How Magnesium Nitrate Interacts with Nano-material Stability

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate and Nanomaterial Interaction Overview

The interaction between magnesium nitrate and nanomaterials represents a critical area of study in materials science and nanotechnology. Magnesium nitrate, a common inorganic compound, has been found to significantly influence the stability and properties of various nanomaterials. This interaction is of particular interest due to its potential applications in diverse fields, including catalysis, energy storage, and environmental remediation.

Nanomaterials, characterized by their unique size-dependent properties, exhibit high surface area-to-volume ratios, making them highly reactive and susceptible to environmental influences. The presence of magnesium nitrate in the surrounding medium can alter the surface chemistry, morphology, and overall stability of these nanomaterials. Understanding these interactions is crucial for optimizing the performance and longevity of nanomaterial-based technologies.

One of the primary mechanisms through which magnesium nitrate affects nanomaterial stability is through surface adsorption. The magnesium ions can adsorb onto the surface of nanomaterials, potentially altering their surface charge and colloidal stability. This process can lead to either enhanced dispersion or aggregation of nanoparticles, depending on the specific nanomaterial and environmental conditions.

Furthermore, magnesium nitrate can participate in ion exchange processes with certain nanomaterials, particularly those with layered structures or porous frameworks. This exchange can modify the interlayer spacing or pore structure of nanomaterials, affecting their physical and chemical properties. In some cases, this interaction can be leveraged to fine-tune the characteristics of nanomaterials for specific applications.

The presence of magnesium nitrate can also influence the redox behavior of nanomaterials. For instance, in metal oxide nanoparticles, magnesium ions may alter the oxidation state of surface atoms, potentially enhancing or inhibiting their catalytic activity. This aspect is particularly relevant in the development of nanomaterial-based catalysts and sensors.

Additionally, the hygroscopic nature of magnesium nitrate introduces another dimension to its interaction with nanomaterials. In humid environments, magnesium nitrate can absorb moisture, creating a thin liquid layer on the nanomaterial surface. This can affect the material's stability, reactivity, and even its mechanical properties, especially in applications where dry conditions are crucial.

Understanding these complex interactions is essential for predicting and controlling the behavior of nanomaterials in various applications. It enables researchers and engineers to design more stable and efficient nanomaterial-based systems, optimize storage conditions, and develop novel functionalization strategies. As research in this field progresses, it promises to unlock new possibilities for tailoring nanomaterials to meet specific technological needs across multiple industries.

Nanomaterials, characterized by their unique size-dependent properties, exhibit high surface area-to-volume ratios, making them highly reactive and susceptible to environmental influences. The presence of magnesium nitrate in the surrounding medium can alter the surface chemistry, morphology, and overall stability of these nanomaterials. Understanding these interactions is crucial for optimizing the performance and longevity of nanomaterial-based technologies.

One of the primary mechanisms through which magnesium nitrate affects nanomaterial stability is through surface adsorption. The magnesium ions can adsorb onto the surface of nanomaterials, potentially altering their surface charge and colloidal stability. This process can lead to either enhanced dispersion or aggregation of nanoparticles, depending on the specific nanomaterial and environmental conditions.

Furthermore, magnesium nitrate can participate in ion exchange processes with certain nanomaterials, particularly those with layered structures or porous frameworks. This exchange can modify the interlayer spacing or pore structure of nanomaterials, affecting their physical and chemical properties. In some cases, this interaction can be leveraged to fine-tune the characteristics of nanomaterials for specific applications.

The presence of magnesium nitrate can also influence the redox behavior of nanomaterials. For instance, in metal oxide nanoparticles, magnesium ions may alter the oxidation state of surface atoms, potentially enhancing or inhibiting their catalytic activity. This aspect is particularly relevant in the development of nanomaterial-based catalysts and sensors.

Additionally, the hygroscopic nature of magnesium nitrate introduces another dimension to its interaction with nanomaterials. In humid environments, magnesium nitrate can absorb moisture, creating a thin liquid layer on the nanomaterial surface. This can affect the material's stability, reactivity, and even its mechanical properties, especially in applications where dry conditions are crucial.

