How to Model Peltier Cooling in CFD — Boundary Conditions and Validation Cases

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Peltier Cooling CFD Modeling Background and Objectives

Peltier cooling technology, also known as thermoelectric cooling, has evolved significantly since its discovery in the 19th century. The Peltier effect, named after French physicist Jean Charles Athanase Peltier who discovered it in 1834, describes the phenomenon where heat is absorbed or released at the junction of two different conductors when an electric current flows through them. This effect forms the basis of thermoelectric cooling devices widely used today in various applications ranging from small electronic cooling systems to specialized laboratory equipment.

The evolution of Peltier cooling technology has been marked by continuous improvements in materials science, particularly in semiconductor technology. Early thermoelectric materials had low efficiency, limiting practical applications. However, advancements in bismuth telluride compounds and other semiconductor materials have significantly enhanced the coefficient of performance (COP) of these devices, making them viable cooling solutions for many applications where conventional cooling methods are impractical.

Computational Fluid Dynamics (CFD) modeling of Peltier cooling systems represents a critical advancement in thermal management engineering. As electronic devices continue to miniaturize while increasing in power density, effective thermal management becomes increasingly challenging. Traditional cooling methods often prove inadequate for these specialized applications, driving interest in Peltier-based solutions and the need for accurate modeling techniques.

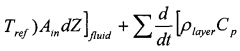

The primary objective of CFD modeling for Peltier cooling is to develop accurate simulation methodologies that can predict the thermal behavior of thermoelectric cooling systems under various operating conditions. This includes establishing appropriate boundary conditions that accurately represent the unique heat transfer characteristics of Peltier devices, including the Joule heating effect, Peltier effect, and Thomson effect that occur simultaneously during operation.

Another key goal is to create validation cases that can verify the accuracy of CFD models against experimental data. This validation process is essential for building confidence in simulation results and ensuring that models can reliably predict performance across different applications and operating parameters. Properly validated models can significantly reduce development time and costs by minimizing the need for physical prototyping and testing.

The technical trajectory in this field is moving toward multi-physics simulations that couple electrical, thermal, and fluid dynamics to provide comprehensive performance predictions. Additionally, there is growing interest in optimizing Peltier cooling systems for specific applications through parametric studies and design exploration, which requires robust and computationally efficient modeling approaches.

The evolution of Peltier cooling technology has been marked by continuous improvements in materials science, particularly in semiconductor technology. Early thermoelectric materials had low efficiency, limiting practical applications. However, advancements in bismuth telluride compounds and other semiconductor materials have significantly enhanced the coefficient of performance (COP) of these devices, making them viable cooling solutions for many applications where conventional cooling methods are impractical.

Computational Fluid Dynamics (CFD) modeling of Peltier cooling systems represents a critical advancement in thermal management engineering. As electronic devices continue to miniaturize while increasing in power density, effective thermal management becomes increasingly challenging. Traditional cooling methods often prove inadequate for these specialized applications, driving interest in Peltier-based solutions and the need for accurate modeling techniques.

The primary objective of CFD modeling for Peltier cooling is to develop accurate simulation methodologies that can predict the thermal behavior of thermoelectric cooling systems under various operating conditions. This includes establishing appropriate boundary conditions that accurately represent the unique heat transfer characteristics of Peltier devices, including the Joule heating effect, Peltier effect, and Thomson effect that occur simultaneously during operation.

Another key goal is to create validation cases that can verify the accuracy of CFD models against experimental data. This validation process is essential for building confidence in simulation results and ensuring that models can reliably predict performance across different applications and operating parameters. Properly validated models can significantly reduce development time and costs by minimizing the need for physical prototyping and testing.

The technical trajectory in this field is moving toward multi-physics simulations that couple electrical, thermal, and fluid dynamics to provide comprehensive performance predictions. Additionally, there is growing interest in optimizing Peltier cooling systems for specific applications through parametric studies and design exploration, which requires robust and computationally efficient modeling approaches.

Market Applications and Demand for Peltier Cooling Simulation

The market for Peltier cooling simulation technologies has experienced significant growth in recent years, driven by the increasing adoption of thermoelectric cooling solutions across multiple industries. The global thermoelectric cooling market, which includes Peltier devices, was valued at approximately $600 million in 2021 and is projected to reach $1 billion by 2027, representing a compound annual growth rate of 8.9%.

