ULED Showcasing Uncompromised Visual Fidelity

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Technology Evolution and Objectives

Ultra-LED (ULED) technology represents a significant leap forward in display technology, promising unparalleled visual fidelity and performance. The evolution of ULED can be traced back to the early 2010s when LED-backlit LCD displays began to dominate the market. However, ULED emerged as a distinct technology around 2015, aiming to address the limitations of traditional LED displays.

The primary objective of ULED technology is to deliver superior image quality with enhanced brightness, contrast, and color accuracy. This is achieved through a combination of advanced hardware and software innovations. ULED displays typically feature a higher number of local dimming zones, allowing for more precise control over backlighting and resulting in deeper blacks and brighter highlights.

As the technology progressed, manufacturers focused on improving color gamut coverage, with many ULED displays now capable of reproducing over 100% of the DCI-P3 color space. This wider color gamut enables more vibrant and lifelike images, particularly beneficial for HDR content. Another key development has been the increase in refresh rates, with some ULED displays now offering up to 240Hz, providing smoother motion and reduced motion blur.

The evolution of ULED has also seen advancements in panel design and manufacturing processes. Quantum dot technology has been integrated into many ULED displays, further enhancing color accuracy and brightness. Additionally, improvements in LED backlighting, such as Mini-LED and Micro-LED technologies, have allowed for even greater control over local dimming, pushing the boundaries of contrast ratios and black levels.

Looking forward, the objectives for ULED technology include further improvements in energy efficiency, as current high-performance displays can be power-hungry. Researchers are also working on increasing pixel density for larger screens, aiming to maintain visual fidelity at closer viewing distances. Another important goal is to reduce production costs, making high-end ULED displays more accessible to a broader consumer base.

The ultimate aim of ULED technology is to achieve perfect visual fidelity, replicating the human eye's capabilities in perceiving color, contrast, and motion. This involves ongoing research into areas such as per-pixel local dimming, advanced color management systems, and AI-driven image processing algorithms. As ULED continues to evolve, it is expected to play a crucial role in various applications beyond consumer electronics, including professional video production, medical imaging, and virtual reality displays.

The primary objective of ULED technology is to deliver superior image quality with enhanced brightness, contrast, and color accuracy. This is achieved through a combination of advanced hardware and software innovations. ULED displays typically feature a higher number of local dimming zones, allowing for more precise control over backlighting and resulting in deeper blacks and brighter highlights.

As the technology progressed, manufacturers focused on improving color gamut coverage, with many ULED displays now capable of reproducing over 100% of the DCI-P3 color space. This wider color gamut enables more vibrant and lifelike images, particularly beneficial for HDR content. Another key development has been the increase in refresh rates, with some ULED displays now offering up to 240Hz, providing smoother motion and reduced motion blur.

The evolution of ULED has also seen advancements in panel design and manufacturing processes. Quantum dot technology has been integrated into many ULED displays, further enhancing color accuracy and brightness. Additionally, improvements in LED backlighting, such as Mini-LED and Micro-LED technologies, have allowed for even greater control over local dimming, pushing the boundaries of contrast ratios and black levels.

Looking forward, the objectives for ULED technology include further improvements in energy efficiency, as current high-performance displays can be power-hungry. Researchers are also working on increasing pixel density for larger screens, aiming to maintain visual fidelity at closer viewing distances. Another important goal is to reduce production costs, making high-end ULED displays more accessible to a broader consumer base.

The ultimate aim of ULED technology is to achieve perfect visual fidelity, replicating the human eye's capabilities in perceiving color, contrast, and motion. This involves ongoing research into areas such as per-pixel local dimming, advanced color management systems, and AI-driven image processing algorithms. As ULED continues to evolve, it is expected to play a crucial role in various applications beyond consumer electronics, including professional video production, medical imaging, and virtual reality displays.

Market Demand for High-Fidelity Displays

The demand for high-fidelity displays has been steadily increasing across various sectors, driven by the growing need for immersive visual experiences and precise image reproduction. ULED (Ultra Light Emitting Diode) technology, with its promise of uncompromised visual fidelity, is poised to address this market demand effectively.