Understanding these complex interactions is essential for predicting and controlling the behavior of nanomaterials in various applications. It enables researchers and engineers to design more stable and efficient nanomaterial-based systems, optimize storage conditions, and develop novel functionalization strategies. As research in this field progresses, it promises to unlock new possibilities for tailoring nanomaterials to meet specific technological needs across multiple industries.

Market Applications of Stable Nanomaterials

The market applications of stable nanomaterials have expanded significantly in recent years, driven by advancements in nanotechnology and the increasing demand for high-performance materials across various industries. Stable nanomaterials, including those enhanced by magnesium nitrate interactions, offer unique properties that make them valuable in a wide range of applications.

In the electronics industry, stable nanomaterials are revolutionizing the development of next-generation devices. These materials are used in the production of flexible displays, high-capacity batteries, and advanced semiconductors. The stability provided by magnesium nitrate interactions allows for improved durability and performance in electronic components, leading to longer-lasting and more efficient devices.

The healthcare sector has also embraced stable nanomaterials for drug delivery systems, diagnostic tools, and tissue engineering. Nanoparticles with enhanced stability can effectively encapsulate and deliver drugs to specific targets within the body, improving treatment efficacy while reducing side effects. In diagnostics, stable nanomaterials enable more sensitive and accurate detection of biomarkers, potentially leading to earlier disease detection and improved patient outcomes.

Environmental applications of stable nanomaterials are gaining traction in water purification and air filtration systems. Nanomaterials with increased stability can effectively remove contaminants from water and air, providing more efficient and cost-effective solutions for environmental remediation. The interaction between magnesium nitrate and nanomaterials can enhance their adsorption capabilities and longevity in these applications.

In the energy sector, stable nanomaterials are contributing to the development of more efficient solar cells, fuel cells, and energy storage systems. The improved stability allows for better performance and longer lifespans of these energy technologies, potentially accelerating the transition to renewable energy sources.

The automotive and aerospace industries are incorporating stable nanomaterials into lightweight, high-strength composites for vehicle and aircraft construction. These materials offer improved fuel efficiency and performance while maintaining structural integrity. The stability provided by magnesium nitrate interactions can enhance the durability of these composites in challenging environments.

Stable nanomaterials are also finding applications in the textile industry, where they are used to create smart fabrics with enhanced properties such as water repellency, UV protection, and antimicrobial activity. The improved stability of these materials ensures that these properties are maintained over extended periods, even after repeated washing and wear.

In the construction sector, stable nanomaterials are being incorporated into concrete and other building materials to improve strength, durability, and thermal insulation properties. The enhanced stability of these materials contributes to longer-lasting and more energy-efficient buildings, potentially reducing maintenance costs and environmental impact.

In the electronics industry, stable nanomaterials are revolutionizing the development of next-generation devices. These materials are used in the production of flexible displays, high-capacity batteries, and advanced semiconductors. The stability provided by magnesium nitrate interactions allows for improved durability and performance in electronic components, leading to longer-lasting and more efficient devices.

The healthcare sector has also embraced stable nanomaterials for drug delivery systems, diagnostic tools, and tissue engineering. Nanoparticles with enhanced stability can effectively encapsulate and deliver drugs to specific targets within the body, improving treatment efficacy while reducing side effects. In diagnostics, stable nanomaterials enable more sensitive and accurate detection of biomarkers, potentially leading to earlier disease detection and improved patient outcomes.

Environmental applications of stable nanomaterials are gaining traction in water purification and air filtration systems. Nanomaterials with increased stability can effectively remove contaminants from water and air, providing more efficient and cost-effective solutions for environmental remediation. The interaction between magnesium nitrate and nanomaterials can enhance their adsorption capabilities and longevity in these applications.

In the energy sector, stable nanomaterials are contributing to the development of more efficient solar cells, fuel cells, and energy storage systems. The improved stability allows for better performance and longer lifespans of these energy technologies, potentially accelerating the transition to renewable energy sources.

