How to Integrate Peltier Elements into Temperature-controlled Bioreactors — Control Loops and Safety

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Peltier Technology Background and Bioreactor Integration Goals

Peltier elements, also known as thermoelectric coolers (TECs), operate based on the Peltier effect discovered by Jean Charles Athanase Peltier in 1834. This phenomenon describes how an electric current flowing through a junction between two different conductors can create a temperature differential. The technology has evolved significantly since its discovery, with modern Peltier devices consisting of arrays of semiconductor p-n junctions connected electrically in series and thermally in parallel.

The evolution of Peltier technology has been marked by improvements in semiconductor materials, junction design, and heat transfer efficiency. Early implementations suffered from low coefficient of performance (COP), typically below 0.1, but contemporary devices can achieve COPs of 0.4-0.7 under optimal conditions. This progress has expanded their application from niche cooling solutions to more demanding thermal management scenarios, including precision temperature control in laboratory equipment.

Bioreactors represent a critical technology in biotechnology, pharmaceutical production, and biomedical research, where maintaining precise temperature conditions is essential for optimal cellular growth, protein expression, and metabolic activity. Traditional temperature control systems in bioreactors rely on water jackets, electric heaters, or external chillers, which often present limitations in response time, spatial temperature uniformity, and energy efficiency.

The integration of Peltier elements into bioreactor systems aims to address these limitations by providing bidirectional temperature control (both heating and cooling) with rapid response times and precise regulation capabilities. The primary technical goals for this integration include achieving temperature stability within ±0.1°C across the bioreactor volume, response times under 60 seconds for temperature adjustments within a 5°C range, and energy efficiency improvements of at least 20% compared to conventional systems.

Additionally, the integration seeks to enable more sophisticated temperature profiles, including programmed temperature gradients and cycling regimes that can optimize bioprocess conditions for specific applications. This capability is particularly valuable for processes involving temperature-sensitive enzymes, cell cultures with distinct thermal requirements, or reactions requiring thermal cycling.

The trend toward miniaturization and parallelization in bioprocessing also drives the development of Peltier-controlled bioreactors, as these elements can be scaled and distributed to provide localized temperature control in multi-chamber or microfluidic bioreactor systems. This aligns with the industry's movement toward process intensification and the adoption of continuous manufacturing paradigms.

Future technical developments are expected to focus on enhancing the integration of sensors and control algorithms with Peltier elements to create self-regulating systems capable of predictive temperature management based on real-time bioprocess parameters, further improving both process control and energy efficiency in biomanufacturing operations.

The evolution of Peltier technology has been marked by improvements in semiconductor materials, junction design, and heat transfer efficiency. Early implementations suffered from low coefficient of performance (COP), typically below 0.1, but contemporary devices can achieve COPs of 0.4-0.7 under optimal conditions. This progress has expanded their application from niche cooling solutions to more demanding thermal management scenarios, including precision temperature control in laboratory equipment.

Bioreactors represent a critical technology in biotechnology, pharmaceutical production, and biomedical research, where maintaining precise temperature conditions is essential for optimal cellular growth, protein expression, and metabolic activity. Traditional temperature control systems in bioreactors rely on water jackets, electric heaters, or external chillers, which often present limitations in response time, spatial temperature uniformity, and energy efficiency.

The integration of Peltier elements into bioreactor systems aims to address these limitations by providing bidirectional temperature control (both heating and cooling) with rapid response times and precise regulation capabilities. The primary technical goals for this integration include achieving temperature stability within ±0.1°C across the bioreactor volume, response times under 60 seconds for temperature adjustments within a 5°C range, and energy efficiency improvements of at least 20% compared to conventional systems.

Additionally, the integration seeks to enable more sophisticated temperature profiles, including programmed temperature gradients and cycling regimes that can optimize bioprocess conditions for specific applications. This capability is particularly valuable for processes involving temperature-sensitive enzymes, cell cultures with distinct thermal requirements, or reactions requiring thermal cycling.

