Improving Energy Efficiency in ULED Displays

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Display Evolution

The evolution of ULED (Ultra Light Emitting Diode) displays represents a significant advancement in display technology, building upon the foundation laid by LED and OLED technologies. This progression has been driven by the constant pursuit of improved image quality, energy efficiency, and form factor flexibility.

In the early stages of ULED development, researchers focused on enhancing the basic LED structure to achieve higher luminance and color accuracy. This involved refining the semiconductor materials used in the diodes and optimizing the quantum well structures to improve light emission efficiency. The introduction of quantum dot technology marked a crucial milestone, allowing for more precise color control and expanded color gamut.

As ULED technology matured, attention shifted towards addressing the limitations of traditional LCD and OLED displays. Engineers worked on developing self-emissive ULED pixels, eliminating the need for backlighting systems and potentially reducing power consumption. This approach also promised to deliver deeper blacks and improved contrast ratios, rivaling the performance of OLED displays.

A key focus in ULED evolution has been the miniaturization of LED chips. The development of micro-LED and subsequently nano-LED technologies has enabled the creation of displays with higher pixel densities and improved energy efficiency. These advancements have opened up new possibilities for high-resolution displays in various form factors, from large-scale video walls to compact wearable devices.

The pursuit of energy efficiency has been a constant theme throughout ULED evolution. Researchers have explored various techniques to reduce power consumption, including the implementation of local dimming algorithms, the use of more efficient phosphors and color conversion materials, and the optimization of driving circuits. These efforts have resulted in ULED displays that offer significant energy savings compared to their predecessors.

Another important aspect of ULED evolution has been the development of flexible and transparent display technologies. By leveraging the unique properties of ultra-thin LED structures, engineers have created displays that can be bent, folded, or even rolled, while maintaining high image quality and energy efficiency. This has paved the way for innovative applications in wearable technology, automotive displays, and architectural design.

The most recent advancements in ULED technology have focused on improving manufacturing processes to reduce costs and increase yield rates. This has involved the development of new transfer and bonding techniques for micro-LEDs, as well as the exploration of novel materials and structures to enhance overall display performance. As a result, ULED displays are becoming increasingly viable for mass-market adoption across a wide range of consumer and professional applications.

In the early stages of ULED development, researchers focused on enhancing the basic LED structure to achieve higher luminance and color accuracy. This involved refining the semiconductor materials used in the diodes and optimizing the quantum well structures to improve light emission efficiency. The introduction of quantum dot technology marked a crucial milestone, allowing for more precise color control and expanded color gamut.

As ULED technology matured, attention shifted towards addressing the limitations of traditional LCD and OLED displays. Engineers worked on developing self-emissive ULED pixels, eliminating the need for backlighting systems and potentially reducing power consumption. This approach also promised to deliver deeper blacks and improved contrast ratios, rivaling the performance of OLED displays.

A key focus in ULED evolution has been the miniaturization of LED chips. The development of micro-LED and subsequently nano-LED technologies has enabled the creation of displays with higher pixel densities and improved energy efficiency. These advancements have opened up new possibilities for high-resolution displays in various form factors, from large-scale video walls to compact wearable devices.

The pursuit of energy efficiency has been a constant theme throughout ULED evolution. Researchers have explored various techniques to reduce power consumption, including the implementation of local dimming algorithms, the use of more efficient phosphors and color conversion materials, and the optimization of driving circuits. These efforts have resulted in ULED displays that offer significant energy savings compared to their predecessors.

Another important aspect of ULED evolution has been the development of flexible and transparent display technologies. By leveraging the unique properties of ultra-thin LED structures, engineers have created displays that can be bent, folded, or even rolled, while maintaining high image quality and energy efficiency. This has paved the way for innovative applications in wearable technology, automotive displays, and architectural design.

The most recent advancements in ULED technology have focused on improving manufacturing processes to reduce costs and increase yield rates. This has involved the development of new transfer and bonding techniques for micro-LEDs, as well as the exploration of novel materials and structures to enhance overall display performance. As a result, ULED displays are becoming increasingly viable for mass-market adoption across a wide range of consumer and professional applications.

Market Demand Analysis

The market demand for energy-efficient ULED displays has been steadily increasing in recent years, driven by several key factors. Consumer electronics, particularly smartphones and televisions, represent the largest segment of this market. As consumers become more environmentally conscious and energy costs continue to rise, there is a growing preference for devices that offer superior display quality while consuming less power.