The automotive and aerospace industries are incorporating stable nanomaterials into lightweight, high-strength composites for vehicle and aircraft construction. These materials offer improved fuel efficiency and performance while maintaining structural integrity. The stability provided by magnesium nitrate interactions can enhance the durability of these composites in challenging environments.

Stable nanomaterials are also finding applications in the textile industry, where they are used to create smart fabrics with enhanced properties such as water repellency, UV protection, and antimicrobial activity. The improved stability of these materials ensures that these properties are maintained over extended periods, even after repeated washing and wear.

In the construction sector, stable nanomaterials are being incorporated into concrete and other building materials to improve strength, durability, and thermal insulation properties. The enhanced stability of these materials contributes to longer-lasting and more energy-efficient buildings, potentially reducing maintenance costs and environmental impact.

Current Challenges in Nanomaterial Stability

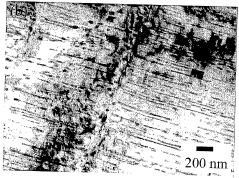

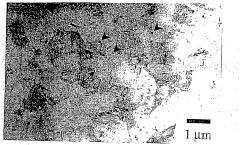

The stability of nanomaterials remains a critical challenge in the field of nanotechnology, particularly when considering their interaction with various chemical compounds such as magnesium nitrate. One of the primary issues faced by researchers and industry professionals is the tendency of nanoparticles to agglomerate, which can significantly alter their unique properties and diminish their effectiveness in various applications.

The interaction between magnesium nitrate and nanomaterials introduces additional complexities to the stability equation. Magnesium nitrate, being a highly soluble salt, can affect the surface charge of nanoparticles, potentially leading to changes in their dispersion characteristics. This interaction may result in either enhanced stability through electrostatic repulsion or increased instability due to charge neutralization, depending on the specific nanomaterial and environmental conditions.

Another significant challenge is the potential for chemical reactions between magnesium nitrate and certain types of nanomaterials. These reactions can lead to the formation of new compounds on the nanoparticle surface, altering their physical and chemical properties. Such changes may impact the intended functionality of the nanomaterials, making it crucial to understand and control these interactions for practical applications.

The presence of magnesium nitrate in the environment of nanomaterials can also influence their oxidation state, particularly for metal and metal oxide nanoparticles. This can lead to changes in their reactivity, catalytic properties, and overall stability. Researchers must consider these potential redox reactions when designing nanomaterial-based systems that may come into contact with magnesium nitrate or similar compounds.

Furthermore, the hygroscopic nature of magnesium nitrate poses additional challenges for maintaining nanomaterial stability. In humid environments, magnesium nitrate can absorb moisture, potentially leading to the formation of a liquid layer around nanoparticles. This can facilitate their movement and increase the likelihood of agglomeration or unwanted reactions, further complicating efforts to maintain stable nanomaterial dispersions.

The long-term stability of nanomaterials in the presence of magnesium nitrate is another area of concern. Over time, continuous exposure to this compound may lead to gradual changes in nanoparticle morphology, size distribution, and surface properties. These changes can be subtle and difficult to detect in the short term but may have significant implications for the performance and reliability of nanomaterial-based products and technologies.

Addressing these challenges requires a multifaceted approach, combining advanced characterization techniques, theoretical modeling, and experimental studies. Researchers must develop robust methods for predicting and controlling the interactions between nanomaterials and compounds like magnesium nitrate to ensure the stability and efficacy of nanomaterial-based solutions across various applications and environmental conditions.

The interaction between magnesium nitrate and nanomaterials introduces additional complexities to the stability equation. Magnesium nitrate, being a highly soluble salt, can affect the surface charge of nanoparticles, potentially leading to changes in their dispersion characteristics. This interaction may result in either enhanced stability through electrostatic repulsion or increased instability due to charge neutralization, depending on the specific nanomaterial and environmental conditions.

Another significant challenge is the potential for chemical reactions between magnesium nitrate and certain types of nanomaterials. These reactions can lead to the formation of new compounds on the nanoparticle surface, altering their physical and chemical properties. Such changes may impact the intended functionality of the nanomaterials, making it crucial to understand and control these interactions for practical applications.