In the consumer electronics sector, there is a significant appetite for premium display technologies. High-end smartphones, tablets, and televisions are increasingly adopting advanced display technologies to differentiate themselves in a competitive market. Consumers are willing to pay a premium for devices that offer superior visual experiences, with crisp details, vibrant colors, and high contrast ratios.

The professional sector, including fields such as graphic design, video editing, and medical imaging, requires displays with exceptional color accuracy and image clarity. These industries demand displays that can faithfully reproduce colors and maintain image integrity across various lighting conditions. ULED technology's potential to deliver uncompromised visual fidelity makes it particularly attractive for these specialized applications.

The gaming industry is another significant driver of demand for high-fidelity displays. Gamers seek displays with high refresh rates, low latency, and excellent color reproduction to enhance their gaming experience. As gaming graphics become more sophisticated, the need for displays that can accurately render these complex visuals continues to grow.

In the automotive sector, there is an increasing trend towards larger, more advanced in-vehicle displays. As cars become more connected and autonomous, high-quality displays are essential for infotainment systems, driver assistance features, and augmented reality applications. ULED technology could potentially address the unique challenges of automotive displays, such as visibility in bright sunlight and durability in varying temperatures.

The digital signage and advertising industry also presents a substantial market opportunity for high-fidelity displays. Large format displays with exceptional visual quality can create more engaging and impactful advertising experiences, particularly in high-traffic areas like airports, shopping malls, and city centers.

As virtual and augmented reality technologies continue to evolve, the demand for high-fidelity displays in head-mounted devices is expected to surge. These applications require displays with high pixel density, wide color gamut, and minimal motion blur to create convincing and comfortable immersive experiences.

The market trend indicates a shift towards larger screen sizes across various applications, from home entertainment to commercial displays. This trend further emphasizes the need for display technologies that can maintain visual quality at larger scales, a challenge that ULED technology aims to address.

In the consumer electronics sector, there is a significant appetite for premium display technologies. High-end smartphones, tablets, and televisions are increasingly adopting advanced display technologies to differentiate themselves in a competitive market. Consumers are willing to pay a premium for devices that offer superior visual experiences, with crisp details, vibrant colors, and high contrast ratios.

The professional sector, including fields such as graphic design, video editing, and medical imaging, requires displays with exceptional color accuracy and image clarity. These industries demand displays that can faithfully reproduce colors and maintain image integrity across various lighting conditions. ULED technology's potential to deliver uncompromised visual fidelity makes it particularly attractive for these specialized applications.

The gaming industry is another significant driver of demand for high-fidelity displays. Gamers seek displays with high refresh rates, low latency, and excellent color reproduction to enhance their gaming experience. As gaming graphics become more sophisticated, the need for displays that can accurately render these complex visuals continues to grow.

In the automotive sector, there is an increasing trend towards larger, more advanced in-vehicle displays. As cars become more connected and autonomous, high-quality displays are essential for infotainment systems, driver assistance features, and augmented reality applications. ULED technology could potentially address the unique challenges of automotive displays, such as visibility in bright sunlight and durability in varying temperatures.

The digital signage and advertising industry also presents a substantial market opportunity for high-fidelity displays. Large format displays with exceptional visual quality can create more engaging and impactful advertising experiences, particularly in high-traffic areas like airports, shopping malls, and city centers.

As virtual and augmented reality technologies continue to evolve, the demand for high-fidelity displays in head-mounted devices is expected to surge. These applications require displays with high pixel density, wide color gamut, and minimal motion blur to create convincing and comfortable immersive experiences.

The market trend indicates a shift towards larger screen sizes across various applications, from home entertainment to commercial displays. This trend further emphasizes the need for display technologies that can maintain visual quality at larger scales, a challenge that ULED technology aims to address.

ULED Technical Challenges and Limitations

ULED (Ultra Light Emitting Diode) technology, while promising unparalleled visual fidelity, faces several significant technical challenges and limitations that hinder its widespread adoption and full potential realization.

