Peltier Element Sizing for Small-scale Refrigeration — Calculation Workbook and Worked Example

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Peltier Technology Background and Objectives

Thermoelectric cooling technology, particularly Peltier elements, has evolved significantly since its discovery in the early 19th century. The Peltier effect, first observed by Jean Charles Athanase Peltier in 1834, describes the phenomenon where heat transfer occurs at the junction of two different conductors when an electric current passes through them. This principle forms the foundation of modern thermoelectric cooling devices, which have progressed from theoretical curiosities to practical cooling solutions over the past century.

The development of semiconductor materials in the mid-20th century marked a pivotal advancement in Peltier technology. The introduction of bismuth telluride (Bi₂Te₃) in the 1950s significantly improved the efficiency of thermoelectric devices, making small-scale refrigeration applications commercially viable. Since then, continuous improvements in material science have steadily enhanced the performance metrics of Peltier elements, including their coefficient of performance (COP) and cooling capacity.

Current Peltier technology offers unique advantages for small-scale refrigeration applications, including compact size, absence of moving parts, precise temperature control, and environmental friendliness due to the lack of refrigerants. These characteristics make them particularly suitable for applications where space constraints, noise limitations, or portability are critical factors.

The primary technical objective of Peltier element sizing for small-scale refrigeration is to develop a systematic approach for accurately calculating and selecting appropriate thermoelectric modules based on specific cooling requirements. This involves creating a comprehensive calculation workbook that accounts for thermal loads, desired temperature differentials, power constraints, and environmental conditions.

The calculation methodology aims to bridge the gap between theoretical thermoelectric principles and practical implementation challenges. By providing worked examples, the approach seeks to demonstrate how to balance competing factors such as cooling capacity, power consumption, physical dimensions, and cost considerations in real-world applications.

Looking forward, the technology trajectory for Peltier elements is focused on improving energy efficiency, which remains a significant limitation compared to conventional vapor-compression refrigeration systems. Research efforts are concentrated on developing new thermoelectric materials with higher figures of merit (ZT values), optimizing heat exchanger designs, and creating more sophisticated control algorithms to maximize performance under varying conditions.

The ultimate goal is to establish a standardized framework for Peltier element selection that enables engineers and designers to confidently implement thermoelectric cooling solutions across diverse applications, from portable medical coolers and electronic device thermal management to small refrigeration units and temperature-controlled scientific instruments.

The development of semiconductor materials in the mid-20th century marked a pivotal advancement in Peltier technology. The introduction of bismuth telluride (Bi₂Te₃) in the 1950s significantly improved the efficiency of thermoelectric devices, making small-scale refrigeration applications commercially viable. Since then, continuous improvements in material science have steadily enhanced the performance metrics of Peltier elements, including their coefficient of performance (COP) and cooling capacity.

Current Peltier technology offers unique advantages for small-scale refrigeration applications, including compact size, absence of moving parts, precise temperature control, and environmental friendliness due to the lack of refrigerants. These characteristics make them particularly suitable for applications where space constraints, noise limitations, or portability are critical factors.

The primary technical objective of Peltier element sizing for small-scale refrigeration is to develop a systematic approach for accurately calculating and selecting appropriate thermoelectric modules based on specific cooling requirements. This involves creating a comprehensive calculation workbook that accounts for thermal loads, desired temperature differentials, power constraints, and environmental conditions.

The calculation methodology aims to bridge the gap between theoretical thermoelectric principles and practical implementation challenges. By providing worked examples, the approach seeks to demonstrate how to balance competing factors such as cooling capacity, power consumption, physical dimensions, and cost considerations in real-world applications.

Looking forward, the technology trajectory for Peltier elements is focused on improving energy efficiency, which remains a significant limitation compared to conventional vapor-compression refrigeration systems. Research efforts are concentrated on developing new thermoelectric materials with higher figures of merit (ZT values), optimizing heat exchanger designs, and creating more sophisticated control algorithms to maximize performance under varying conditions.

The ultimate goal is to establish a standardized framework for Peltier element selection that enables engineers and designers to confidently implement thermoelectric cooling solutions across diverse applications, from portable medical coolers and electronic device thermal management to small refrigeration units and temperature-controlled scientific instruments.

Market Analysis for Small-scale Refrigeration Solutions

The small-scale refrigeration market has experienced significant growth over the past decade, driven by increasing demand across multiple sectors including medical, automotive, consumer electronics, and portable cooling applications. The global market for small-scale refrigeration solutions was valued at approximately $4.2 billion in 2022 and is projected to reach $6.8 billion by 2028, representing a compound annual growth rate of 8.3%.

