ULED Solutions for Next‑Level Digital Impression

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Technology Background and Objectives

Ultra-Light Emitting Diode (ULED) technology represents a significant advancement in the field of digital impression systems for dental applications. This innovative technology has emerged as a promising solution to address the limitations of traditional LED-based systems, offering enhanced precision, efficiency, and patient comfort in dental imaging.

The evolution of digital impression technology in dentistry has been driven by the need for more accurate, faster, and less invasive methods of capturing dental structures. ULED technology builds upon the foundation laid by earlier LED-based systems, pushing the boundaries of what is possible in terms of image quality and operational efficiency.

The primary objective of ULED technology in digital impression systems is to provide a next-level solution that overcomes the challenges faced by current technologies. These challenges include issues related to image resolution, depth perception, and the ability to capture fine details of dental structures. ULED aims to address these concerns by leveraging advanced light emission properties and innovative optical designs.

One of the key goals of ULED technology is to significantly improve the accuracy of digital impressions. By utilizing ultra-light emitting diodes, which offer superior light output and control compared to traditional LEDs, ULED systems can potentially capture more detailed and precise 3D images of dental structures. This enhanced accuracy is crucial for ensuring the proper fit of dental prosthetics and improving overall treatment outcomes.

Another important objective of ULED technology is to reduce scan times and improve the overall efficiency of the digital impression process. The increased light output of ULEDs allows for faster image capture, potentially reducing the time patients need to spend in the dental chair. This not only improves patient comfort but also increases the productivity of dental practices.

ULED technology also aims to expand the range of applications for digital impression systems. With its improved capabilities, ULED-based systems have the potential to be used in more complex dental procedures, such as full-arch restorations or implant planning, where high precision and detailed imaging are critical.

As the dental industry continues to embrace digital technologies, the development of ULED solutions for digital impressions aligns with the broader trend towards digitalization in healthcare. The technology seeks to provide a more seamless integration between digital impression systems and other digital dental workflows, such as CAD/CAM systems for prosthetic design and manufacturing.

In conclusion, the background and objectives of ULED technology in digital impression systems reflect a commitment to advancing the field of dental imaging. By addressing current limitations and pushing the boundaries of what is possible, ULED technology aims to deliver a next-level solution that enhances the quality of dental care while improving the experience for both practitioners and patients.

The evolution of digital impression technology in dentistry has been driven by the need for more accurate, faster, and less invasive methods of capturing dental structures. ULED technology builds upon the foundation laid by earlier LED-based systems, pushing the boundaries of what is possible in terms of image quality and operational efficiency.

The primary objective of ULED technology in digital impression systems is to provide a next-level solution that overcomes the challenges faced by current technologies. These challenges include issues related to image resolution, depth perception, and the ability to capture fine details of dental structures. ULED aims to address these concerns by leveraging advanced light emission properties and innovative optical designs.

One of the key goals of ULED technology is to significantly improve the accuracy of digital impressions. By utilizing ultra-light emitting diodes, which offer superior light output and control compared to traditional LEDs, ULED systems can potentially capture more detailed and precise 3D images of dental structures. This enhanced accuracy is crucial for ensuring the proper fit of dental prosthetics and improving overall treatment outcomes.

Another important objective of ULED technology is to reduce scan times and improve the overall efficiency of the digital impression process. The increased light output of ULEDs allows for faster image capture, potentially reducing the time patients need to spend in the dental chair. This not only improves patient comfort but also increases the productivity of dental practices.

ULED technology also aims to expand the range of applications for digital impression systems. With its improved capabilities, ULED-based systems have the potential to be used in more complex dental procedures, such as full-arch restorations or implant planning, where high precision and detailed imaging are critical.

As the dental industry continues to embrace digital technologies, the development of ULED solutions for digital impressions aligns with the broader trend towards digitalization in healthcare. The technology seeks to provide a more seamless integration between digital impression systems and other digital dental workflows, such as CAD/CAM systems for prosthetic design and manufacturing.

In conclusion, the background and objectives of ULED technology in digital impression systems reflect a commitment to advancing the field of dental imaging. By addressing current limitations and pushing the boundaries of what is possible, ULED technology aims to deliver a next-level solution that enhances the quality of dental care while improving the experience for both practitioners and patients.

Market Demand for Advanced Digital Impression Systems

The market demand for advanced digital impression systems in dentistry has been experiencing significant growth, driven by the increasing adoption of digital technologies in dental practices worldwide. This surge in demand is primarily fueled by the numerous advantages that digital impression systems offer over traditional methods, including improved accuracy, enhanced patient comfort, and streamlined workflow efficiency.

