How to Unlock New Potentials with ULED Expertise?

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Technology Evolution

ULED (Ultra Light Emitting Diode) technology has undergone significant evolution since its inception, marking a revolutionary advancement in display technology. The journey of ULED began with the development of traditional LED displays, which laid the foundation for this cutting-edge innovation.

In the early stages, LED technology primarily focused on improving brightness and energy efficiency. As research progressed, the emphasis shifted towards enhancing color accuracy and contrast ratios. This led to the introduction of quantum dot technology, which greatly improved color reproduction and expanded the color gamut of displays.

The next major milestone in ULED evolution was the development of local dimming techniques. This innovation allowed for precise control of backlight zones, resulting in deeper blacks and improved contrast. As the number of dimming zones increased, the overall picture quality saw substantial improvements, particularly in HDR content reproduction.

Advancements in panel design and manufacturing processes played a crucial role in ULED's evolution. The introduction of nano-scale light-emitting particles and the refinement of pixel structures contributed to higher resolution displays with improved color accuracy and viewing angles.

The integration of artificial intelligence and machine learning algorithms marked another significant leap in ULED technology. These smart features enabled real-time image processing, content-adaptive brightness adjustment, and enhanced motion handling, resulting in a more immersive viewing experience.

Recent developments in ULED technology have focused on sustainability and energy efficiency. Manufacturers have made strides in reducing power consumption while maintaining or even improving display performance. This has been achieved through the use of advanced materials, optimized backlight systems, and more efficient power management algorithms.

The miniaturization of ULED components has opened up new possibilities for flexible and transparent displays. This has paved the way for innovative applications in wearable technology, automotive displays, and smart home devices.

As ULED technology continues to evolve, researchers are exploring new frontiers such as micro-LED and QLED-OLED hybrid technologies. These advancements promise even higher brightness levels, wider color gamuts, and improved energy efficiency, pushing the boundaries of what is possible in display technology.

The ongoing evolution of ULED technology demonstrates its potential to revolutionize various industries beyond traditional consumer electronics. From healthcare and education to advertising and entertainment, ULED's capabilities are being harnessed to create more engaging and interactive experiences across diverse applications.

In the early stages, LED technology primarily focused on improving brightness and energy efficiency. As research progressed, the emphasis shifted towards enhancing color accuracy and contrast ratios. This led to the introduction of quantum dot technology, which greatly improved color reproduction and expanded the color gamut of displays.

The next major milestone in ULED evolution was the development of local dimming techniques. This innovation allowed for precise control of backlight zones, resulting in deeper blacks and improved contrast. As the number of dimming zones increased, the overall picture quality saw substantial improvements, particularly in HDR content reproduction.

Advancements in panel design and manufacturing processes played a crucial role in ULED's evolution. The introduction of nano-scale light-emitting particles and the refinement of pixel structures contributed to higher resolution displays with improved color accuracy and viewing angles.

The integration of artificial intelligence and machine learning algorithms marked another significant leap in ULED technology. These smart features enabled real-time image processing, content-adaptive brightness adjustment, and enhanced motion handling, resulting in a more immersive viewing experience.

Recent developments in ULED technology have focused on sustainability and energy efficiency. Manufacturers have made strides in reducing power consumption while maintaining or even improving display performance. This has been achieved through the use of advanced materials, optimized backlight systems, and more efficient power management algorithms.

The miniaturization of ULED components has opened up new possibilities for flexible and transparent displays. This has paved the way for innovative applications in wearable technology, automotive displays, and smart home devices.

As ULED technology continues to evolve, researchers are exploring new frontiers such as micro-LED and QLED-OLED hybrid technologies. These advancements promise even higher brightness levels, wider color gamuts, and improved energy efficiency, pushing the boundaries of what is possible in display technology.

The ongoing evolution of ULED technology demonstrates its potential to revolutionize various industries beyond traditional consumer electronics. From healthcare and education to advertising and entertainment, ULED's capabilities are being harnessed to create more engaging and interactive experiences across diverse applications.

