How to Tailor ULED Features for Custom Applications?

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Tech Background

Ultra-Light Emitting Diode (ULED) technology represents a significant advancement in the field of display and lighting systems. Originating from the evolution of LED technology, ULEDs have emerged as a promising solution for applications requiring high-efficiency, ultra-thin, and flexible light sources. The development of ULED technology can be traced back to the early 2010s when researchers began exploring ways to miniaturize LED structures while maintaining or improving their performance characteristics.

The primary goal of ULED technology is to overcome the limitations of traditional LEDs, particularly in terms of size, power consumption, and flexibility. By reducing the thickness of the light-emitting layer to nanometer scales, ULEDs achieve remarkable thinness and flexibility, opening up new possibilities for integration into various devices and surfaces. This miniaturization also leads to improved energy efficiency and faster response times, making ULEDs particularly attractive for high-performance display applications.

As the technology has progressed, researchers and manufacturers have focused on enhancing key features such as brightness, color accuracy, and lifespan. The pursuit of these improvements has led to the development of novel materials and manufacturing processes, including the use of quantum dots and advanced thin-film deposition techniques. These advancements have not only improved the performance of ULEDs but also expanded their potential applications across multiple industries.

The evolution of ULED technology has been driven by the growing demand for more efficient and versatile display and lighting solutions. In the consumer electronics sector, ULEDs have enabled the creation of thinner, more energy-efficient smartphones, tablets, and wearable devices. In automotive applications, ULEDs are being used to design sleeker, more customizable lighting systems for both interior and exterior use. The technology has also found applications in the healthcare industry, where its flexibility and low heat generation make it suitable for medical imaging and wearable health monitoring devices.

Looking ahead, the trajectory of ULED technology is expected to continue towards even greater miniaturization, improved energy efficiency, and enhanced durability. Researchers are exploring the potential of organic materials and novel manufacturing techniques to further reduce costs and improve scalability. The integration of ULEDs with other emerging technologies, such as flexible electronics and Internet of Things (IoT) devices, is likely to open up new avenues for innovation and application.

The primary goal of ULED technology is to overcome the limitations of traditional LEDs, particularly in terms of size, power consumption, and flexibility. By reducing the thickness of the light-emitting layer to nanometer scales, ULEDs achieve remarkable thinness and flexibility, opening up new possibilities for integration into various devices and surfaces. This miniaturization also leads to improved energy efficiency and faster response times, making ULEDs particularly attractive for high-performance display applications.

As the technology has progressed, researchers and manufacturers have focused on enhancing key features such as brightness, color accuracy, and lifespan. The pursuit of these improvements has led to the development of novel materials and manufacturing processes, including the use of quantum dots and advanced thin-film deposition techniques. These advancements have not only improved the performance of ULEDs but also expanded their potential applications across multiple industries.

The evolution of ULED technology has been driven by the growing demand for more efficient and versatile display and lighting solutions. In the consumer electronics sector, ULEDs have enabled the creation of thinner, more energy-efficient smartphones, tablets, and wearable devices. In automotive applications, ULEDs are being used to design sleeker, more customizable lighting systems for both interior and exterior use. The technology has also found applications in the healthcare industry, where its flexibility and low heat generation make it suitable for medical imaging and wearable health monitoring devices.

Looking ahead, the trajectory of ULED technology is expected to continue towards even greater miniaturization, improved energy efficiency, and enhanced durability. Researchers are exploring the potential of organic materials and novel manufacturing techniques to further reduce costs and improve scalability. The integration of ULEDs with other emerging technologies, such as flexible electronics and Internet of Things (IoT) devices, is likely to open up new avenues for innovation and application.

ULED Market Analysis

The ULED (Ultra-Light Emitting Diode) market has been experiencing significant growth in recent years, driven by the increasing demand for high-performance display technologies across various industries. The global ULED market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors contributing to the market's expansion is the rising adoption of ULED technology in consumer electronics, particularly in smartphones, tablets, and televisions. The superior image quality, energy efficiency, and slim form factor of ULED displays have made them increasingly popular among consumers seeking premium viewing experiences.

The automotive sector has also emerged as a promising market for ULED technology. As vehicle manufacturers focus on enhancing in-car infotainment systems and dashboard displays, the demand for high-quality, durable, and energy-efficient display solutions has surged. ULED's ability to deliver vibrant colors, high contrast ratios, and excellent visibility in various lighting conditions makes it an attractive option for automotive applications.

