How to Use Thermoelectric Generators (TEG) and Peltier Pairs for Energy Harvesting — Metrics & Tests

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric Generators (TEGs) have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion of temperature differences into electrical voltage. This discovery laid the foundation for thermoelectric technology, which has since progressed through several developmental phases. Initially, TEGs were primarily used in niche applications such as space exploration, where radioisotope thermoelectric generators (RTGs) powered spacecraft like Voyager and Cassini, demonstrating their reliability in extreme conditions.

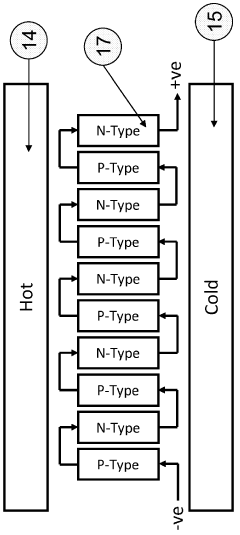

The evolution of TEG technology accelerated in the late 20th century with advancements in semiconductor materials and manufacturing techniques. Traditional bismuth telluride (Bi2Te3) based TEGs have been the industry standard for decades, offering moderate efficiency at low to medium temperatures. Recent developments have focused on improving the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency.

Current research trends are moving toward nano-structured materials, quantum dot super lattices, and skutterudites, which promise significantly higher ZT values and consequently better energy conversion efficiencies. These advanced materials aim to overcome the historical limitation of TEGs, namely their relatively low conversion efficiency compared to other energy harvesting technologies.

The primary objective of modern TEG technology is to efficiently harvest waste heat from various sources and convert it into usable electrical energy. This aligns with global sustainability goals by recovering energy that would otherwise be lost to the environment. Specific technical objectives include achieving higher power density, improving thermal-to-electrical conversion efficiency, reducing manufacturing costs, and enhancing operational reliability across varying temperature gradients.

In industrial settings, TEGs aim to capture waste heat from processes that operate at temperatures ranging from 100°C to over 1000°C. For consumer and IoT applications, the focus shifts to harvesting low-grade heat (typically below 100°C) efficiently enough to power small electronic devices or extend battery life. The automotive sector presents another significant opportunity, with objectives centered on converting exhaust heat into supplementary electrical power to improve fuel efficiency.

The metrics that define success in TEG development include conversion efficiency (typically 5-8% for commercial modules), power density (W/cm²), cost per watt, operational temperature range, and long-term stability. Testing methodologies focus on standardized measurement of these parameters under controlled conditions, allowing for meaningful comparison between different TEG technologies and implementations.

The evolution of TEG technology accelerated in the late 20th century with advancements in semiconductor materials and manufacturing techniques. Traditional bismuth telluride (Bi2Te3) based TEGs have been the industry standard for decades, offering moderate efficiency at low to medium temperatures. Recent developments have focused on improving the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency.

Current research trends are moving toward nano-structured materials, quantum dot super lattices, and skutterudites, which promise significantly higher ZT values and consequently better energy conversion efficiencies. These advanced materials aim to overcome the historical limitation of TEGs, namely their relatively low conversion efficiency compared to other energy harvesting technologies.

The primary objective of modern TEG technology is to efficiently harvest waste heat from various sources and convert it into usable electrical energy. This aligns with global sustainability goals by recovering energy that would otherwise be lost to the environment. Specific technical objectives include achieving higher power density, improving thermal-to-electrical conversion efficiency, reducing manufacturing costs, and enhancing operational reliability across varying temperature gradients.

In industrial settings, TEGs aim to capture waste heat from processes that operate at temperatures ranging from 100°C to over 1000°C. For consumer and IoT applications, the focus shifts to harvesting low-grade heat (typically below 100°C) efficiently enough to power small electronic devices or extend battery life. The automotive sector presents another significant opportunity, with objectives centered on converting exhaust heat into supplementary electrical power to improve fuel efficiency.

The metrics that define success in TEG development include conversion efficiency (typically 5-8% for commercial modules), power density (W/cm²), cost per watt, operational temperature range, and long-term stability. Testing methodologies focus on standardized measurement of these parameters under controlled conditions, allowing for meaningful comparison between different TEG technologies and implementations.

