How to Improve Phospholipid Purification Processes?

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phospholipid Purification Background and Objectives

Phospholipids are essential components of cell membranes and have numerous applications in pharmaceuticals, food, and cosmetics industries. The purification of phospholipids is a critical process that directly impacts the quality and efficacy of end products. Over the years, the field of phospholipid purification has evolved significantly, driven by the increasing demand for high-purity phospholipids in various sectors.

The history of phospholipid purification dates back to the early 20th century when rudimentary extraction methods were first developed. These initial techniques primarily relied on solvent extraction and precipitation, which were often inefficient and yielded low-purity products. As the understanding of phospholipid chemistry improved, more sophisticated purification methods emerged, including chromatography, supercritical fluid extraction, and membrane-based separations.

In recent decades, the focus has shifted towards developing more efficient, cost-effective, and environmentally friendly purification processes. This shift has been propelled by advancements in analytical techniques, such as high-performance liquid chromatography (HPLC) and mass spectrometry, which have enabled better characterization and quantification of phospholipids.

The current technological landscape in phospholipid purification is characterized by a blend of traditional and innovative approaches. While conventional methods like solvent extraction and column chromatography remain widely used, novel techniques such as supercritical CO2 extraction, ultrafiltration, and molecularly imprinted polymers are gaining traction due to their potential for higher selectivity and reduced environmental impact.

The primary objectives in improving phospholipid purification processes are multifaceted. Firstly, there is a pressing need to enhance the purity of isolated phospholipids, as even small impurities can significantly affect their functionality and stability. Secondly, increasing the yield of purification processes is crucial for improving economic viability, especially for large-scale production.

Another key objective is to develop more sustainable purification methods. This includes reducing solvent usage, minimizing waste generation, and lowering energy consumption. The industry is also striving to create more versatile purification techniques that can effectively handle diverse phospholipid sources, from natural extracts to synthetic mixtures.

Furthermore, there is a growing emphasis on developing scalable purification processes that can seamlessly transition from laboratory to industrial settings. This scalability is essential for meeting the increasing global demand for high-purity phospholipids across various industries.

As we look towards the future, the field of phospholipid purification is poised for significant advancements. Emerging technologies such as microfluidics, nanotechnology, and artificial intelligence-driven process optimization hold promise for revolutionizing purification methodologies. These innovations are expected to lead to more precise, efficient, and sustainable phospholipid purification processes, ultimately contributing to advancements in fields ranging from drug delivery systems to functional foods and beyond.

The history of phospholipid purification dates back to the early 20th century when rudimentary extraction methods were first developed. These initial techniques primarily relied on solvent extraction and precipitation, which were often inefficient and yielded low-purity products. As the understanding of phospholipid chemistry improved, more sophisticated purification methods emerged, including chromatography, supercritical fluid extraction, and membrane-based separations.

In recent decades, the focus has shifted towards developing more efficient, cost-effective, and environmentally friendly purification processes. This shift has been propelled by advancements in analytical techniques, such as high-performance liquid chromatography (HPLC) and mass spectrometry, which have enabled better characterization and quantification of phospholipids.

The current technological landscape in phospholipid purification is characterized by a blend of traditional and innovative approaches. While conventional methods like solvent extraction and column chromatography remain widely used, novel techniques such as supercritical CO2 extraction, ultrafiltration, and molecularly imprinted polymers are gaining traction due to their potential for higher selectivity and reduced environmental impact.

The primary objectives in improving phospholipid purification processes are multifaceted. Firstly, there is a pressing need to enhance the purity of isolated phospholipids, as even small impurities can significantly affect their functionality and stability. Secondly, increasing the yield of purification processes is crucial for improving economic viability, especially for large-scale production.

Another key objective is to develop more sustainable purification methods. This includes reducing solvent usage, minimizing waste generation, and lowering energy consumption. The industry is also striving to create more versatile purification techniques that can effectively handle diverse phospholipid sources, from natural extracts to synthetic mixtures.

