less dynamic response to rapid changes in thermal load.

Critical Patents in Dry-Out Prevention Technologies

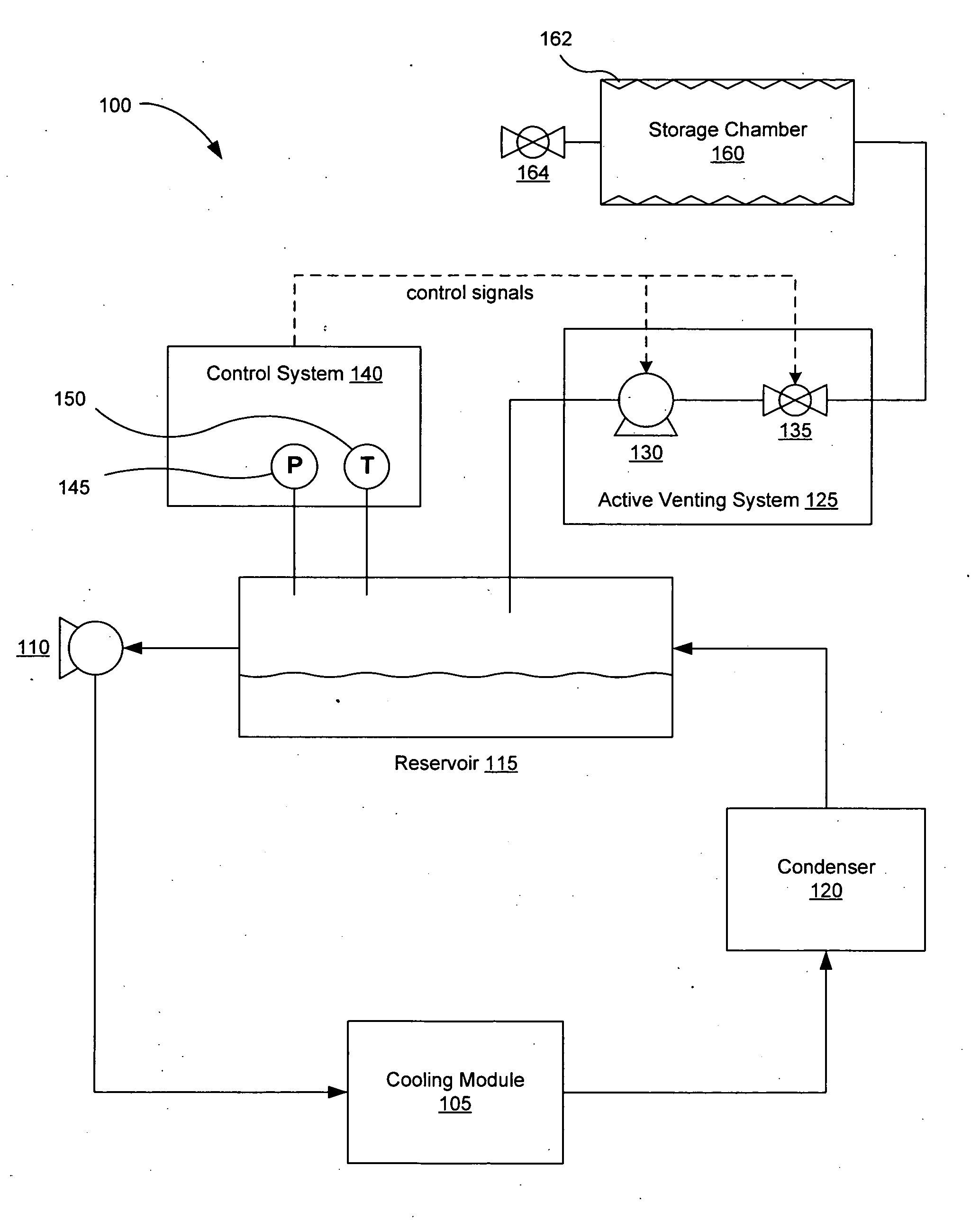

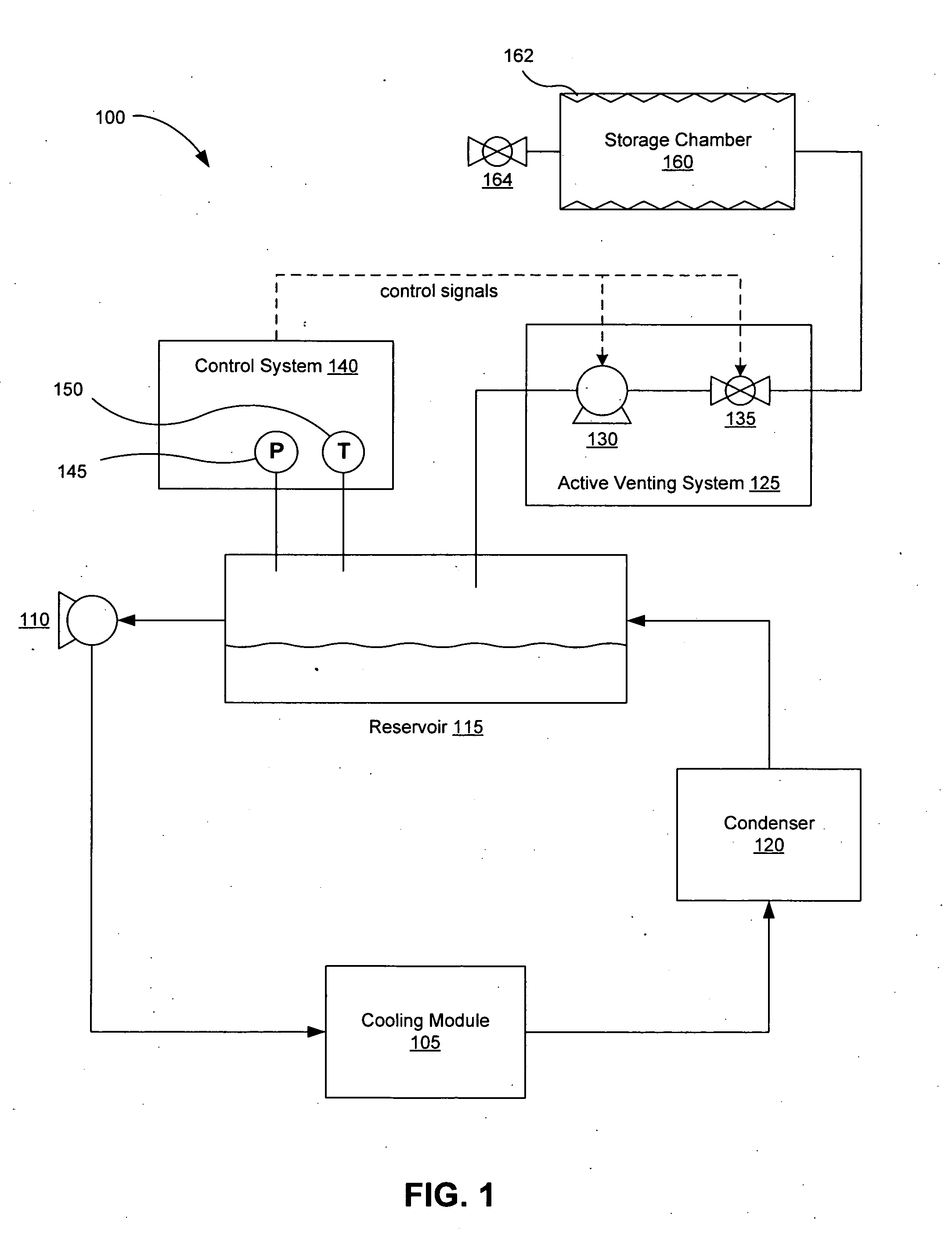

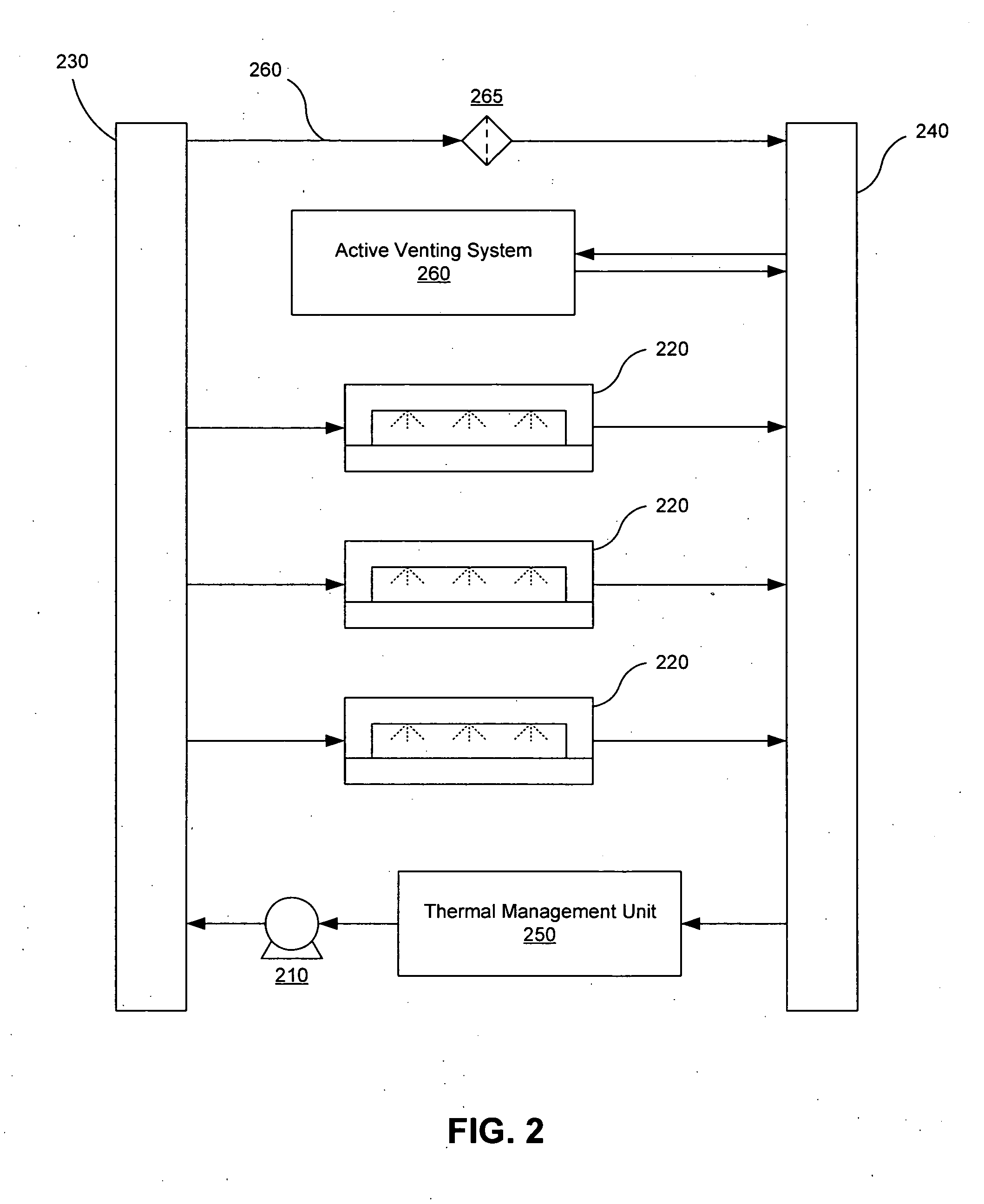

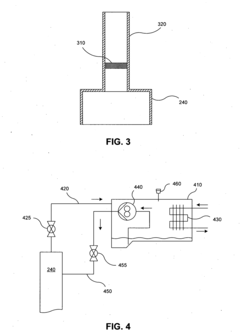

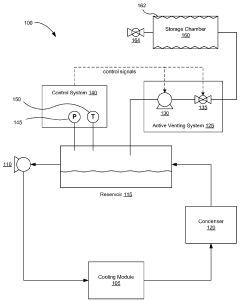

Two-phase liquid cooling system with active venting

PatentInactiveUS20070193300A1

Innovation

- An active venting system is implemented to regulate pressure by removing and adding non-condensable gases, using mechanisms like semi-permeable membrane separators and auxiliary pumps to control gas levels within the cooling system, ensuring optimal operating conditions and preventing coolant loss.

