ULED as the Bedrock of New Age Display Systems

JUN 20, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Technology Evolution

ULED (Ultra Light Emitting Diode) technology has undergone significant evolution since its inception, marking a revolutionary path in display systems. The journey of ULED began with the fundamental advancements in LED technology, particularly in the miniaturization of LED chips and the enhancement of their light-emitting efficiency.

In the early stages, researchers focused on reducing the size of LED chips while maintaining or improving their luminous efficacy. This led to the development of micro-LEDs, which paved the way for ULED technology. The breakthrough came with the ability to manufacture LED chips at the micrometer scale, allowing for higher pixel density and improved image quality.

As the technology progressed, engineers tackled the challenge of mass transfer - the process of accurately placing millions of tiny LED chips onto a display substrate. This hurdle was overcome through innovative pick-and-place techniques and the development of new manufacturing processes, enabling the production of large-scale ULED displays.

The next phase in ULED evolution saw advancements in color reproduction. Initially, ULED displays used a combination of red, green, and blue micro-LEDs to create full-color images. However, researchers soon developed more efficient color conversion technologies, utilizing blue or UV micro-LEDs with color-converting phosphors or quantum dots to achieve a wider color gamut and improved color accuracy.

Power efficiency became a critical focus in the subsequent stages of ULED development. Engineers worked on optimizing the driving circuits and improving the overall system architecture to reduce power consumption while maintaining high brightness levels. This resulted in ULED displays that could deliver exceptional image quality with significantly lower energy requirements compared to traditional display technologies.

Recent advancements in ULED technology have centered on flexibility and form factor. Researchers have made strides in developing flexible ULED displays, opening up new possibilities for curved and foldable devices. This has been achieved through innovations in substrate materials and manufacturing techniques that allow for the integration of ULED elements onto flexible surfaces without compromising performance.

The latest frontier in ULED evolution is the integration of advanced functionalities directly into the display. This includes embedding sensors, such as fingerprint readers and cameras, seamlessly within the ULED array. These developments are pushing ULED technology beyond mere display capabilities, transforming it into a multifunctional interface that can serve as the foundation for next-generation interactive devices.

In the early stages, researchers focused on reducing the size of LED chips while maintaining or improving their luminous efficacy. This led to the development of micro-LEDs, which paved the way for ULED technology. The breakthrough came with the ability to manufacture LED chips at the micrometer scale, allowing for higher pixel density and improved image quality.

As the technology progressed, engineers tackled the challenge of mass transfer - the process of accurately placing millions of tiny LED chips onto a display substrate. This hurdle was overcome through innovative pick-and-place techniques and the development of new manufacturing processes, enabling the production of large-scale ULED displays.

The next phase in ULED evolution saw advancements in color reproduction. Initially, ULED displays used a combination of red, green, and blue micro-LEDs to create full-color images. However, researchers soon developed more efficient color conversion technologies, utilizing blue or UV micro-LEDs with color-converting phosphors or quantum dots to achieve a wider color gamut and improved color accuracy.

Power efficiency became a critical focus in the subsequent stages of ULED development. Engineers worked on optimizing the driving circuits and improving the overall system architecture to reduce power consumption while maintaining high brightness levels. This resulted in ULED displays that could deliver exceptional image quality with significantly lower energy requirements compared to traditional display technologies.

Recent advancements in ULED technology have centered on flexibility and form factor. Researchers have made strides in developing flexible ULED displays, opening up new possibilities for curved and foldable devices. This has been achieved through innovations in substrate materials and manufacturing techniques that allow for the integration of ULED elements onto flexible surfaces without compromising performance.

The latest frontier in ULED evolution is the integration of advanced functionalities directly into the display. This includes embedding sensors, such as fingerprint readers and cameras, seamlessly within the ULED array. These developments are pushing ULED technology beyond mere display capabilities, transforming it into a multifunctional interface that can serve as the foundation for next-generation interactive devices.

Display Market Dynamics

The display market has undergone significant transformations in recent years, driven by technological advancements and changing consumer preferences. ULED (Ultra Light Emitting Diode) technology has emerged as a potential game-changer in this dynamic landscape, promising to revolutionize display systems across various applications.