Medical and healthcare applications constitute the largest segment, accounting for nearly 32% of the market share. This dominance is attributed to the critical need for temperature-controlled storage of vaccines, medications, and biological samples. The COVID-19 pandemic particularly highlighted the importance of reliable small-scale refrigeration for vaccine distribution in remote areas.

Consumer electronics represents the fastest-growing segment, with portable coolers and cooling solutions for electronic devices gaining popularity. The rise in outdoor recreational activities and camping has further boosted demand for compact, energy-efficient cooling solutions that can operate off-grid or with limited power sources.

Peltier-based thermoelectric cooling technology holds approximately 24% of the small-scale refrigeration market, competing with traditional compressor-based systems and emerging technologies like magnetic refrigeration. The appeal of Peltier elements lies in their compact size, lack of moving parts, absence of refrigerants, and precise temperature control capabilities.

Regional analysis indicates North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing disposable income, rapid urbanization, and growing healthcare infrastructure.

Key market drivers include miniaturization trends across industries, increasing focus on energy efficiency, growing demand for portable medical devices, and rising consumer preference for compact living spaces in urban environments. The push toward environmentally friendly cooling solutions has also accelerated interest in alternative technologies like thermoelectric cooling that eliminate the need for harmful refrigerants.

Market challenges include efficiency limitations of current thermoelectric materials, cost considerations compared to traditional cooling methods, and power consumption issues for battery-operated applications. Despite these challenges, ongoing advancements in semiconductor materials and thermal management techniques are gradually improving the performance metrics of Peltier-based cooling systems.

Consumer willingness to pay premium prices for compact, portable cooling solutions has created a viable market for higher-end Peltier-based products, particularly in specialized applications where size constraints and noise limitations outweigh efficiency considerations.

Medical and healthcare applications constitute the largest segment, accounting for nearly 32% of the market share. This dominance is attributed to the critical need for temperature-controlled storage of vaccines, medications, and biological samples. The COVID-19 pandemic particularly highlighted the importance of reliable small-scale refrigeration for vaccine distribution in remote areas.

Consumer electronics represents the fastest-growing segment, with portable coolers and cooling solutions for electronic devices gaining popularity. The rise in outdoor recreational activities and camping has further boosted demand for compact, energy-efficient cooling solutions that can operate off-grid or with limited power sources.

Peltier-based thermoelectric cooling technology holds approximately 24% of the small-scale refrigeration market, competing with traditional compressor-based systems and emerging technologies like magnetic refrigeration. The appeal of Peltier elements lies in their compact size, lack of moving parts, absence of refrigerants, and precise temperature control capabilities.

Regional analysis indicates North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing disposable income, rapid urbanization, and growing healthcare infrastructure.

Key market drivers include miniaturization trends across industries, increasing focus on energy efficiency, growing demand for portable medical devices, and rising consumer preference for compact living spaces in urban environments. The push toward environmentally friendly cooling solutions has also accelerated interest in alternative technologies like thermoelectric cooling that eliminate the need for harmful refrigerants.

Market challenges include efficiency limitations of current thermoelectric materials, cost considerations compared to traditional cooling methods, and power consumption issues for battery-operated applications. Despite these challenges, ongoing advancements in semiconductor materials and thermal management techniques are gradually improving the performance metrics of Peltier-based cooling systems.

Consumer willingness to pay premium prices for compact, portable cooling solutions has created a viable market for higher-end Peltier-based products, particularly in specialized applications where size constraints and noise limitations outweigh efficiency considerations.

Current Challenges in Peltier Element Implementation

Despite the significant advancements in thermoelectric cooling technology, Peltier elements face several critical implementation challenges that limit their widespread adoption in small-scale refrigeration applications. The primary obstacle remains their relatively low coefficient of performance (COP), typically ranging from 0.3 to 0.7, significantly lower than conventional vapor-compression systems that achieve COPs of 2.0-4.0. This efficiency gap translates directly into higher energy consumption, making Peltier-based solutions less economically viable for many applications despite their compact form factor.

Heat dissipation presents another substantial challenge, as Peltier elements generate considerable waste heat that must be effectively managed. Without proper thermal management systems, the hot side temperature rises rapidly, diminishing the temperature differential and overall cooling performance. This necessitates sophisticated heat sink designs and often active cooling solutions, which add complexity, cost, and size to what would otherwise be a simple solid-state system.

Temperature control precision represents a double-edged sword for Peltier implementations. While these devices offer excellent responsiveness to input current changes, maintaining stable temperatures across varying ambient conditions requires complex control algorithms and feedback systems. The non-linear relationship between input power, heat load, and temperature differential further complicates precise sizing calculations for specific applications.

