Liquid Cooling Pump/Loop Sizing: Head Curves, NPSH And Reliability

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Cooling Technology Evolution and Objectives

Liquid cooling technology has evolved significantly over the past several decades, transitioning from specialized applications in mainframe computers and high-performance military systems to becoming increasingly common in data centers, gaming PCs, and various industrial applications. The fundamental principles of liquid cooling leverage the superior thermal conductivity of liquids compared to air, allowing for more efficient heat transfer from components generating substantial thermal loads.

The evolution began in the 1960s with rudimentary liquid cooling systems for mainframe computers, progressing through the 1980s and 1990s with more sophisticated closed-loop systems for supercomputers. By the early 2000s, liquid cooling solutions started appearing in consumer electronics, particularly for overclocked gaming systems, marking a significant democratization of this technology.

Recent advancements have focused on improving efficiency, reliability, and reducing the physical footprint of liquid cooling systems. Modern solutions incorporate advanced materials, precision engineering, and sophisticated control systems to optimize performance while minimizing energy consumption and maintenance requirements.

The critical components in this evolution have been the pumps and loop sizing methodologies. Early systems often suffered from reliability issues, inadequate head pressure, and cavitation problems due to insufficient Net Positive Suction Head (NPSH). Contemporary designs have addressed these challenges through computational fluid dynamics modeling, advanced impeller designs, and more precise matching of pump characteristics to system requirements.

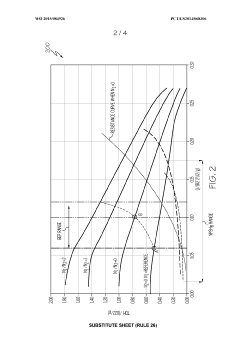

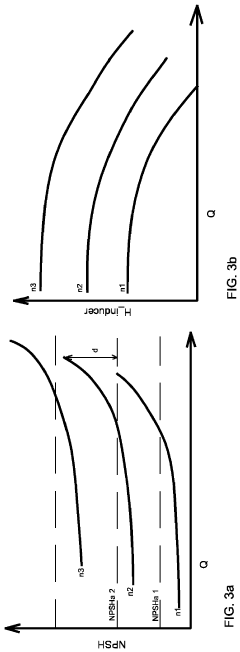

The current technological objectives in liquid cooling pump and loop sizing center around several key areas. First is the development of more accurate predictive models for head curves across various operating conditions, enabling better system design and component selection. Second is enhancing NPSH management to prevent cavitation and ensure long-term reliability, particularly in systems with complex geometries or varying thermal loads.

Additional objectives include miniaturization of pump components without sacrificing performance, reduction of energy consumption through more efficient designs, and integration of smart monitoring capabilities to predict maintenance needs before failures occur. There is also significant focus on developing environmentally friendly coolants with improved thermal properties and reduced environmental impact.

The industry is moving toward standardized methodologies for sizing and selecting liquid cooling components, with particular emphasis on reliability metrics that can predict system longevity under various operating conditions. This standardization aims to simplify design processes and improve interoperability between components from different manufacturers.

The evolution began in the 1960s with rudimentary liquid cooling systems for mainframe computers, progressing through the 1980s and 1990s with more sophisticated closed-loop systems for supercomputers. By the early 2000s, liquid cooling solutions started appearing in consumer electronics, particularly for overclocked gaming systems, marking a significant democratization of this technology.

Recent advancements have focused on improving efficiency, reliability, and reducing the physical footprint of liquid cooling systems. Modern solutions incorporate advanced materials, precision engineering, and sophisticated control systems to optimize performance while minimizing energy consumption and maintenance requirements.

The critical components in this evolution have been the pumps and loop sizing methodologies. Early systems often suffered from reliability issues, inadequate head pressure, and cavitation problems due to insufficient Net Positive Suction Head (NPSH). Contemporary designs have addressed these challenges through computational fluid dynamics modeling, advanced impeller designs, and more precise matching of pump characteristics to system requirements.