One of the primary challenges lies in the manufacturing process of ULED displays. The production of ultra-small LED chips with consistent quality and performance is extremely complex and requires highly advanced fabrication techniques. The miniaturization of LEDs to micro or even nano-scale sizes introduces issues related to quantum effects and thermal management, which can affect the overall efficiency and lifespan of the display.

Color accuracy and uniformity present another major hurdle for ULED technology. As the size of individual LEDs decreases, maintaining precise color control becomes increasingly difficult. This challenge is particularly evident in achieving a wide color gamut and maintaining color consistency across the entire display, especially at different brightness levels.

Power efficiency remains a critical concern for ULED displays. While LEDs are generally known for their energy efficiency, the ultra-high pixel density of ULED displays can lead to increased power consumption. Balancing the need for high brightness and contrast with energy efficiency is a complex task that requires innovative power management solutions.

Heat dissipation is another significant technical limitation. The high density of LEDs in ULED displays generates substantial heat, which can affect both performance and longevity. Developing effective thermal management systems that can efficiently dissipate heat without compromising the display's slim profile is a major engineering challenge.

The yield rate in ULED production is currently a limiting factor for mass adoption. The intricate manufacturing process results in a higher percentage of defective units compared to traditional display technologies. This low yield rate significantly impacts production costs, making ULED displays prohibitively expensive for many applications.

Scaling up production to meet potential market demand presents its own set of challenges. The specialized equipment and expertise required for ULED manufacturing are not widely available, creating bottlenecks in the supply chain. Overcoming these production scaling issues is crucial for making ULED technology commercially viable on a large scale.

Lastly, the integration of ULED displays with existing display driver technologies and content delivery systems poses compatibility challenges. Developing new standards and protocols to fully leverage the capabilities of ULED displays while ensuring backward compatibility with current content and systems is a complex undertaking that requires industry-wide collaboration.

One of the primary challenges lies in the manufacturing process of ULED displays. The production of ultra-small LED chips with consistent quality and performance is extremely complex and requires highly advanced fabrication techniques. The miniaturization of LEDs to micro or even nano-scale sizes introduces issues related to quantum effects and thermal management, which can affect the overall efficiency and lifespan of the display.

Color accuracy and uniformity present another major hurdle for ULED technology. As the size of individual LEDs decreases, maintaining precise color control becomes increasingly difficult. This challenge is particularly evident in achieving a wide color gamut and maintaining color consistency across the entire display, especially at different brightness levels.

Power efficiency remains a critical concern for ULED displays. While LEDs are generally known for their energy efficiency, the ultra-high pixel density of ULED displays can lead to increased power consumption. Balancing the need for high brightness and contrast with energy efficiency is a complex task that requires innovative power management solutions.

Heat dissipation is another significant technical limitation. The high density of LEDs in ULED displays generates substantial heat, which can affect both performance and longevity. Developing effective thermal management systems that can efficiently dissipate heat without compromising the display's slim profile is a major engineering challenge.

The yield rate in ULED production is currently a limiting factor for mass adoption. The intricate manufacturing process results in a higher percentage of defective units compared to traditional display technologies. This low yield rate significantly impacts production costs, making ULED displays prohibitively expensive for many applications.

Scaling up production to meet potential market demand presents its own set of challenges. The specialized equipment and expertise required for ULED manufacturing are not widely available, creating bottlenecks in the supply chain. Overcoming these production scaling issues is crucial for making ULED technology commercially viable on a large scale.

Lastly, the integration of ULED displays with existing display driver technologies and content delivery systems poses compatibility challenges. Developing new standards and protocols to fully leverage the capabilities of ULED displays while ensuring backward compatibility with current content and systems is a complex undertaking that requires industry-wide collaboration.

Current ULED Display Solutions

01 ULED structure and manufacturing

Ultra Light Emitting Diodes (ULEDs) are advanced semiconductor devices designed for high-efficiency light emission. The manufacturing process involves specialized techniques to create ultra-thin layers and precise structures, enabling improved light output and energy efficiency. These innovations in ULED structure contribute to enhanced visual fidelity in display applications.- ULED structure and materials: Ultra Light Emitting Diodes (ULEDs) utilize advanced semiconductor materials and structures to achieve high visual fidelity. These devices often incorporate quantum wells, novel electrode designs, and specialized substrates to enhance light emission efficiency and color accuracy.

