Peltier System Power Electronics: Drive Circuits, PWM and Efficiency Optimization

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Peltier Technology Background and Objectives

Peltier technology, also known as thermoelectric cooling technology, has evolved significantly since its discovery in the 19th century. The Peltier effect, named after French physicist Jean Charles Athanase Peltier who discovered it in 1834, describes the phenomenon where heat is absorbed or released when an electric current flows across a junction between two different conductors. This fundamental principle has enabled the development of solid-state heat pumps that can both cool and heat without moving parts or refrigerants.

The evolution of Peltier technology has been marked by continuous improvements in materials science and semiconductor technology. Early thermoelectric materials had low efficiency, limiting practical applications. However, the development of bismuth telluride (Bi₂Te₃) semiconductors in the mid-20th century significantly improved performance, making commercial applications viable. Recent advances in nanotechnology and material engineering have further enhanced the efficiency of thermoelectric materials through quantum confinement effects and reduced thermal conductivity.

Power electronics for Peltier systems have undergone parallel development, transitioning from simple direct current supplies to sophisticated electronic control systems. Modern Peltier drive circuits incorporate pulse width modulation (PWM), temperature feedback loops, and microprocessor control to optimize performance and energy efficiency. These advancements have addressed historical limitations of high power consumption and relatively low coefficient of performance (COP) compared to traditional vapor-compression cooling systems.

The primary technical objectives in Peltier system power electronics focus on maximizing energy efficiency while maintaining precise temperature control. This involves developing drive circuits that minimize power losses, implementing intelligent PWM strategies to optimize current delivery, and creating adaptive control algorithms that respond to varying thermal loads. Additionally, there is significant emphasis on reducing electromagnetic interference (EMI) generated by switching circuits and improving the reliability of power electronic components under thermal cycling conditions.

Current research trends are exploring bidirectional operation for energy recovery, integration with renewable energy sources, and hybrid systems that combine thermoelectric cooling with conventional technologies. The miniaturization of drive circuits is also a key objective, particularly for portable and wearable applications where space constraints are significant. Furthermore, there is growing interest in developing specialized power electronics for emerging high-ZT (figure of merit) thermoelectric materials that require different operating parameters than traditional Bi₂Te₃ modules.

The ultimate goal of advancements in Peltier system power electronics is to achieve cooling and heating solutions that are competitive with conventional technologies in terms of efficiency while leveraging the unique advantages of solid-state operation: reliability, silent operation, precise temperature control, and form factor flexibility. This requires a holistic approach that considers the entire thermal management system, from material properties to power conversion efficiency to thermal interface design.

The evolution of Peltier technology has been marked by continuous improvements in materials science and semiconductor technology. Early thermoelectric materials had low efficiency, limiting practical applications. However, the development of bismuth telluride (Bi₂Te₃) semiconductors in the mid-20th century significantly improved performance, making commercial applications viable. Recent advances in nanotechnology and material engineering have further enhanced the efficiency of thermoelectric materials through quantum confinement effects and reduced thermal conductivity.

Power electronics for Peltier systems have undergone parallel development, transitioning from simple direct current supplies to sophisticated electronic control systems. Modern Peltier drive circuits incorporate pulse width modulation (PWM), temperature feedback loops, and microprocessor control to optimize performance and energy efficiency. These advancements have addressed historical limitations of high power consumption and relatively low coefficient of performance (COP) compared to traditional vapor-compression cooling systems.

The primary technical objectives in Peltier system power electronics focus on maximizing energy efficiency while maintaining precise temperature control. This involves developing drive circuits that minimize power losses, implementing intelligent PWM strategies to optimize current delivery, and creating adaptive control algorithms that respond to varying thermal loads. Additionally, there is significant emphasis on reducing electromagnetic interference (EMI) generated by switching circuits and improving the reliability of power electronic components under thermal cycling conditions.

Current research trends are exploring bidirectional operation for energy recovery, integration with renewable energy sources, and hybrid systems that combine thermoelectric cooling with conventional technologies. The miniaturization of drive circuits is also a key objective, particularly for portable and wearable applications where space constraints are significant. Furthermore, there is growing interest in developing specialized power electronics for emerging high-ZT (figure of merit) thermoelectric materials that require different operating parameters than traditional Bi₂Te₃ modules.

