How to Apply Microfluidics to Modify Gel Electrophoresis Processes?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Gel Electrophoresis Background and Objectives

Microfluidic gel electrophoresis represents a significant advancement in the field of molecular biology and analytical chemistry. This technique combines the principles of traditional gel electrophoresis with the precision and efficiency of microfluidic systems. The evolution of this technology can be traced back to the 1930s when Arne Tiselius first introduced electrophoresis for protein separation. Over the decades, gel electrophoresis has become a fundamental tool in molecular biology for separating DNA, RNA, and proteins based on their size and charge.

The integration of microfluidics into gel electrophoresis processes marks a pivotal moment in the technology's development. Microfluidics, the science of manipulating and controlling fluids at the microscale, emerged in the 1990s and has since revolutionized various analytical techniques. By applying microfluidic principles to gel electrophoresis, researchers aim to overcome limitations of traditional methods, such as long analysis times, large sample volumes, and limited resolution.

The primary objectives of microfluidic gel electrophoresis are to enhance separation efficiency, reduce sample and reagent consumption, increase throughput, and improve overall analytical performance. These goals align with the broader trends in analytical chemistry and life sciences towards miniaturization, automation, and high-throughput analysis.

One of the key technological trends in this field is the development of lab-on-a-chip devices that integrate multiple analytical steps, including sample preparation, separation, and detection, into a single microfluidic platform. This integration not only simplifies the analytical process but also opens up new possibilities for point-of-care diagnostics and portable analytical devices.

Another significant trend is the exploration of novel materials and fabrication techniques for microfluidic gel electrophoresis devices. Researchers are investigating materials such as hydrogels, paper-based substrates, and nanostructured materials to improve separation performance and device functionality.

The application of microfluidics to gel electrophoresis processes also aims to address specific challenges in genomics and proteomics research. For instance, the ability to perform high-resolution separations of DNA fragments or proteins in miniaturized devices could accelerate genetic analysis and biomarker discovery.

As we look towards the future, the technological objectives for microfluidic gel electrophoresis include further miniaturization, increased automation, and enhanced integration with other analytical techniques. There is also a growing emphasis on developing sustainable and environmentally friendly microfluidic devices, aligning with global efforts towards green chemistry and sustainable laboratory practices.

The integration of microfluidics into gel electrophoresis processes marks a pivotal moment in the technology's development. Microfluidics, the science of manipulating and controlling fluids at the microscale, emerged in the 1990s and has since revolutionized various analytical techniques. By applying microfluidic principles to gel electrophoresis, researchers aim to overcome limitations of traditional methods, such as long analysis times, large sample volumes, and limited resolution.

The primary objectives of microfluidic gel electrophoresis are to enhance separation efficiency, reduce sample and reagent consumption, increase throughput, and improve overall analytical performance. These goals align with the broader trends in analytical chemistry and life sciences towards miniaturization, automation, and high-throughput analysis.

One of the key technological trends in this field is the development of lab-on-a-chip devices that integrate multiple analytical steps, including sample preparation, separation, and detection, into a single microfluidic platform. This integration not only simplifies the analytical process but also opens up new possibilities for point-of-care diagnostics and portable analytical devices.

Another significant trend is the exploration of novel materials and fabrication techniques for microfluidic gel electrophoresis devices. Researchers are investigating materials such as hydrogels, paper-based substrates, and nanostructured materials to improve separation performance and device functionality.

The application of microfluidics to gel electrophoresis processes also aims to address specific challenges in genomics and proteomics research. For instance, the ability to perform high-resolution separations of DNA fragments or proteins in miniaturized devices could accelerate genetic analysis and biomarker discovery.

As we look towards the future, the technological objectives for microfluidic gel electrophoresis include further miniaturization, increased automation, and enhanced integration with other analytical techniques. There is also a growing emphasis on developing sustainable and environmentally friendly microfluidic devices, aligning with global efforts towards green chemistry and sustainable laboratory practices.