In the smartphone sector, manufacturers are constantly seeking ways to extend battery life without compromising on display performance. ULED technology, with its potential for improved energy efficiency, aligns perfectly with this market need. Industry reports suggest that energy-efficient displays could contribute to a 15-20% increase in battery life, a significant selling point for consumers.

The television market is another major driver for energy-efficient ULED displays. With the trend towards larger screen sizes and higher resolutions, power consumption has become a critical concern. Consumers are increasingly looking for televisions that offer vibrant, high-quality images while keeping electricity bills in check. This has led to a surge in demand for ULED displays that can deliver superior picture quality with reduced power consumption.

Commercial applications represent another growing market segment for energy-efficient ULED displays. Digital signage, control rooms, and public information displays are areas where the benefits of ULED technology are particularly appealing. These applications often require displays to operate for extended periods, making energy efficiency a crucial factor in reducing operational costs.

The automotive industry is also showing increased interest in energy-efficient ULED displays. As vehicles become more electrified and autonomous, the demand for high-quality, low-power displays for infotainment systems and instrument clusters is rising. ULED technology's potential to reduce power draw while maintaining visibility in various lighting conditions makes it an attractive option for automotive manufacturers.

Market research indicates that the global ULED display market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is largely attributed to the increasing adoption of ULED technology in various consumer electronics and the push for more energy-efficient display solutions across industries.

Government regulations and environmental policies are also playing a significant role in shaping market demand. Many countries have implemented energy efficiency standards for electronic devices, incentivizing manufacturers to adopt technologies like ULED that can help meet these requirements. This regulatory landscape is expected to further boost the demand for energy-efficient display solutions in the coming years.

In the smartphone sector, manufacturers are constantly seeking ways to extend battery life without compromising on display performance. ULED technology, with its potential for improved energy efficiency, aligns perfectly with this market need. Industry reports suggest that energy-efficient displays could contribute to a 15-20% increase in battery life, a significant selling point for consumers.

The television market is another major driver for energy-efficient ULED displays. With the trend towards larger screen sizes and higher resolutions, power consumption has become a critical concern. Consumers are increasingly looking for televisions that offer vibrant, high-quality images while keeping electricity bills in check. This has led to a surge in demand for ULED displays that can deliver superior picture quality with reduced power consumption.

Commercial applications represent another growing market segment for energy-efficient ULED displays. Digital signage, control rooms, and public information displays are areas where the benefits of ULED technology are particularly appealing. These applications often require displays to operate for extended periods, making energy efficiency a crucial factor in reducing operational costs.

The automotive industry is also showing increased interest in energy-efficient ULED displays. As vehicles become more electrified and autonomous, the demand for high-quality, low-power displays for infotainment systems and instrument clusters is rising. ULED technology's potential to reduce power draw while maintaining visibility in various lighting conditions makes it an attractive option for automotive manufacturers.

Market research indicates that the global ULED display market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is largely attributed to the increasing adoption of ULED technology in various consumer electronics and the push for more energy-efficient display solutions across industries.

Government regulations and environmental policies are also playing a significant role in shaping market demand. Many countries have implemented energy efficiency standards for electronic devices, incentivizing manufacturers to adopt technologies like ULED that can help meet these requirements. This regulatory landscape is expected to further boost the demand for energy-efficient display solutions in the coming years.

Energy Efficiency Challenges

ULED (Ultra Light Emitting Diode) displays have emerged as a promising technology in the display industry, offering superior brightness, contrast, and color gamut compared to traditional LED displays. However, as with any advanced display technology, energy efficiency remains a critical challenge that needs to be addressed to ensure widespread adoption and sustainability.

One of the primary energy efficiency challenges in ULED displays is the high power consumption required to achieve their exceptional brightness levels. While ULEDs are more efficient than conventional LEDs, the pursuit of ever-increasing luminance and contrast ratios often leads to increased energy demands. This challenge is particularly pronounced in large-format displays and outdoor applications where high brightness is essential for visibility in varying ambient light conditions.

Another significant challenge lies in the thermal management of ULED displays. As these displays operate at higher brightness levels, they generate more heat, which can negatively impact both energy efficiency and display longevity. Inefficient heat dissipation not only increases power consumption but also accelerates the degradation of ULED components, potentially leading to reduced lifespan and performance over time.

