Liquid Cooling Materials: Corrosion Couples, Inhibitors And Cleanliness

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Cooling Evolution and Objectives

Liquid cooling technology has evolved significantly over the past several decades, transforming from rudimentary heat exchange systems to sophisticated thermal management solutions. Initially developed for mainframe computers in the 1960s, liquid cooling systems utilized simple water-based solutions with minimal additives. The 1980s marked a significant shift with the introduction of glycol-based coolants, offering improved thermal properties and freeze protection for industrial applications.

The 1990s witnessed the emergence of specialized cooling fluids designed specifically for electronic components, incorporating corrosion inhibitors and biocides to extend system longevity. By the early 2000s, dielectric fluids gained prominence, allowing direct immersion cooling of electronic components without electrical conductivity concerns. The past decade has seen remarkable advancements in nanofluids—suspensions containing nanoparticles that significantly enhance thermal conductivity compared to conventional coolants.

Current liquid cooling technology faces increasing demands from high-performance computing, data centers, and electric vehicle thermal management systems. These applications require coolants that can efficiently dissipate extreme heat loads while maintaining material compatibility across diverse metallurgical interfaces. The materials science challenges are particularly acute in mixed-metal cooling loops where galvanic corrosion can severely compromise system integrity.

The primary objective of modern liquid cooling materials research is to develop formulations that simultaneously address multiple technical requirements: enhanced thermal conductivity, minimal electrical conductivity, chemical stability across wide temperature ranges, and long-term compatibility with diverse materials including aluminum, copper, stainless steel, and various polymers. Additionally, these formulations must maintain effectiveness while meeting increasingly stringent environmental regulations.

Specific technical goals include developing inhibitor packages that can effectively mitigate corrosion in mixed-metal systems without degrading thermal performance, establishing standardized cleanliness protocols to prevent particulate-induced system failures, and creating sustainable coolant formulations with reduced environmental impact. Research aims to extend coolant service life beyond the current industry standard of 3-5 years to 7-10 years while maintaining thermal efficiency.

The evolution trajectory points toward bio-based coolants derived from renewable resources, smart coolants with self-healing properties that can respond to system changes, and hybrid cooling solutions that combine traditional liquid cooling with phase-change materials for enhanced thermal capacity. These developments align with broader industry trends toward sustainability, miniaturization, and increased power density in electronic systems.

The 1990s witnessed the emergence of specialized cooling fluids designed specifically for electronic components, incorporating corrosion inhibitors and biocides to extend system longevity. By the early 2000s, dielectric fluids gained prominence, allowing direct immersion cooling of electronic components without electrical conductivity concerns. The past decade has seen remarkable advancements in nanofluids—suspensions containing nanoparticles that significantly enhance thermal conductivity compared to conventional coolants.

Current liquid cooling technology faces increasing demands from high-performance computing, data centers, and electric vehicle thermal management systems. These applications require coolants that can efficiently dissipate extreme heat loads while maintaining material compatibility across diverse metallurgical interfaces. The materials science challenges are particularly acute in mixed-metal cooling loops where galvanic corrosion can severely compromise system integrity.

The primary objective of modern liquid cooling materials research is to develop formulations that simultaneously address multiple technical requirements: enhanced thermal conductivity, minimal electrical conductivity, chemical stability across wide temperature ranges, and long-term compatibility with diverse materials including aluminum, copper, stainless steel, and various polymers. Additionally, these formulations must maintain effectiveness while meeting increasingly stringent environmental regulations.

Specific technical goals include developing inhibitor packages that can effectively mitigate corrosion in mixed-metal systems without degrading thermal performance, establishing standardized cleanliness protocols to prevent particulate-induced system failures, and creating sustainable coolant formulations with reduced environmental impact. Research aims to extend coolant service life beyond the current industry standard of 3-5 years to 7-10 years while maintaining thermal efficiency.

The evolution trajectory points toward bio-based coolants derived from renewable resources, smart coolants with self-healing properties that can respond to system changes, and hybrid cooling solutions that combine traditional liquid cooling with phase-change materials for enhanced thermal capacity. These developments align with broader industry trends toward sustainability, miniaturization, and increased power density in electronic systems.

