How to Differentiate ULED from QLED Technologies?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED vs QLED Background

ULED (Ultra LED) and QLED (Quantum Dot LED) are two advanced display technologies that have gained significant attention in the consumer electronics market. Both technologies aim to enhance the visual experience by improving color accuracy, brightness, and contrast ratios in television and monitor displays.

ULED, developed by Hisense, is a proprietary technology that combines multiple image-enhancing features to create a superior viewing experience. It incorporates local dimming, wide color gamut, and high dynamic range (HDR) capabilities. ULED displays utilize a traditional LED backlight system with advanced algorithms and hardware improvements to optimize picture quality.

QLED, on the other hand, is a display technology pioneered by Samsung that uses quantum dots to enhance color reproduction and brightness. Quantum dots are nano-sized semiconductor particles that emit light of specific wavelengths when excited by electricity. This allows QLED displays to produce more vibrant and accurate colors compared to conventional LED-LCD screens.

Both technologies have evolved from traditional LED-LCD displays, which use a liquid crystal display (LCD) panel illuminated by LED backlights. The primary goal of both ULED and QLED is to address the limitations of standard LED-LCD technology, such as limited color range and contrast ratios.

The development of these technologies has been driven by the increasing demand for higher-quality displays in home entertainment systems and professional applications. As consumers seek more immersive viewing experiences, manufacturers have been compelled to innovate and improve upon existing display technologies.

ULED and QLED represent different approaches to achieving similar goals. While QLED focuses on enhancing color reproduction through quantum dot technology, ULED employs a combination of various image processing techniques and hardware improvements to enhance overall picture quality.

Understanding the distinctions between ULED and QLED is crucial for consumers, manufacturers, and industry professionals alike. These technologies compete in the premium display market, offering alternatives to OLED (Organic Light-Emitting Diode) displays, which have long been considered the gold standard for picture quality.

As the display technology landscape continues to evolve, differentiating between ULED and QLED becomes increasingly important for making informed decisions about product development, marketing strategies, and consumer purchases. This technical preview report aims to explore the key differences between these two technologies, their respective strengths and limitations, and their potential impact on the future of display technology.

ULED, developed by Hisense, is a proprietary technology that combines multiple image-enhancing features to create a superior viewing experience. It incorporates local dimming, wide color gamut, and high dynamic range (HDR) capabilities. ULED displays utilize a traditional LED backlight system with advanced algorithms and hardware improvements to optimize picture quality.

QLED, on the other hand, is a display technology pioneered by Samsung that uses quantum dots to enhance color reproduction and brightness. Quantum dots are nano-sized semiconductor particles that emit light of specific wavelengths when excited by electricity. This allows QLED displays to produce more vibrant and accurate colors compared to conventional LED-LCD screens.

Both technologies have evolved from traditional LED-LCD displays, which use a liquid crystal display (LCD) panel illuminated by LED backlights. The primary goal of both ULED and QLED is to address the limitations of standard LED-LCD technology, such as limited color range and contrast ratios.

The development of these technologies has been driven by the increasing demand for higher-quality displays in home entertainment systems and professional applications. As consumers seek more immersive viewing experiences, manufacturers have been compelled to innovate and improve upon existing display technologies.

ULED and QLED represent different approaches to achieving similar goals. While QLED focuses on enhancing color reproduction through quantum dot technology, ULED employs a combination of various image processing techniques and hardware improvements to enhance overall picture quality.

Understanding the distinctions between ULED and QLED is crucial for consumers, manufacturers, and industry professionals alike. These technologies compete in the premium display market, offering alternatives to OLED (Organic Light-Emitting Diode) displays, which have long been considered the gold standard for picture quality.

As the display technology landscape continues to evolve, differentiating between ULED and QLED becomes increasingly important for making informed decisions about product development, marketing strategies, and consumer purchases. This technical preview report aims to explore the key differences between these two technologies, their respective strengths and limitations, and their potential impact on the future of display technology.