- Color rendering and spectrum optimization: ULED technology focuses on improving color rendering and spectrum optimization to achieve superior visual fidelity. This involves fine-tuning the emission wavelengths, implementing color conversion layers, and utilizing advanced phosphor materials to produce a wider and more accurate color gamut.

- Driving and control mechanisms: Advanced driving and control mechanisms are crucial for ULED visual fidelity. These include precise current control, temperature compensation, and intelligent dimming techniques to maintain consistent brightness and color accuracy across various operating conditions.

- Integration with display technologies: ULEDs are integrated into various display technologies to enhance visual fidelity. This includes incorporation into micro-LED displays, OLED hybrid systems, and advanced backlighting solutions for LCD panels, enabling higher contrast ratios, improved brightness, and better energy efficiency.

- Optical management and light extraction: Enhancing ULED visual fidelity involves advanced optical management and light extraction techniques. This includes the use of micro-lenses, photonic crystals, and specialized encapsulation materials to improve light output, reduce internal reflections, and achieve more uniform emission patterns.

02 Color rendering and spectrum optimization

ULEDs are engineered to produce a wide color gamut and accurate color reproduction. This is achieved through careful selection of materials and optimization of the emission spectrum. Advanced phosphor technologies and color conversion techniques are employed to enhance the visual fidelity of ULED displays, resulting in more vibrant and lifelike images.Expand Specific Solutions03 Driving and control mechanisms

Sophisticated driving and control mechanisms are crucial for maintaining high visual fidelity in ULED displays. These include advanced current control, pulse-width modulation techniques, and temperature compensation algorithms. Such mechanisms ensure stable and uniform light output across the display, contributing to improved image quality and reduced visual artifacts.Expand Specific Solutions04 Integration with display technologies

ULEDs are integrated into various display technologies to enhance visual fidelity. This includes incorporation into micro-LED displays, OLED-ULED hybrid systems, and advanced backlighting solutions for LCD panels. The integration focuses on maximizing the benefits of ULED technology, such as high brightness, wide color gamut, and energy efficiency, to improve overall display performance.Expand Specific Solutions05 Optical enhancements for improved visual fidelity

Various optical enhancements are applied to ULED systems to improve visual fidelity. These include micro-lens arrays, light-guiding structures, and anti-reflection coatings. Such optical elements help to increase light extraction efficiency, reduce glare, and improve viewing angles, all of which contribute to a higher quality visual experience in ULED-based displays.Expand Specific Solutions

Key Players in ULED Industry

The ULED (Ultra Light Emitting Diode) technology for uncompromised visual fidelity is in a rapidly evolving phase, with significant market potential in high-end display applications. The market is experiencing robust growth, driven by increasing demand for superior image quality in various sectors. While the technology is still maturing, several key players are making substantial advancements. Companies like BOE Technology Group, Samsung Display, and Lumileds LLC are at the forefront, investing heavily in R&D to enhance ULED performance. Other notable contributors include Appotronics Corp. Ltd. and Xiamen San'an Optoelectronics, focusing on innovative ULED solutions. The competitive landscape is characterized by a mix of established display manufacturers and specialized optoelectronics firms, all vying to achieve breakthroughs in ULED technology.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced ULED (Ultra LED) technology, which combines quantum dot technology with Mini-LED backlighting. This approach allows for precise control of local dimming zones, enhancing contrast ratios and color accuracy. BOE's ULED panels utilize a high-density array of Mini-LEDs as the backlight source, with each LED individually controllable. This enables thousands of local dimming zones, resulting in deeper blacks and brighter highlights. The quantum dot layer enhances color gamut, allowing for more vivid and accurate color reproduction. BOE has also implemented advanced algorithms for real-time adjustment of backlight intensity and color, ensuring optimal visual performance across various content types.