In the commercial and industrial sectors, ULED technology is gaining traction for digital signage, control panels, and human-machine interfaces. The technology's long lifespan, low power consumption, and ability to maintain brightness over time have made it a preferred choice for businesses looking to reduce operational costs and improve the longevity of their display installations.

The healthcare industry represents another growing market for ULED technology. Medical imaging equipment, patient monitoring systems, and surgical displays are increasingly adopting ULED displays due to their high resolution, color accuracy, and reliability. These features are crucial for accurate diagnosis and precise medical procedures.

Geographically, Asia-Pacific dominates the ULED market, with China and South Korea leading in both production and consumption. The region's strong presence in consumer electronics manufacturing and the rapid adoption of new display technologies contribute to its market leadership. North America and Europe follow closely, driven by the demand for high-end displays in various sectors.

As the ULED market continues to evolve, customization capabilities are becoming increasingly important. Manufacturers are focusing on developing flexible ULED solutions that can be tailored to specific application requirements across different industries. This trend towards customization is expected to open up new opportunities for market growth and innovation in the coming years.

One of the key factors contributing to the market's expansion is the rising adoption of ULED technology in consumer electronics, particularly in smartphones, tablets, and televisions. The superior image quality, energy efficiency, and slim form factor of ULED displays have made them increasingly popular among consumers seeking premium viewing experiences.

The automotive sector has also emerged as a promising market for ULED technology. As vehicle manufacturers focus on enhancing in-car infotainment systems and dashboard displays, the demand for high-quality, durable, and energy-efficient display solutions has surged. ULED's ability to deliver vibrant colors, high contrast ratios, and excellent visibility in various lighting conditions makes it an attractive option for automotive applications.

In the commercial and industrial sectors, ULED technology is gaining traction for digital signage, control panels, and human-machine interfaces. The technology's long lifespan, low power consumption, and ability to maintain brightness over time have made it a preferred choice for businesses looking to reduce operational costs and improve the longevity of their display installations.

The healthcare industry represents another growing market for ULED technology. Medical imaging equipment, patient monitoring systems, and surgical displays are increasingly adopting ULED displays due to their high resolution, color accuracy, and reliability. These features are crucial for accurate diagnosis and precise medical procedures.

Geographically, Asia-Pacific dominates the ULED market, with China and South Korea leading in both production and consumption. The region's strong presence in consumer electronics manufacturing and the rapid adoption of new display technologies contribute to its market leadership. North America and Europe follow closely, driven by the demand for high-end displays in various sectors.

As the ULED market continues to evolve, customization capabilities are becoming increasingly important. Manufacturers are focusing on developing flexible ULED solutions that can be tailored to specific application requirements across different industries. This trend towards customization is expected to open up new opportunities for market growth and innovation in the coming years.

ULED Customization Challenges

Customizing ULED (Ultra-Low Energy Display) features for specific applications presents several significant challenges that developers and manufacturers must address. One of the primary obstacles is balancing power consumption with display performance. While ULEDs are designed to be energy-efficient, tailoring their features for custom applications often requires optimizing power usage without compromising visual quality or functionality.

Another challenge lies in adapting ULED technology to diverse form factors and environmental conditions. Custom applications may demand displays of various sizes, shapes, and resolutions, each requiring unique design considerations. Moreover, ensuring consistent performance across different lighting conditions and temperatures can be particularly demanding, especially for outdoor or industrial applications.

The integration of touch functionality and other interactive features poses additional complexities. Implementing responsive touch interfaces while maintaining ultra-low power consumption requires sophisticated engineering solutions. This challenge is further compounded when developing applications that require multi-touch capabilities or gesture recognition.

Durability and longevity are critical factors that must be addressed in ULED customization. Depending on the intended application, displays may need to withstand harsh environments, frequent use, or extended operational periods. Balancing these durability requirements with the need for thinness and flexibility in certain applications adds another layer of complexity to the customization process.

Color accuracy and contrast ratio optimization present ongoing challenges, particularly for applications in fields such as medical imaging or professional design. Achieving precise color reproduction and high contrast while adhering to ultra-low energy constraints requires advanced color management techniques and innovative display technologies.