The ultimate goal of advancements in Peltier system power electronics is to achieve cooling and heating solutions that are competitive with conventional technologies in terms of efficiency while leveraging the unique advantages of solid-state operation: reliability, silent operation, precise temperature control, and form factor flexibility. This requires a holistic approach that considers the entire thermal management system, from material properties to power conversion efficiency to thermal interface design.

Market Analysis for Thermoelectric Cooling Applications

The thermoelectric cooling market has experienced significant growth in recent years, driven by increasing demand for precise temperature control solutions across various industries. The global thermoelectric cooling market was valued at approximately 621 million USD in 2020 and is projected to reach 1.2 billion USD by 2027, growing at a CAGR of 9.8% during the forecast period. This growth trajectory is primarily fueled by the expanding application scope of Peltier-based cooling systems in electronics, healthcare, automotive, and telecommunications sectors.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The miniaturization trend in electronic devices has created substantial demand for compact cooling solutions that can effectively manage thermal issues in confined spaces. Smartphones, laptops, and wearable devices manufacturers are increasingly adopting thermoelectric cooling technologies to enhance device performance and reliability.

The healthcare and laboratory equipment segment is emerging as the fastest-growing application area with an estimated CAGR of 11.2%. Peltier-based systems are becoming essential in medical diagnostic equipment, blood analyzers, PCR devices, and pharmaceutical storage, where precise temperature control is critical for accurate results and sample preservation.

Automotive applications are gaining significant traction, particularly in electric vehicles (EVs) and luxury vehicle segments. Thermoelectric cooling systems are being integrated into battery thermal management systems, climate-controlled seats, and beverage coolers. The automotive segment is expected to grow at a CAGR of 10.5% through 2027.

Geographically, North America and Europe currently dominate the market with combined market share of approximately 58%. However, the Asia-Pacific region is witnessing the highest growth rate due to rapid industrialization, increasing electronics manufacturing activities, and rising disposable incomes driving consumer electronics demand.

Key market drivers include increasing energy efficiency concerns, growing demand for noise-free cooling solutions, and rising adoption in emerging applications such as 5G infrastructure cooling. The market is also benefiting from technological advancements in power electronics and control systems that enhance the efficiency of thermoelectric cooling devices.

Market challenges include relatively lower coefficient of performance compared to conventional cooling technologies and higher initial costs. However, ongoing research in advanced semiconductor materials and improved power electronic drive circuits is gradually addressing these limitations, potentially expanding the addressable market for thermoelectric cooling applications.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The miniaturization trend in electronic devices has created substantial demand for compact cooling solutions that can effectively manage thermal issues in confined spaces. Smartphones, laptops, and wearable devices manufacturers are increasingly adopting thermoelectric cooling technologies to enhance device performance and reliability.

The healthcare and laboratory equipment segment is emerging as the fastest-growing application area with an estimated CAGR of 11.2%. Peltier-based systems are becoming essential in medical diagnostic equipment, blood analyzers, PCR devices, and pharmaceutical storage, where precise temperature control is critical for accurate results and sample preservation.

Automotive applications are gaining significant traction, particularly in electric vehicles (EVs) and luxury vehicle segments. Thermoelectric cooling systems are being integrated into battery thermal management systems, climate-controlled seats, and beverage coolers. The automotive segment is expected to grow at a CAGR of 10.5% through 2027.

Geographically, North America and Europe currently dominate the market with combined market share of approximately 58%. However, the Asia-Pacific region is witnessing the highest growth rate due to rapid industrialization, increasing electronics manufacturing activities, and rising disposable incomes driving consumer electronics demand.

Key market drivers include increasing energy efficiency concerns, growing demand for noise-free cooling solutions, and rising adoption in emerging applications such as 5G infrastructure cooling. The market is also benefiting from technological advancements in power electronics and control systems that enhance the efficiency of thermoelectric cooling devices.

Market challenges include relatively lower coefficient of performance compared to conventional cooling technologies and higher initial costs. However, ongoing research in advanced semiconductor materials and improved power electronic drive circuits is gradually addressing these limitations, potentially expanding the addressable market for thermoelectric cooling applications.

Current Challenges in Peltier Drive Electronics

Despite significant advancements in Peltier system technology, the drive electronics domain faces several persistent challenges that limit overall system efficiency and performance. The primary obstacle remains the inherent inefficiency of thermoelectric materials, which typically operate at 5-15% efficiency. This fundamental limitation places extraordinary demands on power electronics to maximize whatever efficiency is available through optimal driving techniques.