The current technological objectives in liquid cooling pump and loop sizing center around several key areas. First is the development of more accurate predictive models for head curves across various operating conditions, enabling better system design and component selection. Second is enhancing NPSH management to prevent cavitation and ensure long-term reliability, particularly in systems with complex geometries or varying thermal loads.

Additional objectives include miniaturization of pump components without sacrificing performance, reduction of energy consumption through more efficient designs, and integration of smart monitoring capabilities to predict maintenance needs before failures occur. There is also significant focus on developing environmentally friendly coolants with improved thermal properties and reduced environmental impact.

The industry is moving toward standardized methodologies for sizing and selecting liquid cooling components, with particular emphasis on reliability metrics that can predict system longevity under various operating conditions. This standardization aims to simplify design processes and improve interoperability between components from different manufacturers.

Market Demand Analysis for Liquid Cooling Systems

The global liquid cooling market is experiencing unprecedented growth, driven primarily by the rapid expansion of data centers and high-performance computing facilities. Market research indicates that the liquid cooling systems market is projected to reach $4.3 billion by 2027, growing at a CAGR of 22.6% from 2022. This significant growth trajectory is fueled by increasing power densities in computing equipment and the need for more efficient thermal management solutions.

Data center operators are facing mounting pressure to reduce energy consumption while managing higher heat loads. Traditional air cooling systems are becoming increasingly inadequate as server rack densities exceed 15-20 kW per rack, creating substantial demand for liquid cooling solutions that can handle 30-50 kW per rack or higher. This trend is particularly evident in hyperscale data centers, where the adoption of liquid cooling has increased by 35% over the past three years.

The high-performance computing (HPC) sector represents another major demand driver, with 78% of new HPC installations considering some form of liquid cooling. As artificial intelligence and machine learning workloads become more prevalent, the thermal management requirements have escalated dramatically, with AI accelerators often generating 300-700W per chip. This has created a specialized market segment demanding precision-engineered liquid cooling pumps with reliable performance characteristics.

Energy efficiency concerns are significantly influencing market demand patterns. Data centers currently consume approximately 1-2% of global electricity, with cooling representing 30-40% of that energy usage. Organizations are increasingly prioritizing solutions that offer lower PUE (Power Usage Effectiveness) ratings, with liquid cooling systems demonstrating the potential to reduce cooling energy consumption by 50-80% compared to traditional air cooling methods.

Reliability has emerged as a critical factor in purchasing decisions, with 92% of data center operators citing pump reliability as "extremely important" in recent industry surveys. The average cost of data center downtime has reached approximately $9,000 per minute, making the reliability aspects of liquid cooling pumps—particularly NPSH (Net Positive Suction Head) considerations and proper loop sizing—essential evaluation criteria for procurement teams.

Geographically, North America currently leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid data center construction in China, Singapore, and India, along with increasing adoption of liquid cooling technologies in these markets to address both thermal management and sustainability objectives.

Data center operators are facing mounting pressure to reduce energy consumption while managing higher heat loads. Traditional air cooling systems are becoming increasingly inadequate as server rack densities exceed 15-20 kW per rack, creating substantial demand for liquid cooling solutions that can handle 30-50 kW per rack or higher. This trend is particularly evident in hyperscale data centers, where the adoption of liquid cooling has increased by 35% over the past three years.

The high-performance computing (HPC) sector represents another major demand driver, with 78% of new HPC installations considering some form of liquid cooling. As artificial intelligence and machine learning workloads become more prevalent, the thermal management requirements have escalated dramatically, with AI accelerators often generating 300-700W per chip. This has created a specialized market segment demanding precision-engineered liquid cooling pumps with reliable performance characteristics.

Energy efficiency concerns are significantly influencing market demand patterns. Data centers currently consume approximately 1-2% of global electricity, with cooling representing 30-40% of that energy usage. Organizations are increasingly prioritizing solutions that offer lower PUE (Power Usage Effectiveness) ratings, with liquid cooling systems demonstrating the potential to reduce cooling energy consumption by 50-80% compared to traditional air cooling methods.