Market Analysis for Advanced Cooling Solutions

The global market for advanced cooling solutions is experiencing robust growth, driven primarily by the increasing power density of electronic components and the rising demand for efficient thermal management systems. The liquid cooling segment, in particular, has seen significant expansion with a compound annual growth rate exceeding 15% over the past five years. This growth trajectory is expected to continue as data centers, high-performance computing, electric vehicles, and industrial applications increasingly adopt liquid cooling technologies to manage thermal loads more effectively.

Data centers represent the largest market segment for advanced liquid cooling solutions, accounting for approximately 40% of the total market share. The shift toward higher rack densities and the deployment of AI accelerators has intensified cooling requirements, pushing traditional air cooling systems to their limits. Liquid cooling offers 1000 times greater heat capacity than air, making it increasingly essential for next-generation computing infrastructure.

The automotive sector, particularly electric vehicles, constitutes the fastest-growing segment for advanced cooling solutions. As battery technologies evolve and charging speeds increase, the need for sophisticated thermal management systems becomes critical. Market research indicates that over 70% of premium electric vehicle manufacturers are incorporating some form of advanced liquid cooling for battery thermal management.

Geographically, North America leads the market with the highest adoption rate of advanced cooling technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate in the coming years due to rapid industrialization, expanding data center infrastructure, and increasing manufacturing of electronic components.

The competitive landscape features both established players and innovative startups. Traditional cooling solution providers have expanded their product portfolios to include advanced liquid cooling technologies, while specialized companies focusing exclusively on liquid cooling materials and systems have emerged. Material science companies developing corrosion-resistant alloys, advanced inhibitors, and filtration technologies are gaining significant market traction.

Customer requirements are increasingly focused on reliability, maintenance intervals, and total cost of ownership rather than initial investment costs alone. The potential for system failure due to corrosion, particulate contamination, or chemical degradation represents a significant concern for end-users, creating market opportunities for solutions addressing these specific challenges.

Regulatory trends are also shaping the market, with increasing emphasis on energy efficiency and environmental sustainability. Cooling solutions that reduce energy consumption and utilize environmentally friendly materials are gaining preference, particularly in regions with stringent environmental regulations.

Data centers represent the largest market segment for advanced liquid cooling solutions, accounting for approximately 40% of the total market share. The shift toward higher rack densities and the deployment of AI accelerators has intensified cooling requirements, pushing traditional air cooling systems to their limits. Liquid cooling offers 1000 times greater heat capacity than air, making it increasingly essential for next-generation computing infrastructure.

The automotive sector, particularly electric vehicles, constitutes the fastest-growing segment for advanced cooling solutions. As battery technologies evolve and charging speeds increase, the need for sophisticated thermal management systems becomes critical. Market research indicates that over 70% of premium electric vehicle manufacturers are incorporating some form of advanced liquid cooling for battery thermal management.

Geographically, North America leads the market with the highest adoption rate of advanced cooling technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate in the coming years due to rapid industrialization, expanding data center infrastructure, and increasing manufacturing of electronic components.

The competitive landscape features both established players and innovative startups. Traditional cooling solution providers have expanded their product portfolios to include advanced liquid cooling technologies, while specialized companies focusing exclusively on liquid cooling materials and systems have emerged. Material science companies developing corrosion-resistant alloys, advanced inhibitors, and filtration technologies are gaining significant market traction.

Customer requirements are increasingly focused on reliability, maintenance intervals, and total cost of ownership rather than initial investment costs alone. The potential for system failure due to corrosion, particulate contamination, or chemical degradation represents a significant concern for end-users, creating market opportunities for solutions addressing these specific challenges.

Regulatory trends are also shaping the market, with increasing emphasis on energy efficiency and environmental sustainability. Cooling solutions that reduce energy consumption and utilize environmentally friendly materials are gaining preference, particularly in regions with stringent environmental regulations.

Current Challenges in Liquid Cooling Materials

The liquid cooling industry faces significant challenges related to material compatibility and corrosion management. The interaction between different metals and alloys in cooling systems creates galvanic couples, accelerating corrosion rates when these dissimilar metals are in electrical contact within an electrolyte solution. This phenomenon is particularly problematic in systems combining copper, aluminum, and steel components, where the electrochemical potential differences drive corrosion of the less noble metals.