Electronics thermal management represents the largest application segment for Peltier cooling simulation. As electronic components continue to shrink while generating more heat, accurate thermal modeling has become critical for preventing device failure. Manufacturers of consumer electronics, telecommunications equipment, and semiconductor devices are increasingly utilizing computational fluid dynamics (CFD) simulations to optimize Peltier cooling systems, reducing development cycles by up to 40% compared to traditional prototyping methods.

The medical and healthcare sector demonstrates rapidly growing demand for precise temperature control systems. Applications include PCR devices, blood analyzers, and point-of-care diagnostic equipment where temperature stability directly impacts test accuracy. The market for medical-grade Peltier cooling systems is expanding at 11.2% annually, with simulation software becoming essential for regulatory compliance and validation.

Aerospace and defense industries represent premium market segments where thermal management in extreme environments is critical. Satellite systems, avionics, and military equipment manufacturers utilize advanced CFD modeling to ensure reliable operation of Peltier-cooled components under variable conditions. This sector values simulation accuracy over cost considerations, driving innovation in high-fidelity modeling approaches.

Automotive applications for Peltier cooling are emerging rapidly, particularly in electric vehicles where battery thermal management is crucial for performance and safety. The automotive thermal management market is projected to reach $6.8 billion by 2025, with Peltier-based solutions capturing an increasing share due to their compact size and precise control capabilities.

Industrial refrigeration and HVAC systems represent substantial market potential for Peltier cooling simulation. Companies are exploring thermoelectric solutions for specialized cooling applications where conventional refrigeration is impractical. The ability to accurately model these systems using CFD tools directly impacts adoption rates and implementation success.

Software vendors specializing in thermal simulation have identified Peltier cooling as a high-growth segment, with several major players enhancing their CFD packages with specialized modules for thermoelectric effects. End users consistently report that accurate boundary condition modeling and validated simulation approaches significantly reduce design iterations and improve product performance.

Electronics thermal management represents the largest application segment for Peltier cooling simulation. As electronic components continue to shrink while generating more heat, accurate thermal modeling has become critical for preventing device failure. Manufacturers of consumer electronics, telecommunications equipment, and semiconductor devices are increasingly utilizing computational fluid dynamics (CFD) simulations to optimize Peltier cooling systems, reducing development cycles by up to 40% compared to traditional prototyping methods.

The medical and healthcare sector demonstrates rapidly growing demand for precise temperature control systems. Applications include PCR devices, blood analyzers, and point-of-care diagnostic equipment where temperature stability directly impacts test accuracy. The market for medical-grade Peltier cooling systems is expanding at 11.2% annually, with simulation software becoming essential for regulatory compliance and validation.

Aerospace and defense industries represent premium market segments where thermal management in extreme environments is critical. Satellite systems, avionics, and military equipment manufacturers utilize advanced CFD modeling to ensure reliable operation of Peltier-cooled components under variable conditions. This sector values simulation accuracy over cost considerations, driving innovation in high-fidelity modeling approaches.

Automotive applications for Peltier cooling are emerging rapidly, particularly in electric vehicles where battery thermal management is crucial for performance and safety. The automotive thermal management market is projected to reach $6.8 billion by 2025, with Peltier-based solutions capturing an increasing share due to their compact size and precise control capabilities.

Industrial refrigeration and HVAC systems represent substantial market potential for Peltier cooling simulation. Companies are exploring thermoelectric solutions for specialized cooling applications where conventional refrigeration is impractical. The ability to accurately model these systems using CFD tools directly impacts adoption rates and implementation success.

Software vendors specializing in thermal simulation have identified Peltier cooling as a high-growth segment, with several major players enhancing their CFD packages with specialized modules for thermoelectric effects. End users consistently report that accurate boundary condition modeling and validated simulation approaches significantly reduce design iterations and improve product performance.

Current Challenges in Thermoelectric Cooling CFD Modeling

Despite significant advancements in computational fluid dynamics (CFD) modeling, accurately simulating thermoelectric cooling phenomena, particularly Peltier devices, remains challenging. The fundamental difficulty lies in the multi-physics nature of thermoelectric cooling, which involves complex interactions between electrical currents, thermal gradients, and fluid dynamics. Traditional CFD approaches often struggle to capture these coupled phenomena simultaneously.