Reliability has emerged as a critical factor in purchasing decisions, with 92% of data center operators citing pump reliability as "extremely important" in recent industry surveys. The average cost of data center downtime has reached approximately $9,000 per minute, making the reliability aspects of liquid cooling pumps—particularly NPSH (Net Positive Suction Head) considerations and proper loop sizing—essential evaluation criteria for procurement teams.

Geographically, North America currently leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid data center construction in China, Singapore, and India, along with increasing adoption of liquid cooling technologies in these markets to address both thermal management and sustainability objectives.

Current Challenges in Pump/Loop Sizing Technology

The liquid cooling industry faces significant challenges in pump and loop sizing technology, particularly concerning the accurate prediction and optimization of system performance. One of the primary obstacles is the complexity of fluid dynamics calculations required for precise head curve determination. Engineers must account for various factors including fluid properties, temperature variations, and system geometry, which often leads to oversimplification and potential system inefficiencies.

Net Positive Suction Head (NPSH) calculations present another substantial challenge. The margin between available and required NPSH is critical for preventing cavitation, yet accurately determining this margin remains difficult due to the dynamic nature of cooling systems under varying operational conditions. This is especially problematic in high-performance computing and data center applications where thermal loads fluctuate significantly.

Reliability prediction models for liquid cooling systems lack standardization across the industry. Current methodologies often fail to adequately account for the interdependence of components within the cooling loop, leading to unreliable Mean Time Between Failure (MTBF) estimates. This creates uncertainty in maintenance scheduling and system lifecycle planning.

The miniaturization trend in electronics has introduced additional complications for pump sizing. As devices become more compact, cooling systems must deliver adequate performance within increasingly constrained spatial dimensions. This has created a demand for smaller yet more efficient pumps, pushing the boundaries of current design capabilities.

Material compatibility issues continue to plague the industry, with coolant chemistry interactions causing degradation of pump components over time. This degradation can alter pump performance characteristics, rendering initial sizing calculations inaccurate as systems age. Current predictive models struggle to account for these long-term effects.

Energy efficiency optimization remains challenging, particularly in balancing pump power consumption against cooling performance. The industry lacks comprehensive tools that can simultaneously optimize for thermal performance, energy usage, and system reliability across varying operational scenarios.

Testing methodologies for pump performance verification show significant inconsistencies across manufacturers and research institutions. The absence of standardized testing protocols makes it difficult to compare performance data and validate sizing calculations, creating barriers to innovation and improvement in the field.

Computational Fluid Dynamics (CFD) simulations, while increasingly sophisticated, still struggle with accurately modeling transient conditions and micro-scale phenomena within cooling loops. This limitation reduces the reliability of simulation-based sizing approaches, particularly for novel cooling system architectures.

AI and machine learning applications for pump sizing optimization are in their infancy, with limited datasets available for training robust predictive models. The potential for these technologies to revolutionize sizing methodologies remains largely unrealized due to implementation challenges and data availability constraints.

Net Positive Suction Head (NPSH) calculations present another substantial challenge. The margin between available and required NPSH is critical for preventing cavitation, yet accurately determining this margin remains difficult due to the dynamic nature of cooling systems under varying operational conditions. This is especially problematic in high-performance computing and data center applications where thermal loads fluctuate significantly.

Reliability prediction models for liquid cooling systems lack standardization across the industry. Current methodologies often fail to adequately account for the interdependence of components within the cooling loop, leading to unreliable Mean Time Between Failure (MTBF) estimates. This creates uncertainty in maintenance scheduling and system lifecycle planning.

The miniaturization trend in electronics has introduced additional complications for pump sizing. As devices become more compact, cooling systems must deliver adequate performance within increasingly constrained spatial dimensions. This has created a demand for smaller yet more efficient pumps, pushing the boundaries of current design capabilities.

Material compatibility issues continue to plague the industry, with coolant chemistry interactions causing degradation of pump components over time. This degradation can alter pump performance characteristics, rendering initial sizing calculations inaccurate as systems age. Current predictive models struggle to account for these long-term effects.

Energy efficiency optimization remains challenging, particularly in balancing pump power consumption against cooling performance. The industry lacks comprehensive tools that can simultaneously optimize for thermal performance, energy usage, and system reliability across varying operational scenarios.