The global display market has been experiencing steady growth, with a notable shift towards higher resolution, larger screens, and improved energy efficiency. Traditional LCD (Liquid Crystal Display) technology has dominated the market for decades, but newer technologies like OLED (Organic Light Emitting Diode) have been gaining traction, particularly in high-end consumer electronics and premium televisions.

ULED technology enters this competitive arena with the potential to address some of the limitations of existing display technologies. It offers advantages such as superior brightness, wider color gamut, and improved energy efficiency compared to conventional LED displays. These characteristics position ULED as a promising candidate for next-generation display systems in various sectors, including consumer electronics, automotive displays, and professional monitors.

The demand for advanced display technologies is being fueled by several factors. In the consumer electronics sector, there is a growing appetite for immersive viewing experiences, driving the adoption of larger, higher-resolution screens in televisions and mobile devices. The automotive industry is increasingly incorporating sophisticated display systems in vehicle interiors, creating opportunities for technologies that can deliver high brightness and readability in diverse lighting conditions.

Furthermore, the professional and commercial display markets are seeking solutions that can provide exceptional color accuracy, high refresh rates, and long-term reliability. ULED technology's potential to meet these requirements positions it as a compelling option for applications in fields such as graphic design, video production, and digital signage.

The market dynamics also reflect a growing emphasis on sustainability and energy efficiency. As governments and consumers become more environmentally conscious, display technologies that can reduce power consumption while maintaining or improving performance are likely to gain favor. ULED's energy-efficient characteristics align well with this trend, potentially giving it a competitive edge in eco-conscious market segments.

As ULED technology continues to mature, its impact on the display market is expected to grow. However, it will face competition from established technologies like OLED and emerging alternatives such as microLED. The success of ULED in reshaping the display market will depend on factors such as manufacturing scalability, cost-effectiveness, and the ability to demonstrate clear advantages over existing solutions across various applications.

The global display market has been experiencing steady growth, with a notable shift towards higher resolution, larger screens, and improved energy efficiency. Traditional LCD (Liquid Crystal Display) technology has dominated the market for decades, but newer technologies like OLED (Organic Light Emitting Diode) have been gaining traction, particularly in high-end consumer electronics and premium televisions.

ULED technology enters this competitive arena with the potential to address some of the limitations of existing display technologies. It offers advantages such as superior brightness, wider color gamut, and improved energy efficiency compared to conventional LED displays. These characteristics position ULED as a promising candidate for next-generation display systems in various sectors, including consumer electronics, automotive displays, and professional monitors.

The demand for advanced display technologies is being fueled by several factors. In the consumer electronics sector, there is a growing appetite for immersive viewing experiences, driving the adoption of larger, higher-resolution screens in televisions and mobile devices. The automotive industry is increasingly incorporating sophisticated display systems in vehicle interiors, creating opportunities for technologies that can deliver high brightness and readability in diverse lighting conditions.

Furthermore, the professional and commercial display markets are seeking solutions that can provide exceptional color accuracy, high refresh rates, and long-term reliability. ULED technology's potential to meet these requirements positions it as a compelling option for applications in fields such as graphic design, video production, and digital signage.

The market dynamics also reflect a growing emphasis on sustainability and energy efficiency. As governments and consumers become more environmentally conscious, display technologies that can reduce power consumption while maintaining or improving performance are likely to gain favor. ULED's energy-efficient characteristics align well with this trend, potentially giving it a competitive edge in eco-conscious market segments.

As ULED technology continues to mature, its impact on the display market is expected to grow. However, it will face competition from established technologies like OLED and emerging alternatives such as microLED. The success of ULED in reshaping the display market will depend on factors such as manufacturing scalability, cost-effectiveness, and the ability to demonstrate clear advantages over existing solutions across various applications.

ULED Technical Challenges

ULED (Ultra Light Emitting Diode) technology, while promising, faces several significant technical challenges that need to be addressed for its widespread adoption in next-generation display systems. One of the primary hurdles is the development of efficient and stable blue ULED emitters. Blue ULEDs are crucial for achieving a full-color gamut, but they currently lag behind their red and green counterparts in terms of efficiency and longevity.