Material limitations constitute a significant barrier to improved performance. Current commercially available Peltier modules primarily utilize bismuth telluride (Bi₂Te₃) semiconductor materials, which have inherent thermodynamic limitations. Research into alternative materials with higher figure of merit (ZT) values has shown promise in laboratory settings but has yet to translate into commercially viable products at competitive price points.

Mechanical reliability concerns also plague Peltier implementations, particularly in applications with frequent thermal cycling. The different thermal expansion coefficients of materials used in Peltier construction can lead to mechanical stress, solder joint fatigue, and eventual failure. This reliability issue becomes particularly problematic in mission-critical cooling applications where system longevity is essential.

Cost factors remain prohibitive for many potential applications. The manufacturing process for high-quality Peltier elements requires precise semiconductor fabrication techniques, contributing to higher unit costs compared to conventional cooling technologies. Additionally, the supplementary components required for effective implementation—heat sinks, thermal interface materials, controllers, and power supplies—further increase system costs, making economic justification difficult for many commercial applications despite the technical advantages of solid-state cooling.

Heat dissipation presents another substantial challenge, as Peltier elements generate considerable waste heat that must be effectively managed. Without proper thermal management systems, the hot side temperature rises rapidly, diminishing the temperature differential and overall cooling performance. This necessitates sophisticated heat sink designs and often active cooling solutions, which add complexity, cost, and size to what would otherwise be a simple solid-state system.

Temperature control precision represents a double-edged sword for Peltier implementations. While these devices offer excellent responsiveness to input current changes, maintaining stable temperatures across varying ambient conditions requires complex control algorithms and feedback systems. The non-linear relationship between input power, heat load, and temperature differential further complicates precise sizing calculations for specific applications.

Material limitations constitute a significant barrier to improved performance. Current commercially available Peltier modules primarily utilize bismuth telluride (Bi₂Te₃) semiconductor materials, which have inherent thermodynamic limitations. Research into alternative materials with higher figure of merit (ZT) values has shown promise in laboratory settings but has yet to translate into commercially viable products at competitive price points.

Mechanical reliability concerns also plague Peltier implementations, particularly in applications with frequent thermal cycling. The different thermal expansion coefficients of materials used in Peltier construction can lead to mechanical stress, solder joint fatigue, and eventual failure. This reliability issue becomes particularly problematic in mission-critical cooling applications where system longevity is essential.

Cost factors remain prohibitive for many potential applications. The manufacturing process for high-quality Peltier elements requires precise semiconductor fabrication techniques, contributing to higher unit costs compared to conventional cooling technologies. Additionally, the supplementary components required for effective implementation—heat sinks, thermal interface materials, controllers, and power supplies—further increase system costs, making economic justification difficult for many commercial applications despite the technical advantages of solid-state cooling.

Calculation Methodologies for Peltier Element Sizing

01 Thermal design considerations for Peltier element sizing

Proper sizing of Peltier elements requires careful thermal design considerations including heat load calculations, thermal resistance analysis, and temperature differential requirements. The sizing process involves determining the cooling capacity needed based on the application's thermal requirements, ambient conditions, and desired temperature control precision. Optimizing the thermal interface between the Peltier element and heat sinks is crucial for efficient heat transfer and overall system performance.- Thermal design considerations for Peltier element sizing: Proper sizing of Peltier elements requires careful thermal design considerations including heat load calculations, temperature differential requirements, and thermal resistance analysis. The sizing process involves determining the cooling capacity needed based on the application's thermal demands, ambient conditions, and desired temperature control precision. Effective heat dissipation systems must be integrated with appropriately sized Peltier elements to achieve optimal performance and energy efficiency.

- Electrical parameters and power optimization: Sizing Peltier elements requires consideration of electrical parameters such as current, voltage, and power consumption. The selection process involves matching the electrical specifications to the available power supply while optimizing energy efficiency. Proper sizing ensures the element operates within its optimal electrical range, preventing overheating and extending operational lifespan. Power management systems may be incorporated to regulate the electrical input based on cooling demands and environmental conditions.

- Dimensional and physical constraints in applications: The physical dimensions and form factor of Peltier elements must be considered when sizing for specific applications. Space constraints in electronic devices, medical equipment, or industrial systems often dictate the maximum allowable dimensions. The sizing process must balance thermal performance requirements with available installation space. Custom-shaped or miniaturized Peltier elements may be designed for applications with severe space limitations while maintaining adequate cooling capacity.