Current drive circuits struggle with thermal management issues, as high current requirements (often 5-15A) generate substantial heat within the driver components themselves. This parasitic heating counteracts the intended cooling effect and creates a negative feedback loop that reduces system performance. The miniaturization trend in electronics further exacerbates this challenge, as compact drivers must handle increasing power densities.

Power supply design presents another significant hurdle. Most Peltier systems require stable DC power with minimal ripple, yet achieving this while maintaining high efficiency across variable load conditions remains problematic. Traditional linear regulators offer clean power but poor efficiency, while switching regulators improve efficiency but introduce electrical noise that can affect sensitive applications.

PWM control systems, while theoretically offering precise temperature regulation, face practical implementation challenges. Current PWM controllers often struggle with the thermal inertia inherent in Peltier systems, leading to temperature oscillations and overshooting. The relationship between PWM frequency, duty cycle, and thermal response is non-linear and application-specific, making universal control algorithms elusive.

Bidirectional control for heating/cooling applications presents additional complexity. Efficient H-bridge configurations for polarity reversal often introduce switching losses and require sophisticated dead-time management to prevent shoot-through conditions. The transition between heating and cooling modes remains particularly challenging to implement without efficiency penalties.

Sensing and feedback mechanisms represent another critical challenge area. Accurate temperature measurement and closed-loop control are essential for optimal performance, yet current solutions often suffer from sensor placement issues, thermal lag, and calibration drift. The integration of multiple sensors with appropriate signal conditioning adds cost and complexity to drive electronics.

Finally, modern applications increasingly demand intelligent power management features such as soft-start capabilities, overcurrent protection, and communication interfaces. Implementing these features while maintaining high efficiency and reasonable cost structures remains difficult, particularly for mass-market consumer applications where price sensitivity is high.

Current drive circuits struggle with thermal management issues, as high current requirements (often 5-15A) generate substantial heat within the driver components themselves. This parasitic heating counteracts the intended cooling effect and creates a negative feedback loop that reduces system performance. The miniaturization trend in electronics further exacerbates this challenge, as compact drivers must handle increasing power densities.

Power supply design presents another significant hurdle. Most Peltier systems require stable DC power with minimal ripple, yet achieving this while maintaining high efficiency across variable load conditions remains problematic. Traditional linear regulators offer clean power but poor efficiency, while switching regulators improve efficiency but introduce electrical noise that can affect sensitive applications.

PWM control systems, while theoretically offering precise temperature regulation, face practical implementation challenges. Current PWM controllers often struggle with the thermal inertia inherent in Peltier systems, leading to temperature oscillations and overshooting. The relationship between PWM frequency, duty cycle, and thermal response is non-linear and application-specific, making universal control algorithms elusive.

Bidirectional control for heating/cooling applications presents additional complexity. Efficient H-bridge configurations for polarity reversal often introduce switching losses and require sophisticated dead-time management to prevent shoot-through conditions. The transition between heating and cooling modes remains particularly challenging to implement without efficiency penalties.

Sensing and feedback mechanisms represent another critical challenge area. Accurate temperature measurement and closed-loop control are essential for optimal performance, yet current solutions often suffer from sensor placement issues, thermal lag, and calibration drift. The integration of multiple sensors with appropriate signal conditioning adds cost and complexity to drive electronics.

Finally, modern applications increasingly demand intelligent power management features such as soft-start capabilities, overcurrent protection, and communication interfaces. Implementing these features while maintaining high efficiency and reasonable cost structures remains difficult, particularly for mass-market consumer applications where price sensitivity is high.

PWM Drive Circuit Architectures for Peltier Modules

01 Power conversion and control circuits for Peltier systems

Specialized power conversion and control circuits are essential for optimizing the efficiency of Peltier systems. These circuits regulate the voltage and current supplied to thermoelectric modules, enabling precise temperature control while minimizing power consumption. Advanced control algorithms can dynamically adjust power delivery based on cooling or heating demands, significantly improving overall system efficiency. Implementation of microcontroller-based feedback systems allows for real-time adjustment of operating parameters to maintain optimal performance across varying conditions.- Power conversion and control circuits for Peltier systems: Specialized power conversion and control circuits are essential for optimizing the efficiency of Peltier systems. These circuits regulate the voltage and current supplied to thermoelectric modules, allowing for precise temperature control while minimizing power consumption. Advanced control algorithms can dynamically adjust power delivery based on cooling or heating demands, significantly improving overall system efficiency. Implementation of microcontroller-based feedback systems enables real-time adjustment of operating parameters to maintain optimal performance under varying conditions.