The drive circuitry and power supply units for ULED displays present additional energy efficiency hurdles. As ULED technology advances, the complexity of driving these displays increases, often resulting in power losses within the electronic components. Optimizing the power delivery and control systems without compromising display performance is a delicate balance that engineers must strike.

Color management and calibration in ULED displays also contribute to energy efficiency challenges. Achieving accurate and consistent color reproduction across the entire display while maintaining energy efficiency is a complex task. The need for precise color control often requires sophisticated algorithms and hardware, which can increase power consumption if not carefully optimized.

Furthermore, the manufacturing processes for ULED displays present their own set of energy-related challenges. The production of high-quality ULED components often involves energy-intensive processes, which indirectly impact the overall energy footprint of the technology. Improving manufacturing efficiency and yield rates is crucial for reducing the embodied energy in ULED displays.

Lastly, the integration of ULED technology with other display features, such as high refresh rates, HDR capabilities, and touch functionality, introduces additional layers of complexity in energy management. Each added feature potentially increases power consumption, requiring innovative solutions to maintain overall energy efficiency without compromising on performance or user experience.

One of the primary energy efficiency challenges in ULED displays is the high power consumption required to achieve their exceptional brightness levels. While ULEDs are more efficient than conventional LEDs, the pursuit of ever-increasing luminance and contrast ratios often leads to increased energy demands. This challenge is particularly pronounced in large-format displays and outdoor applications where high brightness is essential for visibility in varying ambient light conditions.

Another significant challenge lies in the thermal management of ULED displays. As these displays operate at higher brightness levels, they generate more heat, which can negatively impact both energy efficiency and display longevity. Inefficient heat dissipation not only increases power consumption but also accelerates the degradation of ULED components, potentially leading to reduced lifespan and performance over time.

The drive circuitry and power supply units for ULED displays present additional energy efficiency hurdles. As ULED technology advances, the complexity of driving these displays increases, often resulting in power losses within the electronic components. Optimizing the power delivery and control systems without compromising display performance is a delicate balance that engineers must strike.

Color management and calibration in ULED displays also contribute to energy efficiency challenges. Achieving accurate and consistent color reproduction across the entire display while maintaining energy efficiency is a complex task. The need for precise color control often requires sophisticated algorithms and hardware, which can increase power consumption if not carefully optimized.

Furthermore, the manufacturing processes for ULED displays present their own set of energy-related challenges. The production of high-quality ULED components often involves energy-intensive processes, which indirectly impact the overall energy footprint of the technology. Improving manufacturing efficiency and yield rates is crucial for reducing the embodied energy in ULED displays.

Lastly, the integration of ULED technology with other display features, such as high refresh rates, HDR capabilities, and touch functionality, introduces additional layers of complexity in energy management. Each added feature potentially increases power consumption, requiring innovative solutions to maintain overall energy efficiency without compromising on performance or user experience.

Current Energy Solutions

01 Energy-efficient ULED display design

ULED displays incorporate advanced design techniques to enhance energy efficiency. These may include optimized backlight systems, improved pixel structures, and efficient driver circuits. Such designs aim to reduce power consumption while maintaining high image quality and brightness.- Energy-efficient ULED display design: ULED displays incorporate advanced design techniques to enhance energy efficiency. These may include optimized pixel structures, improved backlight systems, and power management algorithms that reduce overall power consumption while maintaining high image quality.

- Power management systems for ULED displays: Innovative power management systems are implemented in ULED displays to minimize energy consumption. These systems may include adaptive brightness control, selective pixel activation, and intelligent power distribution mechanisms that optimize energy usage based on displayed content and ambient conditions.

- Thermal management for energy-efficient ULEDs: Effective thermal management techniques are employed in ULED displays to reduce energy loss through heat dissipation. These may include advanced heat sink designs, thermal interface materials, and active cooling systems that maintain optimal operating temperatures and improve overall energy efficiency.

- Energy-efficient ULED driver circuits: Specialized driver circuits are developed for ULED displays to minimize power consumption. These circuits may incorporate high-efficiency voltage regulators, current control mechanisms, and intelligent switching techniques that optimize power delivery to individual LEDs or LED arrays.

