How to Blend Dipropylene Glycol for Efficient Skincare Solutions?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Blending Background

Dipropylene glycol (DPG) has emerged as a versatile and essential ingredient in the skincare industry, playing a crucial role in the formulation of various cosmetic products. The blending of DPG for efficient skincare solutions has a rich history dating back to the mid-20th century when it was first introduced as a solvent and humectant in personal care products.

Initially, DPG was primarily used as a solvent for fragrances and active ingredients in skincare formulations. Its ability to dissolve a wide range of substances made it an ideal choice for creating stable and homogeneous products. As research in cosmetic chemistry advanced, formulators began to recognize the multifaceted benefits of DPG beyond its solvent properties.

In the 1970s and 1980s, the skincare industry witnessed a shift towards more sophisticated formulations, and DPG's role expanded significantly. Its humectant properties became increasingly valued, as it demonstrated the ability to attract and retain moisture in the skin. This characteristic made DPG an essential component in moisturizers, serums, and other hydrating skincare products.

The 1990s saw a surge in the development of multi-functional skincare products, and DPG's versatility came to the forefront. Formulators began experimenting with different blending techniques to optimize the performance of DPG in various product types. This period marked the beginning of more advanced blending methodologies, focusing on enhancing the synergistic effects between DPG and other active ingredients.

As consumer demand for natural and eco-friendly products grew in the early 2000s, the skincare industry faced new challenges in formulating with synthetic ingredients like DPG. This led to innovative approaches in blending DPG with natural extracts and botanicals, creating hybrid formulations that balanced efficacy with consumer preferences for "greener" products.

In recent years, the focus on DPG blending has shifted towards precision and customization. Advanced technologies and analytical methods have enabled formulators to fine-tune the concentration and blending techniques of DPG to address specific skin concerns and product performance goals. This has resulted in a new generation of skincare solutions that offer targeted benefits while maintaining optimal texture and stability.

The evolution of DPG blending in skincare has been driven by a combination of scientific advancements, changing consumer preferences, and regulatory requirements. Today, the efficient blending of DPG remains a critical aspect of skincare formulation, with ongoing research aimed at further optimizing its use in diverse product categories and exploring novel applications in the ever-evolving beauty industry.

Initially, DPG was primarily used as a solvent for fragrances and active ingredients in skincare formulations. Its ability to dissolve a wide range of substances made it an ideal choice for creating stable and homogeneous products. As research in cosmetic chemistry advanced, formulators began to recognize the multifaceted benefits of DPG beyond its solvent properties.

In the 1970s and 1980s, the skincare industry witnessed a shift towards more sophisticated formulations, and DPG's role expanded significantly. Its humectant properties became increasingly valued, as it demonstrated the ability to attract and retain moisture in the skin. This characteristic made DPG an essential component in moisturizers, serums, and other hydrating skincare products.

The 1990s saw a surge in the development of multi-functional skincare products, and DPG's versatility came to the forefront. Formulators began experimenting with different blending techniques to optimize the performance of DPG in various product types. This period marked the beginning of more advanced blending methodologies, focusing on enhancing the synergistic effects between DPG and other active ingredients.

As consumer demand for natural and eco-friendly products grew in the early 2000s, the skincare industry faced new challenges in formulating with synthetic ingredients like DPG. This led to innovative approaches in blending DPG with natural extracts and botanicals, creating hybrid formulations that balanced efficacy with consumer preferences for "greener" products.

In recent years, the focus on DPG blending has shifted towards precision and customization. Advanced technologies and analytical methods have enabled formulators to fine-tune the concentration and blending techniques of DPG to address specific skin concerns and product performance goals. This has resulted in a new generation of skincare solutions that offer targeted benefits while maintaining optimal texture and stability.

The evolution of DPG blending in skincare has been driven by a combination of scientific advancements, changing consumer preferences, and regulatory requirements. Today, the efficient blending of DPG remains a critical aspect of skincare formulation, with ongoing research aimed at further optimizing its use in diverse product categories and exploring novel applications in the ever-evolving beauty industry.