- Testing and measurement methods for proper sizing: Accurate sizing of Peltier elements requires specific testing and measurement methodologies to evaluate performance under various conditions. These methods include thermal imaging, temperature profiling, and efficiency testing to verify that the selected element meets application requirements. Testing procedures help determine the optimal size by measuring actual heat transfer capabilities, temperature differentials achieved, and response times under varying loads. Simulation tools may be used to predict performance before final sizing decisions.

- Cascaded and multi-element configurations: For applications requiring extreme temperature differentials or precise temperature control, cascaded or multi-element Peltier configurations may be necessary. The sizing process for these systems involves determining the optimal number of elements, their individual specifications, and their arrangement. Proper sizing of cascaded systems requires understanding the thermal interactions between elements and the cumulative cooling effect. These configurations can achieve greater temperature differentials than single elements but require more complex power management and thermal design considerations.

02 Electrical parameters and power optimization

Sizing Peltier elements requires consideration of electrical parameters such as voltage, current, and power consumption. The selection process involves matching the electrical characteristics of the Peltier device with the available power supply and control system. Optimizing the power input to achieve the desired cooling effect while minimizing energy consumption is essential for efficient operation. This includes determining the appropriate number of thermoelectric couples and their configuration based on the electrical requirements of the application.Expand Specific Solutions03 Physical dimensions and arrangement optimization

The physical dimensions and arrangement of Peltier elements significantly impact their performance. Sizing considerations include the surface area required for heat transfer, space constraints of the application, and the geometric configuration of multiple elements when used together. Optimizing the arrangement of elements in series or parallel configurations can enhance cooling capacity and efficiency. The thickness of the element also affects the thermal gradient and response time of the cooling system.Expand Specific Solutions04 Testing and measurement methods for proper sizing

Accurate sizing of Peltier elements requires specific testing and measurement methods to evaluate performance under various conditions. These methods include thermal imaging, temperature coefficient measurements, and performance curve analysis. Testing procedures help determine the optimal size and configuration by measuring parameters such as maximum temperature differential, heat pumping capacity, and coefficient of performance. These measurements ensure that the selected Peltier element meets the specific requirements of the application.Expand Specific Solutions05 Application-specific sizing considerations

Peltier element sizing varies significantly based on the specific application requirements. Different applications such as electronic cooling, medical devices, laboratory equipment, or consumer products have unique thermal management needs. Factors such as duty cycle, operational environment, reliability requirements, and cost constraints influence the sizing process. Specialized sizing approaches may be needed for applications with extreme temperature requirements, space limitations, or high precision temperature control needs.Expand Specific Solutions

Leading Manufacturers and Competitors in Thermoelectric Industry

The Peltier element sizing for small-scale refrigeration market is currently in a growth phase, with increasing demand for compact cooling solutions across various industries. The market size is expanding steadily, driven by applications in electronics cooling, portable refrigeration, and medical devices. Technologically, the field shows varying maturity levels among key players. BSH Hausgeräte and Liebherr demonstrate advanced expertise in consumer refrigeration applications, while Mayekawa MFG and Sharp focus on innovative industrial cooling systems. Guangdong Fuxin Technology has emerged as a specialist in semiconductor thermoelectric technology solutions. Research institutions like Swiss Federal Institute of Technology and South China University of Technology are advancing fundamental thermoelectric principles, bridging the gap between theoretical research and commercial applications.

BSH Hausgeräte GmbH

Technical Solution: BSH Hausgeräte has developed advanced thermoelectric cooling systems using precisely calculated Peltier elements for compact refrigeration applications. Their technology incorporates multi-stage Peltier modules with optimized thermal interfaces to maximize the coefficient of performance (COP). BSH's calculation workbook for Peltier element sizing includes comprehensive thermal load analysis, heat sink optimization parameters, and power consumption modeling. Their approach focuses on maintaining precise temperature control within ±0.5°C while minimizing energy consumption through adaptive control algorithms that adjust power input based on cooling demand and ambient conditions. The company has implemented this technology in premium compact refrigerators and wine coolers where space efficiency and noise reduction are critical factors.

Strengths: Superior temperature stability and precision control; highly space-efficient design suitable for premium compact appliances; silent operation compared to compressor-based systems. Weaknesses: Higher manufacturing costs compared to conventional cooling technologies; lower energy efficiency at larger cooling capacities; limited application in high-temperature differential scenarios.

Mayekawa MFG Co., Ltd.

