How to Set New Benchmarks in Electrophoretic Coupling Efficiency?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrophoretic Coupling Background and Objectives

Electrophoretic coupling, a fundamental process in various scientific and industrial applications, has been a subject of intense research and development for decades. This technique, which leverages the movement of charged particles in an electric field, has found widespread use in fields ranging from molecular biology to materials science. The evolution of electrophoretic coupling technology has been marked by continuous improvements in efficiency, precision, and scalability.

The primary objective in advancing electrophoretic coupling efficiency is to enhance the speed and accuracy of particle separation while minimizing energy consumption and sample degradation. This goal is driven by the increasing demands in areas such as proteomics, genomics, and nanotechnology, where high-throughput and high-resolution analyses are crucial. Achieving new benchmarks in electrophoretic coupling efficiency would significantly impact these fields, enabling faster and more precise analytical processes.

Recent technological advancements have opened up new possibilities for improving electrophoretic coupling. The integration of microfluidics and nanotechnology has led to the development of more sophisticated electrophoretic systems. These innovations allow for better control over particle movement and interaction, potentially leading to substantial improvements in coupling efficiency. Additionally, the application of advanced materials, such as novel electrode compositions and surface modifications, has shown promise in enhancing the overall performance of electrophoretic systems.

The pursuit of higher electrophoretic coupling efficiency is also driven by the need for more sustainable and cost-effective processes in both research and industrial settings. Improved efficiency translates to reduced energy consumption, lower sample volumes, and faster processing times, all of which contribute to more economical and environmentally friendly operations. This aligns with the broader trend towards green technology and sustainable scientific practices.

As we look towards setting new benchmarks in electrophoretic coupling efficiency, several key areas of focus emerge. These include optimizing electric field distribution, enhancing buffer composition for improved particle mobility, developing more sensitive detection methods, and exploring novel electrode designs. The integration of artificial intelligence and machine learning algorithms for real-time process optimization also presents an exciting frontier in this field.

In conclusion, the quest for improved electrophoretic coupling efficiency represents a critical area of technological advancement. Success in this endeavor promises to unlock new capabilities in molecular analysis, materials processing, and beyond, potentially revolutionizing numerous scientific and industrial processes. The following sections of this report will delve deeper into the current state of the technology, challenges, and potential pathways to achieving these ambitious efficiency goals.

The primary objective in advancing electrophoretic coupling efficiency is to enhance the speed and accuracy of particle separation while minimizing energy consumption and sample degradation. This goal is driven by the increasing demands in areas such as proteomics, genomics, and nanotechnology, where high-throughput and high-resolution analyses are crucial. Achieving new benchmarks in electrophoretic coupling efficiency would significantly impact these fields, enabling faster and more precise analytical processes.

Recent technological advancements have opened up new possibilities for improving electrophoretic coupling. The integration of microfluidics and nanotechnology has led to the development of more sophisticated electrophoretic systems. These innovations allow for better control over particle movement and interaction, potentially leading to substantial improvements in coupling efficiency. Additionally, the application of advanced materials, such as novel electrode compositions and surface modifications, has shown promise in enhancing the overall performance of electrophoretic systems.

The pursuit of higher electrophoretic coupling efficiency is also driven by the need for more sustainable and cost-effective processes in both research and industrial settings. Improved efficiency translates to reduced energy consumption, lower sample volumes, and faster processing times, all of which contribute to more economical and environmentally friendly operations. This aligns with the broader trend towards green technology and sustainable scientific practices.

As we look towards setting new benchmarks in electrophoretic coupling efficiency, several key areas of focus emerge. These include optimizing electric field distribution, enhancing buffer composition for improved particle mobility, developing more sensitive detection methods, and exploring novel electrode designs. The integration of artificial intelligence and machine learning algorithms for real-time process optimization also presents an exciting frontier in this field.