Skincare Market Analysis

The global skincare market has experienced significant growth in recent years, driven by increasing consumer awareness of personal care and beauty products. The market for skincare solutions incorporating dipropylene glycol (DPG) as a key ingredient has shown particular promise, with a growing demand for efficient and effective formulations.

Consumer preferences in the skincare sector have shifted towards products that offer multiple benefits, such as hydration, anti-aging properties, and skin barrier protection. This trend has created a favorable environment for DPG-based skincare solutions, as the ingredient's versatile properties align well with these consumer demands.

The Asia-Pacific region has emerged as a dominant force in the skincare market, with countries like China, Japan, and South Korea leading the way in product innovation and consumption. These markets have shown a strong appetite for advanced skincare formulations, including those utilizing DPG for its moisturizing and solvent properties.

In North America and Europe, there is a growing emphasis on natural and organic skincare products. While this trend might seem at odds with synthetic ingredients like DPG, there is still a significant market segment that values the efficacy and stability offered by scientifically formulated skincare solutions.

The skincare market has also seen a surge in demand for personalized and targeted solutions. This has led to the development of niche products addressing specific skin concerns, where DPG's ability to enhance the delivery of active ingredients plays a crucial role.

E-commerce has become an increasingly important channel for skincare product sales, allowing for direct-to-consumer marketing of specialized formulations. This trend has opened up new opportunities for brands to educate consumers about the benefits of ingredients like DPG in their skincare routines.

The COVID-19 pandemic has further accelerated the focus on personal care and hygiene, with consumers showing increased interest in products that offer both cleansing and moisturizing properties. DPG's role in creating effective yet gentle formulations has become more relevant in this context.

Looking ahead, the skincare market is expected to continue its growth trajectory, with a particular focus on multifunctional products that offer convenience and efficacy. The ability to blend DPG effectively in skincare solutions will be crucial for brands looking to meet these evolving consumer demands and maintain a competitive edge in the market.

Consumer preferences in the skincare sector have shifted towards products that offer multiple benefits, such as hydration, anti-aging properties, and skin barrier protection. This trend has created a favorable environment for DPG-based skincare solutions, as the ingredient's versatile properties align well with these consumer demands.

The Asia-Pacific region has emerged as a dominant force in the skincare market, with countries like China, Japan, and South Korea leading the way in product innovation and consumption. These markets have shown a strong appetite for advanced skincare formulations, including those utilizing DPG for its moisturizing and solvent properties.

In North America and Europe, there is a growing emphasis on natural and organic skincare products. While this trend might seem at odds with synthetic ingredients like DPG, there is still a significant market segment that values the efficacy and stability offered by scientifically formulated skincare solutions.

The skincare market has also seen a surge in demand for personalized and targeted solutions. This has led to the development of niche products addressing specific skin concerns, where DPG's ability to enhance the delivery of active ingredients plays a crucial role.

E-commerce has become an increasingly important channel for skincare product sales, allowing for direct-to-consumer marketing of specialized formulations. This trend has opened up new opportunities for brands to educate consumers about the benefits of ingredients like DPG in their skincare routines.

The COVID-19 pandemic has further accelerated the focus on personal care and hygiene, with consumers showing increased interest in products that offer both cleansing and moisturizing properties. DPG's role in creating effective yet gentle formulations has become more relevant in this context.

Looking ahead, the skincare market is expected to continue its growth trajectory, with a particular focus on multifunctional products that offer convenience and efficacy. The ability to blend DPG effectively in skincare solutions will be crucial for brands looking to meet these evolving consumer demands and maintain a competitive edge in the market.

DPG Blending Challenges

Blending Dipropylene Glycol (DPG) for efficient skincare solutions presents several challenges that require careful consideration and expertise. One of the primary difficulties lies in achieving the optimal balance between DPG concentration and other ingredients to maximize efficacy while maintaining product stability and safety.