Another major challenge lies in the miniaturization of ULED devices. As display resolutions continue to increase, the need for smaller pixel sizes becomes more pressing. However, reducing the size of ULEDs while maintaining their performance characteristics is a complex task that requires innovative materials science and nanofabrication techniques.

The issue of color purity and consistency across different ULED colors is also a significant concern. Achieving uniform color output and maintaining it over the lifetime of the display is essential for high-quality image reproduction. This challenge is compounded by the fact that different color ULEDs may degrade at different rates, potentially leading to color shifts over time.

Heat management presents another critical challenge for ULED technology. As display brightness increases, so does the heat generated by the ULEDs. Effective thermal management solutions are necessary to prevent performance degradation and ensure the longevity of ULED displays, particularly in high-brightness applications.

The manufacturing process for ULEDs also poses significant challenges. Scaling up production while maintaining consistent quality and yield is crucial for commercial viability. Current manufacturing techniques need to be refined to achieve higher throughput and lower costs, without compromising on the quality of the ULEDs produced.

Integration of ULEDs with existing display technologies and driver circuits is another area that requires attention. Developing compatible and efficient driving schemes that can handle the unique characteristics of ULEDs, such as their fast response times and high current densities, is essential for optimal performance.

Lastly, the environmental impact and sustainability of ULED production and disposal need to be addressed. As with any emerging technology, ensuring that ULEDs can be manufactured, used, and recycled in an environmentally responsible manner is crucial for their long-term success and acceptance in the market.

Another major challenge lies in the miniaturization of ULED devices. As display resolutions continue to increase, the need for smaller pixel sizes becomes more pressing. However, reducing the size of ULEDs while maintaining their performance characteristics is a complex task that requires innovative materials science and nanofabrication techniques.

The issue of color purity and consistency across different ULED colors is also a significant concern. Achieving uniform color output and maintaining it over the lifetime of the display is essential for high-quality image reproduction. This challenge is compounded by the fact that different color ULEDs may degrade at different rates, potentially leading to color shifts over time.

Heat management presents another critical challenge for ULED technology. As display brightness increases, so does the heat generated by the ULEDs. Effective thermal management solutions are necessary to prevent performance degradation and ensure the longevity of ULED displays, particularly in high-brightness applications.

The manufacturing process for ULEDs also poses significant challenges. Scaling up production while maintaining consistent quality and yield is crucial for commercial viability. Current manufacturing techniques need to be refined to achieve higher throughput and lower costs, without compromising on the quality of the ULEDs produced.

Integration of ULEDs with existing display technologies and driver circuits is another area that requires attention. Developing compatible and efficient driving schemes that can handle the unique characteristics of ULEDs, such as their fast response times and high current densities, is essential for optimal performance.

Lastly, the environmental impact and sustainability of ULED production and disposal need to be addressed. As with any emerging technology, ensuring that ULEDs can be manufactured, used, and recycled in an environmentally responsible manner is crucial for their long-term success and acceptance in the market.

Current ULED Solutions

01 ULED structure and composition

Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices with unique structural and compositional features. They are designed to emit light with high efficiency and brightness while maintaining a compact form factor. The structure typically includes specialized layers and materials to enhance light output and reduce energy consumption.- ULED structure and composition: Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices with unique structural and compositional characteristics. They typically feature ultra-thin layers and specialized materials to achieve high efficiency and brightness. The design may include quantum wells, multiple active layers, or novel electrode configurations to enhance light output and reduce power consumption.

- ULED manufacturing processes: Manufacturing techniques for ULEDs involve precision processes such as epitaxial growth, photolithography, and advanced packaging methods. These processes aim to create ultra-thin, highly efficient light-emitting structures. Innovations in manufacturing may include novel deposition techniques, substrate engineering, or integration of nanoscale features to improve ULED performance and yield.

- ULED applications in displays: ULEDs are increasingly used in display technologies, offering advantages such as high brightness, energy efficiency, and thin form factors. Applications include micro-LED displays, automotive displays, and next-generation mobile device screens. The technology enables improved color gamut, contrast ratios, and potentially flexible or transparent display solutions.