Market Demand Analysis

The market demand for ULED (Ultra Light Emitting Diode) technology has been steadily growing, driven by the increasing need for high-quality display solutions across various industries. As consumers and businesses alike seek more immersive and energy-efficient visual experiences, ULED has emerged as a promising technology to meet these evolving demands.

In the consumer electronics sector, there is a significant appetite for ULED-equipped devices, particularly in the television and smartphone markets. The superior contrast ratios, wider color gamut, and enhanced brightness offered by ULED displays have become key selling points for premium products. This trend is expected to continue as consumers become more discerning about display quality and energy efficiency.

The automotive industry represents another substantial market for ULED technology. As vehicles become more technologically advanced, there is a growing demand for high-quality, durable displays for infotainment systems, digital dashboards, and heads-up displays. ULED's ability to deliver vibrant colors and high contrast ratios, even in bright ambient light conditions, makes it an attractive option for automotive manufacturers.

In the commercial and industrial sectors, ULED technology is gaining traction for large-format displays and digital signage applications. The improved visibility, energy efficiency, and longevity of ULED displays make them ideal for use in retail environments, transportation hubs, and outdoor advertising. The ability to deliver eye-catching visuals while consuming less power aligns well with the sustainability goals of many businesses.

The healthcare industry is another area where ULED technology shows promise. High-resolution medical imaging displays that can accurately reproduce a wide range of colors and contrast levels are crucial for diagnostic accuracy. ULED's capabilities in this regard make it a potential game-changer for medical imaging equipment.

Market analysts project robust growth for the ULED market in the coming years. The technology's ability to offer superior visual performance while addressing energy efficiency concerns positions it well to capture a significant share of the display market. As manufacturing processes improve and economies of scale come into play, the cost of ULED technology is expected to decrease, further driving adoption across various sectors.

However, to fully unlock the potential of ULED expertise, manufacturers and researchers must address several challenges. These include further improving energy efficiency, enhancing durability and lifespan, and developing more cost-effective production methods. Additionally, there is a need to explore new applications and use cases for ULED technology beyond traditional display markets, potentially opening up new revenue streams and market opportunities.

In the consumer electronics sector, there is a significant appetite for ULED-equipped devices, particularly in the television and smartphone markets. The superior contrast ratios, wider color gamut, and enhanced brightness offered by ULED displays have become key selling points for premium products. This trend is expected to continue as consumers become more discerning about display quality and energy efficiency.

The automotive industry represents another substantial market for ULED technology. As vehicles become more technologically advanced, there is a growing demand for high-quality, durable displays for infotainment systems, digital dashboards, and heads-up displays. ULED's ability to deliver vibrant colors and high contrast ratios, even in bright ambient light conditions, makes it an attractive option for automotive manufacturers.

In the commercial and industrial sectors, ULED technology is gaining traction for large-format displays and digital signage applications. The improved visibility, energy efficiency, and longevity of ULED displays make them ideal for use in retail environments, transportation hubs, and outdoor advertising. The ability to deliver eye-catching visuals while consuming less power aligns well with the sustainability goals of many businesses.

The healthcare industry is another area where ULED technology shows promise. High-resolution medical imaging displays that can accurately reproduce a wide range of colors and contrast levels are crucial for diagnostic accuracy. ULED's capabilities in this regard make it a potential game-changer for medical imaging equipment.

Market analysts project robust growth for the ULED market in the coming years. The technology's ability to offer superior visual performance while addressing energy efficiency concerns positions it well to capture a significant share of the display market. As manufacturing processes improve and economies of scale come into play, the cost of ULED technology is expected to decrease, further driving adoption across various sectors.

However, to fully unlock the potential of ULED expertise, manufacturers and researchers must address several challenges. These include further improving energy efficiency, enhancing durability and lifespan, and developing more cost-effective production methods. Additionally, there is a need to explore new applications and use cases for ULED technology beyond traditional display markets, potentially opening up new revenue streams and market opportunities.