Strengths: Superior contrast ratios, wide color gamut, and high brightness capabilities. Weaknesses: Higher production costs compared to traditional LCD panels and potential for blooming effects in high-contrast scenes.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered QD-OLED (Quantum Dot OLED) technology, which combines the benefits of OLED and quantum dot technologies to achieve uncompromised visual fidelity. In this approach, blue OLED material is used as the light source, while red and green quantum dots convert some of the blue light to their respective colors. This results in pure RGB subpixels without the need for color filters, leading to improved color volume and brightness. Samsung's QD-OLED panels also incorporate advanced pixel structures and driving methods to minimize burn-in risks and enhance longevity. The company has implemented sophisticated color management algorithms to ensure accurate color reproduction across a wide range of content types.

Strengths: Exceptional color accuracy, perfect blacks, and wide viewing angles. Weaknesses: Potential for burn-in (though mitigated) and higher production costs compared to traditional OLED or LCD technologies.

Core ULED Innovations

UV-led and display

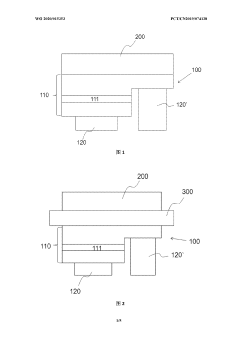

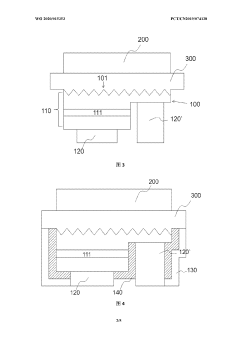

PatentActiveUS20200098832A1

Innovation

- A UV-LED with a quadrate planar shape and a patterned sapphire substrate, featuring a buffer layer, contact layer, and an InGaN light emitting layer, optimized for smaller chip sizes (50 μm or less) to enhance luminous efficiency and reduce power output decrease, incorporating a superlattice structure and specific layer compositions for improved emission recombination and extraction efficiency.

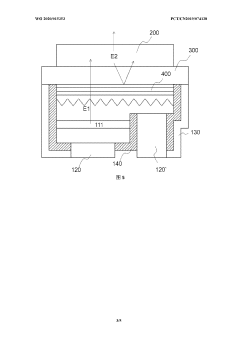

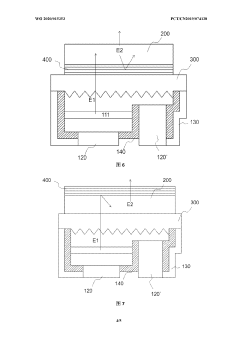

Micro light emitting device and display thereof

PatentWO2020015353A1

Innovation

- Using a micro-light-emitting diode structure with a transparent adhesive layer, the blue/green light is converted into red light through photon conversion technology, the AlInGaP-based quantum well layer is used to achieve efficient photon conversion, and anti-reflection and anti-reflection are set on the micro-light-emitting diode. The film layer and light reflective layer optimize the light emission efficiency.

ULED Manufacturing Processes

The manufacturing processes for ULED (Ultra Light Emitting Diode) technology are critical in achieving uncompromised visual fidelity. These processes involve a series of sophisticated steps that require precision engineering and advanced materials science.

The foundation of ULED manufacturing lies in the epitaxial growth of ultra-thin semiconductor layers. This process utilizes molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD) techniques to create atomically precise layers of materials such as gallium nitride (GaN) and indium gallium nitride (InGaN). The control of layer thickness and composition is paramount in determining the emission wavelength and efficiency of the resulting LEDs.

Following epitaxial growth, the wafer undergoes a series of photolithography and etching steps to define the individual LED structures. Advanced lithography techniques, including extreme ultraviolet (EUV) lithography, are employed to achieve the high resolution necessary for ULED devices. Plasma etching processes are then used to create the desired device architecture, with particular attention paid to minimizing surface damage that could impact light extraction efficiency.