Dental professionals are increasingly recognizing the benefits of digital impression systems, which allow for faster and more precise capture of oral structures. These systems eliminate the need for messy and uncomfortable physical impressions, reducing patient discomfort and anxiety. Moreover, digital impressions can be easily stored, shared, and manipulated, facilitating better communication between dental practitioners and laboratories.

The global dental digital impression systems market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong in the coming years. This growth is attributed to factors such as the rising prevalence of dental disorders, increasing awareness about oral health, and the growing geriatric population worldwide.

Geographically, North America and Europe currently dominate the market for digital impression systems, owing to their advanced healthcare infrastructure and higher adoption rates of new technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by improving healthcare facilities and increasing disposable incomes.

The demand for digital impression systems is particularly high in orthodontics, prosthodontics, and implantology. These specialties benefit greatly from the precision and efficiency offered by digital technologies, leading to improved treatment outcomes and patient satisfaction. Additionally, the integration of artificial intelligence and machine learning in digital impression systems is further enhancing their capabilities, driving market growth.

Dental laboratories are also contributing to the increasing demand for digital impression systems. The ability to receive digital files instantly and start the production process without delay has significantly improved turnaround times and reduced errors associated with traditional impression methods.

As the technology continues to evolve, there is a growing demand for more compact, user-friendly, and affordable digital impression systems. This trend is expected to drive innovation in the field, leading to the development of more advanced ULED (Ultra-Light Emitting Diode) solutions for next-level digital impressions. These advancements aim to address current limitations and expand the accessibility of digital impression technology to a broader range of dental practices.

Dental professionals are increasingly recognizing the benefits of digital impression systems, which allow for faster and more precise capture of oral structures. These systems eliminate the need for messy and uncomfortable physical impressions, reducing patient discomfort and anxiety. Moreover, digital impressions can be easily stored, shared, and manipulated, facilitating better communication between dental practitioners and laboratories.

The global dental digital impression systems market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong in the coming years. This growth is attributed to factors such as the rising prevalence of dental disorders, increasing awareness about oral health, and the growing geriatric population worldwide.

Geographically, North America and Europe currently dominate the market for digital impression systems, owing to their advanced healthcare infrastructure and higher adoption rates of new technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by improving healthcare facilities and increasing disposable incomes.

The demand for digital impression systems is particularly high in orthodontics, prosthodontics, and implantology. These specialties benefit greatly from the precision and efficiency offered by digital technologies, leading to improved treatment outcomes and patient satisfaction. Additionally, the integration of artificial intelligence and machine learning in digital impression systems is further enhancing their capabilities, driving market growth.

Dental laboratories are also contributing to the increasing demand for digital impression systems. The ability to receive digital files instantly and start the production process without delay has significantly improved turnaround times and reduced errors associated with traditional impression methods.

As the technology continues to evolve, there is a growing demand for more compact, user-friendly, and affordable digital impression systems. This trend is expected to drive innovation in the field, leading to the development of more advanced ULED (Ultra-Light Emitting Diode) solutions for next-level digital impressions. These advancements aim to address current limitations and expand the accessibility of digital impression technology to a broader range of dental practices.

Current ULED Technology Challenges

Ultra-Light Emitting Diode (ULED) technology has shown great promise in advancing digital impression systems for dental applications. However, several challenges currently hinder its widespread adoption and optimal performance in next-level digital impression devices.

One of the primary challenges facing ULED technology is the need for improved light output efficiency. While ULEDs offer significant advantages in terms of size and power consumption, their light output intensity still falls short of traditional LED sources. This limitation can affect the accuracy and detail of digital impressions, particularly in deep or hard-to-reach areas of the oral cavity.

Another critical challenge is the thermal management of ULED arrays. As these devices are miniaturized and packed more densely to achieve higher resolution, heat dissipation becomes a significant concern. Excessive heat can lead to reduced lifespan, color shifts, and potential safety issues in intraoral applications. Developing effective cooling solutions that are compatible with the compact form factor of digital impression devices remains a key area of focus.

Color accuracy and consistency pose additional challenges for ULED technology in digital impression systems. Achieving precise and repeatable color rendering across different devices and operating conditions is crucial for accurate shade matching and overall impression quality. This requires advancements in both ULED manufacturing processes and color calibration techniques.