Furthermore, there is a growing emphasis on developing scalable purification processes that can seamlessly transition from laboratory to industrial settings. This scalability is essential for meeting the increasing global demand for high-purity phospholipids across various industries.

As we look towards the future, the field of phospholipid purification is poised for significant advancements. Emerging technologies such as microfluidics, nanotechnology, and artificial intelligence-driven process optimization hold promise for revolutionizing purification methodologies. These innovations are expected to lead to more precise, efficient, and sustainable phospholipid purification processes, ultimately contributing to advancements in fields ranging from drug delivery systems to functional foods and beyond.

Market Analysis for Purified Phospholipids

The global market for purified phospholipids has been experiencing steady growth, driven by increasing demand from various industries, particularly pharmaceuticals, nutraceuticals, and cosmetics. The pharmaceutical sector remains the largest consumer of purified phospholipids, utilizing them in drug delivery systems, liposomal formulations, and as excipients in various medications. This sector's demand is expected to continue its upward trajectory due to the rising prevalence of chronic diseases and the growing emphasis on targeted drug delivery systems.

In the nutraceutical industry, purified phospholipids are gaining traction as functional ingredients in dietary supplements, especially those targeting cognitive health and liver function. The increasing consumer awareness of preventive healthcare and the trend towards natural ingredients have been key factors driving this segment's growth. The cosmetics industry has also shown a growing interest in purified phospholipids, incorporating them into skincare products for their moisturizing and anti-aging properties.

Geographically, North America and Europe currently dominate the market for purified phospholipids, owing to their advanced pharmaceutical and nutraceutical industries. However, the Asia-Pacific region is emerging as a significant market, with rapid growth projected in the coming years. This growth is attributed to the expanding pharmaceutical manufacturing sector in countries like India and China, coupled with increasing healthcare expenditure and rising consumer awareness about health supplements.

The market is characterized by a high degree of fragmentation, with several small to medium-sized players competing alongside a few large multinational corporations. Key market players are focusing on research and development to enhance the purity and functionality of phospholipids, aiming to cater to the specific requirements of different industries. Strategic collaborations and partnerships between phospholipid manufacturers and end-user industries are becoming increasingly common, driving innovation and market expansion.

Despite the positive outlook, the market faces challenges such as the high cost of purification processes and stringent regulatory requirements, particularly in the pharmaceutical sector. These factors can potentially hinder market growth and pose entry barriers for new players. However, ongoing technological advancements in purification techniques are expected to address some of these challenges, potentially reducing production costs and improving product quality in the long term.

In the nutraceutical industry, purified phospholipids are gaining traction as functional ingredients in dietary supplements, especially those targeting cognitive health and liver function. The increasing consumer awareness of preventive healthcare and the trend towards natural ingredients have been key factors driving this segment's growth. The cosmetics industry has also shown a growing interest in purified phospholipids, incorporating them into skincare products for their moisturizing and anti-aging properties.

Geographically, North America and Europe currently dominate the market for purified phospholipids, owing to their advanced pharmaceutical and nutraceutical industries. However, the Asia-Pacific region is emerging as a significant market, with rapid growth projected in the coming years. This growth is attributed to the expanding pharmaceutical manufacturing sector in countries like India and China, coupled with increasing healthcare expenditure and rising consumer awareness about health supplements.

The market is characterized by a high degree of fragmentation, with several small to medium-sized players competing alongside a few large multinational corporations. Key market players are focusing on research and development to enhance the purity and functionality of phospholipids, aiming to cater to the specific requirements of different industries. Strategic collaborations and partnerships between phospholipid manufacturers and end-user industries are becoming increasingly common, driving innovation and market expansion.