Market Demand Analysis

The market demand for advanced display technologies continues to grow, driven by consumers' increasing appetite for high-quality visual experiences across various devices. Both ULED (Ultra Light Emitting Diode) and QLED (Quantum Dot Light Emitting Diode) technologies have emerged as significant players in this competitive landscape, each offering unique advantages in picture quality and performance.

Consumer electronics, particularly televisions and monitors, represent the primary market for these technologies. The global TV market size was valued at over $150 billion in 2020, with premium segments showing stronger growth. High-end displays, including ULED and QLED, are expected to capture an increasing share of this market as consumers seek better picture quality, color accuracy, and energy efficiency.

QLED technology has gained significant traction in recent years, with major manufacturers like Samsung leading the charge. The QLED TV market is projected to grow at a CAGR of around 20% from 2021 to 2026. This growth is fueled by QLED's ability to deliver vibrant colors, high brightness, and improved energy efficiency compared to traditional LED displays.

ULED, while less widely known than QLED, is carving out its own niche in the market. Developed by Hisense, ULED combines several picture enhancement technologies to improve overall display performance. The demand for ULED is growing, particularly in regions where Hisense has a strong presence, such as China and emerging markets.

The commercial display sector also presents significant opportunities for both ULED and QLED technologies. Digital signage, control rooms, and high-end presentation displays are increasingly adopting these advanced technologies to deliver superior visual experiences in professional environments. The global commercial display market is expected to reach $8 billion by 2025, with a growing portion attributed to premium display technologies.

As consumers become more discerning about display quality, there is a rising demand for technologies that can deliver HDR (High Dynamic Range) content effectively. Both ULED and QLED excel in this area, offering enhanced contrast ratios and wider color gamuts compared to standard LED displays. This capability aligns well with the increasing availability of HDR content across streaming platforms and broadcast channels.

Energy efficiency is another key factor driving market demand for these technologies. As environmental concerns grow and energy costs rise, consumers and businesses are increasingly looking for display solutions that offer high performance with lower power consumption. Both ULED and QLED technologies have made strides in this area, positioning themselves as more eco-friendly alternatives to traditional display technologies.

Consumer electronics, particularly televisions and monitors, represent the primary market for these technologies. The global TV market size was valued at over $150 billion in 2020, with premium segments showing stronger growth. High-end displays, including ULED and QLED, are expected to capture an increasing share of this market as consumers seek better picture quality, color accuracy, and energy efficiency.

QLED technology has gained significant traction in recent years, with major manufacturers like Samsung leading the charge. The QLED TV market is projected to grow at a CAGR of around 20% from 2021 to 2026. This growth is fueled by QLED's ability to deliver vibrant colors, high brightness, and improved energy efficiency compared to traditional LED displays.

ULED, while less widely known than QLED, is carving out its own niche in the market. Developed by Hisense, ULED combines several picture enhancement technologies to improve overall display performance. The demand for ULED is growing, particularly in regions where Hisense has a strong presence, such as China and emerging markets.

The commercial display sector also presents significant opportunities for both ULED and QLED technologies. Digital signage, control rooms, and high-end presentation displays are increasingly adopting these advanced technologies to deliver superior visual experiences in professional environments. The global commercial display market is expected to reach $8 billion by 2025, with a growing portion attributed to premium display technologies.

As consumers become more discerning about display quality, there is a rising demand for technologies that can deliver HDR (High Dynamic Range) content effectively. Both ULED and QLED excel in this area, offering enhanced contrast ratios and wider color gamuts compared to standard LED displays. This capability aligns well with the increasing availability of HDR content across streaming platforms and broadcast channels.

Energy efficiency is another key factor driving market demand for these technologies. As environmental concerns grow and energy costs rise, consumers and businesses are increasingly looking for display solutions that offer high performance with lower power consumption. Both ULED and QLED technologies have made strides in this area, positioning themselves as more eco-friendly alternatives to traditional display technologies.