Market Analysis for Thermoelectric Energy Harvesting

The thermoelectric energy harvesting market is experiencing significant growth, driven by increasing demand for sustainable energy solutions and the proliferation of IoT devices requiring autonomous power sources. Current market valuations place the global thermoelectric generator market at approximately 460 million USD in 2022, with projections indicating growth to reach 720 million USD by 2028, representing a compound annual growth rate of 7.8%.

Key market segments for thermoelectric energy harvesting include industrial waste heat recovery, automotive applications, consumer electronics, aerospace, and remote sensing systems. The industrial sector currently dominates market share, utilizing TEGs to convert waste heat from manufacturing processes into usable electricity, thereby improving energy efficiency and reducing operational costs.

Automotive applications represent the fastest-growing segment, with TEGs being integrated into vehicle exhaust systems to harvest waste heat and improve fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have ongoing research programs exploring thermoelectric solutions to meet increasingly stringent emissions standards.

Consumer electronics manufacturers are increasingly exploring thermoelectric solutions for extending battery life in wearable devices and smartphones. This segment shows particular promise for micro-TEGs that can harvest body heat or ambient temperature differentials.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting green energy technologies.

Market challenges include relatively high initial costs compared to alternative energy harvesting technologies, with current TEG solutions averaging $20-30 per watt of generating capacity. Additionally, conversion efficiency limitations (typically 5-8% for commercial systems) remain a significant barrier to wider adoption.

Customer demand trends indicate growing interest in miniaturized, flexible TEG solutions for wearable applications, as well as higher-temperature operation capabilities for industrial applications. Market research suggests that achieving price points below $10 per watt and efficiency improvements to 10-12% would significantly accelerate market adoption.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with approximately 45% combined market share, alongside emerging startups focusing on novel materials and manufacturing techniques to improve performance metrics and reduce costs.

Key market segments for thermoelectric energy harvesting include industrial waste heat recovery, automotive applications, consumer electronics, aerospace, and remote sensing systems. The industrial sector currently dominates market share, utilizing TEGs to convert waste heat from manufacturing processes into usable electricity, thereby improving energy efficiency and reducing operational costs.

Automotive applications represent the fastest-growing segment, with TEGs being integrated into vehicle exhaust systems to harvest waste heat and improve fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have ongoing research programs exploring thermoelectric solutions to meet increasingly stringent emissions standards.

Consumer electronics manufacturers are increasingly exploring thermoelectric solutions for extending battery life in wearable devices and smartphones. This segment shows particular promise for micro-TEGs that can harvest body heat or ambient temperature differentials.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting green energy technologies.

Market challenges include relatively high initial costs compared to alternative energy harvesting technologies, with current TEG solutions averaging $20-30 per watt of generating capacity. Additionally, conversion efficiency limitations (typically 5-8% for commercial systems) remain a significant barrier to wider adoption.

Customer demand trends indicate growing interest in miniaturized, flexible TEG solutions for wearable applications, as well as higher-temperature operation capabilities for industrial applications. Market research suggests that achieving price points below $10 per watt and efficiency improvements to 10-12% would significantly accelerate market adoption.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with approximately 45% combined market share, alongside emerging startups focusing on novel materials and manufacturing techniques to improve performance metrics and reduce costs.

Current TEG Technology Status and Challenges

Thermoelectric Generators (TEGs) have evolved significantly over the past decades, yet their widespread adoption faces several technological barriers. Current commercial TEGs typically operate at efficiency levels between 5-8%, significantly lower than other energy conversion technologies. This efficiency limitation stems primarily from the inherent material properties that govern thermoelectric performance, specifically the figure of merit ZT, which for most commercial materials remains below 2.0 at operating temperatures.

The global TEG market is dominated by bismuth telluride (Bi2Te3) based devices for low to medium temperature applications (up to 250°C) and lead telluride (PbTe) for medium to high temperature ranges (250-600°C). However, these materials present sustainability challenges due to the scarcity and toxicity of tellurium and lead, respectively. Silicon-germanium (SiGe) alloys serve high-temperature applications (600-1000°C) but face cost constraints due to germanium's limited availability.

Manufacturing scalability represents another significant challenge. Current production methods for high-performance TEGs often involve complex processes including precision doping, nanomaterial synthesis, and specialized assembly techniques that are difficult to scale economically. This results in high production costs, with prices ranging from $5-20 per watt of generating capacity, making TEGs less competitive against alternative energy harvesting technologies.