Despite the positive outlook, the market faces challenges such as the high cost of purification processes and stringent regulatory requirements, particularly in the pharmaceutical sector. These factors can potentially hinder market growth and pose entry barriers for new players. However, ongoing technological advancements in purification techniques are expected to address some of these challenges, potentially reducing production costs and improving product quality in the long term.

Current Challenges in Phospholipid Purification

Phospholipid purification processes face several significant challenges that hinder efficiency and yield. One of the primary issues is the complexity of lipid mixtures, which often contain various phospholipid species along with other lipids and contaminants. This heterogeneity makes it difficult to isolate specific phospholipids with high purity.

The current extraction methods, such as solvent extraction and chromatography, often struggle with selectivity. While these techniques can separate lipids from non-lipid components, achieving precise separation between different phospholipid classes remains problematic. This lack of selectivity leads to lower purity levels and increased processing times.

Another major challenge is the sensitivity of phospholipids to oxidation and degradation. Many phospholipids are unstable under standard purification conditions, which can lead to product loss and the formation of unwanted by-products. This instability necessitates careful handling and often requires the use of inert atmospheres or antioxidants, adding complexity and cost to the purification process.

Scale-up issues present a significant hurdle in industrial applications. Methods that work well at laboratory scale often face difficulties when translated to larger production volumes. This scaling challenge is particularly evident in chromatographic techniques, where increased column sizes can lead to reduced resolution and efficiency.

The use of organic solvents in many purification processes poses environmental and safety concerns. These solvents are often toxic, flammable, and difficult to dispose of safely. There is a growing need for more environmentally friendly purification methods that reduce or eliminate the use of harmful solvents.

Cost-effectiveness is another critical challenge. Current purification processes often require expensive equipment, high-purity solvents, and significant energy inputs. These factors contribute to the high cost of purified phospholipids, limiting their broader application in various industries.

Reproducibility and consistency in purification outcomes present ongoing challenges. Variations in raw material composition and process conditions can lead to inconsistent product quality, which is particularly problematic for applications requiring high purity and standardization, such as in pharmaceutical and nutraceutical industries.

Lastly, the development of novel purification technologies is hindered by the complex regulatory landscape, especially for applications in food and pharmaceuticals. New methods must undergo rigorous validation and approval processes, which can be time-consuming and costly, slowing down innovation in the field.

The current extraction methods, such as solvent extraction and chromatography, often struggle with selectivity. While these techniques can separate lipids from non-lipid components, achieving precise separation between different phospholipid classes remains problematic. This lack of selectivity leads to lower purity levels and increased processing times.

Another major challenge is the sensitivity of phospholipids to oxidation and degradation. Many phospholipids are unstable under standard purification conditions, which can lead to product loss and the formation of unwanted by-products. This instability necessitates careful handling and often requires the use of inert atmospheres or antioxidants, adding complexity and cost to the purification process.

Scale-up issues present a significant hurdle in industrial applications. Methods that work well at laboratory scale often face difficulties when translated to larger production volumes. This scaling challenge is particularly evident in chromatographic techniques, where increased column sizes can lead to reduced resolution and efficiency.

The use of organic solvents in many purification processes poses environmental and safety concerns. These solvents are often toxic, flammable, and difficult to dispose of safely. There is a growing need for more environmentally friendly purification methods that reduce or eliminate the use of harmful solvents.

Cost-effectiveness is another critical challenge. Current purification processes often require expensive equipment, high-purity solvents, and significant energy inputs. These factors contribute to the high cost of purified phospholipids, limiting their broader application in various industries.

Reproducibility and consistency in purification outcomes present ongoing challenges. Variations in raw material composition and process conditions can lead to inconsistent product quality, which is particularly problematic for applications requiring high purity and standardization, such as in pharmaceutical and nutraceutical industries.

Lastly, the development of novel purification technologies is hindered by the complex regulatory landscape, especially for applications in food and pharmaceuticals. New methods must undergo rigorous validation and approval processes, which can be time-consuming and costly, slowing down innovation in the field.