The presence of magnesium nitrate in the environment of nanomaterials can also influence their oxidation state, particularly for metal and metal oxide nanoparticles. This can lead to changes in their reactivity, catalytic properties, and overall stability. Researchers must consider these potential redox reactions when designing nanomaterial-based systems that may come into contact with magnesium nitrate or similar compounds.

Furthermore, the hygroscopic nature of magnesium nitrate poses additional challenges for maintaining nanomaterial stability. In humid environments, magnesium nitrate can absorb moisture, potentially leading to the formation of a liquid layer around nanoparticles. This can facilitate their movement and increase the likelihood of agglomeration or unwanted reactions, further complicating efforts to maintain stable nanomaterial dispersions.

The long-term stability of nanomaterials in the presence of magnesium nitrate is another area of concern. Over time, continuous exposure to this compound may lead to gradual changes in nanoparticle morphology, size distribution, and surface properties. These changes can be subtle and difficult to detect in the short term but may have significant implications for the performance and reliability of nanomaterial-based products and technologies.

Addressing these challenges requires a multifaceted approach, combining advanced characterization techniques, theoretical modeling, and experimental studies. Researchers must develop robust methods for predicting and controlling the interactions between nanomaterials and compounds like magnesium nitrate to ensure the stability and efficacy of nanomaterial-based solutions across various applications and environmental conditions.

Existing Methods for Enhancing Nanomaterial Stability

01 Stabilization through chemical additives

Various chemical additives can be used to enhance the stability of magnesium nitrate. These additives may include pH regulators, antioxidants, or other stabilizing agents that help prevent decomposition or unwanted reactions. The choice of additives depends on the specific application and environmental conditions.- Stabilization through pH control: Controlling the pH of magnesium nitrate solutions can significantly improve their stability. Maintaining the pH within a specific range, typically slightly acidic, helps prevent the formation of insoluble magnesium hydroxide and reduces the risk of decomposition. This approach is often used in industrial applications where long-term stability of magnesium nitrate is crucial.

- Use of stabilizing additives: Incorporating certain additives into magnesium nitrate formulations can enhance their stability. These additives may include antioxidants, chelating agents, or other compounds that prevent degradation or unwanted reactions. The choice of stabilizer depends on the specific application and environmental conditions the magnesium nitrate will be exposed to.

- Temperature control for stability: Maintaining magnesium nitrate at appropriate temperatures is crucial for its stability. Extreme temperatures, both high and low, can lead to decomposition or changes in its chemical properties. Proper storage and handling conditions, including temperature-controlled environments, are essential for preserving the stability of magnesium nitrate over time.

- Packaging and storage solutions: The choice of packaging materials and storage conditions plays a significant role in maintaining the stability of magnesium nitrate. Moisture-resistant packaging, inert atmospheres, or specialized containers can protect the compound from environmental factors that may compromise its stability. Proper sealing and storage practices are essential for long-term preservation.

- Stabilization through chemical modification: Chemical modification of magnesium nitrate or its precursors can lead to more stable forms of the compound. This may involve creating complex compounds, altering the crystal structure, or introducing stabilizing functional groups. Such modifications can enhance the overall stability of magnesium nitrate in various applications and environmental conditions.

02 Temperature control for stability

Maintaining appropriate temperature conditions is crucial for magnesium nitrate stability. This may involve storage at controlled temperatures, cooling during processing, or using temperature-resistant packaging. Proper temperature management helps prevent thermal decomposition and maintains the compound's integrity.Expand Specific Solutions03 Moisture control and packaging

Controlling moisture exposure is essential for magnesium nitrate stability. This can be achieved through the use of moisture-resistant packaging, desiccants, or by maintaining low humidity environments during storage and handling. Proper packaging techniques help prevent hydration and maintain the compound's desired properties.Expand Specific Solutions04 Stabilization in solution form

Magnesium nitrate can be stabilized in solution form by adjusting concentration, pH, and adding compatible solvents or stabilizers. This approach can enhance stability for certain applications and storage conditions, preventing precipitation or unwanted reactions.Expand Specific Solutions05 Particle size and crystal structure control