Inhibitor formulation presents another major challenge, as cooling fluids require carefully balanced chemical additives to protect multiple metal types simultaneously. Traditional inhibitors often protect one metal effectively while potentially accelerating corrosion of others. The development of universal inhibitors that can form protective layers on diverse metal surfaces without compromising thermal performance remains elusive, especially as environmental regulations increasingly restrict the use of traditional effective but toxic compounds like nitrites and borates.

Fluid cleanliness standards represent a growing concern as cooling systems become more compact with smaller channels and higher heat flux densities. Particulate contamination from corrosion products, manufacturing residues, or external sources can cause flow restrictions, reduce heat transfer efficiency, and create localized corrosion sites. The industry lacks standardized protocols for measuring and maintaining fluid cleanliness across different applications, making quality control difficult.

Long-term stability of cooling fluids constitutes another significant challenge. Many cooling solutions degrade over time through processes like inhibitor depletion, pH shifts, and microbiological growth. These changes can transform a previously non-corrosive fluid into an aggressive medium. The development of self-healing or regenerative inhibitor systems that maintain protection throughout the fluid's service life remains a technological gap.

Thermal-corrosion coupling effects complicate material selection, as higher operating temperatures accelerate corrosion reactions while simultaneously increasing the importance of maintaining optimal heat transfer. This creates a complex optimization problem where materials must balance corrosion resistance with thermal conductivity, often requiring trade-offs that compromise system performance.

Environmental considerations add another layer of complexity, with increasing pressure to develop biodegradable, non-toxic cooling fluids that maintain the same level of corrosion protection as traditional formulations. The transition away from glycol-based solutions toward more sustainable alternatives requires fundamental research into new inhibitor chemistries and material compatibility.

Inhibitor formulation presents another major challenge, as cooling fluids require carefully balanced chemical additives to protect multiple metal types simultaneously. Traditional inhibitors often protect one metal effectively while potentially accelerating corrosion of others. The development of universal inhibitors that can form protective layers on diverse metal surfaces without compromising thermal performance remains elusive, especially as environmental regulations increasingly restrict the use of traditional effective but toxic compounds like nitrites and borates.

Fluid cleanliness standards represent a growing concern as cooling systems become more compact with smaller channels and higher heat flux densities. Particulate contamination from corrosion products, manufacturing residues, or external sources can cause flow restrictions, reduce heat transfer efficiency, and create localized corrosion sites. The industry lacks standardized protocols for measuring and maintaining fluid cleanliness across different applications, making quality control difficult.

Long-term stability of cooling fluids constitutes another significant challenge. Many cooling solutions degrade over time through processes like inhibitor depletion, pH shifts, and microbiological growth. These changes can transform a previously non-corrosive fluid into an aggressive medium. The development of self-healing or regenerative inhibitor systems that maintain protection throughout the fluid's service life remains a technological gap.

Thermal-corrosion coupling effects complicate material selection, as higher operating temperatures accelerate corrosion reactions while simultaneously increasing the importance of maintaining optimal heat transfer. This creates a complex optimization problem where materials must balance corrosion resistance with thermal conductivity, often requiring trade-offs that compromise system performance.

Environmental considerations add another layer of complexity, with increasing pressure to develop biodegradable, non-toxic cooling fluids that maintain the same level of corrosion protection as traditional formulations. The transition away from glycol-based solutions toward more sustainable alternatives requires fundamental research into new inhibitor chemistries and material compatibility.