The integration of ULED arrays with optical systems and sensors presents another set of challenges. Optimizing the light distribution, minimizing artifacts, and ensuring seamless coordination between the light source and image capture components are essential for producing high-quality digital impressions. This integration becomes increasingly complex as manufacturers strive for higher resolution and faster scanning speeds.

Durability and reliability of ULED components in the harsh oral environment remain ongoing concerns. Exposure to moisture, temperature fluctuations, and potential physical stress during use can impact the long-term performance and stability of ULED-based digital impression systems. Developing robust encapsulation and protection methods without compromising optical performance is a critical area of research.

Cost-effectiveness is another significant challenge in the adoption of ULED technology for digital impressions. While the potential benefits are substantial, the current manufacturing costs of high-quality ULED arrays can be prohibitive for widespread implementation in dental practices. Scaling up production and improving yield rates are necessary steps to make ULED-based systems more economically viable.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, optical engineering, thermal management, and manufacturing processes. As researchers and manufacturers continue to innovate, overcoming these hurdles will pave the way for next-generation digital impression systems that offer unprecedented accuracy, speed, and user experience in dental applications.

One of the primary challenges facing ULED technology is the need for improved light output efficiency. While ULEDs offer significant advantages in terms of size and power consumption, their light output intensity still falls short of traditional LED sources. This limitation can affect the accuracy and detail of digital impressions, particularly in deep or hard-to-reach areas of the oral cavity.

Another critical challenge is the thermal management of ULED arrays. As these devices are miniaturized and packed more densely to achieve higher resolution, heat dissipation becomes a significant concern. Excessive heat can lead to reduced lifespan, color shifts, and potential safety issues in intraoral applications. Developing effective cooling solutions that are compatible with the compact form factor of digital impression devices remains a key area of focus.

Color accuracy and consistency pose additional challenges for ULED technology in digital impression systems. Achieving precise and repeatable color rendering across different devices and operating conditions is crucial for accurate shade matching and overall impression quality. This requires advancements in both ULED manufacturing processes and color calibration techniques.

The integration of ULED arrays with optical systems and sensors presents another set of challenges. Optimizing the light distribution, minimizing artifacts, and ensuring seamless coordination between the light source and image capture components are essential for producing high-quality digital impressions. This integration becomes increasingly complex as manufacturers strive for higher resolution and faster scanning speeds.

Durability and reliability of ULED components in the harsh oral environment remain ongoing concerns. Exposure to moisture, temperature fluctuations, and potential physical stress during use can impact the long-term performance and stability of ULED-based digital impression systems. Developing robust encapsulation and protection methods without compromising optical performance is a critical area of research.

Cost-effectiveness is another significant challenge in the adoption of ULED technology for digital impressions. While the potential benefits are substantial, the current manufacturing costs of high-quality ULED arrays can be prohibitive for widespread implementation in dental practices. Scaling up production and improving yield rates are necessary steps to make ULED-based systems more economically viable.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, optical engineering, thermal management, and manufacturing processes. As researchers and manufacturers continue to innovate, overcoming these hurdles will pave the way for next-generation digital impression systems that offer unprecedented accuracy, speed, and user experience in dental applications.

Existing ULED Solutions for Digital Impression

01 ULED structure and fabrication

Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices designed for high-efficiency light emission. Their structure typically includes specialized layers for improved performance, such as quantum wells or nanostructures. Fabrication techniques focus on enhancing light output and reducing power consumption, often involving novel materials and precise manufacturing processes.- ULED structure and fabrication: Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices designed for high-efficiency light emission. Their structure typically includes multiple layers of semiconductor materials, with specific doping profiles to enhance light output. Fabrication techniques may involve epitaxial growth processes and precise control of material composition to achieve desired optical and electrical properties.

- ULED applications in digital displays: ULEDs are increasingly used in digital display technologies, offering advantages such as high brightness, energy efficiency, and improved color gamut. These diodes can be integrated into various display formats, including micro-LED displays, providing enhanced image quality and potentially revolutionizing digital impression technologies in fields like advertising and information display.

- ULED driver circuits and control systems: Specialized driver circuits and control systems are crucial for optimal ULED performance. These systems manage power delivery, brightness control, and color mixing in ULED-based displays. Advanced control algorithms may be employed to ensure uniform brightness across large arrays of ULEDs and to implement dynamic content display capabilities.