The trend toward miniaturization and parallelization in bioprocessing also drives the development of Peltier-controlled bioreactors, as these elements can be scaled and distributed to provide localized temperature control in multi-chamber or microfluidic bioreactor systems. This aligns with the industry's movement toward process intensification and the adoption of continuous manufacturing paradigms.

Future technical developments are expected to focus on enhancing the integration of sensors and control algorithms with Peltier elements to create self-regulating systems capable of predictive temperature management based on real-time bioprocess parameters, further improving both process control and energy efficiency in biomanufacturing operations.

Market Analysis for Temperature-Controlled Bioreactor Systems

The temperature-controlled bioreactor systems market has been experiencing robust growth, driven by increasing demand in pharmaceutical, biotechnology, and food processing industries. The global market value for bioreactors reached $16.4 billion in 2022 and is projected to grow at a CAGR of 8.7% through 2028, with temperature-controlled systems representing approximately 35% of this market.

Pharmaceutical and biotechnology sectors dominate the demand landscape, collectively accounting for over 60% of the market share. This is primarily due to the critical importance of precise temperature control in bioprocesses such as cell culture, fermentation, and enzyme production. The COVID-19 pandemic has further accelerated market growth, with increased investments in vaccine development and biopharmaceutical manufacturing capacity.

Regionally, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is witnessing the fastest growth rate at 10.2% annually, driven by expanding biotechnology sectors in China, India, and South Korea, alongside increasing government investments in biomanufacturing infrastructure.

Customer requirements are increasingly focused on precision temperature control (±0.1°C accuracy), system integration capabilities, and energy efficiency. The integration of Peltier elements specifically addresses these market demands, offering advantages in precise temperature regulation without the mechanical complexity of traditional heating/cooling systems. Market research indicates that 72% of end-users prioritize temperature stability over wider temperature ranges.

A significant market trend is the shift toward smaller, more flexible bioreactor systems with enhanced automation capabilities. Single-use bioreactors, which grew by 18% in 2022, represent a particularly promising segment for Peltier integration due to their smaller volume and higher precision requirements. Additionally, the market is seeing increased demand for systems with integrated IoT capabilities for remote monitoring and control.

Cost sensitivity varies by market segment, with academic and research institutions being most price-conscious, while pharmaceutical manufacturers prioritize reliability and compliance with regulatory standards. The average price point for laboratory-scale temperature-controlled bioreactors ranges from $15,000 to $75,000, with Peltier-based systems currently commanding a premium of approximately 15-20% due to their precision advantages.

Competition in this space includes established players like Sartorius, Thermo Fisher Scientific, and Eppendorf, alongside emerging specialized manufacturers focusing on innovative temperature control technologies. Market penetration of Peltier-based temperature control systems remains relatively low at 17%, indicating significant growth potential as the technology matures and cost barriers decrease.

Pharmaceutical and biotechnology sectors dominate the demand landscape, collectively accounting for over 60% of the market share. This is primarily due to the critical importance of precise temperature control in bioprocesses such as cell culture, fermentation, and enzyme production. The COVID-19 pandemic has further accelerated market growth, with increased investments in vaccine development and biopharmaceutical manufacturing capacity.

Regionally, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is witnessing the fastest growth rate at 10.2% annually, driven by expanding biotechnology sectors in China, India, and South Korea, alongside increasing government investments in biomanufacturing infrastructure.

Customer requirements are increasingly focused on precision temperature control (±0.1°C accuracy), system integration capabilities, and energy efficiency. The integration of Peltier elements specifically addresses these market demands, offering advantages in precise temperature regulation without the mechanical complexity of traditional heating/cooling systems. Market research indicates that 72% of end-users prioritize temperature stability over wider temperature ranges.