Corrosion Inhibition Strategies and Implementations

01 Corrosion inhibitors for liquid cooling systems

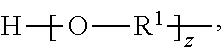

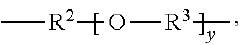

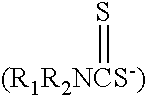

Various corrosion inhibitors can be added to liquid cooling materials to prevent degradation of metal components. These inhibitors form protective films on metal surfaces or neutralize corrosive agents in the coolant. Common inhibitors include azoles, silicates, phosphates, and organic compounds that can significantly extend the lifespan of cooling systems by reducing oxidation and galvanic corrosion, particularly in systems with multiple metal types.- Corrosion inhibitors for liquid cooling systems: Various corrosion inhibitors can be added to liquid cooling materials to prevent degradation of metal components. These inhibitors form protective films on metal surfaces or neutralize corrosive agents in the coolant. Common inhibitors include azoles, silicates, phosphates, and organic compounds that can significantly extend the lifespan of cooling systems by reducing oxidation and galvanic corrosion, particularly in systems with multiple metal types.

- Filtration and purification systems for coolant cleanliness: Maintaining coolant cleanliness through effective filtration and purification systems is essential for optimal performance of liquid cooling systems. These systems remove particulates, biological contaminants, and dissolved impurities that can cause blockages or reduce heat transfer efficiency. Advanced filtration technologies incorporate multi-stage processes, including mechanical filters, ion exchange resins, and activated carbon to ensure coolant purity and system longevity.

- Anti-fouling additives and cleaning agents: Anti-fouling additives and cleaning agents are formulated to prevent deposit formation and remove existing contaminants in liquid cooling systems. These compounds include dispersants that keep particles suspended in the coolant rather than settling on surfaces, biocides that prevent microbial growth, and specialized detergents that dissolve organic residues. Regular use of these additives helps maintain optimal heat transfer efficiency and prevents blockages in cooling channels.

- Material compatibility in cooling system design: Selecting compatible materials for liquid cooling systems is crucial to prevent galvanic corrosion and ensure long-term reliability. This involves careful consideration of the electrochemical properties of different metals and polymers used in the system, as well as their interaction with coolants and additives. Advanced cooling systems often incorporate corrosion-resistant alloys, specialized coatings, or cathodic protection methods to minimize material degradation in challenging operating environments.

- Monitoring and maintenance technologies: Advanced monitoring and maintenance technologies help ensure the ongoing cleanliness and corrosion resistance of liquid cooling systems. These include real-time sensors that detect changes in coolant chemistry, automated dosing systems that maintain optimal inhibitor concentrations, and predictive maintenance algorithms that identify potential issues before they cause system failure. Regular testing protocols for pH, conductivity, and inhibitor levels allow for timely interventions to prevent corrosion and contamination.

02 Filtration and purification systems for coolant cleanliness

Maintaining coolant cleanliness through filtration and purification systems is essential for optimal performance of liquid cooling systems. These systems remove particulates, biological contaminants, and dissolved impurities that could cause blockages or reduce heat transfer efficiency. Advanced filtration technologies include ion exchange resins, activated carbon filters, and mechanical filters with various pore sizes to target specific contaminants, ensuring the cooling system remains clean and efficient.Expand Specific Solutions03 Coolant composition for enhanced thermal performance and cleanliness

Specialized coolant compositions can be formulated to enhance thermal performance while maintaining system cleanliness. These formulations often include a base fluid (water, glycol, or specialized synthetic fluids), thermal conductivity enhancers, anti-fouling agents, and pH stabilizers. Some advanced coolants incorporate nanoparticles to improve heat transfer properties or biodegradable components that reduce environmental impact while providing excellent thermal management capabilities.Expand Specific Solutions04 Monitoring and maintenance systems for liquid cooling

Continuous monitoring and maintenance systems help detect and address corrosion or contamination issues before they cause system failure. These systems may include sensors for pH, conductivity, and metal ion concentration, as well as automated dosing systems for corrosion inhibitors and biocides. Regular maintenance protocols involving fluid analysis, filter replacement, and system flushing ensure long-term reliability and prevent the buildup of deposits that could reduce cooling efficiency.Expand Specific Solutions05 Materials selection and compatibility for liquid cooling systems

Proper selection of materials for liquid cooling systems is crucial to prevent galvanic corrosion and ensure long-term reliability. Compatible materials reduce the risk of electrochemical reactions that can degrade system components. Considerations include using similar metals or properly insulating dissimilar metals, selecting appropriate gasket and seal materials that resist degradation, and choosing surface treatments or coatings that enhance corrosion resistance while maintaining thermal conductivity.Expand Specific Solutions