- Thermal management techniques for Peltier devices: Effective thermal management is crucial for maximizing the efficiency of Peltier-based cooling systems. This includes optimized heat sink designs, improved thermal interfaces, and strategic placement of thermoelectric modules to enhance heat dissipation. Advanced thermal management techniques involve the use of phase-change materials, liquid cooling systems, or hybrid approaches that combine passive and active cooling methods. Proper thermal design ensures that heat is efficiently transferred away from the hot side of Peltier devices, preventing thermal feedback that would otherwise reduce system efficiency.

- Integration of renewable energy sources with Peltier systems: Integrating renewable energy sources with Peltier systems can significantly improve overall energy efficiency and sustainability. Solar panels, wind turbines, or other renewable sources can be coupled with thermoelectric devices to create self-sufficient cooling or heating systems. These integrated systems often incorporate energy storage solutions like batteries to ensure continuous operation during periods of low renewable energy availability. Smart power management systems optimize the flow of energy between renewable sources, storage systems, and Peltier devices to maximize efficiency and minimize reliance on grid power.

- Advanced semiconductor materials for thermoelectric efficiency: The development of advanced semiconductor materials has led to significant improvements in the efficiency of Peltier systems. Novel materials with enhanced thermoelectric properties, such as bismuth telluride alloys, skutterudites, and quantum well structures, offer higher figures of merit (ZT values) compared to conventional materials. Nanostructured thermoelectric materials can reduce thermal conductivity while maintaining electrical conductivity, thereby improving conversion efficiency. These advanced materials enable Peltier devices to operate with lower power consumption while achieving the same cooling or heating performance.

- Intelligent control systems and algorithms for efficiency optimization: Intelligent control systems and algorithms play a crucial role in optimizing the efficiency of Peltier-based thermal management systems. Machine learning approaches can predict cooling or heating needs based on usage patterns and environmental conditions, allowing for proactive power management. Adaptive control algorithms continuously monitor system performance and adjust operating parameters to maintain optimal efficiency under varying loads. These smart systems can integrate with IoT platforms to enable remote monitoring and control, further enhancing energy efficiency through data-driven optimization strategies.

02 Thermal management techniques for Peltier devices

Effective thermal management is crucial for maximizing the efficiency of Peltier-based cooling systems. This includes optimized heat sink designs, thermal interface materials, and airflow management to efficiently dissipate heat from the hot side of thermoelectric modules. Advanced thermal designs incorporate phase-change materials, heat pipes, or liquid cooling solutions to handle peak thermal loads. Proper thermal management prevents temperature gradients that reduce efficiency and extends the operational lifespan of Peltier devices while maintaining optimal performance under varying load conditions.Expand Specific Solutions03 Integration of renewable energy sources with Peltier systems

Integrating renewable energy sources with Peltier cooling systems can significantly improve overall energy efficiency. Solar panels, wind turbines, or other renewable sources can be directly coupled with thermoelectric modules through specialized power electronics that match source characteristics with Peltier requirements. Energy harvesting circuits can capture and utilize ambient energy to supplement or replace grid power for Peltier operation. These integrated systems often incorporate energy storage solutions to ensure continuous operation during fluctuations in renewable energy availability.Expand Specific Solutions04 Advanced semiconductor materials for thermoelectric efficiency

Novel semiconductor materials and fabrication techniques are being developed to enhance the intrinsic efficiency of thermoelectric modules. These include nanostructured materials, quantum dot superlattices, and advanced bismuth telluride compounds with improved figure of merit (ZT). Material innovations focus on increasing the Seebeck coefficient while reducing thermal conductivity, the key parameters affecting thermoelectric conversion efficiency. Manufacturing processes like selective doping, precise deposition techniques, and novel junction designs further optimize the performance of these materials in practical Peltier applications.Expand Specific Solutions05 Intelligent power management systems for Peltier devices