Existing Purification Methods

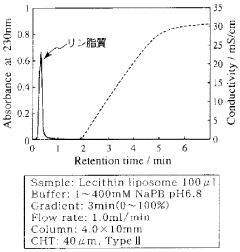

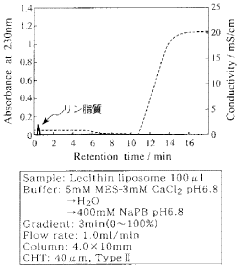

01 Chromatographic purification methods

Various chromatographic techniques are employed for phospholipid purification, including high-performance liquid chromatography (HPLC), thin-layer chromatography (TLC), and column chromatography. These methods separate phospholipids based on their polarity, size, or charge, allowing for efficient isolation and purification of specific phospholipid species.- Chromatographic purification methods: Various chromatographic techniques are employed for phospholipid purification, including column chromatography, high-performance liquid chromatography (HPLC), and thin-layer chromatography (TLC). These methods separate phospholipids based on their physical and chemical properties, allowing for high-purity isolation of specific phospholipid species.

- Solvent extraction and fractionation: Phospholipids can be purified using solvent extraction methods, often involving organic solvents like chloroform, methanol, or hexane. Fractionation techniques, such as cold acetone fractionation, are used to separate different phospholipid classes based on their solubility properties. These methods are effective for bulk purification of phospholipids from various sources.

- Membrane-based purification processes: Membrane technologies, including ultrafiltration and nanofiltration, are utilized for phospholipid purification. These processes can effectively separate phospholipids from other components based on molecular size and charge. Membrane-based methods are particularly useful for large-scale purification and can be combined with other techniques for enhanced purity.

- Enzymatic and chemical modification: Enzymatic treatments and chemical modifications are employed to enhance phospholipid purity or create specific phospholipid derivatives. These methods can involve the use of phospholipases, oxidizing agents, or other chemical reagents to selectively modify or remove unwanted components, resulting in purified phospholipid products with desired characteristics.

- Supercritical fluid extraction: Supercritical fluid extraction, particularly using supercritical carbon dioxide, is an emerging technique for phospholipid purification. This method offers advantages such as high selectivity, low environmental impact, and the ability to operate at relatively low temperatures. It is especially useful for extracting and purifying heat-sensitive phospholipids from various matrices.

02 Solvent extraction and fractionation

Phospholipids can be purified using solvent extraction methods, often involving organic solvents like chloroform, methanol, or hexane. Fractionation techniques, such as cold acetone fractionation or ethanol fractionation, are used to separate different phospholipid classes based on their solubility properties.Expand Specific Solutions03 Membrane-based purification processes

Membrane technologies, including ultrafiltration and nanofiltration, are utilized for phospholipid purification. These processes exploit differences in molecular size and charge to separate phospholipids from other components, allowing for the concentration and purification of specific phospholipid fractions.Expand Specific Solutions04 Enzymatic and chemical modification methods

Enzymatic treatments and chemical modifications are employed to enhance phospholipid purity or to create specific phospholipid derivatives. These methods may involve the use of phospholipases, oxidizing agents, or other chemical reagents to selectively modify or remove unwanted components, resulting in purified phospholipid products.Expand Specific Solutions05 Supercritical fluid extraction and purification

Supercritical fluid extraction, particularly using supercritical carbon dioxide, is an emerging technique for phospholipid purification. This method offers advantages such as low operating temperatures, absence of organic solvents, and high selectivity, making it suitable for obtaining high-purity phospholipids while maintaining their structural integrity.Expand Specific Solutions

Key Players in Phospholipid Industry

The phospholipid purification process market is in a growth phase, driven by increasing demand in pharmaceuticals, nutraceuticals, and food industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Asahi Kasei Pharma, Fidia Farmaceutici, and Neste Oyj leading innovations in purification techniques. These firms are developing more efficient and cost-effective methods, including chromatography and membrane-based technologies. However, the technology is not yet fully mature, with ongoing research focusing on improving yield, purity, and scalability of processes.