Testing methodologies for pump performance verification show significant inconsistencies across manufacturers and research institutions. The absence of standardized testing protocols makes it difficult to compare performance data and validate sizing calculations, creating barriers to innovation and improvement in the field.

Computational Fluid Dynamics (CFD) simulations, while increasingly sophisticated, still struggle with accurately modeling transient conditions and micro-scale phenomena within cooling loops. This limitation reduces the reliability of simulation-based sizing approaches, particularly for novel cooling system architectures.

AI and machine learning applications for pump sizing optimization are in their infancy, with limited datasets available for training robust predictive models. The potential for these technologies to revolutionize sizing methodologies remains largely unrealized due to implementation challenges and data availability constraints.

Current Methodologies for Head Curve Optimization

01 Pump design for improved head curves and reliability

Advanced pump designs focus on optimizing head curves for liquid cooling systems. These designs incorporate features such as specialized impeller geometries, enhanced flow channels, and precision-engineered components to maintain consistent pressure across operating conditions. The improved designs help reduce cavitation risks while providing stable head pressure throughout the operational range, resulting in more reliable performance and extended service life for cooling systems in various applications.- Pump design for improved head curves and reliability: Innovative pump designs focus on optimizing head curves for liquid cooling systems. These designs incorporate features such as specialized impeller geometries, enhanced flow channels, and optimized housing configurations to achieve better pressure-flow characteristics. The improved designs help maintain consistent performance across varying system demands while reducing energy consumption and minimizing wear on components, thereby enhancing overall reliability and service life of liquid cooling systems.

- NPSH (Net Positive Suction Head) optimization techniques: Various techniques are employed to optimize Net Positive Suction Head in liquid cooling pumps, which is critical for preventing cavitation and ensuring reliable operation. These techniques include specialized inlet designs, vapor pressure management systems, and strategic placement of pumps within cooling loops. By maintaining adequate NPSH, these innovations help prevent pump damage, reduce noise, extend operational lifespan, and maintain consistent cooling performance even under challenging operating conditions.

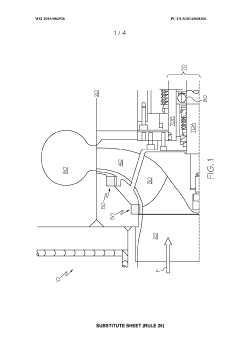

- Cooling loop configuration for enhanced thermal performance: Advanced cooling loop configurations are designed to optimize thermal performance in liquid cooling systems. These configurations feature strategic component placement, optimized flow paths, and specialized heat exchange interfaces. By minimizing flow restrictions, reducing thermal resistance, and ensuring uniform coolant distribution, these designs achieve more efficient heat transfer, lower operating temperatures, and improved system reliability, particularly in high-performance computing and industrial applications.

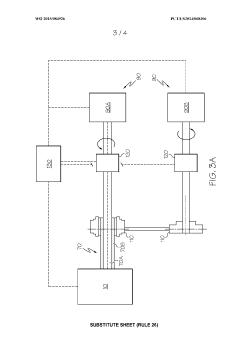

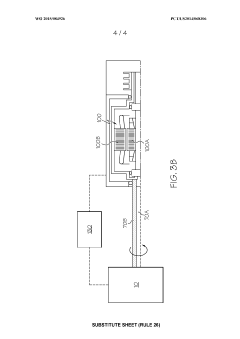

- Reliability enhancement through monitoring and control systems: Sophisticated monitoring and control systems are integrated into liquid cooling pumps and loops to enhance reliability. These systems incorporate sensors for tracking parameters such as flow rate, pressure, temperature, and vibration, along with intelligent controllers that can adjust pump operation in real-time. Advanced algorithms enable predictive maintenance, fault detection, and automatic compensation for changing system conditions, significantly improving system uptime and preventing catastrophic failures in critical cooling applications.