Manufacturing scalability and cost-effectiveness are significant hurdles in ULED customization. Developing efficient production processes that can accommodate various custom designs while maintaining quality and keeping costs competitive is a complex undertaking. This challenge is particularly acute for small-batch or highly specialized applications.

Lastly, ensuring compatibility with existing systems and software platforms can be a formidable task. Custom ULED applications often need to integrate seamlessly with a wide range of devices and operating systems, requiring extensive testing and optimization to guarantee smooth operation across different platforms.

Another challenge lies in adapting ULED technology to diverse form factors and environmental conditions. Custom applications may demand displays of various sizes, shapes, and resolutions, each requiring unique design considerations. Moreover, ensuring consistent performance across different lighting conditions and temperatures can be particularly demanding, especially for outdoor or industrial applications.

The integration of touch functionality and other interactive features poses additional complexities. Implementing responsive touch interfaces while maintaining ultra-low power consumption requires sophisticated engineering solutions. This challenge is further compounded when developing applications that require multi-touch capabilities or gesture recognition.

Durability and longevity are critical factors that must be addressed in ULED customization. Depending on the intended application, displays may need to withstand harsh environments, frequent use, or extended operational periods. Balancing these durability requirements with the need for thinness and flexibility in certain applications adds another layer of complexity to the customization process.

Color accuracy and contrast ratio optimization present ongoing challenges, particularly for applications in fields such as medical imaging or professional design. Achieving precise color reproduction and high contrast while adhering to ultra-low energy constraints requires advanced color management techniques and innovative display technologies.

Manufacturing scalability and cost-effectiveness are significant hurdles in ULED customization. Developing efficient production processes that can accommodate various custom designs while maintaining quality and keeping costs competitive is a complex undertaking. This challenge is particularly acute for small-batch or highly specialized applications.

Lastly, ensuring compatibility with existing systems and software platforms can be a formidable task. Custom ULED applications often need to integrate seamlessly with a wide range of devices and operating systems, requiring extensive testing and optimization to guarantee smooth operation across different platforms.

Current ULED Customization Approaches

01 High efficiency and brightness

ULEDs are characterized by their superior efficiency and brightness compared to traditional LEDs. They utilize advanced semiconductor materials and structures to achieve higher light output with lower power consumption. This technology enables ULEDs to produce intense illumination while maintaining energy efficiency.- High efficiency and brightness: ULEDs are characterized by their superior efficiency and brightness compared to traditional LEDs. They utilize advanced semiconductor materials and structures to achieve higher light output with lower power consumption. This makes them ideal for applications requiring intense illumination or energy-efficient lighting solutions.

- Improved thermal management: ULEDs incorporate advanced thermal management techniques to dissipate heat more effectively. This allows for higher current densities and improved performance without compromising the device's lifespan. Enhanced heat dissipation also contributes to the overall reliability and longevity of ULED-based products.

- Enhanced color rendering and control: ULEDs offer superior color rendering capabilities and precise color control. They can produce a wider range of colors with higher accuracy, making them suitable for applications in displays, lighting, and imaging systems. Advanced phosphor technologies and multi-chip designs contribute to their improved color performance.

- Miniaturization and integration: ULEDs enable further miniaturization of light-emitting components, allowing for more compact and integrated designs. This feature is particularly beneficial in applications such as micro-displays, wearable devices, and automotive lighting. The reduced size also facilitates higher pixel densities in display technologies.

- Improved durability and lifespan: ULEDs are designed with enhanced durability and longer lifespans compared to conventional LEDs. They often incorporate advanced packaging techniques and materials that protect the semiconductor structure from environmental factors. This results in more reliable performance over extended periods, even in challenging operating conditions.

02 Improved thermal management

ULEDs incorporate advanced thermal management techniques to dissipate heat more effectively. This feature allows for higher current densities and improved performance without compromising the device's lifespan. Enhanced heat dissipation also contributes to the overall reliability and longevity of ULED devices.Expand Specific Solutions03 Enhanced color rendering and control

ULEDs offer superior color rendering capabilities and precise color control. They can produce a wide range of colors with high accuracy, making them suitable for various applications such as displays, lighting, and imaging systems. Advanced phosphor technologies and multi-chip designs contribute to this improved color performance.Expand Specific Solutions04 Miniaturization and integration

ULED technology enables the production of extremely small light-emitting devices, facilitating their integration into compact and sophisticated electronic systems. This miniaturization allows for higher pixel densities in displays and more efficient space utilization in lighting applications.Expand Specific Solutions05 Flexible and transparent designs