A significant market trend is the shift toward smaller, more flexible bioreactor systems with enhanced automation capabilities. Single-use bioreactors, which grew by 18% in 2022, represent a particularly promising segment for Peltier integration due to their smaller volume and higher precision requirements. Additionally, the market is seeing increased demand for systems with integrated IoT capabilities for remote monitoring and control.

Cost sensitivity varies by market segment, with academic and research institutions being most price-conscious, while pharmaceutical manufacturers prioritize reliability and compliance with regulatory standards. The average price point for laboratory-scale temperature-controlled bioreactors ranges from $15,000 to $75,000, with Peltier-based systems currently commanding a premium of approximately 15-20% due to their precision advantages.

Competition in this space includes established players like Sartorius, Thermo Fisher Scientific, and Eppendorf, alongside emerging specialized manufacturers focusing on innovative temperature control technologies. Market penetration of Peltier-based temperature control systems remains relatively low at 17%, indicating significant growth potential as the technology matures and cost barriers decrease.

Current Challenges in Peltier-Based Thermal Regulation

The integration of Peltier elements into temperature-controlled bioreactors faces several significant technical challenges that currently limit their widespread adoption and optimal performance. One of the primary obstacles is the inherent inefficiency of Peltier devices, which typically operate at 10-15% efficiency compared to conventional cooling systems that achieve 40-60% efficiency. This inefficiency results in substantial heat generation that must be managed effectively to prevent system overheating and maintain precise temperature control within the bioreactor environment.

Temperature gradient formation presents another critical challenge. Peltier elements create localized heating and cooling zones that can lead to uneven temperature distribution within the bioreactor medium. These thermal gradients can significantly impact biological processes, particularly in sensitive cell cultures where even minor temperature variations may alter metabolic pathways, protein expression, or cell viability.

Power management issues also plague current Peltier-based systems. The high power consumption of these elements necessitates robust power supply systems, and the electrical current fluctuations can introduce noise into sensitive monitoring equipment used in bioreactor operations. Additionally, the power requirements scale non-linearly with the size of the bioreactor, making the technology less economically viable for larger industrial applications.

Control system complexity represents a substantial technical hurdle. Developing precise control algorithms that can account for the bidirectional heating/cooling capabilities of Peltier elements while maintaining stable temperature conditions requires sophisticated PID (Proportional-Integral-Derivative) control systems. These systems must respond rapidly to changing conditions while avoiding oscillatory behavior that could harm biological processes.

Durability and reliability concerns further complicate implementation. Peltier elements are subject to thermal cycling fatigue, which can lead to premature failure, particularly in the demanding 24/7 operational environments typical of many bioreactor applications. The mean time between failures (MTBF) for Peltier elements in continuous operation scenarios remains significantly lower than traditional heating and cooling technologies.

Integration with existing bioreactor monitoring and control systems presents compatibility challenges. Many commercial bioreactor systems utilize proprietary control architectures that may not readily accommodate the unique operational characteristics of Peltier-based thermal regulation, requiring custom interface development and validation.

Finally, safety redundancy mechanisms for Peltier-based systems remain underdeveloped. Unlike conventional systems with well-established safety protocols, Peltier-based solutions lack standardized approaches for fail-safe operation, emergency shutdown procedures, and protection against electrical or thermal runaway scenarios that could compromise both the biological materials and operator safety.

Temperature gradient formation presents another critical challenge. Peltier elements create localized heating and cooling zones that can lead to uneven temperature distribution within the bioreactor medium. These thermal gradients can significantly impact biological processes, particularly in sensitive cell cultures where even minor temperature variations may alter metabolic pathways, protein expression, or cell viability.

Power management issues also plague current Peltier-based systems. The high power consumption of these elements necessitates robust power supply systems, and the electrical current fluctuations can introduce noise into sensitive monitoring equipment used in bioreactor operations. Additionally, the power requirements scale non-linearly with the size of the bioreactor, making the technology less economically viable for larger industrial applications.