In conclusion, the quest for improved electrophoretic coupling efficiency represents a critical area of technological advancement. Success in this endeavor promises to unlock new capabilities in molecular analysis, materials processing, and beyond, potentially revolutionizing numerous scientific and industrial processes. The following sections of this report will delve deeper into the current state of the technology, challenges, and potential pathways to achieving these ambitious efficiency goals.

Market Analysis for High-Efficiency Electrophoretic Coupling

The market for high-efficiency electrophoretic coupling technologies is experiencing significant growth, driven by increasing demand in various industries such as biotechnology, pharmaceuticals, and analytical chemistry. This demand is fueled by the need for more precise and efficient separation techniques in research, diagnostics, and quality control processes.

The global electrophoresis market, which encompasses electrophoretic coupling technologies, is projected to expand at a steady rate over the next five years. This growth is attributed to the rising prevalence of genetic disorders, advancements in proteomics and genomics research, and the increasing adoption of personalized medicine approaches.

Key market segments for high-efficiency electrophoretic coupling include academic and research institutions, pharmaceutical and biotechnology companies, hospitals and diagnostic centers, and forensic laboratories. Among these, academic and research institutions currently hold the largest market share due to extensive use in genomics and proteomics studies.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, leads in market share due to substantial investments in life sciences research and a strong presence of key industry players. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth rates in the coming years, driven by increasing research activities and improving healthcare infrastructure.

The market is characterized by intense competition among major players, including Bio-Rad Laboratories, Thermo Fisher Scientific, and Agilent Technologies. These companies are focusing on product innovations and strategic collaborations to maintain their market positions and gain competitive advantages.

Key factors driving market growth include technological advancements in electrophoresis techniques, increasing funding for proteomics and genomics research, and growing applications in clinical diagnostics. However, the high cost of advanced electrophoresis systems and the availability of alternative technologies may pose challenges to market expansion.

The COVID-19 pandemic has had a mixed impact on the market. While it initially disrupted supply chains and research activities, it also accelerated the demand for rapid diagnostic tools and vaccine development, indirectly boosting the electrophoresis market.

Looking ahead, the market for high-efficiency electrophoretic coupling is expected to continue its growth trajectory. Emerging trends such as miniaturization of electrophoresis systems, integration with other analytical techniques, and the development of automated and high-throughput platforms are likely to shape the future of this market, offering new opportunities for innovation and market expansion.

The global electrophoresis market, which encompasses electrophoretic coupling technologies, is projected to expand at a steady rate over the next five years. This growth is attributed to the rising prevalence of genetic disorders, advancements in proteomics and genomics research, and the increasing adoption of personalized medicine approaches.

Key market segments for high-efficiency electrophoretic coupling include academic and research institutions, pharmaceutical and biotechnology companies, hospitals and diagnostic centers, and forensic laboratories. Among these, academic and research institutions currently hold the largest market share due to extensive use in genomics and proteomics studies.

Geographically, North America dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, leads in market share due to substantial investments in life sciences research and a strong presence of key industry players. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth rates in the coming years, driven by increasing research activities and improving healthcare infrastructure.

The market is characterized by intense competition among major players, including Bio-Rad Laboratories, Thermo Fisher Scientific, and Agilent Technologies. These companies are focusing on product innovations and strategic collaborations to maintain their market positions and gain competitive advantages.

Key factors driving market growth include technological advancements in electrophoresis techniques, increasing funding for proteomics and genomics research, and growing applications in clinical diagnostics. However, the high cost of advanced electrophoresis systems and the availability of alternative technologies may pose challenges to market expansion.

The COVID-19 pandemic has had a mixed impact on the market. While it initially disrupted supply chains and research activities, it also accelerated the demand for rapid diagnostic tools and vaccine development, indirectly boosting the electrophoresis market.

Looking ahead, the market for high-efficiency electrophoretic coupling is expected to continue its growth trajectory. Emerging trends such as miniaturization of electrophoresis systems, integration with other analytical techniques, and the development of automated and high-throughput platforms are likely to shape the future of this market, offering new opportunities for innovation and market expansion.