Market Analysis for Microfluidic Electrophoresis Systems

The market for microfluidic electrophoresis systems has been experiencing significant growth in recent years, driven by the increasing demand for more efficient and precise analytical techniques in various fields, including genomics, proteomics, and drug discovery. This technology combines the advantages of microfluidics with traditional gel electrophoresis, offering enhanced performance, reduced sample and reagent consumption, and faster analysis times.

The global market for microfluidic electrophoresis systems is primarily segmented into academic research institutions, pharmaceutical and biotechnology companies, and clinical diagnostics laboratories. Academic research institutions currently represent the largest market segment, as these systems are extensively used in genomics and proteomics research. However, the pharmaceutical and biotechnology sector is expected to show the highest growth rate in the coming years, driven by the increasing adoption of these systems in drug discovery and development processes.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced research infrastructure and high investment in life sciences research. However, the Asia-Pacific region is anticipated to witness the fastest growth, primarily due to increasing research activities in countries like China, Japan, and South Korea.

Key factors driving the market growth include the rising prevalence of chronic diseases, growing focus on personalized medicine, and increasing funding for genomics and proteomics research. The ability of microfluidic electrophoresis systems to provide high-resolution separation of biomolecules with minimal sample requirements makes them particularly attractive for applications in precision medicine and biomarker discovery.

Despite the positive outlook, the market faces certain challenges. The high cost of advanced microfluidic electrophoresis systems and the need for skilled personnel to operate these sophisticated instruments can limit their adoption, especially in smaller research laboratories and emerging markets. Additionally, the complexity of integrating microfluidic systems with existing laboratory workflows and the lack of standardization across different platforms pose challenges to widespread adoption.

Looking ahead, the market is expected to benefit from ongoing technological advancements, such as the integration of artificial intelligence and machine learning for data analysis, and the development of portable and point-of-care microfluidic electrophoresis devices. These innovations are likely to expand the application scope of microfluidic electrophoresis systems and drive market growth in the coming years.

The global market for microfluidic electrophoresis systems is primarily segmented into academic research institutions, pharmaceutical and biotechnology companies, and clinical diagnostics laboratories. Academic research institutions currently represent the largest market segment, as these systems are extensively used in genomics and proteomics research. However, the pharmaceutical and biotechnology sector is expected to show the highest growth rate in the coming years, driven by the increasing adoption of these systems in drug discovery and development processes.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced research infrastructure and high investment in life sciences research. However, the Asia-Pacific region is anticipated to witness the fastest growth, primarily due to increasing research activities in countries like China, Japan, and South Korea.

Key factors driving the market growth include the rising prevalence of chronic diseases, growing focus on personalized medicine, and increasing funding for genomics and proteomics research. The ability of microfluidic electrophoresis systems to provide high-resolution separation of biomolecules with minimal sample requirements makes them particularly attractive for applications in precision medicine and biomarker discovery.

Despite the positive outlook, the market faces certain challenges. The high cost of advanced microfluidic electrophoresis systems and the need for skilled personnel to operate these sophisticated instruments can limit their adoption, especially in smaller research laboratories and emerging markets. Additionally, the complexity of integrating microfluidic systems with existing laboratory workflows and the lack of standardization across different platforms pose challenges to widespread adoption.

Looking ahead, the market is expected to benefit from ongoing technological advancements, such as the integration of artificial intelligence and machine learning for data analysis, and the development of portable and point-of-care microfluidic electrophoresis devices. These innovations are likely to expand the application scope of microfluidic electrophoresis systems and drive market growth in the coming years.

Current Challenges in Microfluidic Gel Electrophoresis

Microfluidic gel electrophoresis represents a significant advancement in the field of molecular biology and analytical chemistry. However, despite its potential, several challenges persist in its widespread adoption and optimal performance. One of the primary obstacles is the miniaturization of traditional gel electrophoresis systems while maintaining or improving separation efficiency.