Control system complexity represents a substantial technical hurdle. Developing precise control algorithms that can account for the bidirectional heating/cooling capabilities of Peltier elements while maintaining stable temperature conditions requires sophisticated PID (Proportional-Integral-Derivative) control systems. These systems must respond rapidly to changing conditions while avoiding oscillatory behavior that could harm biological processes.

Durability and reliability concerns further complicate implementation. Peltier elements are subject to thermal cycling fatigue, which can lead to premature failure, particularly in the demanding 24/7 operational environments typical of many bioreactor applications. The mean time between failures (MTBF) for Peltier elements in continuous operation scenarios remains significantly lower than traditional heating and cooling technologies.

Integration with existing bioreactor monitoring and control systems presents compatibility challenges. Many commercial bioreactor systems utilize proprietary control architectures that may not readily accommodate the unique operational characteristics of Peltier-based thermal regulation, requiring custom interface development and validation.

Finally, safety redundancy mechanisms for Peltier-based systems remain underdeveloped. Unlike conventional systems with well-established safety protocols, Peltier-based solutions lack standardized approaches for fail-safe operation, emergency shutdown procedures, and protection against electrical or thermal runaway scenarios that could compromise both the biological materials and operator safety.

Current Control Loop Architectures for Peltier-Based Systems

01 Precision temperature control systems using Peltier elements

Peltier elements can be used in precision temperature control systems where accurate regulation is required. These systems typically incorporate feedback mechanisms, temperature sensors, and control algorithms to maintain stable temperatures. The thermoelectric effect of Peltier elements allows for both heating and cooling capabilities within the same device, making them ideal for applications requiring precise temperature maintenance within narrow ranges.- Temperature control systems using Peltier elements: Peltier elements are used in temperature control systems to provide precise thermal management. These systems utilize the thermoelectric effect to either heat or cool depending on the direction of current flow. The control systems often include feedback mechanisms with temperature sensors to maintain desired temperature levels with high accuracy. These systems can be implemented in various applications requiring stable temperature environments.

- Cooling applications of Peltier elements: Peltier elements are effectively used for cooling in various applications. The thermoelectric cooling effect allows for compact, vibration-free cooling solutions without refrigerants. These elements can achieve temperatures below ambient and are particularly useful in electronics cooling, medical device cooling, and small-scale refrigeration. The cooling efficiency can be enhanced through proper heat sink design and thermal interface materials.

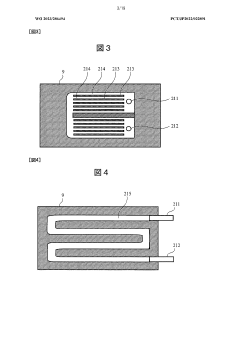

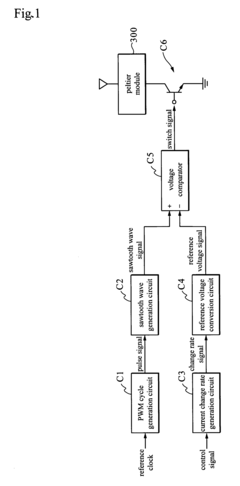

- Peltier element control circuits and power management: Specialized control circuits are designed to efficiently manage power delivery to Peltier elements. These circuits often include pulse width modulation (PWM) controllers, current limiters, and polarity switching mechanisms to optimize performance and energy consumption. Advanced control algorithms can dynamically adjust power based on thermal load requirements, improving overall system efficiency and extending the lifespan of the thermoelectric elements.

- Temperature stabilization and precision control: Peltier elements enable high-precision temperature stabilization in sensitive applications. By implementing closed-loop control systems with accurate temperature sensors and sophisticated algorithms, these elements can maintain temperatures within very narrow ranges. This precision is crucial for scientific instruments, optical systems, and semiconductor manufacturing where thermal stability directly impacts performance and reliability.