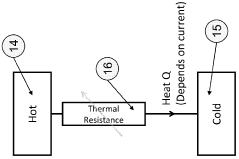

Thermal management presents a persistent engineering challenge in TEG implementation. Effective heat transfer across the hot and cold sides of the device is critical for performance, yet achieving optimal thermal interfaces while minimizing parasitic heat losses remains problematic in real-world applications. This is particularly evident in low-grade waste heat recovery scenarios where temperature differentials are modest.

Geographical distribution of TEG technology development shows concentration in North America, East Asia (particularly Japan, South Korea, and China), and Western Europe. The United States leads in fundamental research through institutions like NASA and Department of Energy laboratories, while Japan and Germany demonstrate strength in industrial applications. China has emerged as a significant player in manufacturing capacity, though often with lower-efficiency devices.

Durability and reliability under thermal cycling conditions continue to challenge widespread adoption. Coefficient of thermal expansion mismatches between different materials in TEG assemblies can lead to mechanical stress, contact degradation, and ultimately performance deterioration over time. Current commercial TEGs typically demonstrate performance degradation of 5-15% after 10,000 hours of operation under thermal cycling conditions.

Integration challenges persist when incorporating TEGs into existing systems, particularly regarding form factor limitations, electrical output characteristics requiring power conditioning, and the need for application-specific thermal interface solutions. These factors collectively constrain the practical implementation of TEG technology despite its theoretical promise for energy harvesting applications.

The global TEG market is dominated by bismuth telluride (Bi2Te3) based devices for low to medium temperature applications (up to 250°C) and lead telluride (PbTe) for medium to high temperature ranges (250-600°C). However, these materials present sustainability challenges due to the scarcity and toxicity of tellurium and lead, respectively. Silicon-germanium (SiGe) alloys serve high-temperature applications (600-1000°C) but face cost constraints due to germanium's limited availability.

Manufacturing scalability represents another significant challenge. Current production methods for high-performance TEGs often involve complex processes including precision doping, nanomaterial synthesis, and specialized assembly techniques that are difficult to scale economically. This results in high production costs, with prices ranging from $5-20 per watt of generating capacity, making TEGs less competitive against alternative energy harvesting technologies.

Thermal management presents a persistent engineering challenge in TEG implementation. Effective heat transfer across the hot and cold sides of the device is critical for performance, yet achieving optimal thermal interfaces while minimizing parasitic heat losses remains problematic in real-world applications. This is particularly evident in low-grade waste heat recovery scenarios where temperature differentials are modest.

Geographical distribution of TEG technology development shows concentration in North America, East Asia (particularly Japan, South Korea, and China), and Western Europe. The United States leads in fundamental research through institutions like NASA and Department of Energy laboratories, while Japan and Germany demonstrate strength in industrial applications. China has emerged as a significant player in manufacturing capacity, though often with lower-efficiency devices.

Durability and reliability under thermal cycling conditions continue to challenge widespread adoption. Coefficient of thermal expansion mismatches between different materials in TEG assemblies can lead to mechanical stress, contact degradation, and ultimately performance deterioration over time. Current commercial TEGs typically demonstrate performance degradation of 5-15% after 10,000 hours of operation under thermal cycling conditions.

Integration challenges persist when incorporating TEGs into existing systems, particularly regarding form factor limitations, electrical output characteristics requiring power conditioning, and the need for application-specific thermal interface solutions. These factors collectively constrain the practical implementation of TEG technology despite its theoretical promise for energy harvesting applications.

Current TEG Implementation Solutions

01 Efficiency metrics and performance optimization of TEGs

Thermoelectric generators (TEGs) can be evaluated using various efficiency metrics to optimize their performance. These metrics include conversion efficiency, power density, and figure of merit (ZT). By improving these parameters through material selection and device design, the overall energy harvesting capability of TEGs can be enhanced. Optimization techniques focus on maximizing the temperature gradient across the device and minimizing thermal resistance to achieve higher power output.- Efficiency metrics and performance optimization of TEGs: Thermoelectric generators (TEGs) can be evaluated using various efficiency metrics to optimize their energy harvesting capabilities. These metrics include conversion efficiency, power density, and figure of merit (ZT). By improving the thermal conductivity and electrical properties of the materials used, the overall performance of TEGs can be enhanced. Advanced designs focus on maximizing the temperature gradient across the device while minimizing thermal losses to achieve higher power output and efficiency.