Industry Leaders in Liquid Cooling Solutions

The liquid cooling materials market is currently in a growth phase, characterized by increasing demand for efficient thermal management solutions across industries. The market size is expanding due to the rising adoption of liquid cooling in data centers, automotive, and electronics sectors. Technologically, the field is moderately mature but continues to evolve, with companies focusing on developing advanced corrosion inhibitors and maintaining system cleanliness. Key players like Henkel AG, BASF Corp., and Ecolab USA lead in chemical solutions, while automotive manufacturers such as Toyota and Honda drive application-specific innovations. Kurita Water Industries and Organo Corp. specialize in water treatment aspects, while companies like ChampionX and Dober Chemical focus on specialized cooling additives and inhibitors. The competitive landscape shows a mix of chemical conglomerates and specialized solution providers addressing corrosion challenges in increasingly complex cooling systems.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced liquid cooling solutions focusing on thermal interface materials (TIMs) and corrosion inhibitors specifically designed for data centers and electric vehicle applications. Their P3 (Prevent, Protect, Preserve) approach addresses corrosion challenges through multi-metal compatible formulations. Their Bergquist liquid metal TIMs provide thermal conductivity up to 79 W/mK while maintaining electrical isolation properties. Henkel's Loctite branded coolants incorporate proprietary organic acid technology (OAT) corrosion inhibitors that form protective layers on metal surfaces without phosphate or silicate deposits. Their solutions are tested for over 10,000 hours in accelerated corrosion environments to ensure long-term reliability. Recent innovations include their non-conductive fluid solutions that maintain cleanliness standards below 100 particles per milliliter for particles >5μm, significantly reducing maintenance requirements in high-performance computing environments.

Strengths: Comprehensive approach combining thermal management and corrosion protection; extensive testing protocols; solutions compatible with mixed-metal systems. Weaknesses: Premium pricing compared to conventional coolants; some formulations may require more frequent monitoring in extreme temperature cycling environments.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed the DReeM Polymer® technology specifically for liquid cooling applications requiring exceptional cleanliness and corrosion protection. Their approach utilizes non-phosphorus organic inhibitors that form protective molecular layers on metal surfaces without contributing to scale formation. Kurita's S.sensing® monitoring technology continuously evaluates corrosion potential in real-time, allowing for proactive intervention before system damage occurs. Their formulations achieve corrosion rates below 0.05 mm/year for copper and below 0.1 mm/year for aluminum in standardized testing. Kurita's CETAMINE® treatment technology combines film-forming amines with dispersants to maintain system cleanliness while providing corrosion protection. Their solutions incorporate proprietary particle monitoring that maintains cleanliness levels below 100 particles/mL for particles >10μm. Kurita has pioneered the development of biodegradable corrosion inhibitors that maintain >95% effectiveness while reducing environmental impact. Their cooling solutions undergo extensive compatibility testing with over 50 different elastomer and polymer materials commonly used in cooling system components.

Strengths: Exceptional cleanliness standards suitable for precision cooling applications; environmentally friendly formulations; comprehensive monitoring capabilities; strong presence in Asian markets with extensive field testing data. Weaknesses: Less established presence in North American markets; some solutions require specialized equipment for optimal implementation; higher initial investment compared to conventional treatments.

Critical Patents in Anti-Corrosion Technologies

Metal corrosion inhibitor for open circulating cooling water system, and corrosion inhibition method for open circulating cooling water system using the same

PatentActiveJP2018028121A

Innovation

- A synergistic combination of phosphoric acid or polymerized phosphoric acids with nicotinic acid or nicotinic acid amide is used, allowing for reduced amounts of these components to achieve enhanced corrosion inhibition, with specific ratios and concentrations optimized for synergistic effects.

Methods of using ionic liquids as corrosion inhibitors

PatentActiveUS20220098494A1

Innovation

- The use of electronically neutral ionic liquids, specifically those with nitrogen or phosphorus-containing cations and various anions, as corrosion inhibitors, which can be combined with other corrosion inhibitors to enhance their performance and stability in aqueous fluids, reducing corrosion rates by up to 50%.