Smart power management systems employ advanced algorithms and sensors to dynamically adjust Peltier operation based on actual cooling needs. These systems incorporate machine learning techniques to predict cooling requirements and optimize power delivery accordingly. Pulse width modulation, variable frequency drives, and adaptive control strategies minimize power consumption while maintaining desired temperature profiles. Network-connected controllers enable remote monitoring and optimization of multiple Peltier units across distributed systems, further enhancing overall energy efficiency through coordinated operation.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The Peltier System Power Electronics market is currently in a growth phase, driven by increasing demand for precise temperature control in various applications. The market size is expanding, with projections indicating significant growth due to adoption in automotive climate systems, consumer electronics cooling, and medical devices. Technologically, the field is moderately mature but evolving rapidly with innovations in efficiency optimization. Leading players include Infineon Technologies and Renesas Electronics, who are advancing PWM control techniques, while ROHM and STMicroelectronics focus on specialized drive circuits. Samsung and Midea Group are integrating these technologies into consumer products, while automotive companies like Continental and BorgWarner are developing vehicle-specific applications. Research institutions such as the University of Windsor are contributing to fundamental advancements in power conversion efficiency.

ROHM Co., Ltd.

Technical Solution: ROHM在Peltier系统电力电子领域提供了创新的驱动解决方案,其核心是高效的SiC MOSFET和专用驱动IC。ROHM的技术方案采用其BD9G341AEFJ PWM控制器,支持高达1MHz的开关频率,实现了精确的温度控制和快速响应时间。该公司的BM6112FV H桥驱动器专为Peltier应用设计,提供高达3A的连续驱动能力,内置过热和过流保护。ROHM的解决方案特别注重效率优化,其专利的自适应死区控制技术可减少开关损耗达20%。该公司还开发了创新的电流检测技术,使用低阻值分流电阻(0.5mΩ)实现精确的电流监控,同时最小化功率损耗。ROHM的Nano Pulse Control™技术允许在轻负载条件下超细粒度PWM控制,提高了系统在部分负载下的效率。其集成式热管理解决方案包括温度传感器和闭环控制算法,可实现±0.5°C的温度精度。

优势:卓越的热效率和功率密度,先进的保护功能提高系统可靠性,广泛的工作温度范围(-40°C至125°C)适合各种应用环境。缺点:高端解决方案成本较高,某些专用IC可能供应链限制,复杂系统需要专业设计知识。

Renesas Electronics Corp.

Technical Solution: Renesas为Peltier系统开发了全面的电力电子解决方案,结合其RA和RX系列微控制器与专用电源管理IC。Renesas的技术方案采用其高精度PWM控制器,如ISL78083,提供16位分辨率和可编程死区控制,实现精确的温度调节。该公司的智能功率级设计集成了先进的电流检测和限制功能,在10μs内响应过载条件,保护Peltier元件免受损坏。Renesas开发了创新的自适应PWM算法,可根据负载条件动态调整开关频率(1kHz至500kHz),在轻负载下提高效率多达35%。其同步整流技术显著减少了导通损耗,将系统效率提高至92%以上。Renesas的解决方案还包括先进的热管理功能,如预测性温度控制和热梯度管理,减少了温度波动和能量消耗。该公司的集成式诊断功能可检测开路和短路故障,提高了系统可靠性。

优势:高度集成的解决方案减少了组件数量和系统复杂性,先进的电源管理算法提高了能效,强大的保护功能延长了系统寿命。缺点:某些高级功能需要专用软件开发,高性能解决方案成本较高,在极端温度条件下可能需要额外的散热措施。

Key Patents in Thermoelectric Power Management

Pulse width modulation driver circuit

PatentPendingGB2624580A

Innovation

- Integration of analog input processing with digital loop filter output, creating a hybrid analog-digital control system for PWM generation.

- Utilization of an analog feedback path from the PWM output, enabling closed-loop control for improved stability and accuracy.

- Combination of digital signal processing with PWM modulation techniques to enhance control precision while maintaining compatibility with analog input signals.

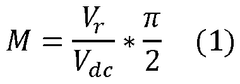

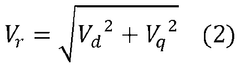

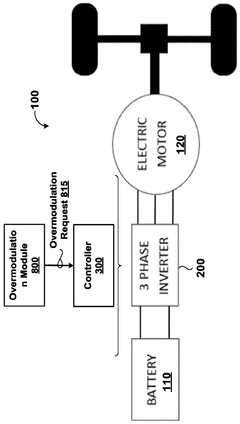

Adaptive pulse width modulation overmodulation in three-phase voltage source inverters

PatentWO2024226474A1

Innovation

- Implementing adaptive pulse width modulation overmodulation in three-phase voltage source inverters, which determines an overmodulation threshold based on vehicle system state information to switch between linear and overmodulation regions, optimizing control signals for the inverter switches to maximize output voltage and reduce switching losses.