ULEDs can be fabricated on flexible and transparent substrates, opening up new possibilities for innovative product designs. This feature allows for the creation of bendable displays, wearable devices, and see-through lighting solutions, expanding the potential applications of LED technology.Expand Specific Solutions

Key ULED Manufacturers

The tailoring of ULED features for custom applications is currently in a growth phase, with increasing market demand and technological advancements. The market size is expanding as more industries recognize the potential of customized ULED solutions. Technologically, the field is progressing rapidly, with companies like Lumileds LLC, Koninklijke Philips NV, and Samsung Electronics Co., Ltd. leading innovation. These firms are developing advanced ULED technologies, focusing on improved efficiency, color accuracy, and integration capabilities. Other players like Barco NV and Microsoft Technology Licensing LLC are exploring niche applications, further driving the technology's maturity. The competitive landscape is diverse, with both established lighting giants and emerging tech companies vying for market share in this promising sector.

Innolux Corp.

Technical Solution: Innolux has developed a flexible ULED technology that allows for customization in both hardware and software aspects. Their approach involves using a modular panel design that can be easily adapted for different sizes and shapes, making it suitable for various applications. Innolux's ULED technology also incorporates advanced local dimming techniques and a proprietary light guide plate design for improved contrast and uniformity. The company offers a software development kit (SDK) that allows customers to create custom display modes and optimize performance for specific use cases.

Strengths: Flexibility in panel design, advanced local dimming, and customizable software. Weaknesses: Potential complexity in integration for some applications, may require specialized manufacturing processes.

Sichuan Changhong Electric Co., Ltd.

Technical Solution: Changhong has developed a ULED technology called "ULED XD" that focuses on customization through software-based controls. Their approach allows for fine-tuning of ULED parameters through a comprehensive software interface, enabling users to adjust various aspects of display performance. This includes control over local dimming zones, color gamut, and motion handling. Changhong's ULED XD also incorporates a unique panel structure that enhances light output and viewing angles, making it suitable for a variety of applications from home entertainment to professional displays.

Strengths: High degree of software-based customization, improved light output, and wide viewing angles. Weaknesses: May require technical expertise to fully utilize customization features, potential complexity in user interface.

ULED Tailoring Innovations

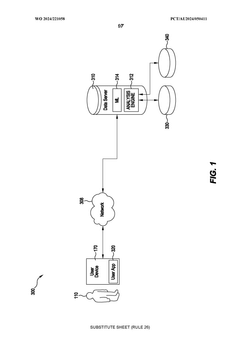

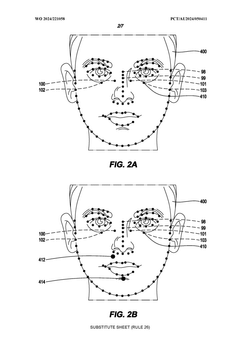

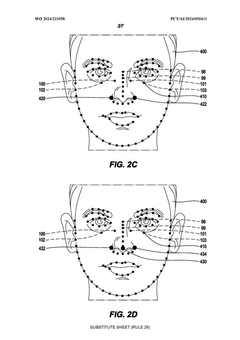

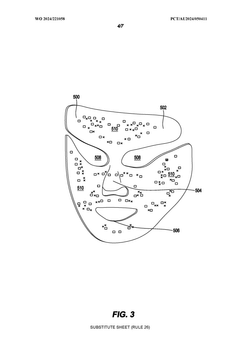

Systems and methods for manufacturing light therapy interfaces

PatentWO2024221058A1

Innovation

- A method and system for manufacturing customized light therapy interfaces using sensor data and machine learning to determine facial morphological features, compute optimal emitter locations, and generate fabrication instructions for personalized LED placement and intensity, allowing for tailored light therapy delivery.