Technical Challenges

The differentiation between ULED (Ultra Light Emitting Diode) and QLED (Quantum Dot Light Emitting Diode) technologies presents several technical challenges. One of the primary difficulties lies in the precise control of light emission at the nanoscale level. Both technologies aim to enhance color accuracy and brightness, but they achieve this through different mechanisms.

ULED technology faces challenges in maintaining consistent color reproduction across different viewing angles. The ultra-thin phosphor layer used in ULED displays can exhibit color shift when viewed off-axis, requiring advanced optical engineering to mitigate this effect. Additionally, the thermal management of ULED panels is crucial, as heat generation can impact the longevity and performance of the phosphor materials.

For QLED technology, the stability of quantum dots remains a significant hurdle. These nanocrystals are sensitive to environmental factors such as temperature and humidity, which can affect their light-emitting properties over time. Ensuring the long-term reliability of QLED displays without color degradation is an ongoing challenge for manufacturers.

Another technical challenge is the optimization of energy efficiency. While both technologies boast improved energy consumption compared to traditional LED displays, there is still room for improvement. ULED systems need to balance the trade-off between brightness and power consumption, particularly in HDR (High Dynamic Range) content. QLED displays, on the other hand, must address the energy loss that occurs during the color conversion process.

The manufacturing processes for both technologies also present unique challenges. ULED production requires precise deposition of ultra-thin phosphor layers, which demands highly controlled manufacturing environments. QLED manufacturing involves the intricate process of quantum dot synthesis and integration, which can be complex and costly to scale up.

Color gamut expansion is another area where both technologies compete. While QLED is known for its wide color gamut, ULED manufacturers are working to narrow this gap. The challenge lies in developing new phosphor materials for ULED that can match or exceed the color range of quantum dots without compromising other performance aspects.

Lastly, the differentiation between ULED and QLED extends to the realm of contrast ratios and black levels. QLED technology, with its ability to selectively dim or turn off individual pixels, has an advantage in producing deep blacks. ULED technology must innovate in backlight control and local dimming techniques to compete effectively in this aspect of display performance.

ULED technology faces challenges in maintaining consistent color reproduction across different viewing angles. The ultra-thin phosphor layer used in ULED displays can exhibit color shift when viewed off-axis, requiring advanced optical engineering to mitigate this effect. Additionally, the thermal management of ULED panels is crucial, as heat generation can impact the longevity and performance of the phosphor materials.

For QLED technology, the stability of quantum dots remains a significant hurdle. These nanocrystals are sensitive to environmental factors such as temperature and humidity, which can affect their light-emitting properties over time. Ensuring the long-term reliability of QLED displays without color degradation is an ongoing challenge for manufacturers.

Another technical challenge is the optimization of energy efficiency. While both technologies boast improved energy consumption compared to traditional LED displays, there is still room for improvement. ULED systems need to balance the trade-off between brightness and power consumption, particularly in HDR (High Dynamic Range) content. QLED displays, on the other hand, must address the energy loss that occurs during the color conversion process.

The manufacturing processes for both technologies also present unique challenges. ULED production requires precise deposition of ultra-thin phosphor layers, which demands highly controlled manufacturing environments. QLED manufacturing involves the intricate process of quantum dot synthesis and integration, which can be complex and costly to scale up.

Color gamut expansion is another area where both technologies compete. While QLED is known for its wide color gamut, ULED manufacturers are working to narrow this gap. The challenge lies in developing new phosphor materials for ULED that can match or exceed the color range of quantum dots without compromising other performance aspects.

Lastly, the differentiation between ULED and QLED extends to the realm of contrast ratios and black levels. QLED technology, with its ability to selectively dim or turn off individual pixels, has an advantage in producing deep blacks. ULED technology must innovate in backlight control and local dimming techniques to compete effectively in this aspect of display performance.