The reduction in scale introduces complexities in sample loading and detection, as the volumes handled are often in the nanoliter range. This necessitates the development of precise microfluidic injection systems and highly sensitive detection methods capable of analyzing minute sample quantities. Additionally, the fabrication of uniform and reproducible gel matrices within microfluidic channels poses significant technical hurdles.

Another critical challenge lies in the management of Joule heating within microfluidic devices. The high electric fields required for efficient separation can lead to excessive heat generation, potentially causing sample degradation, buffer evaporation, and gel deformation. Innovative cooling strategies and materials with superior heat dissipation properties are essential to address this issue effectively.

The integration of multiple analytical steps, such as sample preparation, separation, and detection, into a single microfluidic platform remains a formidable task. Achieving seamless connectivity between these processes while maintaining the integrity of each step requires sophisticated design and fabrication techniques.

Furthermore, the development of standardized protocols and quality control measures for microfluidic gel electrophoresis is crucial for ensuring reproducibility across different laboratories and applications. The lack of standardization hampers the comparison of results and the widespread adoption of this technology in clinical and industrial settings.

Enhancing the resolution and speed of separation in microfluidic systems is an ongoing challenge. While miniaturization offers the potential for faster analysis, achieving high-resolution separation of complex mixtures, particularly for large biomolecules like proteins and nucleic acids, remains difficult. This necessitates the exploration of novel gel formulations and electrode designs tailored specifically for microfluidic environments.

Lastly, the cost-effectiveness and scalability of microfluidic gel electrophoresis systems present significant hurdles. The current fabrication processes for microfluidic devices can be complex and expensive, limiting their accessibility to many research laboratories and industrial applications. Developing more economical manufacturing methods and materials is essential for the widespread adoption of this technology.

The reduction in scale introduces complexities in sample loading and detection, as the volumes handled are often in the nanoliter range. This necessitates the development of precise microfluidic injection systems and highly sensitive detection methods capable of analyzing minute sample quantities. Additionally, the fabrication of uniform and reproducible gel matrices within microfluidic channels poses significant technical hurdles.

Another critical challenge lies in the management of Joule heating within microfluidic devices. The high electric fields required for efficient separation can lead to excessive heat generation, potentially causing sample degradation, buffer evaporation, and gel deformation. Innovative cooling strategies and materials with superior heat dissipation properties are essential to address this issue effectively.

The integration of multiple analytical steps, such as sample preparation, separation, and detection, into a single microfluidic platform remains a formidable task. Achieving seamless connectivity between these processes while maintaining the integrity of each step requires sophisticated design and fabrication techniques.

Furthermore, the development of standardized protocols and quality control measures for microfluidic gel electrophoresis is crucial for ensuring reproducibility across different laboratories and applications. The lack of standardization hampers the comparison of results and the widespread adoption of this technology in clinical and industrial settings.

Enhancing the resolution and speed of separation in microfluidic systems is an ongoing challenge. While miniaturization offers the potential for faster analysis, achieving high-resolution separation of complex mixtures, particularly for large biomolecules like proteins and nucleic acids, remains difficult. This necessitates the exploration of novel gel formulations and electrode designs tailored specifically for microfluidic environments.

Lastly, the cost-effectiveness and scalability of microfluidic gel electrophoresis systems present significant hurdles. The current fabrication processes for microfluidic devices can be complex and expensive, limiting their accessibility to many research laboratories and industrial applications. Developing more economical manufacturing methods and materials is essential for the widespread adoption of this technology.

Existing Microfluidic Gel Electrophoresis Solutions

01 Modification of gel composition

Altering the composition of the gel used in electrophoresis can improve separation efficiency and resolution. This includes adjusting the concentration of agarose or polyacrylamide, incorporating additives, or using novel gel materials. These modifications can enhance the separation of specific types of molecules or improve overall performance.- Modification of gel composition: Improvements in gel electrophoresis can be achieved by modifying the gel composition. This includes using different types of polymers, adjusting the concentration of the gel, or incorporating additives to enhance separation efficiency and resolution. These modifications can lead to better separation of biomolecules and improved overall performance of the electrophoresis process.