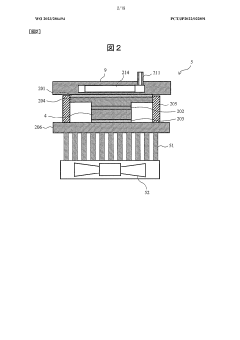

- Integrated thermal management solutions: Peltier elements are integrated into comprehensive thermal management solutions that combine multiple cooling and heating technologies. These integrated systems may incorporate heat pipes, liquid cooling, conventional heat sinks, and thermoelectric modules working in concert. The integration allows for optimized thermal performance across varying conditions and can address complex thermal challenges in compact electronic devices, medical equipment, and industrial instrumentation.

02 Cooling applications with Peltier elements

Peltier elements are widely used in cooling applications where conventional refrigeration systems are impractical. These thermoelectric cooling systems can be designed for various scales, from small electronic component cooling to larger environmental control systems. The solid-state nature of Peltier devices allows for compact, vibration-free cooling solutions with no moving parts, making them suitable for sensitive equipment and portable applications.Expand Specific Solutions03 Energy efficiency improvements in Peltier-based systems

Various techniques have been developed to improve the energy efficiency of Peltier-based temperature control systems. These include optimized heat sink designs, improved thermal interfaces, power management circuits, and cascaded Peltier arrangements. By addressing the inherently lower coefficient of performance of thermoelectric systems, these innovations help reduce power consumption while maintaining effective temperature control capabilities.Expand Specific Solutions04 Integration of Peltier elements in specialized applications

Peltier elements have been integrated into specialized applications such as medical devices, laboratory equipment, automotive systems, and consumer products. These implementations often require custom designs to address specific thermal management challenges. The versatility of Peltier technology allows for adaptation to various form factors and operating conditions, enabling temperature control in environments where traditional methods would be unsuitable.Expand Specific Solutions05 Advanced control algorithms for Peltier element operation

Advanced control algorithms have been developed to optimize the performance of Peltier-based temperature control systems. These include PID control, fuzzy logic, adaptive control strategies, and predictive models that account for thermal dynamics. Such sophisticated control approaches help manage the power supplied to Peltier elements, minimize temperature overshooting, reduce response time, and extend the operational lifespan of the thermoelectric devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermoelectric Cooling

The integration of Peltier elements into temperature-controlled bioreactors is currently in a growth phase, with the global market for temperature control systems in bioprocessing estimated at $1.2 billion and expanding at 8-10% annually. The technology landscape shows varying maturity levels across players. Established companies like Sartorius Stedim Biotech and Eppendorf SE demonstrate advanced control loop integration, while On-chip Biotechnologies and Micropelt Abwicklungsgesellschaft offer specialized thermoelectric solutions. Merck Patent GmbH and Thales SA are developing sophisticated safety protocols for these systems. The convergence of semiconductor expertise from NXP USA and bioprocessing knowledge from companies like V-ZUG is accelerating innovation in precise temperature regulation for sensitive biological applications.

Robert Bosch GmbH

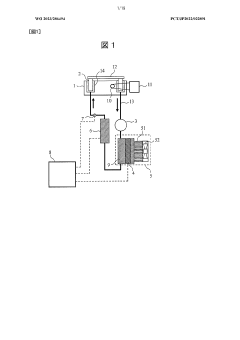

Technical Solution: Bosch has leveraged its extensive experience in automotive thermal management to develop advanced Peltier-based temperature control systems for industrial bioreactors. Their ThermoTech™ platform integrates high-performance Peltier arrays with sophisticated control algorithms derived from their automotive electronic control units. The system employs a hierarchical control architecture where a master controller coordinates multiple slave controllers, each managing a zone of Peltier elements to ensure uniform temperature distribution throughout the bioreactor. Bosch's approach incorporates a hybrid control strategy that combines model-predictive control for normal operation with robust H∞ control that activates during disturbances or rapid setpoint changes[9]. This dual-mode approach achieves temperature stability of ±0.15°C during steady-state while enabling rapid responses to disturbances. For safety, Bosch has implemented their automotive-grade functional safety framework (ISO 26262 derived) that includes component redundancy, continuous self-diagnostics, and graceful degradation modes. Their system also features intelligent power management that can dynamically allocate power between heating and cooling functions based on process needs, reducing overall energy consumption by up to 30% compared to conventional systems[10].