Current ULED QLED Solutions

01 ULED display technology

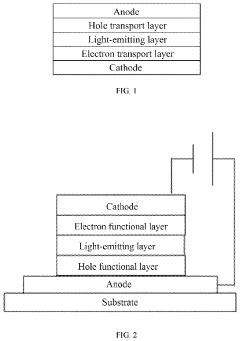

ULED (Ultra Light Emitting Diode) is an advanced display technology that offers improved brightness, contrast, and color accuracy compared to traditional LED displays. It utilizes a combination of quantum dot technology and advanced backlighting systems to achieve superior picture quality and energy efficiency.- ULED display technology: ULED (Ultra Light Emitting Diode) is an advanced display technology that offers improved brightness, contrast, and color accuracy compared to traditional LED displays. It utilizes a combination of quantum dot technology and advanced backlighting systems to enhance picture quality and energy efficiency.

- QLED display technology: QLED (Quantum dot Light Emitting Diode) is a display technology that uses quantum dots to produce vibrant colors and high contrast ratios. It employs a layer of quantum dots in front of an LED backlight, resulting in improved color accuracy and brightness compared to conventional LED displays.

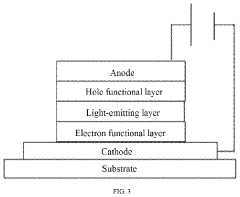

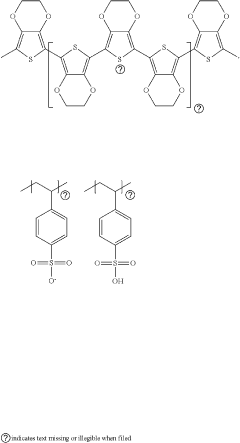

- Quantum dot materials for display applications: Quantum dots are semiconductor nanocrystals that emit light of specific wavelengths when excited. In display applications, quantum dots are used to enhance color gamut and brightness. Various compositions and structures of quantum dots are being developed to improve their efficiency and stability in QLED and ULED displays.

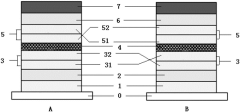

- Backlight and color conversion systems: Advanced backlight and color conversion systems are crucial components in both ULED and QLED displays. These systems utilize innovative light management techniques, such as local dimming and quantum dot color conversion layers, to enhance contrast, color accuracy, and energy efficiency of the displays.

- Manufacturing processes for ULED and QLED displays: The manufacturing of ULED and QLED displays involves specialized processes for integrating quantum dot materials, LED backlights, and other components. These processes include deposition techniques for quantum dot layers, assembly methods for display panels, and quality control measures to ensure consistent performance and longevity of the displays.

02 QLED display technology

QLED (Quantum dot Light Emitting Diode) is a display technology that uses quantum dots to enhance color reproduction and brightness. It employs a layer of quantum dots placed in front of an LED backlight, resulting in improved color accuracy and wider color gamut compared to conventional LED displays.Expand Specific Solutions03 Comparison between ULED and QLED

Both ULED and QLED technologies aim to improve display performance, but they differ in their approach. ULED focuses on enhancing overall picture quality through various optimizations, while QLED specifically targets color reproduction using quantum dot technology. The choice between the two depends on specific application requirements and desired visual characteristics.Expand Specific Solutions04 Manufacturing processes for ULED and QLED displays

The production of ULED and QLED displays involves specialized manufacturing processes. These may include the deposition of quantum dot layers, integration of advanced backlighting systems, and the implementation of proprietary image processing algorithms. Continuous improvements in manufacturing techniques contribute to enhanced display performance and cost-effectiveness.Expand Specific Solutions05 Applications and future developments of ULED and QLED technologies

ULED and QLED technologies find applications in various fields, including consumer electronics, professional displays, and automotive displays. Ongoing research focuses on improving energy efficiency, expanding color gamut, and enhancing durability. Future developments may include the integration of these technologies with flexible or transparent display substrates, opening up new possibilities for innovative display applications.Expand Specific Solutions