Current Challenges in Electrophoretic Coupling Efficiency

Electrophoretic coupling efficiency remains a critical challenge in various scientific and industrial applications. Despite significant advancements in the field, researchers and practitioners continue to face several obstacles in achieving optimal performance. One of the primary challenges is the inherent complexity of the electrophoretic process, which involves the movement of charged particles through a fluid under the influence of an electric field.

The heterogeneity of sample compositions presents a significant hurdle in maintaining consistent coupling efficiency. Different molecules and particles exhibit varying electrophoretic mobilities, leading to disparities in separation and coupling outcomes. This variability often results in reduced overall efficiency and compromised reproducibility of results, particularly when dealing with complex biological samples or industrial mixtures.

Another major challenge lies in the management of Joule heating, a phenomenon that occurs due to the passage of electric current through the electrophoretic medium. Excessive heat generation can lead to temperature gradients within the system, causing convection currents and band broadening. These thermal effects not only diminish the resolution of separation but also potentially degrade sensitive analytes, thereby impacting the coupling efficiency.

The optimization of buffer composition and concentration remains a persistent challenge in electrophoretic coupling. The buffer system plays a crucial role in maintaining pH stability, controlling electroosmotic flow, and facilitating efficient separation. However, finding the ideal buffer formulation that balances these factors while maximizing coupling efficiency often requires extensive experimentation and fine-tuning.

Surface interactions between analytes and the separation medium pose another significant challenge. Adsorption of molecules to capillary walls or gel matrices can lead to peak tailing, reduced efficiency, and potential loss of analytes. Overcoming these non-specific interactions without compromising the separation mechanism is a delicate balance that researchers continually strive to achieve.

The scaling up of electrophoretic processes for industrial applications presents its own set of challenges. Maintaining uniform electric fields and consistent coupling efficiency across larger volumes and dimensions is technically demanding. Issues such as edge effects, flow instabilities, and increased Joule heating become more pronounced at larger scales, necessitating innovative engineering solutions.

Lastly, the integration of electrophoretic coupling with downstream analytical techniques or industrial processes poses significant challenges. Ensuring compatibility in terms of sample volumes, concentrations, and buffer systems while maintaining high coupling efficiency requires careful consideration and often compromises between different system requirements.

The heterogeneity of sample compositions presents a significant hurdle in maintaining consistent coupling efficiency. Different molecules and particles exhibit varying electrophoretic mobilities, leading to disparities in separation and coupling outcomes. This variability often results in reduced overall efficiency and compromised reproducibility of results, particularly when dealing with complex biological samples or industrial mixtures.

Another major challenge lies in the management of Joule heating, a phenomenon that occurs due to the passage of electric current through the electrophoretic medium. Excessive heat generation can lead to temperature gradients within the system, causing convection currents and band broadening. These thermal effects not only diminish the resolution of separation but also potentially degrade sensitive analytes, thereby impacting the coupling efficiency.

The optimization of buffer composition and concentration remains a persistent challenge in electrophoretic coupling. The buffer system plays a crucial role in maintaining pH stability, controlling electroosmotic flow, and facilitating efficient separation. However, finding the ideal buffer formulation that balances these factors while maximizing coupling efficiency often requires extensive experimentation and fine-tuning.

Surface interactions between analytes and the separation medium pose another significant challenge. Adsorption of molecules to capillary walls or gel matrices can lead to peak tailing, reduced efficiency, and potential loss of analytes. Overcoming these non-specific interactions without compromising the separation mechanism is a delicate balance that researchers continually strive to achieve.

The scaling up of electrophoretic processes for industrial applications presents its own set of challenges. Maintaining uniform electric fields and consistent coupling efficiency across larger volumes and dimensions is technically demanding. Issues such as edge effects, flow instabilities, and increased Joule heating become more pronounced at larger scales, necessitating innovative engineering solutions.