Two-phase liquid cooling systems

PatentWO2007098477A2

Innovation

- An active venting system is introduced to regulate pressure by removing and adding non-condensable gases, using mechanisms like semi-permeable membranes and centrifugal separators to separate gases from coolant vapor, and a leak detection method that temporarily increases pressure to detect coolant expulsion.

Thermal Performance Metrics and Testing Standards

Thermal performance metrics and testing standards are critical for evaluating and comparing liquid cooling two-phase loop systems across different applications and environments. The industry has developed several key metrics that quantify cooling efficiency, including the Coefficient of Performance (COP), thermal resistance, heat flux capacity, and temperature uniformity. These metrics provide standardized methods to assess how effectively a cooling system transfers heat from components to the cooling medium.

The COP, defined as the ratio of heat removed to the power input required, serves as a primary efficiency indicator for two-phase cooling systems. Higher COP values indicate more energy-efficient cooling solutions, with advanced two-phase loops typically achieving COP values between 20-40, significantly outperforming traditional air cooling methods which rarely exceed 10-15.

Thermal resistance (measured in °C/W) quantifies a system's opposition to heat flow and represents another fundamental performance metric. Lower thermal resistance values indicate superior heat transfer capabilities. Modern two-phase cooling loops can achieve thermal resistance values below 0.05°C/W under optimal conditions, enabling them to manage high heat flux applications exceeding 500 W/cm².

Testing standards for two-phase cooling systems have evolved significantly over the past decade. JEDEC Standard JESD51 provides guidelines for thermal measurements in electronic devices, while ASTM D5470 offers methods for thermal interface material testing. More specific to liquid cooling, ASHRAE Standard 181 addresses testing methods for liquid cooling systems, though it requires adaptation for two-phase applications.

The semiconductor industry has developed specialized testing protocols for two-phase cooling systems, including the SEMI-T20 standard which outlines thermal performance testing for electronic cooling solutions. These standards typically require measurement of temperature distributions, pressure drops, flow rates, and power consumption under various operating conditions.

Testing methodologies must account for the unique challenges of two-phase systems, particularly the instabilities during phase transitions. Standard test procedures include steady-state thermal performance evaluation, transient response testing, and accelerated life testing to predict long-term reliability. These tests must be conducted across the entire operating envelope, from low-power scenarios to maximum thermal load conditions.

Recent developments in testing standards have begun to address the critical phenomena of boiling stability and dry-out conditions, requiring specialized instrumentation including high-speed thermal imaging, precise flow meters, and distributed temperature sensors. These advanced testing methodologies enable more accurate characterization of system performance limits and control requirements.

The COP, defined as the ratio of heat removed to the power input required, serves as a primary efficiency indicator for two-phase cooling systems. Higher COP values indicate more energy-efficient cooling solutions, with advanced two-phase loops typically achieving COP values between 20-40, significantly outperforming traditional air cooling methods which rarely exceed 10-15.

Thermal resistance (measured in °C/W) quantifies a system's opposition to heat flow and represents another fundamental performance metric. Lower thermal resistance values indicate superior heat transfer capabilities. Modern two-phase cooling loops can achieve thermal resistance values below 0.05°C/W under optimal conditions, enabling them to manage high heat flux applications exceeding 500 W/cm².

Testing standards for two-phase cooling systems have evolved significantly over the past decade. JEDEC Standard JESD51 provides guidelines for thermal measurements in electronic devices, while ASTM D5470 offers methods for thermal interface material testing. More specific to liquid cooling, ASHRAE Standard 181 addresses testing methods for liquid cooling systems, though it requires adaptation for two-phase applications.

The semiconductor industry has developed specialized testing protocols for two-phase cooling systems, including the SEMI-T20 standard which outlines thermal performance testing for electronic cooling solutions. These standards typically require measurement of temperature distributions, pressure drops, flow rates, and power consumption under various operating conditions.

Testing methodologies must account for the unique challenges of two-phase systems, particularly the instabilities during phase transitions. Standard test procedures include steady-state thermal performance evaluation, transient response testing, and accelerated life testing to predict long-term reliability. These tests must be conducted across the entire operating envelope, from low-power scenarios to maximum thermal load conditions.