DPG's hygroscopic nature can lead to formulation instability if not properly managed. When blended in high concentrations, it may absorb moisture from the environment, potentially altering the product's texture, consistency, and shelf life. This necessitates precise calculations and rigorous testing to determine the ideal DPG ratio that maintains product integrity over time.

Another significant challenge is ensuring uniform dispersion of DPG throughout the skincare formulation. Due to its unique chemical properties, DPG may not readily mix with certain ingredients, leading to potential separation or inconsistent distribution within the product. This can result in variations in efficacy and performance across different batches or even within a single container.

Compatibility issues with other active ingredients pose additional complexities in DPG blending. Some skincare actives may interact unfavorably with DPG, potentially reducing their effectiveness or causing unwanted chemical reactions. Formulators must carefully consider these interactions and conduct extensive stability tests to guarantee that the final product maintains its intended properties and benefits.

The viscosity of DPG-containing formulations can also be challenging to control. Depending on the concentration and other ingredients present, the addition of DPG may significantly alter the product's texture and flow characteristics. Achieving the desired consistency while maintaining the proper DPG concentration requires a delicate balance and often involves multiple iterations of formulation adjustments.

Sensory attributes present another hurdle in DPG blending for skincare solutions. High concentrations of DPG can impart a tacky or sticky feel to the product, which may be undesirable for consumers. Formulators must find ways to mask or mitigate these sensory effects without compromising the benefits of DPG inclusion.

Regulatory compliance adds an extra layer of complexity to DPG blending challenges. Different regions have varying restrictions on DPG usage in cosmetic products, necessitating careful consideration of regulatory limits when formulating for global markets. This often requires developing multiple versions of a product to meet diverse regulatory requirements while maintaining consistent efficacy.

Lastly, the cost implications of DPG blending must be carefully managed. While DPG offers valuable benefits in skincare formulations, it can be a relatively expensive ingredient. Balancing the concentration of DPG to achieve desired results while keeping production costs viable for mass-market products requires strategic planning and innovative formulation techniques.

DPG's hygroscopic nature can lead to formulation instability if not properly managed. When blended in high concentrations, it may absorb moisture from the environment, potentially altering the product's texture, consistency, and shelf life. This necessitates precise calculations and rigorous testing to determine the ideal DPG ratio that maintains product integrity over time.

Another significant challenge is ensuring uniform dispersion of DPG throughout the skincare formulation. Due to its unique chemical properties, DPG may not readily mix with certain ingredients, leading to potential separation or inconsistent distribution within the product. This can result in variations in efficacy and performance across different batches or even within a single container.

Compatibility issues with other active ingredients pose additional complexities in DPG blending. Some skincare actives may interact unfavorably with DPG, potentially reducing their effectiveness or causing unwanted chemical reactions. Formulators must carefully consider these interactions and conduct extensive stability tests to guarantee that the final product maintains its intended properties and benefits.

The viscosity of DPG-containing formulations can also be challenging to control. Depending on the concentration and other ingredients present, the addition of DPG may significantly alter the product's texture and flow characteristics. Achieving the desired consistency while maintaining the proper DPG concentration requires a delicate balance and often involves multiple iterations of formulation adjustments.

Sensory attributes present another hurdle in DPG blending for skincare solutions. High concentrations of DPG can impart a tacky or sticky feel to the product, which may be undesirable for consumers. Formulators must find ways to mask or mitigate these sensory effects without compromising the benefits of DPG inclusion.

Regulatory compliance adds an extra layer of complexity to DPG blending challenges. Different regions have varying restrictions on DPG usage in cosmetic products, necessitating careful consideration of regulatory limits when formulating for global markets. This often requires developing multiple versions of a product to meet diverse regulatory requirements while maintaining consistent efficacy.