- Energy consumption monitoring and optimization: ULED display systems integrate advanced monitoring and optimization features to track and reduce energy consumption. These may include real-time power usage analytics, machine learning algorithms for predictive energy management, and user-configurable power-saving modes that balance performance and efficiency.

02 Power management systems for ULED displays

Implementing sophisticated power management systems in ULED displays can significantly improve energy efficiency. These systems may include adaptive brightness control, selective pixel activation, and intelligent power distribution algorithms to minimize energy waste during operation.Expand Specific Solutions03 Thermal management for ULED energy efficiency

Effective thermal management is crucial for maintaining ULED display energy efficiency. Advanced cooling systems and heat dissipation techniques can help reduce power consumption by preventing performance degradation due to overheating and extending the lifespan of display components.Expand Specific Solutions04 Energy-efficient ULED driver technologies

Developing and implementing energy-efficient driver technologies for ULED displays can significantly reduce overall power consumption. These may include low-voltage drivers, current-mode driving schemes, and advanced pulse-width modulation techniques to optimize energy usage.Expand Specific Solutions05 Smart content adaptation for ULED energy savings

Implementing smart content adaptation algorithms in ULED displays can lead to substantial energy savings. These algorithms can dynamically adjust display parameters based on content type, ambient lighting conditions, and user preferences to optimize power consumption without compromising visual quality.Expand Specific Solutions

Key Industry Players

The energy efficiency improvement in ULED displays is in a growth phase, with a rapidly expanding market driven by increasing demand for high-performance, low-power displays. The global ULED market is projected to grow significantly, fueled by advancements in display technology and consumer electronics. Technologically, the field is moderately mature but still evolving, with key players like Samsung Display, BOE Technology, and LG Display leading innovation. These companies are investing heavily in R&D to enhance ULED efficiency, with emerging technologies from Intel and Apple potentially disrupting the market. Smaller players like eLux and Lumileds are also contributing specialized solutions, indicating a competitive and dynamic landscape with opportunities for further technological breakthroughs.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a quantum dot-enhanced ULED display technology that significantly improves energy efficiency. Their approach involves using a layer of quantum dots to convert blue light from LEDs into pure red and green light, reducing the need for color filters and increasing light transmission. This results in brighter displays that consume less power. Additionally, Samsung has implemented advanced local dimming techniques, allowing for precise control of LED backlighting, further reducing energy consumption in dark scenes.

Strengths: Superior color accuracy and brightness. Significant reduction in power consumption. Weaknesses: Higher production costs. Potential for image retention in static content.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has introduced an innovative ULED display technology that utilizes a combination of quantum dot color conversion and mini-LED backlighting. Their approach involves using a high-density array of mini-LEDs for precise local dimming, coupled with a quantum dot layer for enhanced color performance. This combination allows for improved contrast ratios and energy efficiency. BOE has also implemented advanced power management algorithms that dynamically adjust brightness and contrast based on content and ambient light conditions, further optimizing energy consumption.

Strengths: Excellent contrast and black levels. Highly efficient power management. Weaknesses: Complex manufacturing process. Potential for blooming effects in high-contrast scenes.

Core Innovations

Pixel modification to reduce energy consumption of a display device

PatentWO2022238183A1

Innovation

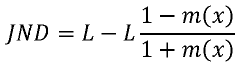

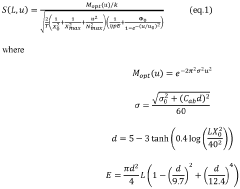

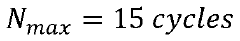

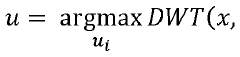

- The method involves determining a minimum detectable modulation value for each pixel based on human visual sensitivity using contrast sensitivity functions like Barten's model, and scaling pixel luminance accordingly to reduce energy consumption while maintaining perceptual indistinguishability, employing discrete or continuous wavelet transforms to analyze frequency content and apply adjustments in a way that ensures processing remains below visible thresholds.