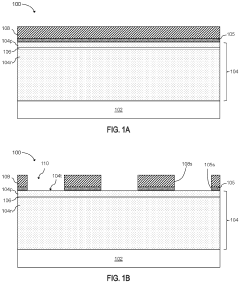

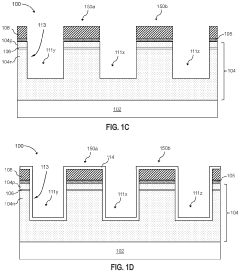

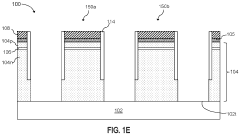

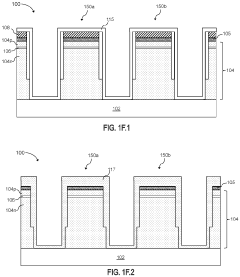

Flip chip micro light emitting diodes

PatentActiveUS11955583B2

Innovation

- A thin film flip-chip (TFFC) design for micro-LEDs with a mesa structure that includes a p-contact layer contacting the p-type layer, a cathode contacting the n-type layer's sidewall, and an anode contacting the p-contact layer's top surface, with dielectric materials isolating these components to enhance light extraction and handling efficiency.

ULED Industry Standards

ULED (Ultra Light Emitting Diode) industry standards play a crucial role in ensuring consistency, quality, and interoperability across various applications. These standards provide a framework for manufacturers, developers, and end-users to adhere to when implementing ULED technology in custom applications.

The International Electrotechnical Commission (IEC) has established several standards specifically for ULED technology. These include IEC 62922, which defines the performance requirements for ULED modules for general lighting, and IEC 62868, which outlines the safety requirements for ULED products. These standards ensure that ULED devices meet minimum performance and safety criteria, regardless of their specific application.

In addition to IEC standards, regional organizations have developed their own guidelines. For instance, the Illuminating Engineering Society (IES) in North America has published TM-30-18, which provides a method for evaluating light source color rendition. This standard is particularly relevant for ULED applications where accurate color reproduction is critical.

When tailoring ULED features for custom applications, adherence to these industry standards is essential. Manufacturers must consider factors such as color consistency, luminous efficacy, and thermal management as outlined in these standards. For example, IEC 62922 specifies methods for measuring and declaring initial colorimetric values and color maintenance of ULED modules, which is crucial for applications requiring precise color control.

The ANSI/UL 8750 standard, specific to LED equipment for use in lighting products, provides guidelines for the safety and performance of ULED drivers and control gear. This standard is particularly important when integrating ULEDs into custom applications that may require unique power supply configurations or control systems.

For applications in automotive lighting, standards such as SAE J3040 and ECE Regulation No. 128 provide specific requirements for ULED performance and safety in vehicle lighting systems. These standards address issues such as color temperature, light distribution, and durability under various environmental conditions.

As ULED technology continues to evolve, industry standards are regularly updated to reflect new developments and applications. For instance, the emergence of micro-LED displays has led to the development of new standards focusing on pixel density, contrast ratio, and power efficiency for these high-resolution applications.

Compliance with these standards not only ensures product quality and safety but also facilitates market acceptance and regulatory approval. As such, developers working on custom ULED applications must stay informed about relevant standards and incorporate them into their design and manufacturing processes to create robust, reliable, and compliant products.

The International Electrotechnical Commission (IEC) has established several standards specifically for ULED technology. These include IEC 62922, which defines the performance requirements for ULED modules for general lighting, and IEC 62868, which outlines the safety requirements for ULED products. These standards ensure that ULED devices meet minimum performance and safety criteria, regardless of their specific application.

In addition to IEC standards, regional organizations have developed their own guidelines. For instance, the Illuminating Engineering Society (IES) in North America has published TM-30-18, which provides a method for evaluating light source color rendition. This standard is particularly relevant for ULED applications where accurate color reproduction is critical.

When tailoring ULED features for custom applications, adherence to these industry standards is essential. Manufacturers must consider factors such as color consistency, luminous efficacy, and thermal management as outlined in these standards. For example, IEC 62922 specifies methods for measuring and declaring initial colorimetric values and color maintenance of ULED modules, which is crucial for applications requiring precise color control.

The ANSI/UL 8750 standard, specific to LED equipment for use in lighting products, provides guidelines for the safety and performance of ULED drivers and control gear. This standard is particularly important when integrating ULEDs into custom applications that may require unique power supply configurations or control systems.

For applications in automotive lighting, standards such as SAE J3040 and ECE Regulation No. 128 provide specific requirements for ULED performance and safety in vehicle lighting systems. These standards address issues such as color temperature, light distribution, and durability under various environmental conditions.

As ULED technology continues to evolve, industry standards are regularly updated to reflect new developments and applications. For instance, the emergence of micro-LED displays has led to the development of new standards focusing on pixel density, contrast ratio, and power efficiency for these high-resolution applications.