- Material innovations for thermoelectric applications: Novel materials are being developed to enhance the performance of thermoelectric devices. These include nanostructured materials, semiconductor alloys, and composite materials that exhibit improved Seebeck coefficients and reduced thermal conductivity. Material innovations focus on increasing the figure of merit (ZT) through band engineering, phonon scattering, and carrier concentration optimization. These advancements lead to more efficient energy harvesting from waste heat and temperature differentials in various applications.

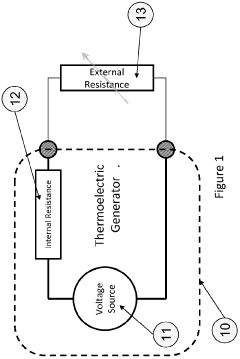

- Energy harvesting systems integration and applications: Thermoelectric generators can be integrated into various systems to harvest waste heat and convert it into usable electrical energy. Applications include wearable devices, industrial waste heat recovery, automotive exhaust systems, and remote sensing equipment. The integration involves optimizing the thermal interface between the heat source and the TEG, implementing power management circuits, and designing appropriate heat sinks to maximize temperature differentials. These systems can provide sustainable power sources for low-power electronics and IoT devices.

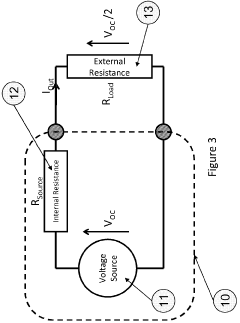

- Power management and conditioning for TEG outputs: Effective power management is crucial for maximizing the usable energy harvested from thermoelectric generators. This includes voltage regulation, impedance matching, and energy storage solutions. Advanced power conditioning circuits can adapt to varying temperature differentials and optimize the power extraction from TEGs under fluctuating conditions. Maximum power point tracking (MPPT) algorithms are implemented to continuously adjust the load impedance for optimal energy transfer. These systems ensure stable and usable power output from inherently variable thermoelectric generation.

- Hybrid energy harvesting systems combining TEGs with other technologies: Hybrid systems that combine thermoelectric generators with other energy harvesting technologies can improve overall efficiency and reliability. These systems may integrate TEGs with photovoltaic cells, piezoelectric generators, or other renewable energy sources to create complementary power generation capabilities. The hybrid approach allows for energy harvesting across different environmental conditions and energy sources, providing more consistent power output. Advanced control systems manage the energy flow between different harvesting technologies and storage elements to optimize overall system performance.

02 Material innovations for thermoelectric applications

Advanced materials play a crucial role in improving the performance of thermoelectric devices. Novel semiconductor materials, nanostructured composites, and thin-film technologies have been developed to enhance the Seebeck coefficient while reducing thermal conductivity. These materials can significantly improve the figure of merit (ZT) of thermoelectric devices, leading to higher energy conversion efficiency in both TEGs and Peltier pairs for energy harvesting applications.Expand Specific Solutions03 System integration and application-specific designs

Thermoelectric generators can be integrated into various systems for specific applications. These include wearable devices, industrial waste heat recovery, automotive applications, and remote sensing systems. The integration involves designing appropriate heat exchangers, electrical circuits, and mechanical interfaces to maximize energy harvesting in the target environment. Application-specific designs consider factors such as available temperature gradients, space constraints, and power requirements.Expand Specific Solutions04 Power management and energy storage solutions

Effective power management is essential for optimizing the energy harvested from thermoelectric generators. This includes voltage regulation, impedance matching, and maximum power point tracking (MPPT) techniques. Additionally, integrating appropriate energy storage solutions such as supercapacitors or batteries allows for buffering the intermittent power generated by TEGs. These systems ensure stable power delivery to the load despite fluctuations in temperature gradients and operating conditions.Expand Specific Solutions05 Hybrid energy harvesting systems

Combining thermoelectric generators with other energy harvesting technologies creates hybrid systems that can capture energy from multiple sources. These systems integrate TEGs with photovoltaic cells, piezoelectric generators, or RF energy harvesters to provide more consistent power output across varying environmental conditions. The complementary nature of different harvesting mechanisms improves overall system reliability and increases the total energy harvested, making them suitable for autonomous sensor networks and IoT applications.Expand Specific Solutions