Lastly, the integration of electrophoretic coupling with downstream analytical techniques or industrial processes poses significant challenges. Ensuring compatibility in terms of sample volumes, concentrations, and buffer systems while maintaining high coupling efficiency requires careful consideration and often compromises between different system requirements.

Existing Solutions for Enhancing Coupling Efficiency

01 Optimization of electrode design

Improving the electrode design in electrophoretic displays can enhance coupling efficiency. This includes optimizing electrode shapes, sizes, and arrangements to maximize the electric field strength and uniformity across the display area. Advanced electrode configurations can lead to better particle movement and improved overall display performance.- Optimization of electrode design: Improving the electrode design in electrophoretic displays can enhance coupling efficiency. This includes optimizing electrode shapes, sizes, and arrangements to maximize the electric field strength and uniformity across the display area. Advanced electrode configurations can lead to better particle movement and improved overall display performance.

- Particle composition and properties: The composition and properties of electrophoretic particles play a crucial role in coupling efficiency. Tailoring particle size, charge, and surface properties can improve their response to electric fields. Developing particles with optimized characteristics enhances their mobility and stability within the electrophoretic medium, leading to better overall display performance.

- Electrophoretic medium formulation: The composition of the electrophoretic medium significantly affects coupling efficiency. Optimizing the fluid properties, such as viscosity and dielectric constant, can improve particle movement and stability. Additives and surfactants can be incorporated to enhance the medium's performance and prevent particle aggregation, resulting in better electrophoretic coupling.

- Driving scheme optimization: Developing advanced driving schemes for electrophoretic displays can improve coupling efficiency. This includes optimizing voltage waveforms, timing sequences, and addressing methods to enhance particle movement and reduce power consumption. Implementing sophisticated driving algorithms can lead to faster response times and improved overall display performance.

- Capsule and cell structure design: The design of electrophoretic capsules or cell structures affects coupling efficiency. Optimizing the size, shape, and arrangement of these structures can improve particle confinement and movement. Advanced capsule or cell designs can enhance the uniformity of the electric field distribution and lead to better overall electrophoretic performance.

02 Development of novel electrophoretic particles

Creating new types of electrophoretic particles with improved charge characteristics and mobility can significantly increase coupling efficiency. These particles may have modified surface properties, optimized size distributions, or novel compositions that respond more effectively to applied electric fields, resulting in faster and more uniform display switching.Expand Specific Solutions03 Improvement of dielectric fluid properties

Enhancing the properties of the dielectric fluid in which the electrophoretic particles are suspended can lead to better coupling efficiency. This may involve adjusting the fluid's viscosity, dielectric constant, or incorporating additives that improve particle dispersion and stability, ultimately resulting in more efficient particle movement and display performance.Expand Specific Solutions04 Advanced driving schemes and waveforms

Developing sophisticated driving schemes and waveforms for electrophoretic displays can improve coupling efficiency. This includes optimizing voltage levels, pulse durations, and sequences to achieve faster and more accurate particle positioning. Advanced algorithms and adaptive driving methods can enhance overall display responsiveness and image quality.Expand Specific Solutions05 Integration of sensing and feedback mechanisms

Incorporating sensing and feedback mechanisms into electrophoretic displays can help optimize coupling efficiency in real-time. These systems can monitor particle movement, electric field distribution, and display performance, allowing for dynamic adjustments to driving parameters and compensating for environmental factors or aging effects.Expand Specific Solutions

Key Players in Electrophoretic Coupling Industry

The electrophoretic coupling efficiency market is in a growth phase, driven by increasing demand for advanced display technologies. The market size is expanding rapidly, with key players like E Ink Corporation and Samsung Electronics leading innovation. Technological maturity varies, with established companies like OSRAM GmbH and Philips offering mature solutions, while emerging players like Prime Planet Energy & Solutions focus on novel applications. Universities such as Chongqing University and Southeast University contribute to R&D efforts, pushing the boundaries of efficiency. As the technology evolves, collaboration between industry leaders and research institutions is crucial for setting new benchmarks in electrophoretic coupling efficiency.