Thermal Management Integration Strategies

The integration of Peltier systems with broader thermal management architectures requires careful consideration of both electrical and thermal interfaces. Effective integration strategies must address the bidirectional relationship between power electronics and thermal performance, as the efficiency of drive circuits directly impacts heat generation and system performance.

When incorporating Peltier modules into comprehensive thermal management solutions, designers must consider the physical mounting requirements that ensure optimal thermal contact while providing electrical isolation. Thermal interface materials (TIMs) with high thermal conductivity yet electrically insulating properties are essential for maximizing heat transfer efficiency while preventing electrical shorts.

Power distribution architecture represents another critical integration consideration. Centralized power supplies versus distributed power electronics each present distinct advantages for different applications. Centralized systems offer simplified maintenance and potentially higher efficiency through economies of scale, while distributed approaches provide redundancy and can reduce thermal concentration at the cost of increased system complexity.

Control system integration presents unique challenges, particularly when PWM-driven Peltier systems must coordinate with other thermal management components such as liquid cooling loops, heat pipes, or variable-speed fans. Implementing hierarchical control architectures allows for coordinated operation across multiple cooling technologies, optimizing overall system performance rather than individual component efficiency.

Electromagnetic compatibility (EMC) considerations become increasingly important as PWM switching frequencies increase. The integration strategy must account for potential electromagnetic interference with nearby sensitive components, implementing appropriate filtering, shielding, and grounding techniques to maintain system integrity.

Thermal feedback mechanisms represent a sophisticated integration approach where temperature sensors strategically placed throughout the system provide real-time data to the Peltier drive circuits. This enables dynamic adjustment of PWM parameters based on actual thermal conditions rather than predetermined profiles, significantly enhancing system responsiveness and efficiency.

Modular design approaches facilitate easier maintenance and upgrades by standardizing electrical and thermal interfaces. This strategy allows for the replacement or upgrade of individual components without redesigning the entire thermal management system, extending overall system lifespan and reducing total cost of ownership.

For applications with varying thermal loads, adaptive integration strategies that incorporate load forecasting algorithms can preemptively adjust Peltier drive parameters to accommodate anticipated thermal changes, further optimizing efficiency across dynamic operating conditions.

When incorporating Peltier modules into comprehensive thermal management solutions, designers must consider the physical mounting requirements that ensure optimal thermal contact while providing electrical isolation. Thermal interface materials (TIMs) with high thermal conductivity yet electrically insulating properties are essential for maximizing heat transfer efficiency while preventing electrical shorts.

Power distribution architecture represents another critical integration consideration. Centralized power supplies versus distributed power electronics each present distinct advantages for different applications. Centralized systems offer simplified maintenance and potentially higher efficiency through economies of scale, while distributed approaches provide redundancy and can reduce thermal concentration at the cost of increased system complexity.

Control system integration presents unique challenges, particularly when PWM-driven Peltier systems must coordinate with other thermal management components such as liquid cooling loops, heat pipes, or variable-speed fans. Implementing hierarchical control architectures allows for coordinated operation across multiple cooling technologies, optimizing overall system performance rather than individual component efficiency.

Electromagnetic compatibility (EMC) considerations become increasingly important as PWM switching frequencies increase. The integration strategy must account for potential electromagnetic interference with nearby sensitive components, implementing appropriate filtering, shielding, and grounding techniques to maintain system integrity.

Thermal feedback mechanisms represent a sophisticated integration approach where temperature sensors strategically placed throughout the system provide real-time data to the Peltier drive circuits. This enables dynamic adjustment of PWM parameters based on actual thermal conditions rather than predetermined profiles, significantly enhancing system responsiveness and efficiency.

Modular design approaches facilitate easier maintenance and upgrades by standardizing electrical and thermal interfaces. This strategy allows for the replacement or upgrade of individual components without redesigning the entire thermal management system, extending overall system lifespan and reducing total cost of ownership.

For applications with varying thermal loads, adaptive integration strategies that incorporate load forecasting algorithms can preemptively adjust Peltier drive parameters to accommodate anticipated thermal changes, further optimizing efficiency across dynamic operating conditions.