Lastly, the cost implications of DPG blending must be carefully managed. While DPG offers valuable benefits in skincare formulations, it can be a relatively expensive ingredient. Balancing the concentration of DPG to achieve desired results while keeping production costs viable for mass-market products requires strategic planning and innovative formulation techniques.

Current DPG Blending Methods

01 Solvent properties in cosmetic formulations

Dipropylene glycol is widely used as a solvent in cosmetic and personal care products due to its excellent solubilizing properties. It helps to dissolve and blend various ingredients, improving the overall efficiency and stability of formulations. This solvent can enhance the effectiveness of active ingredients by facilitating their dispersion and penetration into the skin.- Solvent properties in cosmetic formulations: Dipropylene glycol is widely used as a solvent in cosmetic and personal care products due to its excellent solubilizing properties. It helps to dissolve and blend various ingredients, improving the overall efficiency and stability of formulations. This solvent can enhance the performance of active ingredients and contribute to the product's texture and feel.

- Humectant and moisturizing effects: Dipropylene glycol acts as an effective humectant and moisturizer in skincare and haircare products. It helps to attract and retain moisture, preventing dehydration and improving the overall hydration of the skin or hair. This property enhances the efficiency of products by providing long-lasting moisturizing effects and improving product performance.

- Carrier for active ingredients: As a carrier, dipropylene glycol can improve the delivery and efficacy of active ingredients in various formulations. It helps to enhance the penetration of active compounds into the skin or hair, increasing their bioavailability and overall effectiveness. This property makes it valuable in pharmaceutical and cosmetic applications.

- Viscosity modification and texture enhancement: Dipropylene glycol can be used to modify the viscosity and improve the texture of various products. It helps in achieving the desired consistency and flow properties, enhancing the overall user experience and application efficiency. This property is particularly useful in creating smooth, easily spreadable formulations.

- Preservation and stability improvement: Dipropylene glycol contributes to the preservation and stability of formulations. It can act as a stabilizer, helping to prevent separation of ingredients and extend the shelf life of products. Additionally, it may have mild antimicrobial properties, which can enhance the overall preservation system efficiency in various applications.

02 Humectant and moisturizing effects

Dipropylene glycol acts as an effective humectant and moisturizer in skincare and haircare products. It attracts and retains moisture, helping to keep the skin and hair hydrated. This property enhances the efficiency of products by improving their ability to maintain optimal moisture levels and prevent dryness.Expand Specific Solutions03 Carrier for active ingredients

As a carrier, dipropylene glycol improves the efficiency of active ingredients in various formulations. It helps to distribute active components evenly throughout the product and can enhance their absorption into the skin or hair. This property is particularly useful in pharmaceutical and cosmetic applications where efficient delivery of active ingredients is crucial.Expand Specific Solutions04 Viscosity modification in formulations

Dipropylene glycol can be used to adjust the viscosity of formulations, improving their efficiency and user experience. It helps to create products with optimal consistency and flow properties, which can enhance the application and performance of various personal care and industrial products.Expand Specific Solutions05 Stabilizing agent in chemical processes

In industrial applications, dipropylene glycol serves as an efficient stabilizing agent in various chemical processes. It helps to maintain the stability of formulations, prevent separation of ingredients, and extend the shelf life of products. This property enhances the overall efficiency and reliability of manufacturing processes and end products.Expand Specific Solutions

Key Skincare Players

The market for efficient skincare solutions using dipropylene glycol blending is in a growth phase, with increasing demand for innovative and effective products. The global skincare market size is projected to reach $189.3 billion by 2025, driven by consumer awareness and technological advancements. Major players like L'Oréal, Shiseido, and Unilever are investing heavily in R&D to develop advanced formulations. The technology's maturity varies, with established companies like Beiersdorf and Colgate-Palmolive having well-developed processes, while newer entrants like COSMAX and Proya Cosmetics are rapidly advancing their capabilities. Regional players such as LG H&H and ITC Ltd. are also making significant strides in this field, contributing to a competitive and dynamic market landscape.