- Thermal management in ULED systems: Effective thermal management is essential for ULED systems to maintain performance and longevity. This involves designing heat dissipation structures, using thermally conductive materials, and implementing temperature monitoring and control systems. Proper thermal management ensures consistent light output and prevents degradation of the ULED components over time.

- ULED packaging and integration techniques: Advanced packaging and integration techniques are employed to incorporate ULEDs into various devices and systems. This may include methods for miniaturization, array formation, and integration with other electronic components. Novel packaging approaches can enhance light extraction efficiency, improve reliability, and facilitate the creation of flexible or curved ULED-based displays.

02 Digital impression systems using ULED technology

ULED technology is being integrated into digital impression systems for dental and medical applications. These systems use ultra-bright, miniaturized LEDs to capture highly detailed 3D images of teeth or other body parts. The high intensity and precise control of ULED light sources enable improved accuracy and resolution in digital impressions compared to traditional methods.Expand Specific Solutions03 ULED display technology

ULED display technology represents an advancement in LED-based screens, offering superior brightness, contrast, and energy efficiency. These displays utilize ultra-small LEDs, often at the micrometer scale, to achieve high pixel density and improved image quality. The technology is being developed for various applications, including high-end televisions, smartphones, and automotive displays.Expand Specific Solutions04 Power management and control systems for ULEDs

Specialized power management and control systems are crucial for optimizing ULED performance. These systems focus on precise current regulation, thermal management, and intelligent dimming capabilities. Advanced driver circuits and control algorithms are developed to maintain consistent light output, extend lifespan, and improve overall efficiency of ULED devices across various applications.Expand Specific Solutions05 ULED applications in specific industries

ULEDs are finding applications in diverse industries beyond general lighting and displays. They are being utilized in automotive lighting, horticulture, medical devices, and machine vision systems. The high brightness, small form factor, and energy efficiency of ULEDs make them suitable for specialized applications requiring precise light control and durability.Expand Specific Solutions

Key Players in ULED Industry

The research on ULED solutions for next-level digital impression is in a rapidly evolving phase, with significant market potential. The industry is transitioning from early development to commercialization, driven by increasing demand for high-resolution displays. Major players like Samsung Electronics, LG Electronics, and BOE Technology are leading the charge, investing heavily in R&D to advance ULED technology. The market is expected to grow substantially as ULED solutions offer superior image quality and energy efficiency. While the technology is still maturing, companies such as Sony Group, Panasonic Holdings, and Sharp are making notable progress in enhancing ULED performance and scalability, indicating a competitive landscape with diverse technological approaches.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced ULED (Ultra LED) technology for next-level digital impressions. Their solution incorporates high-density mini-LED backlighting with precise local dimming control, achieving superior contrast ratios and HDR performance. BOE's ULED panels utilize quantum dot color conversion layers to enhance color gamut and accuracy. The company has also implemented AI-driven image processing algorithms to optimize picture quality in real-time, adapting to various content types and ambient lighting conditions.

Strengths: Industry-leading mini-LED manufacturing capabilities, advanced local dimming algorithms, and wide color gamut. Weaknesses: Higher production costs compared to traditional LCD, potential for screen uniformity issues in large panels.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung's ULED solution for next-level digital impression focuses on their Neo QLED technology. This approach combines mini-LED backlighting with their proprietary Quantum Matrix Technology and Neural Quantum Processor. The system uses thousands of densely packed LEDs for precise backlight control, while the quantum dot layer enhances color volume and brightness. Samsung's AI-powered processor analyzes content in real-time, optimizing picture quality on a scene-by-scene basis. Additionally, they have implemented anti-reflection and ultra-viewing angle technologies to improve visibility in various environments.

Strengths: Exceptional brightness and contrast capabilities, advanced AI-driven picture optimization, and wide viewing angles. Weaknesses: Premium pricing may limit market penetration, potential for blooming effects in high-contrast scenes.

Core ULED Innovations for Digital Impression

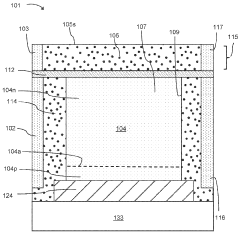

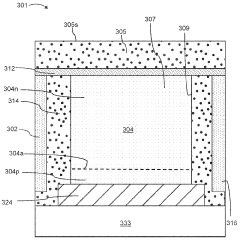

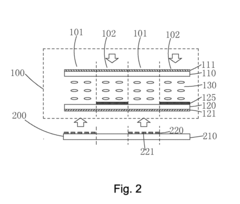

Optical layer for pixels of micro-light emitting diode (LED) devices

PatentWO2024129339A1

Innovation

- An optical layer comprising a dielectric material with reflective sidewalls is introduced on the emitting surface of microLED pixels, functioning as a lens or anti-reflective coating to enhance light directionality and extraction efficiency, while also eliminating cross-talk and maximizing brightness.