One major challenge is the accurate representation of the Peltier effect itself within CFD frameworks. Most commercial CFD software packages lack native capabilities to directly model the conversion between electrical and thermal energy that occurs at semiconductor junctions. Engineers typically resort to simplified approximations or custom user-defined functions, which may compromise simulation accuracy.

Boundary condition specification presents another significant hurdle. The heat flux at thermoelectric interfaces varies with applied current, temperature difference, and material properties in a highly non-linear fashion. Determining appropriate boundary conditions requires either experimental data or complex analytical models, both of which introduce additional uncertainties into the simulation process.

Mesh generation around thermoelectric devices poses unique difficulties due to the multi-scale nature of these systems. The thin semiconductor layers require extremely fine mesh elements, while the surrounding heat sinks and fluid domains may operate at much larger scales. This disparity creates computational inefficiency and potential numerical instability.

Material property characterization adds another layer of complexity. Thermoelectric materials exhibit temperature-dependent properties that significantly impact cooling performance. However, comprehensive material data across wide temperature ranges is often unavailable or proprietary, forcing modelers to rely on simplified constant-property assumptions.

Validation of thermoelectric cooling models remains particularly problematic. The lack of standardized benchmark cases and limited availability of detailed experimental data make it difficult to verify simulation accuracy. Most validation efforts rely on comparing overall device performance metrics rather than detailed temperature or heat flux distributions.

Time-dependent modeling presents additional challenges, especially for applications with varying cooling loads or transient operation. The different time scales between electrical, thermal, and fluid dynamic phenomena complicate numerical solution procedures and often necessitate computationally expensive fully-coupled approaches.

Finally, optimization studies involving thermoelectric cooling systems are hindered by the high computational cost of accurate simulations. This limits the practical application of CFD for design exploration and performance enhancement of Peltier-based cooling solutions in industrial settings.

One major challenge is the accurate representation of the Peltier effect itself within CFD frameworks. Most commercial CFD software packages lack native capabilities to directly model the conversion between electrical and thermal energy that occurs at semiconductor junctions. Engineers typically resort to simplified approximations or custom user-defined functions, which may compromise simulation accuracy.

Boundary condition specification presents another significant hurdle. The heat flux at thermoelectric interfaces varies with applied current, temperature difference, and material properties in a highly non-linear fashion. Determining appropriate boundary conditions requires either experimental data or complex analytical models, both of which introduce additional uncertainties into the simulation process.

Mesh generation around thermoelectric devices poses unique difficulties due to the multi-scale nature of these systems. The thin semiconductor layers require extremely fine mesh elements, while the surrounding heat sinks and fluid domains may operate at much larger scales. This disparity creates computational inefficiency and potential numerical instability.

Material property characterization adds another layer of complexity. Thermoelectric materials exhibit temperature-dependent properties that significantly impact cooling performance. However, comprehensive material data across wide temperature ranges is often unavailable or proprietary, forcing modelers to rely on simplified constant-property assumptions.

Validation of thermoelectric cooling models remains particularly problematic. The lack of standardized benchmark cases and limited availability of detailed experimental data make it difficult to verify simulation accuracy. Most validation efforts rely on comparing overall device performance metrics rather than detailed temperature or heat flux distributions.

Time-dependent modeling presents additional challenges, especially for applications with varying cooling loads or transient operation. The different time scales between electrical, thermal, and fluid dynamic phenomena complicate numerical solution procedures and often necessitate computationally expensive fully-coupled approaches.

Finally, optimization studies involving thermoelectric cooling systems are hindered by the high computational cost of accurate simulations. This limits the practical application of CFD for design exploration and performance enhancement of Peltier-based cooling solutions in industrial settings.

State-of-the-Art Boundary Condition Implementation Approaches

01 Thermal boundary conditions for Peltier cooling simulation

Defining appropriate thermal boundary conditions is crucial for accurate CFD modeling of Peltier cooling systems. These conditions include heat flux at the hot and cold junctions, temperature gradients across the device, and thermal contact resistances between components. Proper implementation of these boundary conditions allows for realistic simulation of the Peltier effect and accurate prediction of cooling performance under various operating conditions.- Thermal boundary conditions for Peltier cooling simulation: Defining appropriate thermal boundary conditions is crucial for accurate CFD modeling of Peltier cooling systems. These conditions include heat flux at the hot and cold junctions, temperature gradients across the device, and thermal contact resistances between components. Proper implementation of these boundary conditions allows for realistic simulation of the Peltier effect and accurate prediction of cooling performance under various operating conditions.