Key Industry Players

The differentiation between ULED and QLED technologies is currently in a competitive growth phase, with the market size expanding rapidly as consumers seek advanced display solutions. The technical maturity of these technologies varies among key players. Companies like BOE Technology Group, Sharp Corp., and TCL China Star Optoelectronics are at the forefront, pushing the boundaries of both ULED and QLED. Huawei Technologies and IBM are also making significant strides in research and development. The competition is further intensified by emerging players such as Appotronics Corp. and eLux, Inc., who are introducing innovative approaches to display technology. As the market evolves, collaboration between industry leaders and research institutions like Beijing Normal University and The Hong Kong University of Science & Technology is driving technological advancements and shaping the future of display technologies.

BOE Technology Group Co., Ltd.

Technical Solution: BOE's ULED technology utilizes advanced quantum dot materials and precise light control algorithms to enhance color gamut and contrast. Their approach involves a unique combination of quantum dot film and mini-LED backlight, allowing for more precise local dimming. BOE's ULED panels incorporate AI-driven image processing to optimize picture quality in real-time, adapting to various content types and ambient lighting conditions. The company has also developed proprietary color management systems to ensure color accuracy and consistency across different ULED models.

Strengths: Wide color gamut, high contrast ratios, and advanced local dimming capabilities. Weaknesses: Higher production costs compared to traditional LED displays, and potential for color shift over time.

Sharp Corp.

Technical Solution: Sharp's approach to QLED technology involves the use of proprietary quantum dot materials and advanced color management systems. Their QLED displays incorporate a quantum dot enhancement film (QDEF) layer to expand the color gamut and improve color accuracy. Sharp has developed unique backlight designs that optimize the interaction between the LED light source and quantum dot layer, resulting in improved energy efficiency. The company also employs AI-driven image processing algorithms to enhance picture quality and adapt to various viewing environments.

Strengths: High color accuracy, energy efficiency, and good brightness levels. Weaknesses: Limited local dimming capabilities compared to some competitors, and potential for color uniformity issues in larger screen sizes.

Core Tech Innovations

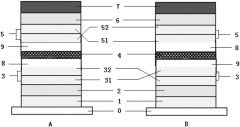

Optoelectronic device

PatentPendingUS20240107791A1

Innovation

- An optoelectronic device with a quantum dot light-emitting layer in a core-shell structure, where the valence band top energy level difference between the shell layer material and the hole transport material is greater than or equal to 0.5 eV, and the electron transport layer comprises zinc oxide nanomaterials bound with amine/carboxyl ligands of 3-8 carbon atoms, optimizing hole and electron injection balance and reducing charge accumulation.

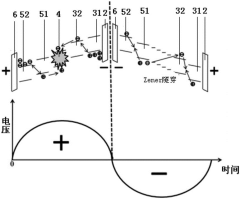

Alternating-current drive quantum dot light-emitting diode (QLED) and preparation method thereof

PatentActiveCN105161629A

Innovation

- An AC-driven QLED is designed that contains a p-n junction type charge generation layer and a dielectric layer that prevents electrode charge injection. The first dielectric layer, the first and second p-n junction type charge generation layers, and the quantum dot light-emitting layer are stacked. and a second dielectric layer, realizing the possibility of driving QLED using alternating current.

Performance Benchmarks

Performance benchmarks play a crucial role in differentiating ULED (Ultra Light Emitting Diode) from QLED (Quantum Dot Light Emitting Diode) technologies. These benchmarks provide quantitative and qualitative measures to compare the two display technologies across various parameters.

One of the primary performance indicators is color gamut coverage. QLED typically offers a wider color gamut, often achieving over 90% of the DCI-P3 color space, while ULED generally covers around 80-85%. This difference results in QLED displays producing more vibrant and saturated colors, particularly in the red and green spectrum.