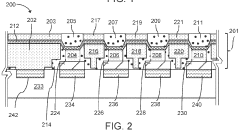

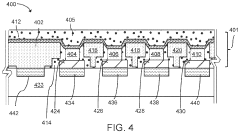

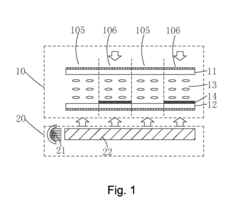

Transflective liquid crystal display

PatentInactiveUS20180307096A1

Innovation

- Incorporating micro light-emitting diode (uLED) arrays on the backlight substrate directly below the transmissive regions of the LCD panel, ensuring that light only propagates and emits from these areas, thereby reducing waste and improving light efficiency.

ULED Manufacturing Processes

The manufacturing processes for Ultra-Light Emitting Diodes (ULEDs) are critical to achieving the next level of digital impression technology. These processes involve a series of sophisticated steps that require precision engineering and advanced materials science.

The foundation of ULED manufacturing begins with the selection of high-quality semiconductor materials, typically gallium nitride (GaN) or indium gallium nitride (InGaN). These materials are chosen for their superior light-emitting properties and efficiency. The substrate, often sapphire or silicon carbide, is carefully prepared to ensure a clean and uniform surface for epitaxial growth.

Epitaxial growth is a key process in ULED manufacturing, where thin layers of semiconductor materials are deposited onto the substrate using techniques such as Metal-Organic Chemical Vapor Deposition (MOCVD). This process allows for precise control over the thickness and composition of the layers, which is crucial for optimizing the light emission characteristics of the ULED.

Following epitaxial growth, the wafer undergoes a series of photolithography and etching steps to define the individual ULED structures. Advanced lithography techniques, such as electron-beam lithography or nanoimprint lithography, are employed to achieve the ultra-fine features required for high-resolution digital displays.

The next stage involves the deposition of metal contacts and passivation layers. This is typically done using physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques. The metal contacts are crucial for current injection and must be designed to minimize resistance while maximizing light extraction.

A critical step in ULED manufacturing is the implementation of light extraction techniques. These may include surface texturing, the use of photonic crystals, or the integration of micro-lenses. These features are designed to increase the external quantum efficiency of the ULEDs by reducing total internal reflection and allowing more light to escape the device.

The final stages of ULED manufacturing involve packaging and integration. This includes dicing the wafer into individual chips, attaching these chips to a suitable substrate or driver circuitry, and encapsulating them to protect against environmental factors. Advanced packaging techniques, such as flip-chip bonding or wafer-level packaging, are often employed to optimize thermal management and electrical performance.

Throughout the manufacturing process, stringent quality control measures are implemented. This includes in-line monitoring of epitaxial growth, automated optical inspection of patterned wafers, and comprehensive testing of electrical and optical characteristics of the finished ULEDs. These measures ensure consistency and reliability in the final product, which is essential for high-performance digital impression systems.

The foundation of ULED manufacturing begins with the selection of high-quality semiconductor materials, typically gallium nitride (GaN) or indium gallium nitride (InGaN). These materials are chosen for their superior light-emitting properties and efficiency. The substrate, often sapphire or silicon carbide, is carefully prepared to ensure a clean and uniform surface for epitaxial growth.

Epitaxial growth is a key process in ULED manufacturing, where thin layers of semiconductor materials are deposited onto the substrate using techniques such as Metal-Organic Chemical Vapor Deposition (MOCVD). This process allows for precise control over the thickness and composition of the layers, which is crucial for optimizing the light emission characteristics of the ULED.

Following epitaxial growth, the wafer undergoes a series of photolithography and etching steps to define the individual ULED structures. Advanced lithography techniques, such as electron-beam lithography or nanoimprint lithography, are employed to achieve the ultra-fine features required for high-resolution digital displays.

The next stage involves the deposition of metal contacts and passivation layers. This is typically done using physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques. The metal contacts are crucial for current injection and must be designed to minimize resistance while maximizing light extraction.