The next crucial stage in ULED manufacturing is the deposition of transparent conductive oxides (TCOs) and metal contacts. Indium tin oxide (ITO) is commonly used as a TCO due to its excellent combination of transparency and conductivity. However, research into alternative materials such as graphene and silver nanowires is ongoing to further improve performance. The metal contacts are typically deposited using physical vapor deposition (PVD) techniques, with careful optimization of the contact geometry to ensure uniform current spreading.

Packaging is a critical aspect of ULED manufacturing that significantly impacts the device's overall performance and longevity. Advanced packaging techniques, such as chip-scale packaging (CSP) and wafer-level packaging (WLP), are employed to minimize the footprint of individual LEDs while maximizing light extraction. These packaging methods often incorporate specialized optical elements, such as micro-lenses or photonic crystals, to enhance light output and directionality.

Quality control and testing are integral parts of the ULED manufacturing process. Each device undergoes rigorous testing for parameters such as luminous efficacy, color rendering index (CRI), and thermal stability. Advanced imaging techniques, including hyperspectral imaging and near-field scanning optical microscopy (NSOM), are used to characterize the spatial and spectral properties of ULED emissions at the nanoscale.

Continuous improvement in manufacturing processes is driven by research into novel materials and fabrication techniques. For instance, the development of quantum dot LEDs (QLEDs) and micro-LED displays represents the cutting edge of ULED technology, promising even higher levels of visual fidelity and energy efficiency. These advancements require the integration of new materials and processes into existing manufacturing workflows, presenting both challenges and opportunities for innovation in the field of ULED production.

The foundation of ULED manufacturing lies in the epitaxial growth of ultra-thin semiconductor layers. This process utilizes molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD) techniques to create atomically precise layers of materials such as gallium nitride (GaN) and indium gallium nitride (InGaN). The control of layer thickness and composition is paramount in determining the emission wavelength and efficiency of the resulting LEDs.

Following epitaxial growth, the wafer undergoes a series of photolithography and etching steps to define the individual LED structures. Advanced lithography techniques, including extreme ultraviolet (EUV) lithography, are employed to achieve the high resolution necessary for ULED devices. Plasma etching processes are then used to create the desired device architecture, with particular attention paid to minimizing surface damage that could impact light extraction efficiency.

The next crucial stage in ULED manufacturing is the deposition of transparent conductive oxides (TCOs) and metal contacts. Indium tin oxide (ITO) is commonly used as a TCO due to its excellent combination of transparency and conductivity. However, research into alternative materials such as graphene and silver nanowires is ongoing to further improve performance. The metal contacts are typically deposited using physical vapor deposition (PVD) techniques, with careful optimization of the contact geometry to ensure uniform current spreading.

Packaging is a critical aspect of ULED manufacturing that significantly impacts the device's overall performance and longevity. Advanced packaging techniques, such as chip-scale packaging (CSP) and wafer-level packaging (WLP), are employed to minimize the footprint of individual LEDs while maximizing light extraction. These packaging methods often incorporate specialized optical elements, such as micro-lenses or photonic crystals, to enhance light output and directionality.

Quality control and testing are integral parts of the ULED manufacturing process. Each device undergoes rigorous testing for parameters such as luminous efficacy, color rendering index (CRI), and thermal stability. Advanced imaging techniques, including hyperspectral imaging and near-field scanning optical microscopy (NSOM), are used to characterize the spatial and spectral properties of ULED emissions at the nanoscale.

Continuous improvement in manufacturing processes is driven by research into novel materials and fabrication techniques. For instance, the development of quantum dot LEDs (QLEDs) and micro-LED displays represents the cutting edge of ULED technology, promising even higher levels of visual fidelity and energy efficiency. These advancements require the integration of new materials and processes into existing manufacturing workflows, presenting both challenges and opportunities for innovation in the field of ULED production.

Environmental Impact of ULED Technology

The environmental impact of ULED (Ultra Light Emitting Diode) technology is a crucial aspect to consider as this innovative display solution gains traction in the market. ULED technology, while offering uncompromised visual fidelity, also presents potential benefits and challenges in terms of its ecological footprint.