International Business Machines Corp.

Technical Solution: IBM has made contributions to electrophoretic coupling efficiency through their research in advanced materials and nanotechnology. They have explored the use of carbon nanotubes as electrode materials, which offer high conductivity and flexibility, potentially improving the overall performance of electrophoretic displays[9]. IBM's approach also includes the development of smart fluid systems that can dynamically adjust their properties based on applied electric fields, leading to more efficient particle movement. Additionally, they have investigated machine learning algorithms to optimize driving schemes for electrophoretic displays, potentially reducing power consumption and improving response times[10].

Strengths: Strong research capabilities in materials science and AI. Weaknesses: Less direct involvement in commercial e-paper products.

E Ink Corp.

Technical Solution: E Ink Corporation has developed advanced electrophoretic display (EPD) technology that significantly improves coupling efficiency. Their latest innovation involves a dual-particle electrophoretic system with charged pigment particles of different colors suspended in a dielectric fluid[1]. This system utilizes specially designed electrodes and voltage control mechanisms to enhance particle movement and reduce power consumption. E Ink has also implemented microcapsule technology, encapsulating the electrophoretic fluid and particles in tiny spheres, which allows for better control over particle movement and improves overall display performance[2]. Additionally, they have introduced a new electrode structure that minimizes the distance particles need to travel, thereby increasing response time and efficiency[3].

Strengths: Industry leader in EPD technology, low power consumption, high contrast ratios. Weaknesses: Limited color capabilities compared to other display technologies, slower refresh rates for complex images.

Innovative Approaches in Electrophoretic Coupling

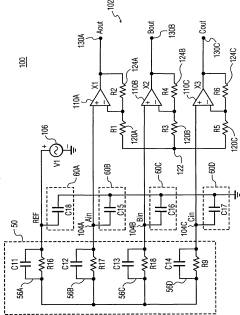

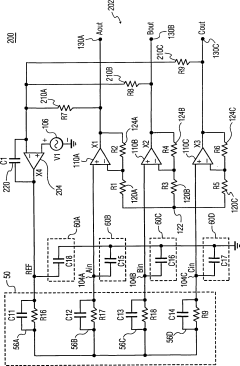

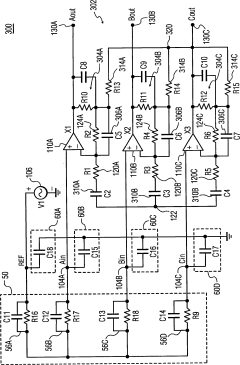

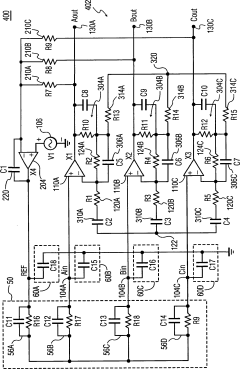

Ecg electrode contact quality measurement system

PatentInactiveCN101534708A

Innovation

- A differential array amplifier and alternating signal generator are used to inject AC signals through the reference electrode. The common-mode suppression capability of the differential amplifier is used to dynamically measure the electrode contact quality, and the electrode contact quality is evaluated through the phase shift and attenuation of the output signal.

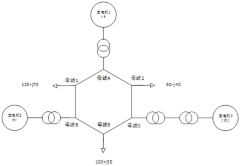

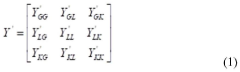

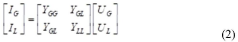

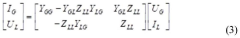

Phase modifier configuration optimization method for improving voltage supporting capability

PatentPendingCN117039916A

Innovation

- By dividing the system nodes into load nodes, connection nodes and power nodes, the node admittance matrix is established, the node voltage equation is derived according to Kirchhoff's current law and node voltage method, the load participation factor matrix is defined, and the voltage stability index L index is derived and its sensitivity to determine the access location and capacity of the condenser.