A critical step in ULED manufacturing is the implementation of light extraction techniques. These may include surface texturing, the use of photonic crystals, or the integration of micro-lenses. These features are designed to increase the external quantum efficiency of the ULEDs by reducing total internal reflection and allowing more light to escape the device.

The final stages of ULED manufacturing involve packaging and integration. This includes dicing the wafer into individual chips, attaching these chips to a suitable substrate or driver circuitry, and encapsulating them to protect against environmental factors. Advanced packaging techniques, such as flip-chip bonding or wafer-level packaging, are often employed to optimize thermal management and electrical performance.

Throughout the manufacturing process, stringent quality control measures are implemented. This includes in-line monitoring of epitaxial growth, automated optical inspection of patterned wafers, and comprehensive testing of electrical and optical characteristics of the finished ULEDs. These measures ensure consistency and reliability in the final product, which is essential for high-performance digital impression systems.

ULED Integration in Dental Imaging Systems

The integration of Ultra-Light Emitting Diodes (ULEDs) in dental imaging systems represents a significant advancement in digital impression technology. ULEDs offer several advantages over traditional light sources, including higher energy efficiency, longer lifespan, and improved color accuracy. These characteristics make them particularly suitable for intraoral scanners and other dental imaging devices.

ULED technology allows for the miniaturization of light sources, enabling the development of more compact and ergonomic dental imaging tools. This is crucial in the confined space of the oral cavity, where maneuverability is often limited. The reduced size of ULED-based devices can improve patient comfort during scanning procedures and enhance the dentist's ability to capture accurate impressions of hard-to-reach areas.

The spectral output of ULEDs can be fine-tuned to optimize the capture of dental structures. By utilizing specific wavelengths, these systems can enhance the contrast between different oral tissues, leading to more precise digital impressions. This level of control over the light source contributes to improved detection of tooth margins, preparation lines, and soft tissue boundaries.

Furthermore, the integration of ULEDs in dental imaging systems allows for real-time adjustments in light intensity and color temperature. This adaptability is particularly beneficial when scanning different types of dental materials, such as natural teeth, various restorative materials, and soft tissues. The ability to dynamically modify the lighting conditions can result in more accurate color matching and surface detail capture across a wide range of clinical scenarios.

The low power consumption of ULEDs also addresses the thermal management challenges often associated with intraoral scanning devices. Reduced heat generation not only enhances patient comfort but also prolongs the operational time of battery-powered scanners. This improvement in energy efficiency can lead to more extended scanning sessions without the need for frequent battery changes or recharging.

As ULED technology continues to evolve, its integration into dental imaging systems is expected to drive further innovations in digital impression techniques. Future developments may include advanced multi-spectral imaging capabilities, enabling the simultaneous capture of both structural and material composition data. This could potentially revolutionize diagnostic procedures and treatment planning in dentistry, offering a more comprehensive view of oral health beyond traditional visual examination.

ULED technology allows for the miniaturization of light sources, enabling the development of more compact and ergonomic dental imaging tools. This is crucial in the confined space of the oral cavity, where maneuverability is often limited. The reduced size of ULED-based devices can improve patient comfort during scanning procedures and enhance the dentist's ability to capture accurate impressions of hard-to-reach areas.

The spectral output of ULEDs can be fine-tuned to optimize the capture of dental structures. By utilizing specific wavelengths, these systems can enhance the contrast between different oral tissues, leading to more precise digital impressions. This level of control over the light source contributes to improved detection of tooth margins, preparation lines, and soft tissue boundaries.

Furthermore, the integration of ULEDs in dental imaging systems allows for real-time adjustments in light intensity and color temperature. This adaptability is particularly beneficial when scanning different types of dental materials, such as natural teeth, various restorative materials, and soft tissues. The ability to dynamically modify the lighting conditions can result in more accurate color matching and surface detail capture across a wide range of clinical scenarios.

The low power consumption of ULEDs also addresses the thermal management challenges often associated with intraoral scanning devices. Reduced heat generation not only enhances patient comfort but also prolongs the operational time of battery-powered scanners. This improvement in energy efficiency can lead to more extended scanning sessions without the need for frequent battery changes or recharging.

As ULED technology continues to evolve, its integration into dental imaging systems is expected to drive further innovations in digital impression techniques. Future developments may include advanced multi-spectral imaging capabilities, enabling the simultaneous capture of both structural and material composition data. This could potentially revolutionize diagnostic procedures and treatment planning in dentistry, offering a more comprehensive view of oral health beyond traditional visual examination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!