Energy Harvesting Opportunities with Peltier Systems

Peltier systems, traditionally viewed as cooling devices, present significant untapped potential for energy harvesting applications. When operated in reverse mode, these thermoelectric systems can generate electrical power from temperature differentials, offering a sustainable approach to energy recovery from waste heat sources. This capability positions Peltier technology as a valuable contributor to the growing field of energy harvesting.

The fundamental principle behind Peltier-based energy harvesting lies in the Seebeck effect, where temperature differences across thermoelectric materials generate voltage potential. Industrial environments, automotive systems, and even consumer electronics produce substantial waste heat that can be captured and converted into usable electricity through properly configured Peltier arrays. Recent advancements in material science have improved conversion efficiencies, making these systems increasingly viable for commercial applications.

Power electronics play a crucial role in optimizing the energy harvesting capabilities of Peltier systems. Advanced Maximum Power Point Tracking (MPPT) algorithms, specifically designed for thermoelectric generators, can significantly enhance energy capture efficiency across varying temperature differentials. These algorithms dynamically adjust the electrical load to maintain optimal power extraction as conditions change, addressing one of the primary challenges in thermoelectric energy harvesting.

Integration opportunities exist across multiple sectors. In automotive applications, Peltier arrays can recover energy from exhaust systems and engine cooling circuits, supplementing vehicle electrical systems and reducing alternator load. Industrial facilities can implement these systems to harvest energy from process heat, potentially powering wireless sensor networks for monitoring and control systems without requiring battery replacement or wired power connections.

The emerging Internet of Things (IoT) ecosystem presents perhaps the most promising application area. Self-powered wireless sensors utilizing Peltier-based energy harvesting can operate indefinitely in environments with reliable temperature differentials, eliminating battery replacement logistics and costs. This capability enables deployment in remote or difficult-to-access locations where conventional power sources are impractical.

Challenges remain in scaling this technology for broader implementation. Current limitations include relatively low conversion efficiencies compared to other energy harvesting technologies and the need for specialized power conditioning circuits to handle the low-voltage, variable output characteristics of thermoelectric generators. However, ongoing research in nanomaterials and advanced semiconductor compounds shows promise for overcoming these efficiency barriers.

The economic viability of Peltier-based energy harvesting continues to improve as manufacturing costs decrease and system efficiencies increase. When evaluated on a total cost of ownership basis, including elimination of battery replacement and associated maintenance, these systems increasingly present compelling value propositions for specific applications where temperature differentials naturally exist.

The fundamental principle behind Peltier-based energy harvesting lies in the Seebeck effect, where temperature differences across thermoelectric materials generate voltage potential. Industrial environments, automotive systems, and even consumer electronics produce substantial waste heat that can be captured and converted into usable electricity through properly configured Peltier arrays. Recent advancements in material science have improved conversion efficiencies, making these systems increasingly viable for commercial applications.

Power electronics play a crucial role in optimizing the energy harvesting capabilities of Peltier systems. Advanced Maximum Power Point Tracking (MPPT) algorithms, specifically designed for thermoelectric generators, can significantly enhance energy capture efficiency across varying temperature differentials. These algorithms dynamically adjust the electrical load to maintain optimal power extraction as conditions change, addressing one of the primary challenges in thermoelectric energy harvesting.

Integration opportunities exist across multiple sectors. In automotive applications, Peltier arrays can recover energy from exhaust systems and engine cooling circuits, supplementing vehicle electrical systems and reducing alternator load. Industrial facilities can implement these systems to harvest energy from process heat, potentially powering wireless sensor networks for monitoring and control systems without requiring battery replacement or wired power connections.

The emerging Internet of Things (IoT) ecosystem presents perhaps the most promising application area. Self-powered wireless sensors utilizing Peltier-based energy harvesting can operate indefinitely in environments with reliable temperature differentials, eliminating battery replacement logistics and costs. This capability enables deployment in remote or difficult-to-access locations where conventional power sources are impractical.

Challenges remain in scaling this technology for broader implementation. Current limitations include relatively low conversion efficiencies compared to other energy harvesting technologies and the need for specialized power conditioning circuits to handle the low-voltage, variable output characteristics of thermoelectric generators. However, ongoing research in nanomaterials and advanced semiconductor compounds shows promise for overcoming these efficiency barriers.

The economic viability of Peltier-based energy harvesting continues to improve as manufacturing costs decrease and system efficiencies increase. When evaluated on a total cost of ownership basis, including elimination of battery replacement and associated maintenance, these systems increasingly present compelling value propositions for specific applications where temperature differentials naturally exist.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!