- Materials and manufacturing techniques for pump durability: Specialized materials and manufacturing techniques are employed to enhance the durability of liquid cooling pumps. These include corrosion-resistant alloys, advanced polymers, ceramic components, and precision manufacturing processes that improve dimensional accuracy and surface finish. Innovations in sealing technologies and bearing designs further contribute to pump longevity by reducing wear, preventing leakage, and minimizing maintenance requirements, resulting in cooling systems that maintain performance characteristics over extended operational periods.

02 NPSH (Net Positive Suction Head) optimization techniques

Various techniques are employed to optimize Net Positive Suction Head in liquid cooling pumps. These include specialized inlet designs, anti-vortex structures, and strategic placement of pump components to minimize pressure losses. By maintaining adequate NPSH, these systems prevent cavitation damage and ensure consistent fluid flow. The optimization techniques account for factors such as fluid temperature, system pressure, and flow rate variations to maintain reliable operation under diverse conditions.Expand Specific Solutions03 Cooling loop reliability enhancement methods

Reliability in liquid cooling loops is enhanced through redundant pump configurations, advanced monitoring systems, and fault-tolerant designs. These methods incorporate sensors for real-time performance tracking, automatic failure detection, and bypass mechanisms to prevent system shutdown. Materials selected for these systems offer superior corrosion resistance and thermal stability, while specialized sealing technologies minimize the risk of leakage. These enhancements collectively extend system lifespan and reduce maintenance requirements in critical cooling applications.Expand Specific Solutions04 Thermal management integration with pump performance

Integrated approaches to thermal management consider the relationship between pump performance and overall cooling efficiency. These systems dynamically adjust pump speed and flow characteristics based on thermal load requirements, optimizing energy consumption while maintaining adequate cooling. Advanced control algorithms monitor multiple parameters including fluid temperature, component temperatures, and system pressure to balance cooling performance with pump reliability. This integration enables more efficient operation across varying thermal conditions and extends the operational range of cooling systems.Expand Specific Solutions05 Innovative pump configurations for specialized cooling applications

Novel pump configurations address the unique requirements of specialized cooling applications such as electronics cooling, industrial processes, and high-performance computing. These designs include modular pump assemblies, compact integrated cooling units, and application-specific flow path geometries. Some configurations incorporate multiple stages or parallel pumping elements to achieve the required head pressure while maintaining reliability. Materials and construction techniques are selected to withstand specific environmental challenges such as high temperatures, vibration, or space constraints.Expand Specific Solutions

Key Industry Players in Liquid Cooling Solutions

The liquid cooling pump/loop sizing market is in a growth phase, characterized by increasing demand for efficient thermal management solutions in data centers, high-performance computing, and electric vehicles. The market size is expanding rapidly, projected to reach several billion dollars by 2025, driven by the growing need for more effective cooling solutions as computing power densities increase. From a technical maturity perspective, the industry shows varied development levels. Established players like Hitachi, Mitsubishi Heavy Industries, and CoolIT Systems offer advanced solutions with sophisticated head curve modeling and NPSH (Net Positive Suction Head) optimization. Academic institutions such as Jiangsu University and Yangzhou University are contributing fundamental research, while specialized cooling companies like AURAS Technology and Cooler Master are developing innovative reliability-focused approaches. The competitive landscape is diversifying with new entrants from adjacent industries bringing cross-domain expertise to address reliability challenges.

AURAS Technology Co., Ltd.

Technical Solution: AURAS Technology has developed specialized liquid cooling solutions with a focus on compact, efficient pump designs for electronics cooling applications. Their approach to liquid cooling pump sizing emphasizes miniaturization while maintaining adequate head pressure for effective thermal management. AURAS employs proprietary computational fluid dynamics (CFD) modeling to optimize pump impeller designs for specific application requirements, balancing flow rate capabilities with power consumption. Their pumps feature ceramic bearing systems that extend operational lifespan while reducing noise and vibration. For NPSH considerations, AURAS has developed specialized reservoir designs that ensure positive pressure at the pump inlet across various mounting orientations, which is particularly important for compact systems with space constraints. Their reliability engineering includes extensive thermal cycling tests and accelerated life testing under elevated temperatures to validate long-term performance. AURAS's pumps are designed with redundant protection features including thermal cutoff and dry-run protection to prevent catastrophic failures. Their newer generation pumps incorporate PWM control capabilities that allow dynamic adjustment of pump performance based on thermal load, significantly improving energy efficiency while extending component lifespan through reduced wear during low-demand periods.