- ULED power efficiency and thermal management: A key focus in ULED development is maximizing power efficiency while managing heat generation. This involves optimizing the electrical-to-optical conversion process, improving current spreading, and developing advanced thermal management solutions. Innovations may include novel heat sink designs, improved substrate materials, or integration of thermal management features directly into the ULED structure.

- ULED color tuning and light quality: Advancements in ULED technology focus on improving color quality, tunability, and spectral characteristics. This may involve developing new phosphor materials, implementing quantum dot technologies, or creating novel multi-color ULED arrays. The goal is to achieve a wider color gamut, better color rendering, and the ability to dynamically adjust light output characteristics for various applications.

02 ULED manufacturing processes

The manufacturing of ULEDs involves sophisticated processes to achieve their ultra-light and high-performance characteristics. These processes may include advanced epitaxial growth techniques, precise doping methods, and specialized packaging approaches. The manufacturing methods aim to optimize light extraction and minimize energy loss.Expand Specific Solutions03 ULED applications in display technology

ULEDs are increasingly being utilized in display technologies due to their superior brightness and energy efficiency. They are particularly suitable for high-resolution displays, offering improved color accuracy and contrast ratios. Applications range from small mobile device screens to large-format displays and televisions.Expand Specific Solutions04 ULED power efficiency and thermal management

A key advantage of ULEDs is their high power efficiency, which results in reduced heat generation compared to traditional LEDs. However, effective thermal management remains crucial for optimal performance and longevity. Innovative heat dissipation techniques and materials are employed to maintain the ultra-light characteristics while ensuring reliable operation.Expand Specific Solutions05 Integration of ULEDs in smart lighting systems

ULEDs are being integrated into smart lighting systems, leveraging their compact size and high efficiency. These systems can include advanced control mechanisms, allowing for dynamic adjustment of brightness and color temperature. The integration enables energy-saving features and customizable lighting environments for various applications.Expand Specific Solutions

Key ULED Industry Players

The ULED (Ultra Light Emitting Diode) technology is emerging as a foundational element in next-generation display systems, with the market currently in its early growth phase. Major players like BOE Technology, LG Electronics, and Samsung Display are driving innovation in this sector. The technology's maturity is rapidly advancing, with companies such as TCL China Star Optoelectronics and Lumileds LLC making significant contributions. The market size is expanding, fueled by increasing demand for high-performance displays in various industries. As ULED technology continues to evolve, we're seeing a competitive landscape where established electronics giants compete with specialized optoelectronics firms like Nitride Semiconductors and eLux, Inc., each striving to develop more efficient and cost-effective ULED solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a ULED (Ultra LED) technology that combines quantum dot and mini-LED technologies. Their ULED displays use a mini-LED backlight array with thousands of local dimming zones, coupled with a quantum dot color conversion layer. This allows for precise control of brightness and contrast, resulting in high dynamic range (HDR) performance with deep blacks and bright highlights. BOE's ULED technology also incorporates AI-driven image processing algorithms to optimize picture quality in real-time based on content and ambient lighting conditions.

Strengths: Superior contrast and color performance compared to traditional LCD. Energy-efficient due to local dimming. Weaknesses: Higher production costs than conventional displays. Potential for blooming effects around bright objects on dark backgrounds.

Samsung Display Co., Ltd.

Technical Solution: Samsung has developed its own version of ULED technology, which they call Neo QLED. This technology uses mini-LED backlighting combined with quantum dot color conversion. Samsung's approach involves using extremely small LEDs (as small as 1/40th the size of conventional LEDs) for the backlight, allowing for more precise local dimming and improved contrast. They also employ an advanced light diffusion technology and a quantum matrix controller to enhance brightness and reduce blooming effects. Samsung's Neo QLED displays also feature AI-powered upscaling to improve the quality of lower resolution content.

Strengths: Excellent picture quality with high brightness and deep blacks. Advanced AI-driven picture processing. Weaknesses: Premium pricing. Potential for slight color shift at extreme viewing angles.