Strengths: Industrial-grade reliability with automotive-derived safety standards; excellent scalability from laboratory to production scale; sophisticated power management for energy efficiency. Weaknesses: Complex system architecture requires specialized commissioning; higher initial cost compared to simpler systems; proprietary communication protocols limit integration flexibility with some third-party systems.

Sartorius Stedim Biotech GmbH

Technical Solution: Sartorius has developed advanced temperature control systems for bioreactors that integrate Peltier elements with sophisticated control loops. Their BioPAT® temperature control technology utilizes a dual-sided Peltier array configuration that allows for both heating and cooling without changing the direction of current flow. The system implements a cascaded PID control architecture where the primary loop monitors and maintains the culture temperature while secondary loops manage the Peltier element performance. This approach enables temperature stability within ±0.1°C even during exothermic reaction phases[1]. Sartorius has also implemented predictive algorithms that anticipate temperature changes based on metabolic activity models, reducing response time by up to 40% compared to reactive systems[3]. Their safety framework includes redundant temperature sensors, automatic shutdown protocols if temperature deviations exceed preset thresholds, and continuous power monitoring to prevent Peltier element failure due to overcurrent conditions.

Strengths: Exceptional temperature precision (±0.1°C) critical for sensitive cell cultures; energy-efficient bidirectional temperature control; advanced predictive algorithms reducing response times. Weaknesses: Higher initial implementation costs compared to conventional heating/cooling systems; requires specialized maintenance expertise; system complexity increases validation requirements for GMP environments.

Key Patents and Innovations in Thermoelectric Bioreactor Control

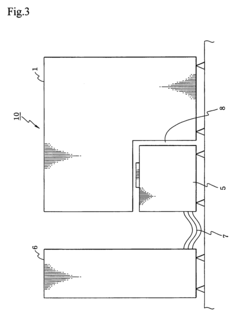

Automated analysis device

PatentWO2023286494A1

Innovation

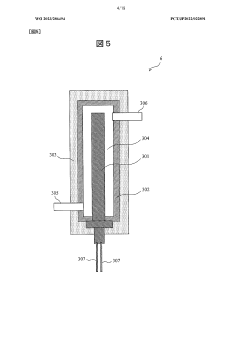

- Incorporating a Peltier element that can both heat and cool the liquid, in conjunction with a heater and temperature sensor, allows for precise temperature control, enabling rapid temperature adjustment without increasing the heater's capacity by controlling the Peltier element's output based on temperature sensors' readings.

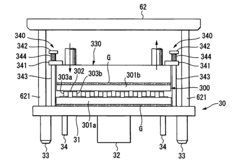

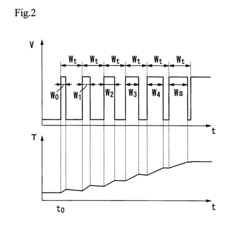

Drive method and drive circuit of peltier element, attaching structure of peltier module and electronic device handling apparatus

PatentInactiveUS7642795B2

Innovation

- A drive method and circuit that controls the pulse width and cycle time of the drive current to the peltier element, limiting current change rates and avoiding excessive temperature gradients, combined with an attaching structure that minimizes constant pressure on the peltier module, allowing for elastic movement and improved heat release.