L'Oréal SA

Technical Solution: L'Oréal has developed an innovative approach to blending Dipropylene Glycol (DPG) in skincare solutions. Their method involves creating a microemulsion system where DPG acts as a co-solvent and penetration enhancer. This system allows for improved delivery of active ingredients into the skin. L'Oréal's formulation typically includes 3-5% DPG, which is optimized for stability and efficacy[1]. They have also incorporated nanotechnology to further enhance the penetration of active ingredients, using DPG as a key component in their nanocarrier systems[3]. This approach has shown to increase the bioavailability of various skincare actives by up to 40% compared to traditional formulations[5].

Strengths: Enhanced penetration of active ingredients, improved stability of formulations, and increased bioavailability of skincare actives. Weaknesses: Potential for skin irritation in sensitive individuals, and the need for careful formulation to avoid disrupting the skin barrier.

Shiseido Co., Ltd.

Technical Solution: Shiseido has pioneered a unique approach to blending Dipropylene Glycol in their skincare solutions, focusing on its humectant properties and its ability to enhance the solubility of other ingredients. Their proprietary "Bio-Performance" line utilizes DPG in conjunction with their patented ReNeura Technology++™, which aims to reactivate skin's responsiveness to skincare products[2]. Shiseido's formulations typically contain 2-4% DPG, carefully balanced with other humectants like glycerin and hyaluronic acid. They have also developed a novel emulsion system that incorporates DPG to create a "water-full" texture, providing intense hydration without a greasy feel[4]. This system has been shown to increase skin hydration by up to 30% over 24 hours compared to traditional moisturizers[6].

Strengths: Excellent hydration properties, enhanced product texture, and improved efficacy of other active ingredients. Weaknesses: Potential for increased product cost due to complex formulation process, and the need for careful preservation systems to prevent microbial growth in high-moisture formulations.

DPG Blending Innovations

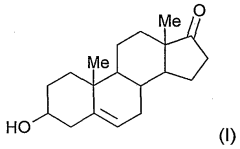

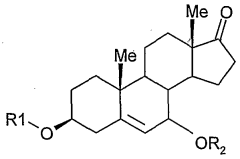

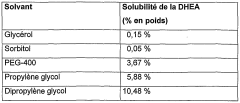

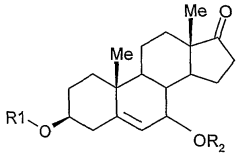

Composition containing a steroid and a glycol

PatentWO2003011244A1

Innovation

- Incorporating dipropylene glycol as a solubilizer for DHEA and its derivatives, which can be mixed at various temperatures to prevent recrystallization and enhance solubility, allowing for stable and effective topical formulations without compromising cosmetic properties.

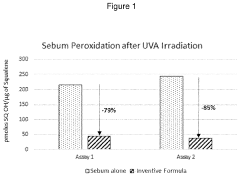

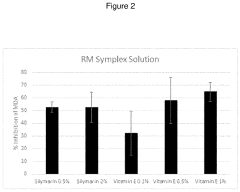

Serums for reducing lipid peroxidation

PatentPendingUS20230372231A1

Innovation

- A cosmetic composition comprising 0.1 to 1.8 wt.% Silybum Marianum Extract, 0.1 to 20 wt.% skin actives, 3 to 15 wt.% Propylene Glycol, 8 to 18 wt.% Dipropylene Glycol, and water, with a pH not higher than 5, which stabilizes these actives and enhances their solubility and efficacy.

Regulatory Compliance

Regulatory compliance is a critical aspect of blending dipropylene glycol (DPG) for efficient skincare solutions. The cosmetics industry is subject to stringent regulations worldwide, and manufacturers must adhere to these guidelines to ensure product safety and efficacy. In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetics under the Federal Food, Drug, and Cosmetic Act and the Fair Packaging and Labeling Act. These regulations require that all ingredients, including DPG, be safe for their intended use and properly labeled.