- Enhanced sample loading techniques: Advancements in sample loading techniques for gel electrophoresis can significantly improve the process. This includes developing new methods for sample preparation, designing innovative loading devices, or implementing automated loading systems. These enhancements can lead to more precise sample application, reduced contamination, and increased reproducibility of results.

- Optimization of buffer systems: Modifying buffer systems used in gel electrophoresis can enhance separation and resolution. This involves developing new buffer formulations, adjusting pH levels, or incorporating additives to improve conductivity and stability. Optimized buffer systems can lead to better separation of biomolecules, reduced background noise, and increased overall efficiency of the electrophoresis process.

- Integration of detection and imaging systems: Incorporating advanced detection and imaging systems into gel electrophoresis setups can enhance the analysis of separated biomolecules. This includes developing high-sensitivity cameras, fluorescence detection systems, or real-time imaging capabilities. These improvements can lead to more accurate quantification, faster analysis, and the ability to detect low-abundance molecules.

- Miniaturization and microfluidic approaches: Adapting gel electrophoresis to miniaturized and microfluidic formats can offer advantages in terms of speed, sample volume, and automation. This involves developing microchip-based electrophoresis systems, integrating multiple analytical steps on a single device, or creating high-throughput platforms. These approaches can lead to faster analysis times, reduced reagent consumption, and improved portability of gel electrophoresis systems.

02 Electrode and buffer system improvements

Enhancements to the electrode design and buffer system can optimize the electrophoresis process. This may involve using specialized electrodes, modifying buffer compositions, or implementing pulsed field techniques. These improvements can lead to better control over the electric field and more efficient separation of molecules.Expand Specific Solutions03 Integration of detection and analysis systems

Incorporating advanced detection and analysis systems directly into the gel electrophoresis apparatus can streamline the process and improve data quality. This may include fluorescence detection, real-time imaging, or automated band analysis. Such integrations can enhance the accuracy and speed of result interpretation.Expand Specific Solutions04 Miniaturization and microfluidic approaches

Developing miniaturized or microfluidic gel electrophoresis systems can reduce sample and reagent consumption while increasing throughput. These approaches often involve creating microchannels or arrays for parallel processing. Miniaturization can lead to faster analysis times and the ability to work with smaller sample volumes.Expand Specific Solutions05 Novel sample loading and preparation techniques

Improving sample loading and preparation methods can enhance the overall efficiency of gel electrophoresis. This may include developing new loading devices, optimizing sample concentration techniques, or implementing automated sample preparation systems. These advancements can lead to more consistent results and reduced operator variability.Expand Specific Solutions

Key Players in Microfluidic Electrophoresis Industry

The microfluidics-enhanced gel electrophoresis market is in a growth phase, driven by increasing demand for more efficient and precise separation techniques in genomics and proteomics research. The global market size is projected to expand significantly, fueled by advancements in life sciences and biotechnology. While the technology is maturing, there's still room for innovation. Key players like Agilent Technologies and Life Technologies Corp. are leading the field, with academic institutions such as Columbia University and the University of Tokyo contributing cutting-edge research. Emerging companies like Focused Photonics and ibidi GmbH are also making strides, indicating a competitive and dynamic landscape with potential for further technological breakthroughs and market expansion.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a microfluidic gel electrophoresis system that integrates sample preparation, separation, and detection on a single chip. Their approach uses a network of microchannels etched into a glass or polymer substrate, with integrated electrodes for applying electric fields. The system employs a sieving matrix optimized for microfluidic environments, allowing for rapid and high-resolution separation of DNA, RNA, and proteins. Agilent's technology incorporates on-chip fluorescence detection, enabling real-time monitoring of analyte migration[1][3]. The microfluidic design significantly reduces sample and reagent consumption, typically requiring only nanoliters of material compared to traditional gel electrophoresis methods[2].