Key Industry Players in TEG Development

Thermoelectric Generators (TEG) and Peltier technology for energy harvesting is currently in a growth phase, with the market expected to expand significantly due to increasing demand for sustainable energy solutions. The global TEG market is projected to reach several billion dollars by 2030, driven by applications in automotive, industrial, and consumer electronics sectors. Technologically, the field shows varying maturity levels across companies. Industry leaders like Texas Instruments, Qualcomm, and Samsung Electronics have established advanced R&D capabilities, while specialized firms such as European Thermodynamics and Applied Thermoelectric Solutions focus on niche applications. Academic institutions including Nanyang Technological University and North Carolina State University are contributing breakthrough research, particularly in material science improvements. The collaboration between commercial entities and research institutions is accelerating development of more efficient thermoelectric materials and systems, pushing the technology toward broader commercial viability.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced TEG systems for industrial energy harvesting applications, focusing on high-temperature waste heat recovery (300-600°C). Their proprietary skutterudite-based materials demonstrate ZT values exceeding 1.2 at elevated temperatures, significantly outperforming traditional bismuth telluride in high-temperature applications. Honeywell's integrated approach combines TEG modules with sophisticated power conditioning electronics that optimize output under variable thermal conditions. Their testing methodology incorporates real-world industrial conditions, measuring performance metrics under thermal cycling, vibration, and atmospheric contaminants. Honeywell has pioneered the use of advanced thermal interface materials that reduce contact resistance by up to 40% compared to conventional interfaces, significantly improving system-level efficiency in industrial deployments.

Strengths: Extensive industrial application experience with proven reliability in harsh environments. Their integrated systems approach provides turnkey solutions that address both thermoelectric generation and power management. Weaknesses: Higher cost structure than specialized TEG manufacturers and less competitive in low-temperature applications compared to bismuth telluride specialists.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed specialized power management integrated circuits (PMICs) specifically optimized for thermoelectric energy harvesting applications. Their BQ25570 ultra-low-power harvester IC can operate from input voltages as low as 100mV, making it ideal for small temperature differential TEG applications. The system incorporates maximum power point tracking (MPPT) that dynamically adjusts to extract optimal power as thermal conditions fluctuate. TI's testing methodology focuses on end-to-end system efficiency, measuring not just TEG performance but the complete power conversion chain from thermal energy to usable electrical output. Their reference designs include comprehensive thermal management solutions that address both electrical and thermal optimization, critical for maximizing real-world TEG performance. TI has also developed specialized testing protocols for evaluating TEG performance in IoT and wearable applications, where intermittent operation and varying thermal conditions are common.

Strengths: Industry-leading expertise in power management for energy harvesting with unmatched low-power operation capabilities. Their integrated solutions simplify implementation for designers without specialized thermoelectric knowledge. Weaknesses: Reliance on third-party TEG modules rather than in-house thermoelectric material development, and limited focus on high-temperature or high-power applications.

Core TEG and Peltier Pair Technical Analysis

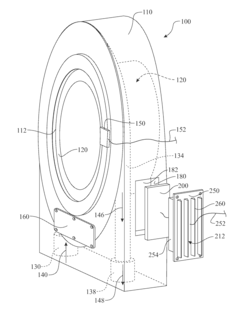

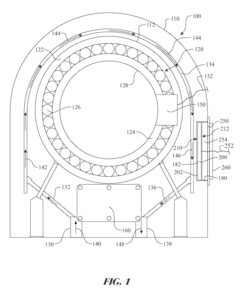

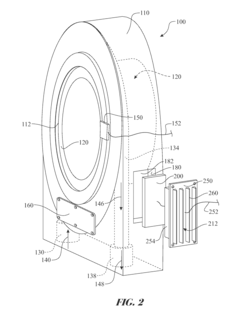

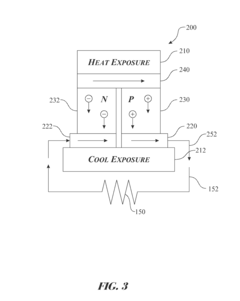

Thermo-electric power harvesting bearing configuration

PatentInactiveUS20140376849A1

Innovation

- Integration of a Thermo-Electric Generator (TEG) within the bearing assembly, utilizing thermal energy to generate electric power through a thermo-generator cavity and liquid cooling system, which enhances heat transfer and reduces the need for external power sources.