ULED Technical Challenges

ULED (Ultra Light Emitting Diode) technology faces several significant technical challenges that need to be addressed to unlock its full potential. One of the primary hurdles is improving the efficiency of light extraction. Current ULED structures suffer from total internal reflection, which traps a substantial portion of the generated light within the device, reducing overall luminous efficacy.

Another critical challenge lies in the development of more stable and efficient blue ULED emitters. While red and green ULEDs have made considerable progress, blue ULEDs still lag behind in terms of efficiency and longevity. This imbalance affects the color rendering and overall performance of ULED displays and lighting systems.

Thermal management presents a formidable obstacle in ULED development. As these devices become increasingly miniaturized and densely packed, heat dissipation becomes a crucial factor. Excessive heat can lead to decreased efficiency, shortened lifespan, and color shift, compromising the overall performance and reliability of ULED-based products.

The manufacturing process for ULEDs also poses significant challenges. Achieving uniform and precise deposition of ultra-thin layers on a large scale remains difficult. This issue directly impacts the consistency and yield of ULED production, affecting both performance and cost-effectiveness.

Addressing the issue of color shift over time is another key technical challenge. ULEDs, particularly those emitting blue light, tend to experience a gradual change in their emission spectrum as they age. This phenomenon can lead to noticeable changes in display quality and lighting characteristics over the product's lifetime.

The development of flexible and stretchable ULEDs represents a frontier challenge in the field. While progress has been made in creating bendable displays, achieving fully flexible and durable ULED systems that maintain high performance under repeated deformation remains a significant hurdle.

Lastly, the integration of ULEDs with other emerging technologies, such as quantum dots for color conversion or advanced driver circuits for precise control, presents both opportunities and challenges. Seamlessly combining these technologies to enhance overall system performance while maintaining cost-effectiveness and reliability is a complex task that requires innovative solutions.

Another critical challenge lies in the development of more stable and efficient blue ULED emitters. While red and green ULEDs have made considerable progress, blue ULEDs still lag behind in terms of efficiency and longevity. This imbalance affects the color rendering and overall performance of ULED displays and lighting systems.

Thermal management presents a formidable obstacle in ULED development. As these devices become increasingly miniaturized and densely packed, heat dissipation becomes a crucial factor. Excessive heat can lead to decreased efficiency, shortened lifespan, and color shift, compromising the overall performance and reliability of ULED-based products.

The manufacturing process for ULEDs also poses significant challenges. Achieving uniform and precise deposition of ultra-thin layers on a large scale remains difficult. This issue directly impacts the consistency and yield of ULED production, affecting both performance and cost-effectiveness.

Addressing the issue of color shift over time is another key technical challenge. ULEDs, particularly those emitting blue light, tend to experience a gradual change in their emission spectrum as they age. This phenomenon can lead to noticeable changes in display quality and lighting characteristics over the product's lifetime.

The development of flexible and stretchable ULEDs represents a frontier challenge in the field. While progress has been made in creating bendable displays, achieving fully flexible and durable ULED systems that maintain high performance under repeated deformation remains a significant hurdle.

Lastly, the integration of ULEDs with other emerging technologies, such as quantum dots for color conversion or advanced driver circuits for precise control, presents both opportunities and challenges. Seamlessly combining these technologies to enhance overall system performance while maintaining cost-effectiveness and reliability is a complex task that requires innovative solutions.