Neste Oyj

Technical Solution: Neste Oyj has developed a proprietary NEXBTL technology for producing renewable diesel, which includes a phospholipid purification step. Their process involves a combination of physical and chemical methods to remove phospholipids from vegetable oils and animal fats[4]. The company employs a multi-stage degumming process, utilizing enzymes to break down phospholipids, followed by centrifugation and membrane filtration[5]. Neste has also implemented a novel supercritical fluid extraction technique using CO2, which allows for efficient separation of phospholipids without the use of organic solvents[6]. This environmentally friendly approach aligns with their sustainability goals and reduces processing costs.

Strengths: Environmentally friendly processes, integration with biofuel production, and reduced solvent usage. Weaknesses: May be less applicable to small-scale or pharmaceutical-grade purification needs.

Waters Technology Corp.

Technical Solution: Waters Technology Corp. has developed advanced chromatography techniques for phospholipid purification. Their UPLC (Ultra Performance Liquid Chromatography) systems, coupled with mass spectrometry, offer high-resolution separation of phospholipids[1]. They utilize a combination of normal-phase and reversed-phase chromatography to achieve optimal separation. The company has also introduced novel column technologies, such as charged surface hybrid (CSH) particles, which enhance the separation of phospholipids based on their polar head groups[2]. Additionally, Waters has developed specialized software for lipid analysis, enabling automated identification and quantification of phospholipid species[3].

Strengths: High-resolution separation, versatile chromatography options, and advanced software integration. Weaknesses: High equipment costs and complexity may limit accessibility for smaller laboratories.

Innovative Purification Technologies

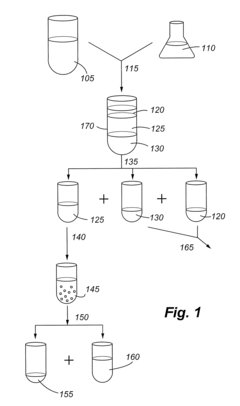

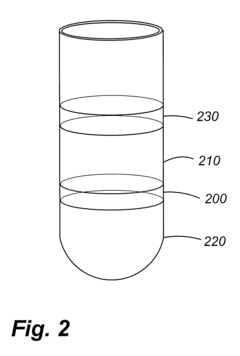

Method for the separation of phospholipids from phospholipid-containing materials

PatentInactiveUS20100145085A1

Innovation

- A process involving the use of a water-soluble aliphatic alcohol, such as propanol, at slightly elevated temperatures to form a true solution of phospholipids, which can then be cooled to precipitate out, allowing for easier separation through centrifugation or filtration, reducing the need for high solvent concentrations and drying steps.

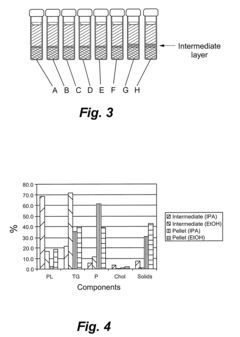

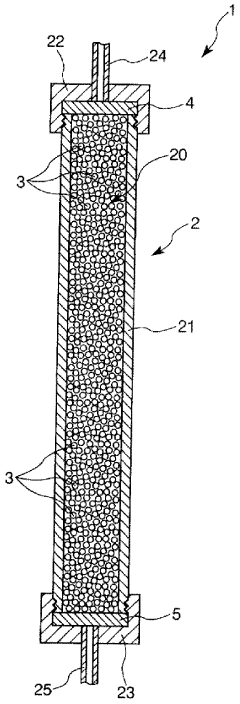

Method of separation

PatentWO2011037094A1

Innovation

- A method involving calcium ion adsorption onto a filler composed of a calcium phosphate-based compound, followed by supplying a sample liquid and an organic solvent-based eluate to selectively separate phospholipids, using a calcium-containing liquid like aqueous calcium chloride, and fractionating with isopropanol to achieve high purity and sensitivity in detection.