Thermoelectric generators

PatentInactiveGB2515446A

Innovation

- A thermoelectric generator with multiple stages of different materials, thermally in series but electrically independent, allowing control of mid-temperature and temperature gradient across stages to enhance thermal-to-electrical conversion efficiency and provide thermal protection, using Maximum Power Point Tracker (MPPT) technology with separate converters for each stage.

Performance Metrics and Testing Methodologies

Effective evaluation of Thermoelectric Generators (TEGs) and Peltier devices requires standardized performance metrics and rigorous testing methodologies. The primary performance indicator for TEGs is the figure of merit ZT, which combines the Seebeck coefficient, electrical conductivity, and thermal conductivity into a dimensionless value that directly correlates with conversion efficiency. Higher ZT values indicate superior thermoelectric performance, with current commercial materials typically achieving ZT values between 0.8 and 2.0.

Power density measurement (W/cm²) provides critical insight into practical application potential, particularly for space-constrained energy harvesting scenarios. This metric varies significantly with temperature differential and must be measured under conditions that simulate the intended operating environment.

Conversion efficiency, expressed as a percentage of heat energy converted to electrical energy, typically ranges from 3-8% in commercial TEGs. Laboratory testing should employ precision temperature controllers to maintain stable temperature differentials across the device, as efficiency is highly temperature-dependent.

Thermal resistance characterization is essential for system integration planning, requiring specialized test setups that can accurately measure heat flow through the device while minimizing parasitic heat paths. The thermal interface quality significantly impacts overall system performance and must be carefully controlled during testing.

Long-term stability testing protocols should include thermal cycling between operational extremes (typically -40°C to 200°C for commercial devices) and continuous operation tests lasting 1,000+ hours. Degradation rates under various environmental conditions provide critical reliability data for application planning.

Load matching characterization requires variable electronic loads to determine optimal operating points across different temperature differentials. Maximum power point tracking (MPPT) efficiency should be evaluated using standardized temperature profiles that reflect real-world conditions.

Standardized test fixtures that minimize measurement uncertainties are essential for comparative evaluation. These fixtures should control thermal interface pressure, minimize convective heat losses, and provide precise temperature and electrical measurements. Industry standards such as ASTM E1225 for thermal conductivity measurement and IEC 62108 for reliability testing provide foundational methodologies that should be adapted specifically for thermoelectric applications.

Comparative benchmarking against established reference materials enables meaningful performance evaluation across different device technologies and manufacturers, facilitating objective technology assessment for specific application requirements.

Power density measurement (W/cm²) provides critical insight into practical application potential, particularly for space-constrained energy harvesting scenarios. This metric varies significantly with temperature differential and must be measured under conditions that simulate the intended operating environment.

Conversion efficiency, expressed as a percentage of heat energy converted to electrical energy, typically ranges from 3-8% in commercial TEGs. Laboratory testing should employ precision temperature controllers to maintain stable temperature differentials across the device, as efficiency is highly temperature-dependent.

Thermal resistance characterization is essential for system integration planning, requiring specialized test setups that can accurately measure heat flow through the device while minimizing parasitic heat paths. The thermal interface quality significantly impacts overall system performance and must be carefully controlled during testing.

Long-term stability testing protocols should include thermal cycling between operational extremes (typically -40°C to 200°C for commercial devices) and continuous operation tests lasting 1,000+ hours. Degradation rates under various environmental conditions provide critical reliability data for application planning.

Load matching characterization requires variable electronic loads to determine optimal operating points across different temperature differentials. Maximum power point tracking (MPPT) efficiency should be evaluated using standardized temperature profiles that reflect real-world conditions.

Standardized test fixtures that minimize measurement uncertainties are essential for comparative evaluation. These fixtures should control thermal interface pressure, minimize convective heat losses, and provide precise temperature and electrical measurements. Industry standards such as ASTM E1225 for thermal conductivity measurement and IEC 62108 for reliability testing provide foundational methodologies that should be adapted specifically for thermoelectric applications.

Comparative benchmarking against established reference materials enables meaningful performance evaluation across different device technologies and manufacturers, facilitating objective technology assessment for specific application requirements.