Strengths: Specialized expertise in compact cooling solutions for electronics; efficient pump designs optimized for size-constrained applications; strong focus on energy efficiency and noise reduction. Weaknesses: Limited experience in large-scale industrial cooling applications; pump designs primarily optimized for electronics cooling rather than more demanding industrial processes.

Hitachi Ltd.

Technical Solution: Hitachi has developed comprehensive liquid cooling solutions with advanced pump technology based on decades of experience in fluid dynamics and industrial equipment. Their approach to liquid cooling pump sizing incorporates sophisticated computational fluid dynamics (CFD) modeling to optimize head curves for specific applications. Hitachi's pumps feature variable frequency drives that allow dynamic adjustment of pump performance to match changing system requirements, significantly improving energy efficiency. For critical applications, Hitachi employs a proprietary NPSH (Net Positive Suction Head) analysis methodology that accounts for temperature fluctuations, fluid properties, and system geometry to prevent cavitation across the entire operating range. Their reliability engineering includes accelerated life testing under extreme conditions, with pumps designed to achieve MTBF (Mean Time Between Failures) exceeding 100,000 hours. Hitachi's cooling loops incorporate smart sensors that continuously monitor pressure, temperature, and flow rates, enabling predictive maintenance capabilities through their digital twin technology. This allows for real-time optimization of pump performance and early detection of potential issues before they affect system reliability.

Strengths: Extensive industrial experience in fluid systems engineering; comprehensive approach integrating CFD modeling with practical applications; advanced predictive maintenance capabilities through digital twin technology. Weaknesses: Solutions may be overengineered and costly for simpler applications; complex integration requirements may necessitate specialized technical support.

Critical NPSH Requirements and Technical Standards

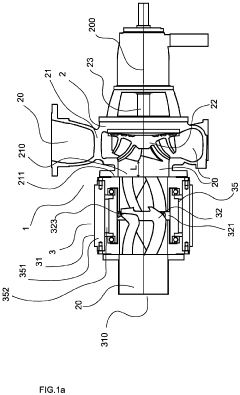

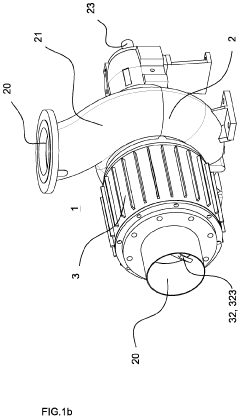

Rotating diffuser pump

PatentWO2015084926A1

Innovation

- A centrifugal pump design where the diffuser rotates independently with controlled speed, either through motors or a variable speed drive, allowing for counter-rotation with the impeller to optimize energy transfer and operational range, thereby increasing power density and reducing net positive suction head requirements.

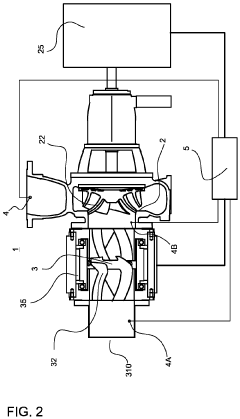

A pump unit for pumping liquid or suspension and a method for controlling of a pump unit

PatentInactiveEP4296517A1

Innovation

- A pump unit comprising a centrifugal pump and an independently controllable inducer with an annular motor, allowing for variable rotation speed control of the inducer relative to the impeller, enhancing NPSH and operational flexibility by adjusting the inducer's rotation speed and output power based on detected cavitation and fluid properties.

Thermal Management System Integration Approaches

Thermal Management System Integration Approaches for liquid cooling systems require careful consideration of pump and loop sizing to ensure optimal performance. The integration process begins with a comprehensive assessment of the thermal load requirements across the entire system, which determines the necessary cooling capacity and flow rates. This assessment must account for both steady-state operation and transient thermal events that may create peak demands.