Environmental Impact Assessment

The environmental impact of phospholipid purification processes is a critical consideration in the development and implementation of these technologies. Traditional purification methods often involve the use of large volumes of organic solvents, which can pose significant environmental risks if not properly managed. These solvents, such as chloroform and methanol, are known to be toxic and potentially harmful to ecosystems if released into the environment.

Recent advancements in purification techniques have aimed to reduce the environmental footprint of these processes. Supercritical fluid extraction, for instance, utilizes carbon dioxide as a more environmentally friendly alternative to conventional organic solvents. This method not only minimizes the use of hazardous chemicals but also reduces energy consumption and waste generation.

Water consumption is another important environmental factor in phospholipid purification. Many processes require substantial amounts of water for extraction and washing steps. Implementing water recycling systems and optimizing process parameters can significantly reduce water usage, thereby minimizing the strain on local water resources.

The disposal of waste products from purification processes also presents environmental challenges. Spent solvents, filtration residues, and other by-products must be carefully managed to prevent contamination of soil and water sources. Developing more efficient purification methods that generate less waste is crucial for improving the overall environmental performance of these processes.

Energy consumption is a key contributor to the carbon footprint of phospholipid purification. High-pressure homogenization, centrifugation, and drying steps often require substantial energy inputs. Implementing energy-efficient equipment and exploring alternative technologies, such as membrane-based separations, can help reduce energy demands and associated greenhouse gas emissions.

Life cycle assessments (LCAs) of phospholipid purification processes have revealed opportunities for improvement in various stages of production. These assessments consider factors such as raw material sourcing, transportation, processing, and end-of-life disposal. By identifying hotspots of environmental impact, researchers and industry professionals can focus their efforts on developing more sustainable practices throughout the entire production chain.

Biodegradability of materials used in purification processes is another important consideration. Developing bio-based alternatives to synthetic materials used in filtration and chromatography can reduce the long-term environmental impact of these processes. Additionally, exploring the potential for valorization of by-products and waste streams can contribute to a more circular and sustainable approach to phospholipid production.

Recent advancements in purification techniques have aimed to reduce the environmental footprint of these processes. Supercritical fluid extraction, for instance, utilizes carbon dioxide as a more environmentally friendly alternative to conventional organic solvents. This method not only minimizes the use of hazardous chemicals but also reduces energy consumption and waste generation.

Water consumption is another important environmental factor in phospholipid purification. Many processes require substantial amounts of water for extraction and washing steps. Implementing water recycling systems and optimizing process parameters can significantly reduce water usage, thereby minimizing the strain on local water resources.

The disposal of waste products from purification processes also presents environmental challenges. Spent solvents, filtration residues, and other by-products must be carefully managed to prevent contamination of soil and water sources. Developing more efficient purification methods that generate less waste is crucial for improving the overall environmental performance of these processes.

Energy consumption is a key contributor to the carbon footprint of phospholipid purification. High-pressure homogenization, centrifugation, and drying steps often require substantial energy inputs. Implementing energy-efficient equipment and exploring alternative technologies, such as membrane-based separations, can help reduce energy demands and associated greenhouse gas emissions.

Life cycle assessments (LCAs) of phospholipid purification processes have revealed opportunities for improvement in various stages of production. These assessments consider factors such as raw material sourcing, transportation, processing, and end-of-life disposal. By identifying hotspots of environmental impact, researchers and industry professionals can focus their efforts on developing more sustainable practices throughout the entire production chain.

Biodegradability of materials used in purification processes is another important consideration. Developing bio-based alternatives to synthetic materials used in filtration and chromatography can reduce the long-term environmental impact of these processes. Additionally, exploring the potential for valorization of by-products and waste streams can contribute to a more circular and sustainable approach to phospholipid production.