Recent developments in testing standards have begun to address the critical phenomena of boiling stability and dry-out conditions, requiring specialized instrumentation including high-speed thermal imaging, precise flow meters, and distributed temperature sensors. These advanced testing methodologies enable more accurate characterization of system performance limits and control requirements.

Energy Efficiency and Sustainability Considerations

Two-phase liquid cooling systems represent a significant advancement in thermal management technology, offering substantial energy efficiency benefits compared to traditional cooling methods. These systems leverage the latent heat of vaporization, which enables them to transfer heat more efficiently with lower pumping power requirements. Quantitative analyses indicate that two-phase cooling can achieve 5-10 times higher heat transfer coefficients than single-phase systems while consuming 20-40% less pumping energy, resulting in overall system coefficient of performance (COP) improvements of 30-60% in various applications.

The sustainability advantages of two-phase liquid cooling extend beyond direct energy savings. By enabling more efficient thermal management, these systems allow for higher power densities in electronic components without corresponding increases in energy consumption. This translates to more compact designs that require fewer raw materials and smaller physical footprints, contributing to resource conservation throughout the product lifecycle.

From a refrigerant perspective, modern two-phase cooling systems have evolved to utilize environmentally friendly working fluids with minimal global warming potential (GWP) and zero ozone depletion potential (ODP). The transition from traditional refrigerants to newer alternatives such as HFO-1234yf, R-1233zd(E), and even natural refrigerants like CO2 in specialized applications has significantly reduced the environmental impact of these systems.

The integration of two-phase cooling with renewable energy sources presents another dimension of sustainability. The improved efficiency of these systems means they can be more effectively powered by limited renewable energy resources. In data center applications, for instance, the reduced cooling energy requirement enables greater utilization of variable renewable power sources, potentially decreasing carbon footprint by 40-70% compared to conventional air cooling when coupled with clean energy.

Life cycle assessment (LCA) studies of two-phase cooling implementations reveal favorable environmental profiles when properly designed for stability and controlled operation. The primary environmental challenges occur during manufacturing and end-of-life phases, particularly regarding refrigerant handling and specialized component production. However, these impacts are typically offset by the operational efficiency gains over the system lifetime, especially in high-power density applications where cooling represents a significant portion of total energy consumption.

The economic sustainability of two-phase cooling systems has improved as the technology has matured. While initial capital costs remain 15-30% higher than conventional cooling solutions, the operational savings typically yield return on investment periods of 2-4 years in high-performance computing and 3-5 years in industrial applications. This economic viability is crucial for widespread adoption and the resulting environmental benefits at scale.

The sustainability advantages of two-phase liquid cooling extend beyond direct energy savings. By enabling more efficient thermal management, these systems allow for higher power densities in electronic components without corresponding increases in energy consumption. This translates to more compact designs that require fewer raw materials and smaller physical footprints, contributing to resource conservation throughout the product lifecycle.

From a refrigerant perspective, modern two-phase cooling systems have evolved to utilize environmentally friendly working fluids with minimal global warming potential (GWP) and zero ozone depletion potential (ODP). The transition from traditional refrigerants to newer alternatives such as HFO-1234yf, R-1233zd(E), and even natural refrigerants like CO2 in specialized applications has significantly reduced the environmental impact of these systems.

The integration of two-phase cooling with renewable energy sources presents another dimension of sustainability. The improved efficiency of these systems means they can be more effectively powered by limited renewable energy resources. In data center applications, for instance, the reduced cooling energy requirement enables greater utilization of variable renewable power sources, potentially decreasing carbon footprint by 40-70% compared to conventional air cooling when coupled with clean energy.

Life cycle assessment (LCA) studies of two-phase cooling implementations reveal favorable environmental profiles when properly designed for stability and controlled operation. The primary environmental challenges occur during manufacturing and end-of-life phases, particularly regarding refrigerant handling and specialized component production. However, these impacts are typically offset by the operational efficiency gains over the system lifetime, especially in high-power density applications where cooling represents a significant portion of total energy consumption.

The economic sustainability of two-phase cooling systems has improved as the technology has matured. While initial capital costs remain 15-30% higher than conventional cooling solutions, the operational savings typically yield return on investment periods of 2-4 years in high-performance computing and 3-5 years in industrial applications. This economic viability is crucial for widespread adoption and the resulting environmental benefits at scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!