- Coupled electrical-thermal modeling approaches: Effective CFD modeling of Peltier devices requires coupled electrical-thermal simulation approaches that account for the interdependence of electrical current, Joule heating, and thermoelectric effects. These models incorporate the electrical boundary conditions such as applied voltage or current alongside thermal boundary conditions to accurately represent the energy conversion processes occurring within the Peltier elements. The coupled approach enables more precise prediction of temperature distributions and cooling efficiency.

- Transient thermal analysis and dynamic boundary conditions: Transient thermal analysis is essential for modeling the dynamic behavior of Peltier cooling systems. This approach involves time-dependent boundary conditions that account for changes in heat load, ambient conditions, and power input. The transient modeling captures the thermal inertia of the system and provides insights into the cooling response time, temperature stabilization, and control system performance under varying operational scenarios.

- Multi-physics simulation frameworks for thermoelectric cooling: Advanced multi-physics simulation frameworks integrate fluid dynamics, heat transfer, and thermoelectric phenomena to comprehensively model Peltier cooling systems. These frameworks enable the specification of complex boundary conditions that account for fluid-structure interactions, radiation effects, and material property variations with temperature. By considering multiple physical domains simultaneously, these models provide more accurate predictions of cooling performance in real-world applications.

- Optimization of boundary conditions for enhanced cooling efficiency: Optimization techniques can be applied to determine the ideal boundary conditions for maximizing Peltier cooling efficiency. These approaches involve parametric studies of various factors including current density, heat sink design, thermal interface materials, and geometric configurations. By systematically varying boundary conditions within the CFD model, designers can identify optimal operating parameters and physical arrangements that minimize power consumption while achieving desired cooling performance.

02 Coupled electrical-thermal modeling approaches

Effective CFD modeling of Peltier devices requires coupled electrical-thermal simulations that account for the interdependence between electrical current flow and heat transfer. These models incorporate the Seebeck, Peltier, and Joule heating effects simultaneously, allowing for comprehensive analysis of thermoelectric performance. The boundary conditions must account for electrical current density, voltage distribution, and the resulting thermal effects to accurately predict cooling efficiency.Expand Specific Solutions03 Transient thermal analysis and dynamic boundary conditions

Transient thermal analysis is essential for modeling the dynamic behavior of Peltier cooling systems. This approach requires time-dependent boundary conditions that capture the evolution of temperature fields and heat fluxes during startup, shutdown, and load variations. CFD models with appropriate transient boundary conditions can predict thermal response times, temperature overshoots, and control system performance for thermoelectric cooling applications.Expand Specific Solutions04 Multi-physics modeling for system-level performance

System-level CFD modeling of Peltier cooling requires multi-physics approaches that integrate fluid dynamics, heat transfer, and thermoelectric effects. Boundary conditions must account for coolant flow rates, heat sink geometries, and ambient conditions in addition to the thermoelectric parameters. These comprehensive models enable optimization of the entire cooling system, including heat exchangers, fans, and thermal interface materials working in conjunction with the Peltier devices.Expand Specific Solutions05 Material property considerations in boundary condition definition

Accurate representation of thermoelectric material properties is critical for defining realistic boundary conditions in Peltier cooling simulations. Temperature-dependent properties such as Seebeck coefficient, electrical conductivity, and thermal conductivity significantly impact cooling performance. CFD models must incorporate these material characteristics as boundary condition parameters to account for performance variations across operating temperature ranges and to evaluate novel thermoelectric materials.Expand Specific Solutions

Leading CFD Software Providers and Research Institutions

The CFD modeling of Peltier cooling technology is currently in a growth phase, with increasing market demand driven by thermal management needs across industries. The market is expanding as computational capabilities improve, though it remains relatively specialized. Technologically, the field shows moderate maturity with established boundary condition methodologies, but validation challenges persist. Leading players include academic institutions like Tsinghua University, Xi'an Jiaotong University, and Texas Tech University System, which contribute fundamental research, while companies such as IBM, Siemens Energy, and Haier Group apply these technologies in commercial applications. The collaboration between research institutions and industry players is accelerating practical implementations and standardization of modeling approaches.