Environmental Impact of Electrophoretic Processes

Electrophoretic processes, while highly effective in various applications, can have significant environmental impacts that warrant careful consideration. The primary environmental concerns associated with these processes stem from the use of chemicals, energy consumption, and waste generation.

One of the most pressing environmental issues is the disposal of electrophoretic baths and associated waste materials. These baths often contain heavy metals, organic solvents, and other potentially hazardous substances. Improper disposal can lead to soil and water contamination, posing risks to ecosystems and human health. To mitigate these risks, stringent waste management protocols and treatment systems are essential.

Energy consumption is another critical factor in the environmental footprint of electrophoretic processes. The high voltage requirements and extended processing times contribute to substantial energy usage, which, depending on the energy source, can result in increased greenhouse gas emissions. Efforts to improve energy efficiency and transition to renewable energy sources can significantly reduce this impact.

Water usage is also a concern, particularly in regions facing water scarcity. Electrophoretic processes often require large volumes of water for rinsing and cleaning stages. Implementing water recycling systems and optimizing process parameters can help reduce water consumption and minimize wastewater generation.

The production and use of chemicals in electrophoretic processes present additional environmental challenges. Many of these chemicals are derived from non-renewable resources and may have toxic properties. Developing and adopting more environmentally friendly alternatives, such as bio-based or low-toxicity chemicals, can help reduce the overall environmental impact.

Air emissions from electrophoretic processes, although generally less significant than other environmental aspects, should not be overlooked. Volatile organic compounds (VOCs) and particulate matter can be released during certain stages of the process, potentially contributing to air pollution and health risks for workers and surrounding communities.

To address these environmental concerns, the industry is increasingly focusing on developing more sustainable electrophoretic technologies. This includes research into low-temperature processes, solvent-free systems, and the use of recyclable materials. Additionally, the implementation of closed-loop systems and advanced filtration technologies is helping to minimize waste generation and improve resource efficiency.

As regulatory pressures and environmental awareness continue to grow, the electrophoretic industry must prioritize sustainability and environmental stewardship. This involves not only improving existing processes but also exploring entirely new approaches that can deliver comparable or superior performance with reduced environmental impact.

One of the most pressing environmental issues is the disposal of electrophoretic baths and associated waste materials. These baths often contain heavy metals, organic solvents, and other potentially hazardous substances. Improper disposal can lead to soil and water contamination, posing risks to ecosystems and human health. To mitigate these risks, stringent waste management protocols and treatment systems are essential.

Energy consumption is another critical factor in the environmental footprint of electrophoretic processes. The high voltage requirements and extended processing times contribute to substantial energy usage, which, depending on the energy source, can result in increased greenhouse gas emissions. Efforts to improve energy efficiency and transition to renewable energy sources can significantly reduce this impact.

Water usage is also a concern, particularly in regions facing water scarcity. Electrophoretic processes often require large volumes of water for rinsing and cleaning stages. Implementing water recycling systems and optimizing process parameters can help reduce water consumption and minimize wastewater generation.

The production and use of chemicals in electrophoretic processes present additional environmental challenges. Many of these chemicals are derived from non-renewable resources and may have toxic properties. Developing and adopting more environmentally friendly alternatives, such as bio-based or low-toxicity chemicals, can help reduce the overall environmental impact.

Air emissions from electrophoretic processes, although generally less significant than other environmental aspects, should not be overlooked. Volatile organic compounds (VOCs) and particulate matter can be released during certain stages of the process, potentially contributing to air pollution and health risks for workers and surrounding communities.

To address these environmental concerns, the industry is increasingly focusing on developing more sustainable electrophoretic technologies. This includes research into low-temperature processes, solvent-free systems, and the use of recyclable materials. Additionally, the implementation of closed-loop systems and advanced filtration technologies is helping to minimize waste generation and improve resource efficiency.

As regulatory pressures and environmental awareness continue to grow, the electrophoretic industry must prioritize sustainability and environmental stewardship. This involves not only improving existing processes but also exploring entirely new approaches that can deliver comparable or superior performance with reduced environmental impact.