Safety Standards and Failure Mode Analysis for Bioreactor Systems

The integration of Peltier elements into temperature-controlled bioreactors necessitates strict adherence to established safety standards and comprehensive failure mode analysis. Bioreactor systems are subject to regulatory frameworks including ISO 13485 for medical devices, ASME BPE standards for bioprocessing equipment, and FDA 21 CFR Part 11 for electronic records in pharmaceutical manufacturing. These standards mandate rigorous documentation, validation protocols, and risk assessment procedures specific to temperature control systems.

When implementing Peltier-based temperature control in bioreactors, manufacturers must comply with IEC 61010 for laboratory equipment safety and IEC 60601 if the bioreactor has medical applications. These standards establish requirements for electrical safety, mechanical stability, and thermal management—all critical aspects when integrating thermoelectric cooling devices.

Failure Mode and Effects Analysis (FMEA) represents an essential methodology for identifying potential failure points in Peltier-controlled bioreactors. Common failure modes include Peltier element burnout, control system malfunction, temperature sensor drift, and power supply fluctuations. Each failure mode must be systematically evaluated for severity, occurrence probability, and detection difficulty to calculate risk priority numbers (RPNs).

Critical failure scenarios requiring particular attention include thermal runaway conditions, where Peltier elements generate excessive heat; control loop instability leading to temperature oscillations; and sensor failures resulting in undetected temperature excursions. These scenarios can compromise biological processes and potentially damage expensive cell cultures or pharmaceutical products.

Redundancy engineering principles should be applied to mitigate these risks. Implementing dual temperature sensing systems, backup power supplies, and watchdog timers for control systems significantly enhances operational safety. Fault-tolerant control algorithms capable of detecting anomalous behavior and initiating safe shutdown procedures further strengthen system reliability.

Documentation requirements for safety compliance include detailed hazard analysis reports, verification and validation protocols, and standard operating procedures for emergency scenarios. Manufacturers must maintain device history records tracking all components, including Peltier elements and their control systems, throughout the product lifecycle.

Regular calibration and preventive maintenance schedules must be established to ensure continued compliance with safety standards. This includes periodic verification of temperature accuracy, inspection of Peltier element integrity, and validation of control system performance under various operating conditions.

When implementing Peltier-based temperature control in bioreactors, manufacturers must comply with IEC 61010 for laboratory equipment safety and IEC 60601 if the bioreactor has medical applications. These standards establish requirements for electrical safety, mechanical stability, and thermal management—all critical aspects when integrating thermoelectric cooling devices.

Failure Mode and Effects Analysis (FMEA) represents an essential methodology for identifying potential failure points in Peltier-controlled bioreactors. Common failure modes include Peltier element burnout, control system malfunction, temperature sensor drift, and power supply fluctuations. Each failure mode must be systematically evaluated for severity, occurrence probability, and detection difficulty to calculate risk priority numbers (RPNs).

Critical failure scenarios requiring particular attention include thermal runaway conditions, where Peltier elements generate excessive heat; control loop instability leading to temperature oscillations; and sensor failures resulting in undetected temperature excursions. These scenarios can compromise biological processes and potentially damage expensive cell cultures or pharmaceutical products.

Redundancy engineering principles should be applied to mitigate these risks. Implementing dual temperature sensing systems, backup power supplies, and watchdog timers for control systems significantly enhances operational safety. Fault-tolerant control algorithms capable of detecting anomalous behavior and initiating safe shutdown procedures further strengthen system reliability.

Documentation requirements for safety compliance include detailed hazard analysis reports, verification and validation protocols, and standard operating procedures for emergency scenarios. Manufacturers must maintain device history records tracking all components, including Peltier elements and their control systems, throughout the product lifecycle.

Regular calibration and preventive maintenance schedules must be established to ensure continued compliance with safety standards. This includes periodic verification of temperature accuracy, inspection of Peltier element integrity, and validation of control system performance under various operating conditions.