Brightness is another key benchmark where QLED often outperforms ULED. QLED displays can achieve peak brightness levels of up to 2,000 nits or more, whereas ULED displays typically max out around 1,000-1,500 nits. This higher brightness capability allows QLED to deliver better HDR performance and improved visibility in well-lit environments.

Contrast ratio is an area where both technologies have made significant strides. QLED, with its quantum dot layer, can achieve deeper blacks and higher contrast ratios, often exceeding 1,000,000:1. ULED, while improving, generally falls short of these figures, with contrast ratios typically in the range of 400,000:1 to 600,000:1.

Power efficiency is a benchmark where ULED may have an edge. ULED displays often consume less power compared to QLED, especially at lower brightness levels. This can translate to better energy efficiency in real-world usage scenarios, particularly for users who don't require maximum brightness settings.

Response time and input lag are critical for gaming and fast-motion content. Both technologies perform well in this aspect, with response times typically under 5ms. However, QLED often has a slight edge, with some models achieving response times as low as 1ms.

Viewing angles represent another differentiating factor. QLED displays generally maintain better color accuracy and brightness when viewed from off-center angles compared to ULED. This is due to the quantum dot layer's ability to emit light more uniformly in all directions.

Longevity and burn-in resistance are important considerations for long-term performance. QLED displays are generally more resistant to burn-in compared to ULED, which can be prone to image retention over time, especially with static content.

These performance benchmarks provide a comprehensive framework for differentiating ULED and QLED technologies, highlighting the strengths and weaknesses of each. While QLED often leads in color, brightness, and contrast, ULED can offer advantages in power efficiency and potentially cost-effectiveness.

One of the primary performance indicators is color gamut coverage. QLED typically offers a wider color gamut, often achieving over 90% of the DCI-P3 color space, while ULED generally covers around 80-85%. This difference results in QLED displays producing more vibrant and saturated colors, particularly in the red and green spectrum.

Brightness is another key benchmark where QLED often outperforms ULED. QLED displays can achieve peak brightness levels of up to 2,000 nits or more, whereas ULED displays typically max out around 1,000-1,500 nits. This higher brightness capability allows QLED to deliver better HDR performance and improved visibility in well-lit environments.

Contrast ratio is an area where both technologies have made significant strides. QLED, with its quantum dot layer, can achieve deeper blacks and higher contrast ratios, often exceeding 1,000,000:1. ULED, while improving, generally falls short of these figures, with contrast ratios typically in the range of 400,000:1 to 600,000:1.

Power efficiency is a benchmark where ULED may have an edge. ULED displays often consume less power compared to QLED, especially at lower brightness levels. This can translate to better energy efficiency in real-world usage scenarios, particularly for users who don't require maximum brightness settings.

Response time and input lag are critical for gaming and fast-motion content. Both technologies perform well in this aspect, with response times typically under 5ms. However, QLED often has a slight edge, with some models achieving response times as low as 1ms.

Viewing angles represent another differentiating factor. QLED displays generally maintain better color accuracy and brightness when viewed from off-center angles compared to ULED. This is due to the quantum dot layer's ability to emit light more uniformly in all directions.

Longevity and burn-in resistance are important considerations for long-term performance. QLED displays are generally more resistant to burn-in compared to ULED, which can be prone to image retention over time, especially with static content.

These performance benchmarks provide a comprehensive framework for differentiating ULED and QLED technologies, highlighting the strengths and weaknesses of each. While QLED often leads in color, brightness, and contrast, ULED can offer advantages in power efficiency and potentially cost-effectiveness.

Environmental Impact

The environmental impact of display technologies is an increasingly important consideration in the consumer electronics industry. When comparing ULED (Ultra Light Emitting Diode) and QLED (Quantum Dot Light Emitting Diode) technologies, several factors come into play regarding their ecological footprint.