ULED Core Innovations

Inorganic light emitting diode (ILED) assembly via direct bonding

PatentActiveUS20180261582A1

Innovation

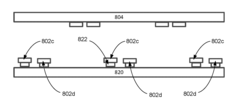

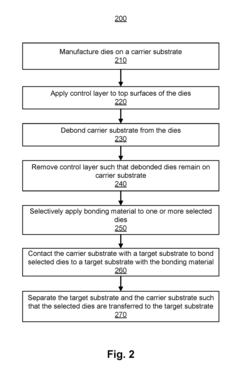

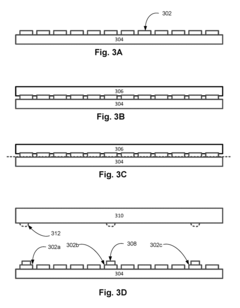

- A direct bonding method is employed, where a bonding material is applied to selected LED dies on a carrier substrate, allowing them to be transferred to a target substrate with greater adhesive force than to the carrier substrate, enabling efficient and cost-effective assembly of LED dies, such as MicroLEDs, onto display substrates without the need for sophisticated pick-up tools.

UV-led and display

PatentActiveUS20200098832A1

Innovation

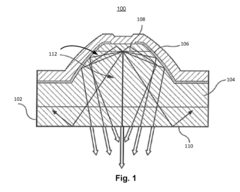

- A UV-LED with a quadrate planar shape and a patterned sapphire substrate, featuring a buffer layer, contact layer, and an InGaN light emitting layer, optimized for smaller chip sizes (50 μm or less) to enhance luminous efficiency and reduce power output decrease, incorporating a superlattice structure and specific layer compositions for improved emission recombination and extraction efficiency.

ULED Supply Chain Analysis

The ULED (Ultra Light Emitting Diode) supply chain is a complex network of manufacturers, suppliers, and distributors that play crucial roles in the production and delivery of ULED display systems. This emerging technology has created a new ecosystem within the display industry, involving various components and materials essential for ULED production.

At the core of the ULED supply chain are the manufacturers of the ultra-small LED chips. These companies specialize in producing high-quality, miniaturized LED components that form the foundation of ULED displays. The production process requires advanced semiconductor manufacturing techniques and precision engineering to achieve the necessary size and performance characteristics.

Substrate suppliers form another critical link in the chain, providing the base materials upon which ULED arrays are constructed. These substrates must meet stringent requirements for thermal management, electrical conductivity, and mechanical stability to ensure optimal performance of the final display.

Specialized equipment manufacturers contribute to the supply chain by developing and producing the machinery needed for ULED assembly and testing. This includes pick-and-place machines capable of handling extremely small components, as well as advanced inspection and quality control systems.

Chemical suppliers play a vital role in providing the materials necessary for ULED production, including phosphors, encapsulants, and other specialty chemicals that enhance the performance and longevity of the displays.

The supply chain also encompasses manufacturers of driver ICs and control systems, which are essential for managing the complex array of LEDs in a ULED display. These components require expertise in both semiconductor design and display technology.

Packaging and integration specialists form another crucial segment of the supply chain, responsible for assembling the various components into functional display modules. This process demands precision and expertise in handling delicate electronic components.

Distribution networks complete the supply chain, ensuring that ULED displays and components reach manufacturers of consumer electronics, automotive displays, and other end-use applications. These networks must be capable of handling the unique requirements of ULED technology, including temperature-controlled transportation and storage.

As ULED technology continues to evolve, the supply chain is expected to adapt and expand. This may include the emergence of new specialized suppliers and the development of more efficient production processes to meet growing demand. The robustness and flexibility of the ULED supply chain will be critical factors in determining the widespread adoption and success of this next-generation display technology.

At the core of the ULED supply chain are the manufacturers of the ultra-small LED chips. These companies specialize in producing high-quality, miniaturized LED components that form the foundation of ULED displays. The production process requires advanced semiconductor manufacturing techniques and precision engineering to achieve the necessary size and performance characteristics.

Substrate suppliers form another critical link in the chain, providing the base materials upon which ULED arrays are constructed. These substrates must meet stringent requirements for thermal management, electrical conductivity, and mechanical stability to ensure optimal performance of the final display.