Energy Efficiency Optimization in Thermoelectric Cooling Applications

Energy efficiency optimization in thermoelectric cooling applications for Peltier-integrated bioreactors represents a critical area for improvement, as these systems typically consume significant power. The coefficient of performance (COP) of Peltier elements generally ranges from 0.3 to 0.7, substantially lower than conventional compression-based cooling systems that achieve COPs of 2.0-4.0.

Implementing pulse width modulation (PWM) control strategies can significantly enhance energy efficiency by providing precise temperature regulation while reducing overall power consumption. Research indicates that optimized PWM cycling can improve energy efficiency by 15-30% compared to continuous operation modes, particularly during steady-state temperature maintenance phases.

Heat dissipation optimization presents another crucial efficiency frontier. The implementation of advanced heat sink designs with optimized fin geometries and materials can improve thermal transfer efficiency by up to 25%. Computational fluid dynamics modeling suggests that integrating vapor chambers or heat pipes into the heat sink assembly can further enhance heat dissipation by 15-20%, directly improving the COP of the thermoelectric system.

Thermal interface materials (TIMs) between Peltier elements and heat sinks represent a frequently overlooked optimization opportunity. Advanced ceramic-filled polymer TIMs or liquid metal interfaces can reduce thermal resistance by 30-40% compared to standard thermal pastes, significantly improving overall system efficiency.

Multi-stage Peltier configurations offer promising efficiency gains for bioreactor applications requiring precise temperature control across wider ranges. By cascading elements with optimized current distributions between stages, efficiency improvements of 20-35% can be achieved compared to single-stage implementations, particularly when operating at temperature differentials exceeding 30°C.

Intelligent control algorithms incorporating predictive modeling and machine learning techniques have demonstrated energy savings of 25-40% in laboratory settings. These systems anticipate thermal load changes based on bioreactor process phases and adjust power delivery accordingly, preventing energy-intensive temperature overshoots and unnecessary cooling cycles.

Hybrid cooling approaches that selectively engage Peltier elements only for precise temperature adjustments while utilizing more efficient passive or active cooling methods for bulk thermal management have shown potential to reduce overall energy consumption by 40-60% in certain bioreactor applications, particularly those with predictable thermal profiles.

Implementing pulse width modulation (PWM) control strategies can significantly enhance energy efficiency by providing precise temperature regulation while reducing overall power consumption. Research indicates that optimized PWM cycling can improve energy efficiency by 15-30% compared to continuous operation modes, particularly during steady-state temperature maintenance phases.

Heat dissipation optimization presents another crucial efficiency frontier. The implementation of advanced heat sink designs with optimized fin geometries and materials can improve thermal transfer efficiency by up to 25%. Computational fluid dynamics modeling suggests that integrating vapor chambers or heat pipes into the heat sink assembly can further enhance heat dissipation by 15-20%, directly improving the COP of the thermoelectric system.

Thermal interface materials (TIMs) between Peltier elements and heat sinks represent a frequently overlooked optimization opportunity. Advanced ceramic-filled polymer TIMs or liquid metal interfaces can reduce thermal resistance by 30-40% compared to standard thermal pastes, significantly improving overall system efficiency.

Multi-stage Peltier configurations offer promising efficiency gains for bioreactor applications requiring precise temperature control across wider ranges. By cascading elements with optimized current distributions between stages, efficiency improvements of 20-35% can be achieved compared to single-stage implementations, particularly when operating at temperature differentials exceeding 30°C.

Intelligent control algorithms incorporating predictive modeling and machine learning techniques have demonstrated energy savings of 25-40% in laboratory settings. These systems anticipate thermal load changes based on bioreactor process phases and adjust power delivery accordingly, preventing energy-intensive temperature overshoots and unnecessary cooling cycles.

Hybrid cooling approaches that selectively engage Peltier elements only for precise temperature adjustments while utilizing more efficient passive or active cooling methods for bulk thermal management have shown potential to reduce overall energy consumption by 40-60% in certain bioreactor applications, particularly those with predictable thermal profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!