When integrating liquid cooling pumps into thermal management systems, engineers must evaluate the compatibility between pump characteristics and system requirements. This includes matching the pump's head curve with the system's pressure-flow characteristics to identify the operating point. The system integration approach should incorporate sufficient margin in the pump selection to accommodate potential changes in system resistance over time due to fouling or component degradation.

Net Positive Suction Head (NPSH) considerations are critical during integration to prevent cavitation issues. The system layout must ensure that the available NPSH exceeds the required NPSH at all operating conditions, with particular attention to reservoir placement, pipe routing, and elevation changes. Integration approaches often include strategic placement of the pump at the lowest point in the system with the reservoir positioned directly before the pump inlet.

Reliability-focused integration methodologies incorporate redundancy strategies such as parallel pump configurations or backup systems that can be automatically activated upon primary system failure. These approaches must include monitoring systems with sensors for flow rate, pressure, temperature, and vibration to provide early warning of potential failures. The integration design should also facilitate easy maintenance access and component replacement without extensive system disassembly.

System integration must address thermal expansion considerations through the incorporation of expansion tanks or flexible components that can accommodate volume changes without creating excessive pressure. Additionally, the integration approach should include proper air bleeding mechanisms to prevent air pockets that can reduce cooling efficiency and cause pump damage.

Material compatibility represents another crucial aspect of system integration, ensuring that all components in contact with the cooling fluid are chemically compatible to prevent corrosion and degradation. This includes selecting appropriate gaskets, seals, and metallurgy based on the coolant chemistry and operating temperature range.

Finally, effective thermal management system integration approaches incorporate comprehensive testing protocols that validate performance across the entire operating envelope. This includes pressure testing, flow verification, thermal performance validation, and accelerated life testing to ensure the integrated system meets reliability targets under all anticipated operating conditions.

When integrating liquid cooling pumps into thermal management systems, engineers must evaluate the compatibility between pump characteristics and system requirements. This includes matching the pump's head curve with the system's pressure-flow characteristics to identify the operating point. The system integration approach should incorporate sufficient margin in the pump selection to accommodate potential changes in system resistance over time due to fouling or component degradation.

Net Positive Suction Head (NPSH) considerations are critical during integration to prevent cavitation issues. The system layout must ensure that the available NPSH exceeds the required NPSH at all operating conditions, with particular attention to reservoir placement, pipe routing, and elevation changes. Integration approaches often include strategic placement of the pump at the lowest point in the system with the reservoir positioned directly before the pump inlet.

Reliability-focused integration methodologies incorporate redundancy strategies such as parallel pump configurations or backup systems that can be automatically activated upon primary system failure. These approaches must include monitoring systems with sensors for flow rate, pressure, temperature, and vibration to provide early warning of potential failures. The integration design should also facilitate easy maintenance access and component replacement without extensive system disassembly.

System integration must address thermal expansion considerations through the incorporation of expansion tanks or flexible components that can accommodate volume changes without creating excessive pressure. Additionally, the integration approach should include proper air bleeding mechanisms to prevent air pockets that can reduce cooling efficiency and cause pump damage.

Material compatibility represents another crucial aspect of system integration, ensuring that all components in contact with the cooling fluid are chemically compatible to prevent corrosion and degradation. This includes selecting appropriate gaskets, seals, and metallurgy based on the coolant chemistry and operating temperature range.

Finally, effective thermal management system integration approaches incorporate comprehensive testing protocols that validate performance across the entire operating envelope. This includes pressure testing, flow verification, thermal performance validation, and accelerated life testing to ensure the integrated system meets reliability targets under all anticipated operating conditions.

Environmental Impact and Energy Efficiency Factors

The environmental impact and energy efficiency of liquid cooling systems are increasingly critical considerations in modern technological deployments. Liquid cooling pumps consume significant electrical energy during operation, with efficiency rates typically ranging from 60% to 85% depending on design and operational parameters. This energy consumption directly translates to carbon emissions in fossil fuel-dependent power grids, with estimates suggesting that optimized pump sizing can reduce related emissions by 15-30% compared to oversized systems.