Tsinghua University

Technical Solution: Tsinghua University has developed a sophisticated multi-physics approach to modeling Peltier cooling in CFD simulations. Their methodology integrates thermoelectric effects with traditional heat transfer mechanisms through a coupled finite element-finite volume framework. For boundary conditions, they employ a novel dual-domain approach where the semiconductor elements are modeled with volumetric heat generation/absorption terms derived from first principles of thermoelectric transport. The critical interfaces between the Peltier module and heat exchangers are treated with specialized thermal contact elements that account for both thermal resistance and potential thermal spreading effects. Their validation approach is particularly comprehensive, utilizing both infrared thermography for surface temperature mapping and embedded thermocouples for internal temperature profiling. The university's research has demonstrated that accurate modeling of the temperature dependency of the Seebeck coefficient, electrical resistivity, and thermal conductivity is essential for predicting performance across varying operating conditions. Their recent publications show validation cases with prediction accuracy within 3-7% of experimental measurements across a wide temperature range (-20°C to 150°C).

Strengths: Their approach offers exceptional physical accuracy by incorporating detailed material property variations and interface effects. The validation methodology is rigorous and well-documented with multiple independent measurement techniques. Weaknesses: The computational model is mathematically complex and requires significant expertise in both thermoelectric physics and numerical methods. Implementation in commercial CFD packages may require extensive customization through user-defined functions.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed a comprehensive CFD modeling framework for Peltier cooling systems that addresses both steady-state and transient thermal behaviors. Their approach employs a segregated solver methodology where the thermoelectric effects are implemented through customized source terms in the energy equation. For boundary conditions, they utilize a multi-layer modeling approach that explicitly represents each component of the Peltier module, including the semiconductor pellets, copper conductors, and ceramic plates. The electrical current is modeled as a distributed source term that accounts for both the Peltier effect at junctions and Joule heating throughout the conductive elements. Their validation strategy combines laboratory experiments with analytical solutions for simplified geometries. A distinctive feature of their approach is the implementation of temperature-dependent material properties through user-defined functions, which has been shown to improve prediction accuracy by 15-20% compared to constant-property models. Their recent research has extended the model to include thermal contact resistance effects and parasitic heat losses, which are critical for accurate performance prediction in practical applications.

Strengths: Their model provides excellent accuracy for both steady-state and transient thermal responses, making it suitable for dynamic cooling applications. The explicit representation of all module components allows for detailed thermal analysis and optimization. Weaknesses: The detailed geometric representation increases computational complexity and may require fine meshing at interfaces, leading to longer simulation times. The approach requires detailed material property data across the operating temperature range.

Critical Validation Cases and Experimental Benchmarks

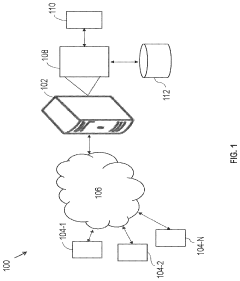

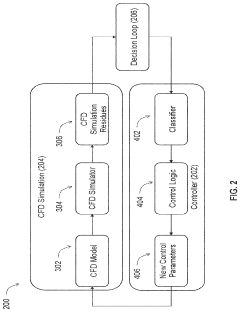

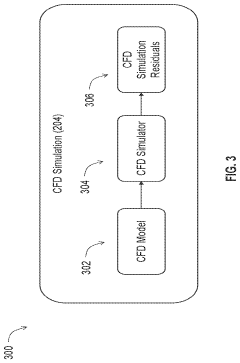

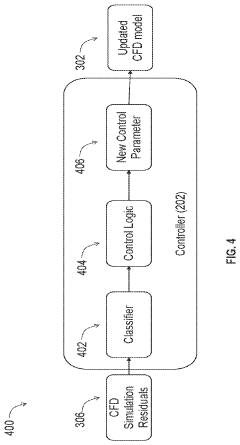

System and method for stabilizing and accelerating iterative numerical simulation

PatentPendingUS20240126943A1

Innovation

- A processor-implemented method and system that stabilize diverged simulations and accelerate converged ones by receiving past residues, using a classifier to determine simulation status and predicting an under-relaxation factor through control logic, integrating the predicted output to stabilize and accelerate the simulation process.