Strengths: Miniaturization allows for faster analysis times and reduced sample consumption. Integration of multiple steps improves workflow efficiency. Weaknesses: May have limitations in separating very large molecules or complex mixtures compared to traditional slab gels.

Life Technologies Corp.

Technical Solution: Life Technologies has pioneered a microfluidic gel electrophoresis platform that utilizes a lab-on-a-chip approach for nucleic acid analysis. Their system employs a polymer-based microfluidic chip with pre-cast gel matrices, eliminating the need for manual gel preparation. The technology incorporates capillary electrophoresis principles within a microfluidic format, allowing for high-throughput analysis of DNA and RNA samples. Life Technologies' platform features automated sample loading and integrated fluorescence detection, enabling quantitative analysis of nucleic acids with high sensitivity[4]. The system can perform sizing and quantitation of DNA fragments ranging from 25 to 1500 base pairs in as little as 30 minutes, significantly faster than traditional gel electrophoresis methods[5].

Strengths: High-throughput capability and automation reduce hands-on time and improve reproducibility. Rapid analysis times increase laboratory efficiency. Weaknesses: Limited to specific size ranges of nucleic acids, may not be suitable for all applications.

Core Innovations in Microfluidic Electrophoresis

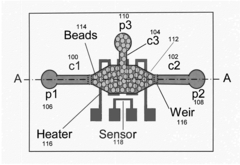

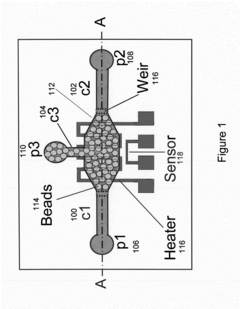

Selective Capture and Release of Analytes

PatentInactiveUS20100151465A1

Innovation

- The use of aptamers functionalized on a solid phase, such as microbeads, for selective binding and thermally controlled release of analytes, allowing for specific capture and minimal invasive release without altering the solvent composition or polarity, and enabling reuse of the aptamer surfaces.

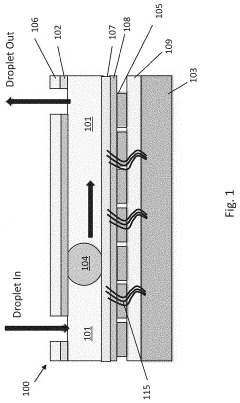

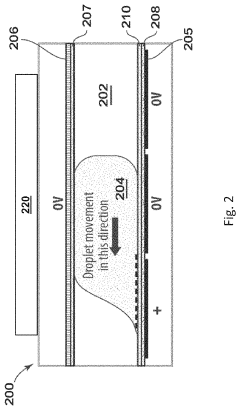

Method for degassing liquid droplets by electrical actuation at higher temperatures

PatentActiveUS20210231606A1

Innovation

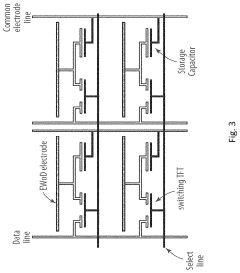

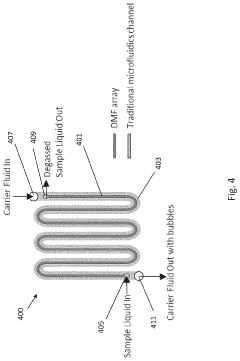

- A microfluidic device with a combination of electrowetting and heating is used to induce the formation of gaseous bubbles in droplets, which are then removed by moving the droplet along an electrode path or with a carrier fluid, allowing for efficient degassing without the need for vacuum or high-frequency sonication.

Regulatory Considerations for Microfluidic Devices

The integration of microfluidics into gel electrophoresis processes introduces new regulatory considerations that must be addressed to ensure compliance with existing standards and guidelines. Regulatory bodies such as the FDA in the United States and the EMA in Europe have established frameworks for evaluating and approving microfluidic devices used in medical and diagnostic applications.