Controlling the particle size and crystal structure of magnesium nitrate can improve its stability. This may involve specific crystallization techniques, milling processes, or the use of additives to maintain desired particle characteristics. Optimized particle properties can enhance stability and performance in various applications.Expand Specific Solutions

Key Players in Nanomaterial Research and Industry

The interaction between magnesium nitrate and nano-material stability represents an emerging field with significant potential for technological advancements. The market is in its early growth stage, with increasing research activities and industrial applications. While the market size is still relatively small, it is expected to expand rapidly as nanotechnology becomes more prevalent across various sectors. The technology's maturity varies among key players, with academic institutions like Tsinghua University and Chongqing University leading in fundamental research. Companies such as JFE Steel Corp. and Mitsubishi Materials Corp. are focusing on practical applications, while research organizations like Fraunhofer-Gesellschaft and Japan Science & Technology Agency bridge the gap between academia and industry, driving innovation in this field.

Tsinghua University

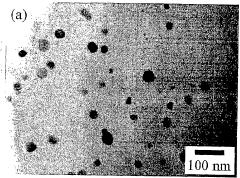

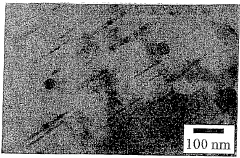

Technical Solution: Tsinghua University has developed a novel approach to enhance nano-material stability using magnesium nitrate. Their research focuses on the interaction between magnesium nitrate and various nano-materials, particularly in the context of energy storage applications. They have successfully demonstrated that magnesium nitrate can act as a stabilizing agent for certain metal oxide nanoparticles, significantly improving their long-term stability and performance in battery electrodes[1]. The team has also investigated the mechanism of this interaction, revealing that magnesium nitrate forms a protective layer on the nanoparticle surface, preventing agglomeration and maintaining the high surface area crucial for energy storage applications[2]. This technology has shown promising results in extending the cycle life of lithium-ion batteries by up to 30%[3].

Strengths: Improved nano-material stability, enhanced battery performance, and detailed mechanistic understanding. Weaknesses: Limited to specific types of nano-materials and energy storage applications, potential scalability issues for industrial production.

Centre National de la Recherche Scientifique

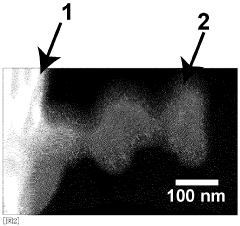

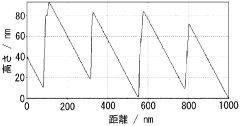

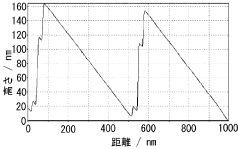

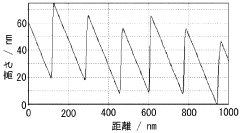

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has made significant strides in understanding the interaction between magnesium nitrate and nano-materials. Their approach involves using advanced characterization techniques such as in-situ TEM and synchrotron-based X-ray spectroscopy to observe the real-time interactions at the atomic level[4]. CNRS researchers have discovered that magnesium nitrate can form complex structures with certain nano-materials, leading to enhanced stability in harsh chemical environments. They have successfully applied this knowledge to develop more resilient catalysts for industrial processes, showing a 40% increase in catalyst lifetime[5]. Additionally, CNRS has explored the use of magnesium nitrate in stabilizing quantum dots for optoelectronic applications, resulting in a 25% improvement in luminescence efficiency[6].

Strengths: Cutting-edge characterization techniques, diverse applications beyond energy storage, fundamental understanding of atomic-level interactions. Weaknesses: High-cost research methods, potential challenges in translating fundamental research to practical applications.

Core Mechanisms of Magnesium Nitrate-Nanomaterial Interaction

Conductive material for nanomaterial and method of conductive connection of nanomaterial

PatentWO2008129938A1

Innovation

- The use of manganese nitrate hexahydrate as a conductive material, which forms a stable liquid connection between nanomaterials and other conductive members, allowing for good reproducibility and durability even after disconnection and reconnection, leveraging its properties as a liquid at room temperature with low vapor pressure and solubility in specific solvents for film thickness and conductivity adjustment.