Standardization and Quality Control Measures

Standardization and quality control measures are crucial for setting new benchmarks in electrophoretic coupling efficiency. To achieve consistent and reliable results, it is essential to establish a comprehensive framework that encompasses all aspects of the electrophoretic coupling process.

One of the primary steps in standardization is the development of detailed protocols for sample preparation, buffer composition, and electrophoresis conditions. These protocols should be meticulously documented and validated across different laboratories to ensure reproducibility. Standardized reagents and materials, including pre-cast gels and calibrated power supplies, should be utilized to minimize variability between experiments.

Quality control measures must be implemented at various stages of the electrophoretic coupling process. Regular calibration and maintenance of equipment, such as power supplies and gel imaging systems, are essential for optimal performance. The use of internal standards and control samples in each experiment allows for the assessment of run-to-run consistency and helps identify any deviations from expected results.

To further enhance standardization, it is recommended to establish a system of proficiency testing among laboratories involved in electrophoretic coupling research. This approach involves distributing identical samples to multiple laboratories and comparing the results to identify and address any discrepancies in methodologies or interpretations.

The development and adoption of reference materials is another critical aspect of standardization. These materials, certified for specific electrophoretic properties, can serve as benchmarks for calibrating instruments and validating experimental procedures. Collaborative efforts between research institutions and regulatory bodies can facilitate the creation and distribution of such reference materials.

Data analysis and reporting standards are equally important in achieving consistent benchmarks. Implementing standardized data analysis software and establishing guidelines for data interpretation can help reduce subjectivity and improve the comparability of results across different studies. Additionally, the use of electronic laboratory notebooks and standardized reporting formats can enhance data traceability and facilitate meta-analyses of multiple studies.

Continuous improvement of quality control measures is essential for advancing electrophoretic coupling efficiency. Regular review and updating of standard operating procedures (SOPs) based on new research findings and technological advancements ensure that the field remains at the cutting edge. Encouraging open communication and knowledge sharing among researchers through workshops, conferences, and collaborative projects can accelerate the development and adoption of best practices in standardization and quality control.

One of the primary steps in standardization is the development of detailed protocols for sample preparation, buffer composition, and electrophoresis conditions. These protocols should be meticulously documented and validated across different laboratories to ensure reproducibility. Standardized reagents and materials, including pre-cast gels and calibrated power supplies, should be utilized to minimize variability between experiments.

Quality control measures must be implemented at various stages of the electrophoretic coupling process. Regular calibration and maintenance of equipment, such as power supplies and gel imaging systems, are essential for optimal performance. The use of internal standards and control samples in each experiment allows for the assessment of run-to-run consistency and helps identify any deviations from expected results.

To further enhance standardization, it is recommended to establish a system of proficiency testing among laboratories involved in electrophoretic coupling research. This approach involves distributing identical samples to multiple laboratories and comparing the results to identify and address any discrepancies in methodologies or interpretations.

The development and adoption of reference materials is another critical aspect of standardization. These materials, certified for specific electrophoretic properties, can serve as benchmarks for calibrating instruments and validating experimental procedures. Collaborative efforts between research institutions and regulatory bodies can facilitate the creation and distribution of such reference materials.

Data analysis and reporting standards are equally important in achieving consistent benchmarks. Implementing standardized data analysis software and establishing guidelines for data interpretation can help reduce subjectivity and improve the comparability of results across different studies. Additionally, the use of electronic laboratory notebooks and standardized reporting formats can enhance data traceability and facilitate meta-analyses of multiple studies.

Continuous improvement of quality control measures is essential for advancing electrophoretic coupling efficiency. Regular review and updating of standard operating procedures (SOPs) based on new research findings and technological advancements ensure that the field remains at the cutting edge. Encouraging open communication and knowledge sharing among researchers through workshops, conferences, and collaborative projects can accelerate the development and adoption of best practices in standardization and quality control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!