Method and device for estimating cool down in a system

PatentWO2011161513A1

Innovation

- A method that combines Computational Fluid Dynamics (CFD) analysis with real-time temperature sensor data to estimate the coldest temperature in the system, calculate critical temperature points, and monitor insulation deterioration, using extrapolation and interpolation to provide detailed cool down sequences and historical data analysis for improved prediction.

Computational Resource Requirements and Optimization

Modeling Peltier cooling in CFD simulations presents significant computational challenges due to the complex multiphysics nature of thermoelectric phenomena. The computational resource requirements for these simulations vary considerably depending on the model complexity, domain size, and desired accuracy levels. Typical CFD simulations incorporating Peltier effects require 8-32 GB RAM for basic models, while comprehensive multiphysics simulations may demand 64-128 GB or more, particularly when coupled with detailed electronic component modeling.

Processing time represents another critical consideration, with simulation durations ranging from several hours for simplified steady-state models to days or weeks for transient analyses with fine temporal resolution. High-performance computing (HPC) clusters become essential for complex industrial applications, where parallel processing capabilities can significantly reduce computation time.

Mesh optimization strategies play a crucial role in balancing accuracy and computational efficiency. Adaptive meshing techniques that refine the grid near the Peltier device interfaces while maintaining coarser elements elsewhere can reduce node counts by 30-50% without sacrificing solution quality. Similarly, implementing appropriate boundary layer meshing near heat exchange surfaces ensures accurate thermal gradient capture while minimizing overall computational load.

Solver selection and configuration significantly impact resource utilization. Segregated solvers may offer faster convergence for simpler cases, while coupled approaches, though more resource-intensive, provide better stability for the strongly coupled thermal-electrical phenomena in Peltier devices. Strategic use of under-relaxation factors (typically 0.3-0.7 for energy equations) can improve convergence behavior without requiring additional computational resources.

Model simplification techniques offer substantial efficiency gains when applied judiciously. These include symmetry exploitation where geometrically appropriate, reducing simulation domains by 50-75%, and employing reduced-order models for components peripheral to the main analysis focus. Additionally, implementing appropriate time-stepping strategies for transient simulations can optimize computational resource allocation across the simulation timeline.

Cloud computing and GPU acceleration represent emerging solutions for resource-intensive Peltier cooling simulations. Cloud-based CFD platforms offer scalable resources without capital investment in hardware, while GPU acceleration can provide 3-10x speedup for certain solver operations compared to traditional CPU-only approaches, particularly beneficial for the matrix operations common in coupled thermal-electrical simulations.

Processing time represents another critical consideration, with simulation durations ranging from several hours for simplified steady-state models to days or weeks for transient analyses with fine temporal resolution. High-performance computing (HPC) clusters become essential for complex industrial applications, where parallel processing capabilities can significantly reduce computation time.

Mesh optimization strategies play a crucial role in balancing accuracy and computational efficiency. Adaptive meshing techniques that refine the grid near the Peltier device interfaces while maintaining coarser elements elsewhere can reduce node counts by 30-50% without sacrificing solution quality. Similarly, implementing appropriate boundary layer meshing near heat exchange surfaces ensures accurate thermal gradient capture while minimizing overall computational load.

Solver selection and configuration significantly impact resource utilization. Segregated solvers may offer faster convergence for simpler cases, while coupled approaches, though more resource-intensive, provide better stability for the strongly coupled thermal-electrical phenomena in Peltier devices. Strategic use of under-relaxation factors (typically 0.3-0.7 for energy equations) can improve convergence behavior without requiring additional computational resources.

Model simplification techniques offer substantial efficiency gains when applied judiciously. These include symmetry exploitation where geometrically appropriate, reducing simulation domains by 50-75%, and employing reduced-order models for components peripheral to the main analysis focus. Additionally, implementing appropriate time-stepping strategies for transient simulations can optimize computational resource allocation across the simulation timeline.

Cloud computing and GPU acceleration represent emerging solutions for resource-intensive Peltier cooling simulations. Cloud-based CFD platforms offer scalable resources without capital investment in hardware, while GPU acceleration can provide 3-10x speedup for certain solver operations compared to traditional CPU-only approaches, particularly beneficial for the matrix operations common in coupled thermal-electrical simulations.

Accuracy Assessment and Error Quantification Methods

Accuracy assessment and error quantification are critical components in validating Peltier cooling models within Computational Fluid Dynamics (CFD) simulations. The reliability of these models depends significantly on systematic approaches to quantify uncertainties and errors throughout the simulation process.