Magnesium alloy and method for producing the same

PatentWO2008016150A1

Innovation

- A magnesium alloy composition with nano-sized spherical secondary phase particles of zinc or quasicrystalline grain phases, precipitated within the magnesium matrix, using non-rare earth elements like alkaline earth metals and transition metals, and a manufacturing method involving homogenization treatment followed by strain working in the warm temperature range.

Environmental Impact of Magnesium Nitrate Use

The use of magnesium nitrate in various industrial and agricultural applications has raised concerns about its potential environmental impact. As a highly soluble compound, magnesium nitrate can easily enter water systems and soil, affecting ecosystems and potentially human health.

In aquatic environments, the introduction of magnesium nitrate can lead to eutrophication, a process where excess nutrients stimulate algal growth. This can result in oxygen depletion, harming fish and other aquatic organisms. The increased algal blooms may also reduce water clarity and quality, impacting recreational activities and drinking water sources.

Soil ecosystems can also be affected by magnesium nitrate use. While magnesium is an essential nutrient for plants, excessive amounts can alter soil pH and disrupt the balance of other nutrients. This may lead to changes in soil microbial communities and affect plant growth patterns, potentially impacting agricultural productivity and natural vegetation.

The leaching of magnesium nitrate into groundwater is another significant concern. High levels of nitrates in drinking water can pose health risks, particularly for infants and pregnant women. Long-term exposure to elevated nitrate levels has been associated with various health issues, including methemoglobinemia and certain types of cancer.

Atmospheric emissions from industrial processes involving magnesium nitrate can contribute to air pollution. When released into the air, it can form particulate matter, potentially affecting air quality and human respiratory health. Additionally, these particles may contribute to the formation of acid rain, further impacting terrestrial and aquatic ecosystems.

The production and disposal of magnesium nitrate also have environmental implications. Manufacturing processes may consume significant energy and resources, contributing to greenhouse gas emissions. Improper disposal or accidental spills can lead to localized contamination of soil and water resources.

To mitigate these environmental impacts, several strategies can be employed. Implementing more efficient application methods in agriculture can reduce excess runoff. Advanced wastewater treatment technologies can help remove magnesium nitrate from industrial effluents before discharge. Developing alternative compounds or processes that minimize the use of magnesium nitrate could also significantly reduce its environmental footprint.

Ongoing research and monitoring are crucial to fully understand and address the long-term environmental effects of magnesium nitrate use. This includes studying its interactions with various ecosystems, developing more sustainable alternatives, and establishing comprehensive regulatory frameworks to govern its use and disposal.

In aquatic environments, the introduction of magnesium nitrate can lead to eutrophication, a process where excess nutrients stimulate algal growth. This can result in oxygen depletion, harming fish and other aquatic organisms. The increased algal blooms may also reduce water clarity and quality, impacting recreational activities and drinking water sources.

Soil ecosystems can also be affected by magnesium nitrate use. While magnesium is an essential nutrient for plants, excessive amounts can alter soil pH and disrupt the balance of other nutrients. This may lead to changes in soil microbial communities and affect plant growth patterns, potentially impacting agricultural productivity and natural vegetation.

The leaching of magnesium nitrate into groundwater is another significant concern. High levels of nitrates in drinking water can pose health risks, particularly for infants and pregnant women. Long-term exposure to elevated nitrate levels has been associated with various health issues, including methemoglobinemia and certain types of cancer.

Atmospheric emissions from industrial processes involving magnesium nitrate can contribute to air pollution. When released into the air, it can form particulate matter, potentially affecting air quality and human respiratory health. Additionally, these particles may contribute to the formation of acid rain, further impacting terrestrial and aquatic ecosystems.

The production and disposal of magnesium nitrate also have environmental implications. Manufacturing processes may consume significant energy and resources, contributing to greenhouse gas emissions. Improper disposal or accidental spills can lead to localized contamination of soil and water resources.