Environmental Impact and Sustainability Factors

Thermoelectric generators (TEGs) and Peltier pairs represent a significant opportunity for sustainable energy harvesting, offering environmental benefits that extend beyond their primary function of converting temperature differentials into electrical energy. The environmental impact assessment of these technologies reveals several key sustainability factors that warrant consideration in their development and deployment.

The manufacturing process of TEGs involves semiconductor materials such as bismuth telluride, lead telluride, and silicon-germanium alloys. While these materials enable efficient thermoelectric conversion, their extraction and processing can contribute to environmental degradation through mining activities and energy-intensive refinement processes. Life cycle assessments indicate that the environmental footprint of TEG production is heavily influenced by material selection and manufacturing techniques.

When evaluating the operational phase, TEGs demonstrate remarkable environmental advantages. They operate silently with no moving parts, eliminating noise pollution and reducing maintenance requirements. More importantly, TEGs can harvest waste heat from industrial processes, vehicle exhaust systems, and other thermal sources that would otherwise be released into the environment, effectively reducing thermal pollution while generating useful electricity.

The carbon offset potential of TEG implementation varies significantly based on application context. In remote sensing applications, TEGs can replace conventional batteries, reducing electronic waste and eliminating the need for frequent battery replacement and disposal. In industrial settings, large-scale TEG arrays can contribute to improved energy efficiency by recapturing waste heat, potentially reducing fossil fuel consumption and associated greenhouse gas emissions.

Material sustainability represents a critical challenge for widespread TEG adoption. Current high-performance thermoelectric materials often contain rare or toxic elements with limited global reserves. Research into alternative materials using earth-abundant elements shows promise for addressing these concerns, with recent advances in silicide, oxide, and organic-based thermoelectric materials demonstrating improved sustainability profiles while maintaining acceptable performance metrics.

End-of-life considerations for TEG systems reveal both challenges and opportunities. The semiconductor components require specialized recycling processes to recover valuable materials and prevent environmental contamination. However, the long operational lifespan of properly designed TEG systems—often exceeding 15-20 years with minimal degradation—provides a favorable sustainability profile compared to technologies requiring frequent replacement.

The integration of TEGs into circular economy frameworks represents an emerging opportunity. By designing TEG systems with modularity and recyclability in mind, manufacturers can facilitate material recovery and component reuse, further enhancing the technology's environmental credentials and economic viability in long-term sustainability strategies.

The manufacturing process of TEGs involves semiconductor materials such as bismuth telluride, lead telluride, and silicon-germanium alloys. While these materials enable efficient thermoelectric conversion, their extraction and processing can contribute to environmental degradation through mining activities and energy-intensive refinement processes. Life cycle assessments indicate that the environmental footprint of TEG production is heavily influenced by material selection and manufacturing techniques.

When evaluating the operational phase, TEGs demonstrate remarkable environmental advantages. They operate silently with no moving parts, eliminating noise pollution and reducing maintenance requirements. More importantly, TEGs can harvest waste heat from industrial processes, vehicle exhaust systems, and other thermal sources that would otherwise be released into the environment, effectively reducing thermal pollution while generating useful electricity.

The carbon offset potential of TEG implementation varies significantly based on application context. In remote sensing applications, TEGs can replace conventional batteries, reducing electronic waste and eliminating the need for frequent battery replacement and disposal. In industrial settings, large-scale TEG arrays can contribute to improved energy efficiency by recapturing waste heat, potentially reducing fossil fuel consumption and associated greenhouse gas emissions.

Material sustainability represents a critical challenge for widespread TEG adoption. Current high-performance thermoelectric materials often contain rare or toxic elements with limited global reserves. Research into alternative materials using earth-abundant elements shows promise for addressing these concerns, with recent advances in silicide, oxide, and organic-based thermoelectric materials demonstrating improved sustainability profiles while maintaining acceptable performance metrics.

End-of-life considerations for TEG systems reveal both challenges and opportunities. The semiconductor components require specialized recycling processes to recover valuable materials and prevent environmental contamination. However, the long operational lifespan of properly designed TEG systems—often exceeding 15-20 years with minimal degradation—provides a favorable sustainability profile compared to technologies requiring frequent replacement.

The integration of TEGs into circular economy frameworks represents an emerging opportunity. By designing TEG systems with modularity and recyclability in mind, manufacturers can facilitate material recovery and component reuse, further enhancing the technology's environmental credentials and economic viability in long-term sustainability strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!