Quality Control and Standardization

Quality control and standardization are crucial aspects of improving phospholipid purification processes. Establishing robust quality control measures ensures consistent product quality and compliance with regulatory requirements. Standardization of processes and methods across the industry facilitates comparability and reproducibility of results.

One key element of quality control in phospholipid purification is the implementation of analytical methods to assess purity and composition. High-performance liquid chromatography (HPLC) and mass spectrometry are widely used techniques for this purpose. These methods allow for the quantification of individual phospholipid species and the detection of impurities. Developing standardized protocols for sample preparation, analysis, and data interpretation is essential for reliable and comparable results across different laboratories and production facilities.

Spectroscopic techniques, such as nuclear magnetic resonance (NMR) and Fourier-transform infrared spectroscopy (FTIR), provide complementary information on phospholipid structure and purity. Standardizing the use of these techniques can enhance the overall quality control process and provide a more comprehensive assessment of the purified phospholipids.

The establishment of reference standards is another critical aspect of quality control and standardization. These standards serve as benchmarks for evaluating the purity and composition of phospholipid products. Collaborative efforts between industry, academia, and regulatory bodies are necessary to develop and validate widely accepted reference materials.

Process validation is an integral part of quality control in phospholipid purification. This involves systematically evaluating each step of the purification process to ensure consistency and reproducibility. Implementing in-process controls and monitoring critical process parameters can help identify and address potential issues before they affect the final product quality.

Standardization of equipment and instrumentation used in phospholipid purification is also essential. This includes calibration protocols, maintenance schedules, and performance qualification procedures. By ensuring that all equipment meets specified standards, variability in purification outcomes can be minimized.

The development and implementation of Good Manufacturing Practices (GMP) specific to phospholipid purification can further enhance quality control and standardization efforts. These guidelines should cover all aspects of the production process, from raw material sourcing to final product packaging and storage.

Continuous improvement initiatives, such as Six Sigma or Lean Manufacturing principles, can be applied to phospholipid purification processes. These methodologies focus on reducing variability and eliminating defects, ultimately leading to more consistent and higher-quality products.

One key element of quality control in phospholipid purification is the implementation of analytical methods to assess purity and composition. High-performance liquid chromatography (HPLC) and mass spectrometry are widely used techniques for this purpose. These methods allow for the quantification of individual phospholipid species and the detection of impurities. Developing standardized protocols for sample preparation, analysis, and data interpretation is essential for reliable and comparable results across different laboratories and production facilities.

Spectroscopic techniques, such as nuclear magnetic resonance (NMR) and Fourier-transform infrared spectroscopy (FTIR), provide complementary information on phospholipid structure and purity. Standardizing the use of these techniques can enhance the overall quality control process and provide a more comprehensive assessment of the purified phospholipids.

The establishment of reference standards is another critical aspect of quality control and standardization. These standards serve as benchmarks for evaluating the purity and composition of phospholipid products. Collaborative efforts between industry, academia, and regulatory bodies are necessary to develop and validate widely accepted reference materials.

Process validation is an integral part of quality control in phospholipid purification. This involves systematically evaluating each step of the purification process to ensure consistency and reproducibility. Implementing in-process controls and monitoring critical process parameters can help identify and address potential issues before they affect the final product quality.

Standardization of equipment and instrumentation used in phospholipid purification is also essential. This includes calibration protocols, maintenance schedules, and performance qualification procedures. By ensuring that all equipment meets specified standards, variability in purification outcomes can be minimized.

The development and implementation of Good Manufacturing Practices (GMP) specific to phospholipid purification can further enhance quality control and standardization efforts. These guidelines should cover all aspects of the production process, from raw material sourcing to final product packaging and storage.

Continuous improvement initiatives, such as Six Sigma or Lean Manufacturing principles, can be applied to phospholipid purification processes. These methodologies focus on reducing variability and eliminating defects, ultimately leading to more consistent and higher-quality products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!