Specialized equipment manufacturers contribute to the supply chain by developing and producing the machinery needed for ULED assembly and testing. This includes pick-and-place machines capable of handling extremely small components, as well as advanced inspection and quality control systems.

Chemical suppliers play a vital role in providing the materials necessary for ULED production, including phosphors, encapsulants, and other specialty chemicals that enhance the performance and longevity of the displays.

The supply chain also encompasses manufacturers of driver ICs and control systems, which are essential for managing the complex array of LEDs in a ULED display. These components require expertise in both semiconductor design and display technology.

Packaging and integration specialists form another crucial segment of the supply chain, responsible for assembling the various components into functional display modules. This process demands precision and expertise in handling delicate electronic components.

Distribution networks complete the supply chain, ensuring that ULED displays and components reach manufacturers of consumer electronics, automotive displays, and other end-use applications. These networks must be capable of handling the unique requirements of ULED technology, including temperature-controlled transportation and storage.

As ULED technology continues to evolve, the supply chain is expected to adapt and expand. This may include the emergence of new specialized suppliers and the development of more efficient production processes to meet growing demand. The robustness and flexibility of the ULED supply chain will be critical factors in determining the widespread adoption and success of this next-generation display technology.

Environmental Impact of ULED

The environmental impact of ULED (Ultra Light Emitting Diode) technology is a crucial consideration as it emerges as a potential bedrock for new age display systems. ULED offers significant improvements in energy efficiency compared to traditional display technologies, potentially reducing the overall carbon footprint of electronic devices.

ULED displays consume less power than their LCD and OLED counterparts, particularly when displaying darker content. This energy efficiency translates to reduced electricity consumption over the lifetime of devices, contributing to lower greenhouse gas emissions associated with power generation. The improved energy efficiency also extends battery life in portable devices, potentially reducing the frequency of battery replacements and associated e-waste.

The manufacturing process of ULED displays involves fewer toxic materials compared to some existing technologies. This reduction in hazardous substances not only makes the production process safer but also simplifies end-of-life recycling and disposal. The decreased use of rare earth elements in ULED production may also alleviate some of the environmental concerns associated with mining these materials.

ULED's longer lifespan compared to traditional display technologies can significantly reduce electronic waste. With improved durability and resistance to image retention, ULED displays are less likely to require frequent replacements, potentially decreasing the volume of discarded electronic devices and their associated environmental impact.

The enhanced brightness and color accuracy of ULED displays may lead to reduced power requirements for ambient lighting in various settings, such as offices and homes. This indirect effect could further contribute to energy savings and reduced environmental impact on a broader scale.

However, it is important to note that the full environmental impact of ULED technology is still being assessed. As with any new technology, there may be unforeseen environmental challenges that emerge as production scales up and the technology becomes more widespread. Ongoing research and life cycle assessments will be crucial in fully understanding and optimizing the environmental performance of ULED displays.

ULED displays consume less power than their LCD and OLED counterparts, particularly when displaying darker content. This energy efficiency translates to reduced electricity consumption over the lifetime of devices, contributing to lower greenhouse gas emissions associated with power generation. The improved energy efficiency also extends battery life in portable devices, potentially reducing the frequency of battery replacements and associated e-waste.

The manufacturing process of ULED displays involves fewer toxic materials compared to some existing technologies. This reduction in hazardous substances not only makes the production process safer but also simplifies end-of-life recycling and disposal. The decreased use of rare earth elements in ULED production may also alleviate some of the environmental concerns associated with mining these materials.

ULED's longer lifespan compared to traditional display technologies can significantly reduce electronic waste. With improved durability and resistance to image retention, ULED displays are less likely to require frequent replacements, potentially decreasing the volume of discarded electronic devices and their associated environmental impact.

The enhanced brightness and color accuracy of ULED displays may lead to reduced power requirements for ambient lighting in various settings, such as offices and homes. This indirect effect could further contribute to energy savings and reduced environmental impact on a broader scale.

However, it is important to note that the full environmental impact of ULED technology is still being assessed. As with any new technology, there may be unforeseen environmental challenges that emerge as production scales up and the technology becomes more widespread. Ongoing research and life cycle assessments will be crucial in fully understanding and optimizing the environmental performance of ULED displays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!