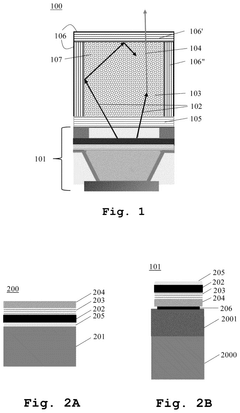

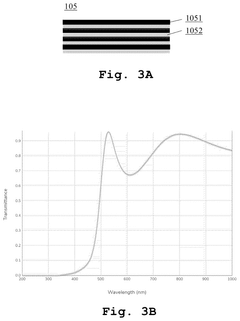

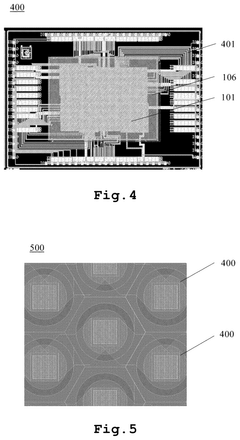

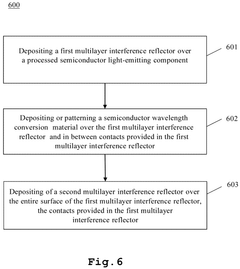

An optoelectronic device with color conversion and with conformal DBR and an associated fabrication method

PatentPendingUS20250151479A1

Innovation

- The proposed optoelectronic device incorporates a semiconductor light-emitting component with a cavity filled with wavelength conversion material, surrounded by multilayer interference reflectors that enhance light conversion and isolation, allowing for improved light emission efficiency and longer device lifetime.

Environmental Impact

The environmental impact of ULED (Ultra Light Emitting Diode) displays is a critical consideration in the ongoing efforts to improve their energy efficiency. As these displays become increasingly prevalent in various applications, from consumer electronics to large-scale digital signage, their cumulative effect on the environment becomes more significant.

ULED technology has already demonstrated substantial improvements in energy efficiency compared to traditional LED and LCD displays. However, the pursuit of even greater energy efficiency is not only driven by economic factors but also by the pressing need to reduce the carbon footprint of electronic devices. The manufacturing process of ULED displays involves the use of rare earth elements and other materials that can have environmental implications if not properly managed.

One of the primary environmental benefits of improving ULED energy efficiency is the reduction in power consumption during operation. This directly translates to lower greenhouse gas emissions from power generation, particularly in regions where fossil fuels remain a significant part of the energy mix. As ULED displays often operate for extended periods, even small improvements in efficiency can lead to substantial energy savings over time.

The longevity of ULED displays also plays a crucial role in their environmental impact. More energy-efficient displays tend to generate less heat, which can extend their operational lifespan. This reduction in heat output not only improves the durability of the display but also decreases the need for cooling systems in environments where these displays are used, further reducing overall energy consumption.

As research continues to push the boundaries of ULED efficiency, there is potential for these displays to contribute to broader sustainability goals. For instance, more efficient displays could enable the wider adoption of digital signage for public information and advertising, potentially reducing the need for paper-based alternatives and their associated environmental costs.

However, it is essential to consider the full lifecycle of ULED displays when assessing their environmental impact. This includes the sourcing of raw materials, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. Improvements in energy efficiency must be balanced against any potential increase in environmental impact during other stages of the lifecycle.

In conclusion, the drive to improve energy efficiency in ULED displays has significant positive implications for environmental sustainability. As technology advances, it is crucial to maintain a holistic view of environmental impact, ensuring that gains in operational efficiency are not offset by increased environmental costs in other areas of the product lifecycle.

ULED technology has already demonstrated substantial improvements in energy efficiency compared to traditional LED and LCD displays. However, the pursuit of even greater energy efficiency is not only driven by economic factors but also by the pressing need to reduce the carbon footprint of electronic devices. The manufacturing process of ULED displays involves the use of rare earth elements and other materials that can have environmental implications if not properly managed.

One of the primary environmental benefits of improving ULED energy efficiency is the reduction in power consumption during operation. This directly translates to lower greenhouse gas emissions from power generation, particularly in regions where fossil fuels remain a significant part of the energy mix. As ULED displays often operate for extended periods, even small improvements in efficiency can lead to substantial energy savings over time.

The longevity of ULED displays also plays a crucial role in their environmental impact. More energy-efficient displays tend to generate less heat, which can extend their operational lifespan. This reduction in heat output not only improves the durability of the display but also decreases the need for cooling systems in environments where these displays are used, further reducing overall energy consumption.

As research continues to push the boundaries of ULED efficiency, there is potential for these displays to contribute to broader sustainability goals. For instance, more efficient displays could enable the wider adoption of digital signage for public information and advertising, potentially reducing the need for paper-based alternatives and their associated environmental costs.