Verification and validation (V&V) methodologies provide the foundation for accuracy assessment in Peltier cooling simulations. These methodologies typically involve comparing simulation results against analytical solutions, experimental data, or higher-fidelity models. For Peltier cooling specifically, temperature distributions and heat flux measurements serve as primary validation metrics, with deviations quantified using statistical measures such as root mean square error (RMSE) and normalized mean bias error (NMBE).

Grid convergence studies represent another essential technique for error quantification. By systematically refining mesh resolution and analyzing the resulting changes in temperature predictions and heat transfer rates, researchers can establish the discretization error bounds. The Grid Convergence Index (GCI) method, based on Richardson extrapolation, provides a standardized approach to estimate numerical uncertainty in Peltier cooling simulations across different mesh densities.

Sensitivity analysis techniques help identify which input parameters most significantly impact simulation accuracy. For Peltier devices, these typically include material properties (Seebeck coefficient, electrical conductivity, thermal conductivity), boundary condition specifications, and geometric tolerances. Monte Carlo simulations and variance-based methods like Sobol indices can quantify how uncertainties in these parameters propagate through the model.

Uncertainty quantification (UQ) frameworks provide comprehensive approaches to characterize total prediction uncertainty. These frameworks typically decompose uncertainty into aleatory (inherent randomness) and epistemic (knowledge-based) components. For Peltier cooling models, aleatory uncertainties may include manufacturing variations in thermoelectric properties, while epistemic uncertainties often relate to simplifications in the physical model or boundary condition assumptions.

Model validation metrics must be carefully selected to ensure they capture the phenomena of interest. For Peltier cooling applications, these metrics should include not only temperature distributions but also power consumption, coefficient of performance (COP), and transient response characteristics. Validation experiments should be designed to isolate and measure these specific quantities under controlled conditions that minimize experimental uncertainties.

Documentation of validation procedures, including experimental setups, measurement uncertainties, and simulation parameters, is essential for establishing model credibility. This documentation should follow established standards such as those proposed by the American Society of Mechanical Engineers (ASME) V&V 20 committee, ensuring transparency and reproducibility in the validation process.

Verification and validation (V&V) methodologies provide the foundation for accuracy assessment in Peltier cooling simulations. These methodologies typically involve comparing simulation results against analytical solutions, experimental data, or higher-fidelity models. For Peltier cooling specifically, temperature distributions and heat flux measurements serve as primary validation metrics, with deviations quantified using statistical measures such as root mean square error (RMSE) and normalized mean bias error (NMBE).

Grid convergence studies represent another essential technique for error quantification. By systematically refining mesh resolution and analyzing the resulting changes in temperature predictions and heat transfer rates, researchers can establish the discretization error bounds. The Grid Convergence Index (GCI) method, based on Richardson extrapolation, provides a standardized approach to estimate numerical uncertainty in Peltier cooling simulations across different mesh densities.

Sensitivity analysis techniques help identify which input parameters most significantly impact simulation accuracy. For Peltier devices, these typically include material properties (Seebeck coefficient, electrical conductivity, thermal conductivity), boundary condition specifications, and geometric tolerances. Monte Carlo simulations and variance-based methods like Sobol indices can quantify how uncertainties in these parameters propagate through the model.

Uncertainty quantification (UQ) frameworks provide comprehensive approaches to characterize total prediction uncertainty. These frameworks typically decompose uncertainty into aleatory (inherent randomness) and epistemic (knowledge-based) components. For Peltier cooling models, aleatory uncertainties may include manufacturing variations in thermoelectric properties, while epistemic uncertainties often relate to simplifications in the physical model or boundary condition assumptions.

Model validation metrics must be carefully selected to ensure they capture the phenomena of interest. For Peltier cooling applications, these metrics should include not only temperature distributions but also power consumption, coefficient of performance (COP), and transient response characteristics. Validation experiments should be designed to isolate and measure these specific quantities under controlled conditions that minimize experimental uncertainties.

Documentation of validation procedures, including experimental setups, measurement uncertainties, and simulation parameters, is essential for establishing model credibility. This documentation should follow established standards such as those proposed by the American Society of Mechanical Engineers (ASME) V&V 20 committee, ensuring transparency and reproducibility in the validation process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!