One primary regulatory concern is the classification of microfluidic devices used in gel electrophoresis. Depending on their intended use and risk level, these devices may be categorized as Class I, II, or III medical devices. Class I devices typically require general controls, while Class II and III devices may necessitate additional premarket approval processes.

Quality control and validation procedures are critical aspects of regulatory compliance for microfluidic gel electrophoresis systems. Manufacturers must demonstrate the reliability, reproducibility, and accuracy of their devices through rigorous testing protocols. This includes validating the performance of microfluidic channels, flow control mechanisms, and detection systems under various operating conditions.

Biocompatibility and material safety are also key regulatory considerations. Materials used in microfluidic devices that come into contact with biological samples or reagents must be thoroughly evaluated for potential toxicity, reactivity, and leaching. Compliance with standards such as ISO 10993 for biocompatibility testing may be required.

Data integrity and security are increasingly important in the regulatory landscape, especially for microfluidic devices that incorporate digital components or connect to external systems. Manufacturers must implement robust data management practices and cybersecurity measures to protect sensitive information and ensure the integrity of test results.

Regulatory bodies also focus on the manufacturing processes of microfluidic devices. Good Manufacturing Practices (GMP) must be followed to ensure consistent quality and performance. This includes maintaining detailed documentation of design specifications, production processes, and quality control measures.

As microfluidic technologies continue to evolve, regulatory frameworks are adapting to address new challenges. Manufacturers and researchers must stay informed about emerging regulations and guidelines specific to microfluidic applications in gel electrophoresis. Engaging with regulatory agencies early in the development process can help identify potential compliance issues and streamline the approval process for innovative microfluidic gel electrophoresis systems.

One primary regulatory concern is the classification of microfluidic devices used in gel electrophoresis. Depending on their intended use and risk level, these devices may be categorized as Class I, II, or III medical devices. Class I devices typically require general controls, while Class II and III devices may necessitate additional premarket approval processes.

Quality control and validation procedures are critical aspects of regulatory compliance for microfluidic gel electrophoresis systems. Manufacturers must demonstrate the reliability, reproducibility, and accuracy of their devices through rigorous testing protocols. This includes validating the performance of microfluidic channels, flow control mechanisms, and detection systems under various operating conditions.

Biocompatibility and material safety are also key regulatory considerations. Materials used in microfluidic devices that come into contact with biological samples or reagents must be thoroughly evaluated for potential toxicity, reactivity, and leaching. Compliance with standards such as ISO 10993 for biocompatibility testing may be required.

Data integrity and security are increasingly important in the regulatory landscape, especially for microfluidic devices that incorporate digital components or connect to external systems. Manufacturers must implement robust data management practices and cybersecurity measures to protect sensitive information and ensure the integrity of test results.

Regulatory bodies also focus on the manufacturing processes of microfluidic devices. Good Manufacturing Practices (GMP) must be followed to ensure consistent quality and performance. This includes maintaining detailed documentation of design specifications, production processes, and quality control measures.

As microfluidic technologies continue to evolve, regulatory frameworks are adapting to address new challenges. Manufacturers and researchers must stay informed about emerging regulations and guidelines specific to microfluidic applications in gel electrophoresis. Engaging with regulatory agencies early in the development process can help identify potential compliance issues and streamline the approval process for innovative microfluidic gel electrophoresis systems.

Environmental Impact of Microfluidic Electrophoresis

The integration of microfluidics into gel electrophoresis processes has significant implications for environmental sustainability. Traditional gel electrophoresis methods often require substantial amounts of reagents and generate considerable waste. In contrast, microfluidic electrophoresis systems dramatically reduce the volume of chemicals needed, minimizing the environmental footprint of these analytical procedures.

Microfluidic devices typically operate on a microscale, utilizing channels with dimensions in the range of micrometers. This miniaturization leads to a substantial decrease in sample and reagent consumption, often by several orders of magnitude compared to conventional methods. Consequently, the production and disposal of hazardous chemicals associated with electrophoresis are significantly reduced, lessening the burden on waste management systems and decreasing the risk of environmental contamination.