Current ULED Solutions

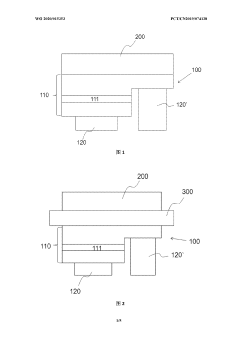

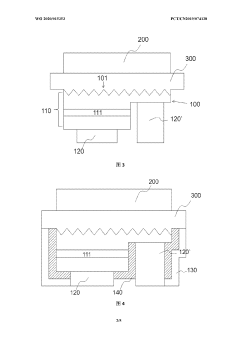

01 ULED structure and fabrication

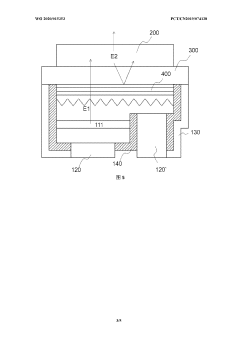

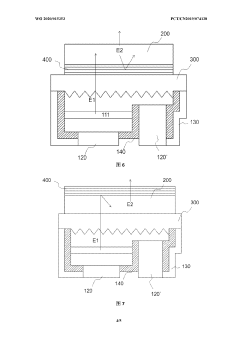

Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices with unique structural designs and fabrication methods. These innovations aim to enhance light emission efficiency, reduce power consumption, and improve overall performance. The manufacturing process may involve novel materials, layering techniques, and miniaturization strategies to achieve ultra-thin and highly efficient light-emitting structures.- ULED structure and fabrication: Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices with unique structural designs and fabrication methods. These innovations aim to enhance light emission efficiency, reduce power consumption, and improve overall performance. The manufacturing process may involve novel materials, layering techniques, and miniaturization to achieve ultra-thin and highly efficient light-emitting structures.

- ULED applications in display technology: ULEDs show significant potential in display technology, offering advantages such as higher brightness, better color accuracy, and improved energy efficiency compared to traditional LED displays. They can be integrated into various display types, including micro-LED displays, flexible screens, and high-resolution panels for smartphones, televisions, and other electronic devices.

- ULED power management and control systems: Advanced power management and control systems are crucial for optimizing ULED performance. These systems may include innovative driver circuits, voltage regulators, and intelligent control mechanisms to enhance energy efficiency, extend lifespan, and enable precise control over brightness and color output. Such technologies are essential for realizing the full potential of ULEDs in various applications.

- ULED thermal management solutions: Effective thermal management is critical for maintaining ULED performance and longevity. Innovative cooling solutions and heat dissipation techniques are developed to address the challenges of high-density ULED arrays. These may include advanced materials with superior thermal conductivity, novel heat sink designs, or active cooling systems to ensure optimal operating temperatures and prevent performance degradation.

- ULED integration with other technologies: ULEDs show promising potential for integration with other emerging technologies. This includes combining ULEDs with quantum dot technology for enhanced color performance, incorporating them into flexible and wearable electronics, or integrating them with advanced optical systems for augmented reality (AR) and virtual reality (VR) applications. Such integrations could lead to novel products and applications across various industries.

02 ULED applications in display technology

ULEDs show significant potential in display technology, offering advantages such as higher brightness, better color accuracy, and improved energy efficiency compared to traditional LED displays. They can be integrated into various display types, including micro-LED displays, flexible screens, and high-resolution panels for smartphones, televisions, and other electronic devices.Expand Specific Solutions03 Energy efficiency and power management

ULEDs are designed to achieve superior energy efficiency, potentially revolutionizing lighting and display technologies. Advanced power management systems and driver circuits are developed to optimize ULED performance, reduce power consumption, and extend battery life in portable devices. These improvements contribute to overall energy savings and environmental sustainability.Expand Specific Solutions04 ULED color rendering and light quality

ULEDs offer enhanced color rendering capabilities and improved light quality compared to conventional LEDs. Research focuses on developing ULEDs with a wider color gamut, better color accuracy, and the ability to produce more natural-looking light. This advancement has implications for various applications, including high-fidelity displays, medical imaging, and specialized lighting solutions.Expand Specific Solutions05 Integration of ULEDs in emerging technologies

ULEDs show promise for integration into various emerging technologies. This includes applications in augmented and virtual reality devices, automotive lighting and displays, wearable technology, and IoT devices. The compact size, high efficiency, and superior performance of ULEDs make them suitable for these advanced applications, potentially driving innovation across multiple industries.Expand Specific Solutions

Key ULED Industry Players

The ULED (Ultra Light Emitting Diode) technology market is in a growth phase, with increasing adoption across various industries. The market size is expanding rapidly, driven by demand for high-performance displays in consumer electronics, automotive, and industrial applications. Technologically, ULED is advancing quickly, with companies like Samsung Electronics, LG Electronics, and TCL China Star Optoelectronics leading innovation. These firms, along with others like Lumileds LLC and Appotronics Corp. Ltd., are pushing the boundaries of ULED efficiency, brightness, and color accuracy. The competitive landscape is intense, with both established players and emerging startups like eLux, Inc. and Micledi Microdisplays BV contributing to technological advancements, indicating a maturing but still evolving field.