Energy efficiency is a key differentiator between ULED and QLED. ULED displays generally consume less power than their QLED counterparts, particularly in high-brightness scenarios. This reduced energy consumption translates to lower carbon emissions over the lifetime of the device, making ULED a potentially more environmentally friendly option in terms of operational impact.

Manufacturing processes also contribute significantly to the environmental profile of these technologies. QLED production involves the use of quantum dots, which are typically made from heavy metals such as cadmium. While efforts have been made to develop cadmium-free quantum dots, the production of these nanoparticles still raises concerns about potential environmental contamination and resource depletion.

In contrast, ULED technology relies on more conventional LED components, which have a well-established manufacturing process with potentially lower environmental risks. However, the production of high-quality LEDs for ULED displays may require rare earth elements, which have their own environmental concerns related to mining and processing.

Lifespan and durability are important factors in assessing the long-term environmental impact of display technologies. ULED displays often boast longer lifespans compared to QLED, potentially reducing the frequency of replacements and associated electronic waste. This extended durability can contribute to a lower overall environmental footprint throughout the product lifecycle.

End-of-life considerations also play a role in differentiating the environmental impact of ULED and QLED technologies. The recyclability of ULED components may be higher due to the use of more conventional materials. QLED displays, with their quantum dot layers, may present additional challenges in recycling and safe disposal, potentially leading to increased environmental risks if not properly managed.

Water usage and chemical emissions during the manufacturing process are additional factors to consider. QLED production may involve more water-intensive processes and the use of specialized chemicals for quantum dot synthesis. ULED manufacturing, while not without its environmental impacts, may have a lower water footprint and fewer chemical-related risks.

In conclusion, while both ULED and QLED technologies have environmental implications, ULED appears to have some advantages in terms of energy efficiency, lifespan, and potentially lower risks associated with manufacturing and disposal. However, ongoing research and development in both fields may alter this balance, emphasizing the need for continuous assessment of their environmental impacts.

Energy efficiency is a key differentiator between ULED and QLED. ULED displays generally consume less power than their QLED counterparts, particularly in high-brightness scenarios. This reduced energy consumption translates to lower carbon emissions over the lifetime of the device, making ULED a potentially more environmentally friendly option in terms of operational impact.

Manufacturing processes also contribute significantly to the environmental profile of these technologies. QLED production involves the use of quantum dots, which are typically made from heavy metals such as cadmium. While efforts have been made to develop cadmium-free quantum dots, the production of these nanoparticles still raises concerns about potential environmental contamination and resource depletion.

In contrast, ULED technology relies on more conventional LED components, which have a well-established manufacturing process with potentially lower environmental risks. However, the production of high-quality LEDs for ULED displays may require rare earth elements, which have their own environmental concerns related to mining and processing.

Lifespan and durability are important factors in assessing the long-term environmental impact of display technologies. ULED displays often boast longer lifespans compared to QLED, potentially reducing the frequency of replacements and associated electronic waste. This extended durability can contribute to a lower overall environmental footprint throughout the product lifecycle.

End-of-life considerations also play a role in differentiating the environmental impact of ULED and QLED technologies. The recyclability of ULED components may be higher due to the use of more conventional materials. QLED displays, with their quantum dot layers, may present additional challenges in recycling and safe disposal, potentially leading to increased environmental risks if not properly managed.

Water usage and chemical emissions during the manufacturing process are additional factors to consider. QLED production may involve more water-intensive processes and the use of specialized chemicals for quantum dot synthesis. ULED manufacturing, while not without its environmental impacts, may have a lower water footprint and fewer chemical-related risks.

In conclusion, while both ULED and QLED technologies have environmental implications, ULED appears to have some advantages in terms of energy efficiency, lifespan, and potentially lower risks associated with manufacturing and disposal. However, ongoing research and development in both fields may alter this balance, emphasizing the need for continuous assessment of their environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!