However, it is essential to consider the full lifecycle of ULED displays when assessing their environmental impact. This includes the sourcing of raw materials, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. Improvements in energy efficiency must be balanced against any potential increase in environmental impact during other stages of the lifecycle.

In conclusion, the drive to improve energy efficiency in ULED displays has significant positive implications for environmental sustainability. As technology advances, it is crucial to maintain a holistic view of environmental impact, ensuring that gains in operational efficiency are not offset by increased environmental costs in other areas of the product lifecycle.

Manufacturing Processes

The manufacturing processes for ULED displays play a crucial role in improving their energy efficiency. One of the key aspects is the development of advanced deposition techniques for the ultra-thin quantum dot layers. Molecular beam epitaxy (MBE) and atomic layer deposition (ALD) have emerged as promising methods for creating highly uniform and precise quantum dot structures. These techniques allow for better control over the size and distribution of quantum dots, which directly impacts the display's color accuracy and energy consumption.

Another significant area of focus is the optimization of the backplane manufacturing process. The use of low-temperature polycrystalline silicon (LTPS) technology has shown great potential in reducing power consumption. LTPS enables the creation of smaller and more efficient transistors, leading to improved electron mobility and reduced leakage current. This, in turn, contributes to overall energy savings in ULED displays.

The integration of advanced materials in the manufacturing process is also vital for enhancing energy efficiency. The incorporation of high-mobility oxide semiconductors, such as indium gallium zinc oxide (IGZO), has demonstrated significant improvements in power efficiency. These materials allow for faster switching speeds and lower operating voltages, resulting in reduced power consumption during display operation.

Furthermore, the development of novel encapsulation techniques has become increasingly important in ULED manufacturing. Advanced thin-film encapsulation methods, utilizing alternating layers of organic and inorganic materials, provide superior protection against moisture and oxygen ingress. This not only extends the lifespan of ULED displays but also helps maintain their energy efficiency over time by preventing degradation of the quantum dot layers.

The implementation of laser-assisted manufacturing processes has shown promise in improving the precision and efficiency of ULED production. Laser lift-off techniques, for instance, enable the transfer of ultra-thin quantum dot layers onto flexible substrates with minimal damage. This process allows for the creation of more flexible and energy-efficient displays while maintaining high image quality.

Lastly, the adoption of roll-to-roll manufacturing techniques has the potential to revolutionize ULED production. This continuous processing method not only increases production efficiency but also enables the creation of larger display panels with improved uniformity. By reducing material waste and energy consumption during manufacturing, roll-to-roll processes contribute to the overall energy efficiency of ULED displays throughout their lifecycle.

Another significant area of focus is the optimization of the backplane manufacturing process. The use of low-temperature polycrystalline silicon (LTPS) technology has shown great potential in reducing power consumption. LTPS enables the creation of smaller and more efficient transistors, leading to improved electron mobility and reduced leakage current. This, in turn, contributes to overall energy savings in ULED displays.

The integration of advanced materials in the manufacturing process is also vital for enhancing energy efficiency. The incorporation of high-mobility oxide semiconductors, such as indium gallium zinc oxide (IGZO), has demonstrated significant improvements in power efficiency. These materials allow for faster switching speeds and lower operating voltages, resulting in reduced power consumption during display operation.

Furthermore, the development of novel encapsulation techniques has become increasingly important in ULED manufacturing. Advanced thin-film encapsulation methods, utilizing alternating layers of organic and inorganic materials, provide superior protection against moisture and oxygen ingress. This not only extends the lifespan of ULED displays but also helps maintain their energy efficiency over time by preventing degradation of the quantum dot layers.

The implementation of laser-assisted manufacturing processes has shown promise in improving the precision and efficiency of ULED production. Laser lift-off techniques, for instance, enable the transfer of ultra-thin quantum dot layers onto flexible substrates with minimal damage. This process allows for the creation of more flexible and energy-efficient displays while maintaining high image quality.

Lastly, the adoption of roll-to-roll manufacturing techniques has the potential to revolutionize ULED production. This continuous processing method not only increases production efficiency but also enables the creation of larger display panels with improved uniformity. By reducing material waste and energy consumption during manufacturing, roll-to-roll processes contribute to the overall energy efficiency of ULED displays throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!