Xiamen San'an Optoelectronics Co., Ltd.

Technical Solution: San'an Optoelectronics has focused on developing advanced LED and Mini-LED technologies that serve as the foundation for ULED displays. Their approach involves creating high-performance, ultra-small LED chips that can be used in Mini-LED backlighting systems. These Mini-LEDs allow for more precise local dimming, resulting in improved contrast and brightness control. San'an's technology also emphasizes energy efficiency and color accuracy, aiming to provide ULED displays that offer OLED-like performance with the longevity and brightness advantages of LED technology.

Strengths: High brightness capabilities, improved energy efficiency, and potential for cost-effective production at scale. Weaknesses: Less established in the consumer market compared to some competitors, may require partnerships for full display integration.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL's ULED technology, branded as QLED, utilizes quantum dot technology to enhance color performance and brightness. Their approach involves a quantum dot layer placed between the LED backlight and LCD panel, which converts blue light into pure red and green light. This results in a wider color gamut and higher peak brightness compared to traditional LED-LCD displays. TCL's ULED also incorporates mini-LED backlighting technology, allowing for more precise local dimming and improved contrast ratios. Additionally, they use AI-powered image processing to optimize picture quality in real-time.

Strengths: High brightness levels, wide color gamut, and improved contrast over standard LED-LCD. More cost-effective than OLED. Weaknesses: Not as thin as OLED displays, slightly less perfect blacks compared to OLED.

ULED Core Innovations

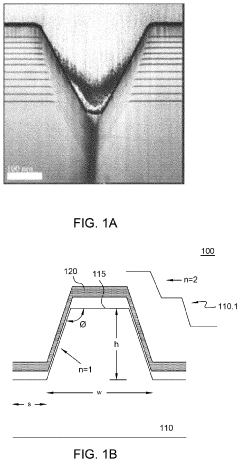

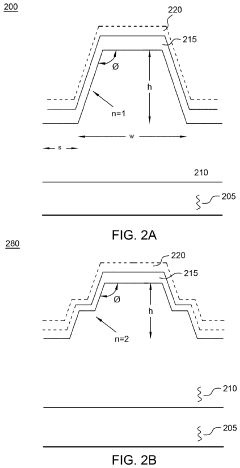

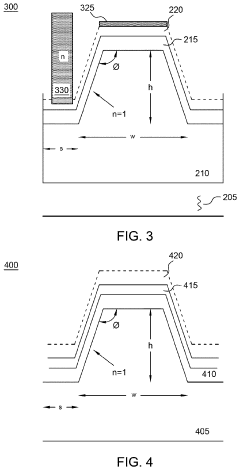

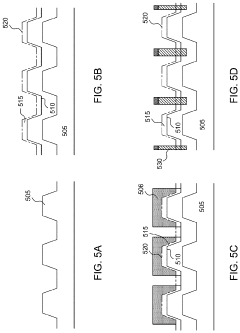

Micrometer scale light emitting diode displays on patterned templates and substrates

PatentActiveUS20200105824A1

Innovation

- A patterned substrate and epitaxial structure design that reduces growth rates on sloped sidewalls, blocking p-side carrier transport and maintaining n-side lateral current flow, eliminating the need for passivation layers and reducing processing steps, thereby enhancing efficiency and simplifying fabrication.

Micro light emitting device and display thereof

PatentWO2020015353A1

Innovation

- Using a micro-light-emitting diode structure with a transparent adhesive layer, the blue/green light is converted into red light through photon conversion technology, the AlInGaP-based quantum well layer is used to achieve efficient photon conversion, and anti-reflection and anti-reflection are set on the micro-light-emitting diode. The film layer and light reflective layer optimize the light emission efficiency.