Properly sized cooling loops minimize unnecessary fluid circulation, reducing pumping power requirements while maintaining thermal performance. Research indicates that for every 10% reduction in pump power consumption through appropriate sizing, approximately 5-8% total system energy savings can be achieved. This relationship becomes particularly significant in large-scale data centers where cooling can represent 30-40% of total energy usage.

The working fluid selection also carries substantial environmental implications. Traditional coolants often contain glycol compounds or refrigerants with high Global Warming Potential (GWP). Modern alternatives such as engineered fluids with lower GWP values and biodegradable options are emerging, though these must be evaluated against their thermal performance characteristics and compatibility with pump materials.

Pump reliability factors directly into environmental considerations through lifecycle assessment metrics. Premature pump failures necessitate manufacturing and transportation of replacement components, with associated embodied carbon costs. Studies demonstrate that pumps operating within their optimal efficiency range experience 40-60% longer service lives, significantly reducing waste generation and resource consumption over system lifetimes.

Heat recovery opportunities represent another dimension of environmental impact. Well-designed liquid cooling systems can capture and repurpose waste heat for facility heating or other processes. This requires careful consideration of temperature differentials and flow rates during the sizing process, potentially allowing for 30-50% recapture of thermal energy that would otherwise be rejected to the environment.

Water consumption concerns are particularly relevant for open-loop cooling systems or those requiring regular fluid replacement. Closed-loop systems with minimal maintenance requirements offer substantial water conservation benefits, with properly sized systems experiencing lower evaporation and leakage rates. Quantitative analysis suggests water savings of 40-70% compared to traditional cooling approaches when implementing optimized closed-loop designs with appropriate pump sizing.

Noise pollution, while often overlooked, represents another environmental consideration. Oversized pumps typically generate excess noise and vibration, potentially requiring additional damping materials with their own environmental footprints. Right-sized pumps operating at optimal efficiency points produce measurably lower acoustic emissions, contributing to healthier working environments and reduced need for noise mitigation measures.

Properly sized cooling loops minimize unnecessary fluid circulation, reducing pumping power requirements while maintaining thermal performance. Research indicates that for every 10% reduction in pump power consumption through appropriate sizing, approximately 5-8% total system energy savings can be achieved. This relationship becomes particularly significant in large-scale data centers where cooling can represent 30-40% of total energy usage.

The working fluid selection also carries substantial environmental implications. Traditional coolants often contain glycol compounds or refrigerants with high Global Warming Potential (GWP). Modern alternatives such as engineered fluids with lower GWP values and biodegradable options are emerging, though these must be evaluated against their thermal performance characteristics and compatibility with pump materials.

Pump reliability factors directly into environmental considerations through lifecycle assessment metrics. Premature pump failures necessitate manufacturing and transportation of replacement components, with associated embodied carbon costs. Studies demonstrate that pumps operating within their optimal efficiency range experience 40-60% longer service lives, significantly reducing waste generation and resource consumption over system lifetimes.

Heat recovery opportunities represent another dimension of environmental impact. Well-designed liquid cooling systems can capture and repurpose waste heat for facility heating or other processes. This requires careful consideration of temperature differentials and flow rates during the sizing process, potentially allowing for 30-50% recapture of thermal energy that would otherwise be rejected to the environment.

Water consumption concerns are particularly relevant for open-loop cooling systems or those requiring regular fluid replacement. Closed-loop systems with minimal maintenance requirements offer substantial water conservation benefits, with properly sized systems experiencing lower evaporation and leakage rates. Quantitative analysis suggests water savings of 40-70% compared to traditional cooling approaches when implementing optimized closed-loop designs with appropriate pump sizing.

Noise pollution, while often overlooked, represents another environmental consideration. Oversized pumps typically generate excess noise and vibration, potentially requiring additional damping materials with their own environmental footprints. Right-sized pumps operating at optimal efficiency points produce measurably lower acoustic emissions, contributing to healthier working environments and reduced need for noise mitigation measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!