The European Union (EU) has its own set of regulations, primarily governed by the EU Cosmetics Regulation (EC) No. 1223/2009. This regulation establishes safety standards, labeling requirements, and restrictions on certain ingredients. DPG is generally considered safe for use in cosmetics within specified concentration limits. However, manufacturers must ensure that their formulations comply with the EU's Cosmetic Ingredient Database (CosIng) guidelines.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law, while South Korea's Ministry of Food and Drug Safety oversees cosmetic regulations. Both countries have specific requirements for ingredient safety, labeling, and product registration.

When blending DPG for skincare solutions, manufacturers must consider the maximum allowable concentrations in different product types. For example, in leave-on products, the concentration of DPG may be limited to ensure skin compatibility and minimize the risk of irritation. Additionally, the purity of DPG used in cosmetic formulations must meet specific standards to comply with regulatory requirements.

Manufacturers must also maintain detailed documentation of their formulation processes, ingredient sources, and safety assessments. This documentation is essential for regulatory compliance and may be subject to inspection by relevant authorities. Good Manufacturing Practices (GMP) should be followed to ensure consistent product quality and safety.

Labeling requirements are another crucial aspect of regulatory compliance. Product labels must accurately list all ingredients, including DPG, using their International Nomenclature of Cosmetic Ingredients (INCI) names. Any claims made about the product's benefits or effects must be substantiated and comply with advertising regulations in the target markets.

As regulations evolve, companies must stay informed about changes that may affect their DPG-containing skincare products. This includes monitoring updates to ingredient safety assessments, changes in allowable concentrations, and new labeling requirements. Compliance with international standards, such as ISO 22716 for cosmetic GMP, can help ensure that products meet global regulatory expectations.

In conclusion, regulatory compliance for blending DPG in skincare solutions requires a comprehensive understanding of diverse regulatory frameworks, adherence to safety standards, proper documentation, and accurate labeling. By prioritizing compliance, manufacturers can ensure the safety and marketability of their DPG-containing skincare products across various global markets.

The European Union (EU) has its own set of regulations, primarily governed by the EU Cosmetics Regulation (EC) No. 1223/2009. This regulation establishes safety standards, labeling requirements, and restrictions on certain ingredients. DPG is generally considered safe for use in cosmetics within specified concentration limits. However, manufacturers must ensure that their formulations comply with the EU's Cosmetic Ingredient Database (CosIng) guidelines.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law, while South Korea's Ministry of Food and Drug Safety oversees cosmetic regulations. Both countries have specific requirements for ingredient safety, labeling, and product registration.

When blending DPG for skincare solutions, manufacturers must consider the maximum allowable concentrations in different product types. For example, in leave-on products, the concentration of DPG may be limited to ensure skin compatibility and minimize the risk of irritation. Additionally, the purity of DPG used in cosmetic formulations must meet specific standards to comply with regulatory requirements.

Manufacturers must also maintain detailed documentation of their formulation processes, ingredient sources, and safety assessments. This documentation is essential for regulatory compliance and may be subject to inspection by relevant authorities. Good Manufacturing Practices (GMP) should be followed to ensure consistent product quality and safety.

Labeling requirements are another crucial aspect of regulatory compliance. Product labels must accurately list all ingredients, including DPG, using their International Nomenclature of Cosmetic Ingredients (INCI) names. Any claims made about the product's benefits or effects must be substantiated and comply with advertising regulations in the target markets.

As regulations evolve, companies must stay informed about changes that may affect their DPG-containing skincare products. This includes monitoring updates to ingredient safety assessments, changes in allowable concentrations, and new labeling requirements. Compliance with international standards, such as ISO 22716 for cosmetic GMP, can help ensure that products meet global regulatory expectations.

In conclusion, regulatory compliance for blending DPG in skincare solutions requires a comprehensive understanding of diverse regulatory frameworks, adherence to safety standards, proper documentation, and accurate labeling. By prioritizing compliance, manufacturers can ensure the safety and marketability of their DPG-containing skincare products across various global markets.