One of the primary environmental advantages of ULED technology is its energy efficiency. Compared to traditional LED and LCD displays, ULEDs consume significantly less power while delivering superior brightness and contrast. This reduced energy consumption translates to lower greenhouse gas emissions associated with electricity generation, contributing to a decrease in the overall carbon footprint of display devices.

The manufacturing process of ULED panels also demonstrates potential for reduced environmental impact. The production of ULEDs typically requires fewer materials and chemicals compared to conventional display technologies. This streamlined manufacturing process can lead to decreased waste generation and lower resource consumption, aligning with sustainable production practices.

However, the environmental impact of ULED technology extends beyond energy efficiency and manufacturing. The lifespan of ULED displays is a critical factor to consider. While ULEDs generally offer longer lifespans than traditional displays, the rapid pace of technological advancement may lead to premature obsolescence. This could potentially result in increased electronic waste if not properly managed through effective recycling and disposal programs.

The materials used in ULED production also warrant attention from an environmental perspective. While some components may be more eco-friendly, others might contain rare earth elements or potentially hazardous materials. Proper sourcing, handling, and end-of-life management of these materials are essential to mitigate any negative environmental impacts.

As ULED technology continues to evolve, there is a growing focus on developing more sustainable production methods and materials. Research into bio-based and recyclable components for ULED displays is underway, aiming to further reduce the environmental footprint of this technology. Additionally, advancements in circular economy principles are being applied to ULED manufacturing, with an emphasis on design for disassembly and recyclability.

The adoption of ULED technology may also indirectly impact the environment through changes in consumer behavior. The superior visual quality offered by ULEDs could potentially lead to increased screen time and higher energy consumption in households and businesses. However, this could be offset by the technology's energy efficiency and the potential for ULEDs to replace multiple display devices with a single, more versatile unit.

In conclusion, while ULED technology shows promise in terms of energy efficiency and potential for sustainable manufacturing, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. As the technology matures, ongoing research and development efforts focused on sustainability will be crucial in maximizing the environmental benefits of ULED displays.

One of the primary environmental advantages of ULED technology is its energy efficiency. Compared to traditional LED and LCD displays, ULEDs consume significantly less power while delivering superior brightness and contrast. This reduced energy consumption translates to lower greenhouse gas emissions associated with electricity generation, contributing to a decrease in the overall carbon footprint of display devices.

The manufacturing process of ULED panels also demonstrates potential for reduced environmental impact. The production of ULEDs typically requires fewer materials and chemicals compared to conventional display technologies. This streamlined manufacturing process can lead to decreased waste generation and lower resource consumption, aligning with sustainable production practices.

However, the environmental impact of ULED technology extends beyond energy efficiency and manufacturing. The lifespan of ULED displays is a critical factor to consider. While ULEDs generally offer longer lifespans than traditional displays, the rapid pace of technological advancement may lead to premature obsolescence. This could potentially result in increased electronic waste if not properly managed through effective recycling and disposal programs.

The materials used in ULED production also warrant attention from an environmental perspective. While some components may be more eco-friendly, others might contain rare earth elements or potentially hazardous materials. Proper sourcing, handling, and end-of-life management of these materials are essential to mitigate any negative environmental impacts.

As ULED technology continues to evolve, there is a growing focus on developing more sustainable production methods and materials. Research into bio-based and recyclable components for ULED displays is underway, aiming to further reduce the environmental footprint of this technology. Additionally, advancements in circular economy principles are being applied to ULED manufacturing, with an emphasis on design for disassembly and recyclability.

The adoption of ULED technology may also indirectly impact the environment through changes in consumer behavior. The superior visual quality offered by ULEDs could potentially lead to increased screen time and higher energy consumption in households and businesses. However, this could be offset by the technology's energy efficiency and the potential for ULEDs to replace multiple display devices with a single, more versatile unit.

In conclusion, while ULED technology shows promise in terms of energy efficiency and potential for sustainable manufacturing, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. As the technology matures, ongoing research and development efforts focused on sustainability will be crucial in maximizing the environmental benefits of ULED displays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!