Compliance with these standards not only ensures product quality and safety but also facilitates market acceptance and regulatory approval. As such, developers working on custom ULED applications must stay informed about relevant standards and incorporate them into their design and manufacturing processes to create robust, reliable, and compliant products.

ULED Energy Efficiency

ULED (Ultra-Light Emitting Diode) technology has made significant strides in energy efficiency, positioning itself as a frontrunner in sustainable lighting solutions. The energy efficiency of ULED systems is primarily attributed to their advanced semiconductor materials and innovative design principles, which allow for superior light output with minimal power consumption.

One of the key factors contributing to ULED's energy efficiency is its ability to convert a higher percentage of electrical energy into visible light compared to traditional lighting technologies. This is achieved through the use of advanced phosphor materials and precise control of the electron flow within the semiconductor layers. As a result, ULEDs can produce the same level of illumination as conventional LEDs while consuming up to 30% less power.

The thermal management of ULEDs also plays a crucial role in their energy efficiency. By implementing advanced heat dissipation techniques, such as improved substrate materials and optimized package designs, ULEDs can operate at lower temperatures. This not only extends their lifespan but also reduces energy loss through heat, further enhancing overall efficiency.

Another aspect of ULED energy efficiency lies in their ability to provide directional light output. This feature allows for more precise control over light distribution, reducing wasted illumination and minimizing light pollution. In custom applications, this directional capability can be tailored to specific requirements, ensuring that energy is used only where needed.

The driver circuitry in ULED systems has also undergone significant improvements, contributing to their energy efficiency. Advanced power management techniques, such as adaptive dimming and intelligent control systems, allow ULEDs to adjust their output based on ambient light conditions or user preferences. This dynamic adjustment capability ensures that energy is not wasted when full illumination is unnecessary.

Furthermore, the long lifespan of ULEDs contributes to their overall energy efficiency from a lifecycle perspective. With operational lifetimes exceeding 50,000 hours, ULEDs require less frequent replacement than traditional lighting solutions. This longevity not only reduces the energy and resources required for manufacturing and disposal but also minimizes maintenance-related energy expenditures.

In custom applications, the energy efficiency of ULEDs can be further optimized through the integration of smart control systems. These systems can leverage sensors and connectivity features to create adaptive lighting environments that respond to occupancy, time of day, and other environmental factors. By intelligently managing light output, these smart ULED systems can achieve even greater energy savings while maintaining optimal illumination levels for specific use cases.

One of the key factors contributing to ULED's energy efficiency is its ability to convert a higher percentage of electrical energy into visible light compared to traditional lighting technologies. This is achieved through the use of advanced phosphor materials and precise control of the electron flow within the semiconductor layers. As a result, ULEDs can produce the same level of illumination as conventional LEDs while consuming up to 30% less power.

The thermal management of ULEDs also plays a crucial role in their energy efficiency. By implementing advanced heat dissipation techniques, such as improved substrate materials and optimized package designs, ULEDs can operate at lower temperatures. This not only extends their lifespan but also reduces energy loss through heat, further enhancing overall efficiency.

Another aspect of ULED energy efficiency lies in their ability to provide directional light output. This feature allows for more precise control over light distribution, reducing wasted illumination and minimizing light pollution. In custom applications, this directional capability can be tailored to specific requirements, ensuring that energy is used only where needed.

The driver circuitry in ULED systems has also undergone significant improvements, contributing to their energy efficiency. Advanced power management techniques, such as adaptive dimming and intelligent control systems, allow ULEDs to adjust their output based on ambient light conditions or user preferences. This dynamic adjustment capability ensures that energy is not wasted when full illumination is unnecessary.

Furthermore, the long lifespan of ULEDs contributes to their overall energy efficiency from a lifecycle perspective. With operational lifetimes exceeding 50,000 hours, ULEDs require less frequent replacement than traditional lighting solutions. This longevity not only reduces the energy and resources required for manufacturing and disposal but also minimizes maintenance-related energy expenditures.

In custom applications, the energy efficiency of ULEDs can be further optimized through the integration of smart control systems. These systems can leverage sensors and connectivity features to create adaptive lighting environments that respond to occupancy, time of day, and other environmental factors. By intelligently managing light output, these smart ULED systems can achieve even greater energy savings while maintaining optimal illumination levels for specific use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!