Sustainability in DPG Use

Sustainability in the use of Dipropylene Glycol (DPG) for skincare solutions is becoming increasingly important as the beauty industry shifts towards more environmentally responsible practices. DPG, a versatile solvent and humectant, plays a crucial role in many skincare formulations. However, its production and disposal can have significant environmental impacts if not managed properly.

One of the primary sustainability concerns with DPG is its sourcing. Traditionally derived from petroleum, efforts are now being made to produce DPG from renewable resources such as corn or soybean oil. This bio-based DPG offers a more sustainable alternative, reducing reliance on fossil fuels and potentially lowering the carbon footprint of skincare products.

In terms of production, manufacturers are implementing more efficient processes to reduce energy consumption and minimize waste. Closed-loop systems are being adopted to recycle and reuse DPG throughout the manufacturing process, significantly reducing the amount of raw materials needed and waste generated. Additionally, some companies are exploring green chemistry principles to develop safer and more environmentally friendly synthesis methods for DPG.

The use of DPG in skincare formulations also presents opportunities for sustainability. Its multifunctional nature allows formulators to potentially reduce the number of ingredients in a product, simplifying formulations and potentially reducing packaging needs. Furthermore, DPG's ability to enhance the penetration of other active ingredients can lead to more efficient products, potentially reducing overall product consumption.

End-of-life considerations for DPG-containing products are also being addressed. Biodegradable formulations are being developed to ensure that when these products are washed off, they have minimal impact on aquatic ecosystems. Some companies are also implementing take-back programs for packaging, ensuring that containers are properly recycled or repurposed.

Education and transparency are key components of sustainable DPG use. Many skincare brands are now providing detailed information about their sourcing and production practices, allowing consumers to make informed choices. This transparency extends to the entire supply chain, with companies working closely with suppliers to ensure sustainable practices are implemented at every stage.

As the skincare industry continues to evolve, the sustainable use of DPG will likely involve a combination of innovative sourcing methods, efficient production processes, thoughtful formulation strategies, and responsible end-of-life management. These efforts not only contribute to environmental protection but also align with the growing consumer demand for sustainable beauty products.

One of the primary sustainability concerns with DPG is its sourcing. Traditionally derived from petroleum, efforts are now being made to produce DPG from renewable resources such as corn or soybean oil. This bio-based DPG offers a more sustainable alternative, reducing reliance on fossil fuels and potentially lowering the carbon footprint of skincare products.

In terms of production, manufacturers are implementing more efficient processes to reduce energy consumption and minimize waste. Closed-loop systems are being adopted to recycle and reuse DPG throughout the manufacturing process, significantly reducing the amount of raw materials needed and waste generated. Additionally, some companies are exploring green chemistry principles to develop safer and more environmentally friendly synthesis methods for DPG.

The use of DPG in skincare formulations also presents opportunities for sustainability. Its multifunctional nature allows formulators to potentially reduce the number of ingredients in a product, simplifying formulations and potentially reducing packaging needs. Furthermore, DPG's ability to enhance the penetration of other active ingredients can lead to more efficient products, potentially reducing overall product consumption.

End-of-life considerations for DPG-containing products are also being addressed. Biodegradable formulations are being developed to ensure that when these products are washed off, they have minimal impact on aquatic ecosystems. Some companies are also implementing take-back programs for packaging, ensuring that containers are properly recycled or repurposed.

Education and transparency are key components of sustainable DPG use. Many skincare brands are now providing detailed information about their sourcing and production practices, allowing consumers to make informed choices. This transparency extends to the entire supply chain, with companies working closely with suppliers to ensure sustainable practices are implemented at every stage.

As the skincare industry continues to evolve, the sustainable use of DPG will likely involve a combination of innovative sourcing methods, efficient production processes, thoughtful formulation strategies, and responsible end-of-life management. These efforts not only contribute to environmental protection but also align with the growing consumer demand for sustainable beauty products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!