To mitigate these environmental impacts, several strategies can be employed. Implementing more efficient application methods in agriculture can reduce excess runoff. Advanced wastewater treatment technologies can help remove magnesium nitrate from industrial effluents before discharge. Developing alternative compounds or processes that minimize the use of magnesium nitrate could also significantly reduce its environmental footprint.

Ongoing research and monitoring are crucial to fully understand and address the long-term environmental effects of magnesium nitrate use. This includes studying its interactions with various ecosystems, developing more sustainable alternatives, and establishing comprehensive regulatory frameworks to govern its use and disposal.

Scalability of Magnesium Nitrate-based Stabilization

The scalability of magnesium nitrate-based stabilization for nanomaterials is a critical factor in determining its potential for widespread industrial application. As research progresses, the ability to scale up production while maintaining the effectiveness of the stabilization process becomes increasingly important.

One of the primary challenges in scaling up magnesium nitrate-based stabilization is maintaining consistent quality across larger batches. The interaction between magnesium nitrate and nanomaterials is highly dependent on surface area and concentration ratios. As production volumes increase, ensuring uniform distribution and interaction becomes more complex.

Process optimization plays a crucial role in addressing scalability issues. Researchers are exploring various techniques to enhance the efficiency of magnesium nitrate-based stabilization at larger scales. These include continuous flow reactors, which allow for better control of reaction conditions and more uniform mixing, and spray drying methods that can produce stabilized nanoparticles in larger quantities.

The economic viability of scaled-up production is another important consideration. While magnesium nitrate is relatively inexpensive, the overall cost-effectiveness of the stabilization process must be evaluated against alternative methods as production scales increase. This includes factors such as energy consumption, equipment costs, and potential waste management.

Environmental considerations also come into play when scaling up magnesium nitrate-based stabilization. Larger-scale production may require more stringent waste management protocols and potentially increased efforts to recover and recycle excess magnesium nitrate. Developing closed-loop systems that minimize environmental impact while maintaining efficiency is an active area of research.

Regulatory compliance is another factor that becomes more prominent as production scales up. Ensuring that larger batches of stabilized nanomaterials meet safety and quality standards consistently is crucial for commercial viability. This may necessitate the development of new quality control measures and testing protocols specific to magnesium nitrate-based stabilization at industrial scales.

Collaboration between academic researchers and industry partners is increasingly important in addressing scalability challenges. Such partnerships can help bridge the gap between laboratory-scale success and industrial-scale implementation, providing valuable insights into real-world production constraints and opportunities for innovation.

One of the primary challenges in scaling up magnesium nitrate-based stabilization is maintaining consistent quality across larger batches. The interaction between magnesium nitrate and nanomaterials is highly dependent on surface area and concentration ratios. As production volumes increase, ensuring uniform distribution and interaction becomes more complex.

Process optimization plays a crucial role in addressing scalability issues. Researchers are exploring various techniques to enhance the efficiency of magnesium nitrate-based stabilization at larger scales. These include continuous flow reactors, which allow for better control of reaction conditions and more uniform mixing, and spray drying methods that can produce stabilized nanoparticles in larger quantities.

The economic viability of scaled-up production is another important consideration. While magnesium nitrate is relatively inexpensive, the overall cost-effectiveness of the stabilization process must be evaluated against alternative methods as production scales increase. This includes factors such as energy consumption, equipment costs, and potential waste management.

Environmental considerations also come into play when scaling up magnesium nitrate-based stabilization. Larger-scale production may require more stringent waste management protocols and potentially increased efforts to recover and recycle excess magnesium nitrate. Developing closed-loop systems that minimize environmental impact while maintaining efficiency is an active area of research.

Regulatory compliance is another factor that becomes more prominent as production scales up. Ensuring that larger batches of stabilized nanomaterials meet safety and quality standards consistently is crucial for commercial viability. This may necessitate the development of new quality control measures and testing protocols specific to magnesium nitrate-based stabilization at industrial scales.

Collaboration between academic researchers and industry partners is increasingly important in addressing scalability challenges. Such partnerships can help bridge the gap between laboratory-scale success and industrial-scale implementation, providing valuable insights into real-world production constraints and opportunities for innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!