ULED Energy Efficiency

ULED (Ultra Light Emitting Diode) technology has emerged as a promising solution for enhancing energy efficiency in display and lighting applications. The energy efficiency of ULED systems is significantly higher than traditional LED technologies, offering substantial potential for reducing power consumption and environmental impact.

ULED's superior energy efficiency stems from its unique structure and advanced materials. The ultra-thin layers of semiconductor materials used in ULED allow for more efficient electron-hole recombination, resulting in higher light output per unit of energy input. This improved quantum efficiency translates directly into reduced power consumption for the same level of brightness.

One of the key factors contributing to ULED's energy efficiency is its ability to achieve higher luminance levels at lower current densities. This characteristic not only reduces power consumption but also extends the lifespan of the devices by minimizing heat generation and material degradation. The reduced thermal load also simplifies cooling requirements, further enhancing overall system efficiency.

ULED technology also demonstrates excellent color purity and a wide color gamut. This allows for more accurate color reproduction with less energy waste, as less power is needed to achieve the desired color output. The precise control over color emission also enables the implementation of advanced color management techniques, further optimizing energy usage in display applications.

In lighting applications, ULED's energy efficiency is particularly noteworthy. The technology's ability to produce high-quality white light with minimal energy input makes it an attractive option for both residential and commercial lighting solutions. The directional nature of ULED emission also allows for more efficient light distribution, reducing wasted illumination and further improving overall energy efficiency.

The scalability of ULED technology is another factor that contributes to its energy-saving potential. From small-scale applications in wearable devices to large-scale implementations in outdoor displays, ULED can maintain its high efficiency across various sizes and configurations. This versatility enables widespread adoption and cumulative energy savings across multiple industries.

As research and development in ULED technology continue, we can expect further improvements in energy efficiency. Ongoing efforts to optimize materials, refine manufacturing processes, and enhance device architectures are likely to yield even more energy-efficient ULED solutions in the future. This continuous improvement cycle positions ULED as a key technology in the pursuit of sustainable and energy-efficient lighting and display solutions.

ULED's superior energy efficiency stems from its unique structure and advanced materials. The ultra-thin layers of semiconductor materials used in ULED allow for more efficient electron-hole recombination, resulting in higher light output per unit of energy input. This improved quantum efficiency translates directly into reduced power consumption for the same level of brightness.

One of the key factors contributing to ULED's energy efficiency is its ability to achieve higher luminance levels at lower current densities. This characteristic not only reduces power consumption but also extends the lifespan of the devices by minimizing heat generation and material degradation. The reduced thermal load also simplifies cooling requirements, further enhancing overall system efficiency.

ULED technology also demonstrates excellent color purity and a wide color gamut. This allows for more accurate color reproduction with less energy waste, as less power is needed to achieve the desired color output. The precise control over color emission also enables the implementation of advanced color management techniques, further optimizing energy usage in display applications.

In lighting applications, ULED's energy efficiency is particularly noteworthy. The technology's ability to produce high-quality white light with minimal energy input makes it an attractive option for both residential and commercial lighting solutions. The directional nature of ULED emission also allows for more efficient light distribution, reducing wasted illumination and further improving overall energy efficiency.

The scalability of ULED technology is another factor that contributes to its energy-saving potential. From small-scale applications in wearable devices to large-scale implementations in outdoor displays, ULED can maintain its high efficiency across various sizes and configurations. This versatility enables widespread adoption and cumulative energy savings across multiple industries.

As research and development in ULED technology continue, we can expect further improvements in energy efficiency. Ongoing efforts to optimize materials, refine manufacturing processes, and enhance device architectures are likely to yield even more energy-efficient ULED solutions in the future. This continuous improvement cycle positions ULED as a key technology in the pursuit of sustainable and energy-efficient lighting and display solutions.

ULED Manufacturing Process

The ULED (Ultra Light Emitting Diode) manufacturing process represents a critical aspect of unlocking new potentials in display technology. This advanced process involves several key stages, each contributing to the production of high-performance, energy-efficient displays.