Environmental Impact and Sustainability Considerations

The environmental impact of liquid cooling systems extends beyond their operational efficiency to include the entire lifecycle of cooling materials. The selection of coolants, inhibitors, and cleaning agents must consider their ecological footprint from production through disposal. Traditional coolants often contain glycol-based compounds or mineral oils that can pose significant environmental hazards if released into ecosystems, potentially contaminating soil and water resources.

Corrosion inhibitors, while essential for system longevity, frequently contain chemicals such as azoles, nitrites, and phosphates that may persist in the environment and contribute to eutrophication of water bodies. The environmental persistence of these compounds necessitates careful consideration of biodegradability and bioaccumulation potential when formulating cooling solutions.

The cleaning processes for liquid cooling systems also present environmental challenges. Conventional cleaning agents may contain volatile organic compounds (VOCs) or other harmful substances that contribute to air pollution and pose health risks to workers. The wastewater generated during cleaning operations requires appropriate treatment before discharge to prevent environmental contamination.

Sustainable approaches to liquid cooling materials are emerging as a response to these concerns. Bio-based coolants derived from renewable resources offer reduced carbon footprints compared to petroleum-based alternatives. These formulations typically demonstrate improved biodegradability while maintaining thermal performance comparable to conventional options.

Advanced inhibitor technologies are being developed with environmental compatibility as a primary design criterion. Green inhibitors derived from plant extracts, amino acids, and other naturally occurring substances show promising corrosion protection capabilities while minimizing ecological impact. These alternatives often exhibit lower toxicity and higher biodegradability than their synthetic counterparts.

Cleanliness maintenance strategies are evolving toward more sustainable practices through the implementation of filtration systems that extend coolant life and reduce waste generation. Closed-loop recycling processes for spent coolants are becoming more prevalent, allowing for the recovery and reuse of valuable components while minimizing disposal requirements.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of industrial fluids, including cooling materials. Compliance with regulations such as REACH in Europe and similar initiatives globally is driving innovation toward greener cooling solutions. Companies adopting environmentally responsible cooling practices not only meet regulatory requirements but also enhance their sustainability credentials and potentially reduce long-term operational costs through improved resource efficiency.

Corrosion inhibitors, while essential for system longevity, frequently contain chemicals such as azoles, nitrites, and phosphates that may persist in the environment and contribute to eutrophication of water bodies. The environmental persistence of these compounds necessitates careful consideration of biodegradability and bioaccumulation potential when formulating cooling solutions.

The cleaning processes for liquid cooling systems also present environmental challenges. Conventional cleaning agents may contain volatile organic compounds (VOCs) or other harmful substances that contribute to air pollution and pose health risks to workers. The wastewater generated during cleaning operations requires appropriate treatment before discharge to prevent environmental contamination.

Sustainable approaches to liquid cooling materials are emerging as a response to these concerns. Bio-based coolants derived from renewable resources offer reduced carbon footprints compared to petroleum-based alternatives. These formulations typically demonstrate improved biodegradability while maintaining thermal performance comparable to conventional options.

Advanced inhibitor technologies are being developed with environmental compatibility as a primary design criterion. Green inhibitors derived from plant extracts, amino acids, and other naturally occurring substances show promising corrosion protection capabilities while minimizing ecological impact. These alternatives often exhibit lower toxicity and higher biodegradability than their synthetic counterparts.

Cleanliness maintenance strategies are evolving toward more sustainable practices through the implementation of filtration systems that extend coolant life and reduce waste generation. Closed-loop recycling processes for spent coolants are becoming more prevalent, allowing for the recovery and reuse of valuable components while minimizing disposal requirements.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of industrial fluids, including cooling materials. Compliance with regulations such as REACH in Europe and similar initiatives globally is driving innovation toward greener cooling solutions. Companies adopting environmentally responsible cooling practices not only meet regulatory requirements but also enhance their sustainability credentials and potentially reduce long-term operational costs through improved resource efficiency.