The energy efficiency of microfluidic electrophoresis systems also contributes to their positive environmental impact. These devices generally require less power to operate due to their smaller size and more efficient heat dissipation. The reduced energy consumption translates to lower greenhouse gas emissions associated with electricity generation, aligning with global efforts to combat climate change.

Furthermore, the compact nature of microfluidic devices allows for the development of portable, field-deployable systems. This portability enables on-site analysis, reducing the need for sample transportation to centralized laboratories. By minimizing transportation requirements, microfluidic electrophoresis indirectly contributes to reducing carbon emissions from vehicles and logistics operations.

The materials used in microfluidic devices also play a role in their environmental impact. Many microfluidic chips are fabricated from polymers that can be recycled or biodegraded, offering a more sustainable alternative to traditional glass or acrylic gel electrophoresis apparatus. Advances in green chemistry and materials science are continually improving the eco-friendliness of these devices, with ongoing research into biodegradable and renewable materials for microfluidic chip production.

Additionally, the precision and efficiency of microfluidic electrophoresis can lead to reduced experimental repetition and waste generation. The improved resolution and sensitivity of these systems often result in more accurate and reliable data, potentially decreasing the number of experiments required to achieve conclusive results. This efficiency not only saves resources but also minimizes the environmental impact associated with repeated analyses.

In conclusion, the application of microfluidics to modify gel electrophoresis processes offers substantial environmental benefits. From reduced chemical usage and waste generation to improved energy efficiency and the potential for sustainable materials, microfluidic electrophoresis aligns well with the principles of green chemistry and sustainable laboratory practices. As this technology continues to evolve, its positive environmental impact is likely to expand, contributing to more eco-friendly analytical processes across various scientific and industrial fields.

Microfluidic devices typically operate on a microscale, utilizing channels with dimensions in the range of micrometers. This miniaturization leads to a substantial decrease in sample and reagent consumption, often by several orders of magnitude compared to conventional methods. Consequently, the production and disposal of hazardous chemicals associated with electrophoresis are significantly reduced, lessening the burden on waste management systems and decreasing the risk of environmental contamination.

The energy efficiency of microfluidic electrophoresis systems also contributes to their positive environmental impact. These devices generally require less power to operate due to their smaller size and more efficient heat dissipation. The reduced energy consumption translates to lower greenhouse gas emissions associated with electricity generation, aligning with global efforts to combat climate change.

Furthermore, the compact nature of microfluidic devices allows for the development of portable, field-deployable systems. This portability enables on-site analysis, reducing the need for sample transportation to centralized laboratories. By minimizing transportation requirements, microfluidic electrophoresis indirectly contributes to reducing carbon emissions from vehicles and logistics operations.

The materials used in microfluidic devices also play a role in their environmental impact. Many microfluidic chips are fabricated from polymers that can be recycled or biodegraded, offering a more sustainable alternative to traditional glass or acrylic gel electrophoresis apparatus. Advances in green chemistry and materials science are continually improving the eco-friendliness of these devices, with ongoing research into biodegradable and renewable materials for microfluidic chip production.

Additionally, the precision and efficiency of microfluidic electrophoresis can lead to reduced experimental repetition and waste generation. The improved resolution and sensitivity of these systems often result in more accurate and reliable data, potentially decreasing the number of experiments required to achieve conclusive results. This efficiency not only saves resources but also minimizes the environmental impact associated with repeated analyses.

In conclusion, the application of microfluidics to modify gel electrophoresis processes offers substantial environmental benefits. From reduced chemical usage and waste generation to improved energy efficiency and the potential for sustainable materials, microfluidic electrophoresis aligns well with the principles of green chemistry and sustainable laboratory practices. As this technology continues to evolve, its positive environmental impact is likely to expand, contributing to more eco-friendly analytical processes across various scientific and industrial fields.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!