The process begins with the preparation of the substrate, typically a glass or flexible material, which serves as the foundation for the ULED structure. This substrate undergoes rigorous cleaning and surface treatment to ensure optimal adhesion and uniformity of subsequent layers.

Next, the deposition of thin-film transistors (TFTs) takes place. These transistors are crucial for controlling individual pixels in the display. Advanced techniques such as low-temperature polycrystalline silicon (LTPS) or oxide TFT technologies are employed to achieve high electron mobility and stability.

The ULED emissive layer is then deposited using precision techniques such as thermal evaporation or inkjet printing. This layer consists of carefully engineered organic compounds that emit light when electrically stimulated. The composition and structure of this layer are tailored to achieve specific color output and efficiency.

Following the emissive layer, a series of functional layers are deposited, including electron transport layers, hole transport layers, and electron injection layers. These layers optimize charge carrier movement and recombination, enhancing the overall efficiency and longevity of the ULED device.

The cathode layer, typically a thin metal film, is then applied to complete the basic ULED structure. This layer is often deposited through vacuum evaporation techniques to ensure uniform coverage and optimal electrical properties.

Encapsulation is a critical step in the ULED manufacturing process. Advanced barrier technologies are employed to protect the sensitive organic materials from moisture and oxygen, which can significantly degrade device performance. This may involve the application of thin-film encapsulation layers or the use of specialized packaging materials.

The final stages of the manufacturing process involve the integration of the ULED panel with driving circuits and other components. This includes the attachment of flexible printed circuits (FPCs) and the implementation of advanced driving schemes to optimize display performance.

Throughout the manufacturing process, stringent quality control measures are implemented. This includes in-line monitoring of layer thicknesses, defect detection, and performance testing of individual pixels and complete panels.

Continuous innovation in the ULED manufacturing process focuses on improving yield rates, reducing material consumption, and enhancing overall device efficiency. Advancements in areas such as solution-processed materials, roll-to-roll manufacturing techniques, and AI-driven process optimization are actively being explored to unlock new potentials in ULED technology.

The process begins with the preparation of the substrate, typically a glass or flexible material, which serves as the foundation for the ULED structure. This substrate undergoes rigorous cleaning and surface treatment to ensure optimal adhesion and uniformity of subsequent layers.

Next, the deposition of thin-film transistors (TFTs) takes place. These transistors are crucial for controlling individual pixels in the display. Advanced techniques such as low-temperature polycrystalline silicon (LTPS) or oxide TFT technologies are employed to achieve high electron mobility and stability.

The ULED emissive layer is then deposited using precision techniques such as thermal evaporation or inkjet printing. This layer consists of carefully engineered organic compounds that emit light when electrically stimulated. The composition and structure of this layer are tailored to achieve specific color output and efficiency.

Following the emissive layer, a series of functional layers are deposited, including electron transport layers, hole transport layers, and electron injection layers. These layers optimize charge carrier movement and recombination, enhancing the overall efficiency and longevity of the ULED device.

The cathode layer, typically a thin metal film, is then applied to complete the basic ULED structure. This layer is often deposited through vacuum evaporation techniques to ensure uniform coverage and optimal electrical properties.

Encapsulation is a critical step in the ULED manufacturing process. Advanced barrier technologies are employed to protect the sensitive organic materials from moisture and oxygen, which can significantly degrade device performance. This may involve the application of thin-film encapsulation layers or the use of specialized packaging materials.

The final stages of the manufacturing process involve the integration of the ULED panel with driving circuits and other components. This includes the attachment of flexible printed circuits (FPCs) and the implementation of advanced driving schemes to optimize display performance.

Throughout the manufacturing process, stringent quality control measures are implemented. This includes in-line monitoring of layer thicknesses, defect detection, and performance testing of individual pixels and complete panels.

Continuous innovation in the ULED manufacturing process focuses on improving yield rates, reducing material consumption, and enhancing overall device efficiency. Advancements in areas such as solution-processed materials, roll-to-roll manufacturing techniques, and AI-driven process optimization are actively being explored to unlock new potentials in ULED technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!