Thermal Performance Testing and Quality Standards

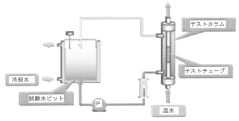

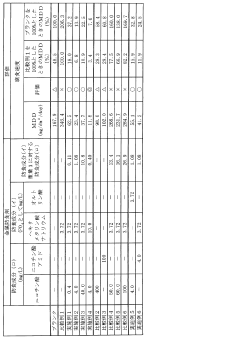

Thermal performance testing for liquid cooling systems requires standardized methodologies to ensure consistent evaluation across different materials and configurations. Industry standards such as ASTM D3306 and ASTM D4985 provide guidelines for testing coolant performance, particularly focusing on heat transfer efficiency and material compatibility. These standards establish minimum requirements for thermal conductivity, specific heat capacity, and viscosity across varying temperature ranges.

Testing protocols typically involve both laboratory simulations and real-world operational scenarios. Calorimetric testing measures the heat absorption and dissipation capabilities of cooling fluids under controlled conditions, while flow rate testing evaluates the fluid dynamics and pressure drop characteristics. Advanced thermal imaging techniques are employed to identify potential hotspots and flow distribution anomalies within cooling systems.

Quality standards for liquid cooling materials emphasize cleanliness metrics that directly impact thermal performance. Particulate contamination is measured according to ISO 4406 or NAS 1638 standards, with most high-performance cooling systems requiring cleanliness levels of ISO 16/14/12 or better. Ionic contamination is equally critical, as dissolved ions can accelerate corrosion processes and form insulating deposits on heat exchange surfaces.

Manufacturers must adhere to strict quality control procedures during production and handling of cooling fluids. This includes filtration processes capable of removing particles down to 1-5 microns and regular testing for pH stability, reserve alkalinity, and inhibitor concentration. Documentation requirements typically include batch testing certificates and material traceability records.

Performance degradation testing represents another crucial aspect of quality assurance. Accelerated aging tests expose cooling materials to elevated temperatures and thermal cycling to predict long-term performance. These tests typically measure changes in thermal conductivity, corrosion protection capabilities, and fluid stability over simulated operational lifespans of 3-5 years.

Emerging standards are beginning to address the environmental impact of cooling materials, incorporating biodegradability assessments and toxicity profiles into quality metrics. The trend toward more environmentally responsible cooling solutions has led to the development of bio-based coolants with comparable thermal performance to traditional formulations but significantly reduced environmental footprints.

Compliance with these thermal performance standards and quality metrics ensures optimal heat transfer efficiency while minimizing maintenance requirements and extending system longevity in liquid cooling applications.

Testing protocols typically involve both laboratory simulations and real-world operational scenarios. Calorimetric testing measures the heat absorption and dissipation capabilities of cooling fluids under controlled conditions, while flow rate testing evaluates the fluid dynamics and pressure drop characteristics. Advanced thermal imaging techniques are employed to identify potential hotspots and flow distribution anomalies within cooling systems.

Quality standards for liquid cooling materials emphasize cleanliness metrics that directly impact thermal performance. Particulate contamination is measured according to ISO 4406 or NAS 1638 standards, with most high-performance cooling systems requiring cleanliness levels of ISO 16/14/12 or better. Ionic contamination is equally critical, as dissolved ions can accelerate corrosion processes and form insulating deposits on heat exchange surfaces.

Manufacturers must adhere to strict quality control procedures during production and handling of cooling fluids. This includes filtration processes capable of removing particles down to 1-5 microns and regular testing for pH stability, reserve alkalinity, and inhibitor concentration. Documentation requirements typically include batch testing certificates and material traceability records.

Performance degradation testing represents another crucial aspect of quality assurance. Accelerated aging tests expose cooling materials to elevated temperatures and thermal cycling to predict long-term performance. These tests typically measure changes in thermal conductivity, corrosion protection capabilities, and fluid stability over simulated operational lifespans of 3-5 years.

Emerging standards are beginning to address the environmental impact of cooling materials, incorporating biodegradability assessments and toxicity profiles into quality metrics. The trend toward more environmentally responsible cooling solutions has led to the development of bio-based coolants with comparable thermal performance to traditional formulations but significantly reduced environmental footprints.

Compliance with these thermal performance standards and quality metrics ensures optimal heat transfer efficiency while minimizing maintenance requirements and extending system longevity in liquid cooling applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!