Technical Solution: Mayekawa has developed an innovative approach to Peltier element sizing for specialized industrial refrigeration applications where precise temperature control is critical. Their methodology incorporates comprehensive thermal modeling that accounts for transient heat loads and variable operating conditions. Mayekawa's calculation workbook includes detailed analysis of thermal interfaces, heat sink optimization, and power supply requirements based on cooling capacity needs. Their system features a modular design approach that allows for scalable cooling solutions while maintaining high efficiency. The company has implemented this technology in pharmaceutical storage, semiconductor manufacturing, and food processing applications where temperature precision directly impacts product quality. Their worked examples demonstrate how to calculate optimal Peltier configurations for different thermal loads while accounting for environmental variables and system constraints.

Strengths: Exceptional precision in temperature control for critical industrial processes; scalable design methodology for varying capacity requirements; robust performance in demanding industrial environments. Weaknesses: Higher implementation costs compared to conventional cooling systems; requires specialized engineering knowledge for optimal deployment; limited cost-effectiveness for large-scale cooling applications.

Key Technical Parameters and Performance Metrics

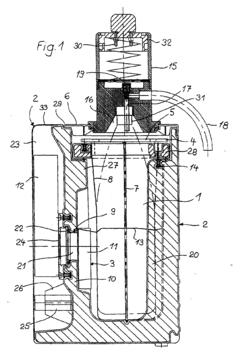

Tempering device for liquid contained in receptacles

PatentInactiveEP1069388A3

Innovation

- A device utilizing Peltier elements with a water-filled housing and a water-impermeable film stocking for intensive heat transfer, allowing for rapid temperature control of bottles of different sizes, with optional heating capability and a pump system to manage contents without removing the bottle.

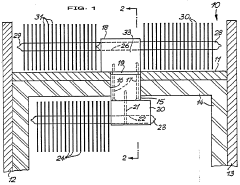

Refrigerating unit for refrigerator

PatentWO1989006335A1

Innovation

- A thermoelectric Peltier element-based cooling unit with a heat-conducting connection between an internal and external heat exchanger, regulated by an electrical circuit arrangement to manage energy supply, eliminating moving parts and ensuring efficient heat transfer without power peaks.

Energy Consumption and Sustainability Considerations

The energy consumption of Peltier-based refrigeration systems represents a significant consideration in their practical application, particularly for small-scale implementations. Thermoelectric cooling devices typically exhibit lower coefficient of performance (COP) values compared to conventional vapor-compression refrigeration systems, with Peltier elements generally operating at COPs between 0.3-0.7 under optimal conditions. This inherent inefficiency translates to higher energy consumption per unit of cooling capacity, making energy usage a critical factor in system design and implementation.

When sizing Peltier elements for small-scale refrigeration applications, designers must carefully balance the cooling requirements against power consumption constraints. The calculation workbook demonstrates that power requirements increase non-linearly with the desired temperature differential, with significant energy penalties observed when attempting to achieve temperature differentials exceeding 30°C. This relationship necessitates careful optimization to avoid oversizing, which would result in unnecessary energy expenditure.

From a sustainability perspective, the direct energy consumption of Peltier-based systems must be evaluated within a broader lifecycle assessment framework. While operational efficiency remains lower than conventional cooling technologies, thermoelectric systems offer advantages including the absence of refrigerants with high global warming potential (GWP), longer operational lifespans due to no moving parts, and reduced maintenance requirements. These factors can partially offset the higher energy consumption when conducting comprehensive environmental impact analyses.

Material considerations also factor prominently in sustainability assessments. Peltier elements typically contain bismuth telluride semiconductor materials, which present resource scarcity and extraction impact concerns. The manufacturing process energy intensity and end-of-life recyclability of these materials must be factored into holistic sustainability evaluations. Current research indicates that the embodied energy in Peltier element production represents a significant portion of their lifetime environmental footprint.

Application-specific energy optimization strategies can substantially improve the sustainability profile of Peltier-based cooling systems. The calculation workbook demonstrates that implementing variable power control based on dynamic cooling needs, optimizing thermal insulation to reduce heat leakage, and employing heat sink designs that maximize heat dissipation efficiency can collectively reduce energy consumption by 15-30% compared to basic implementations. These optimizations are particularly valuable in battery-powered or renewable energy applications where energy efficiency directly impacts system viability.

Emerging research directions in this field include the development of segmented thermoelectric materials with improved efficiency across wider temperature ranges, hybrid cooling systems that combine Peltier elements with passive cooling techniques, and advanced control algorithms that continuously optimize power delivery based on real-time cooling demands and ambient conditions.

When sizing Peltier elements for small-scale refrigeration applications, designers must carefully balance the cooling requirements against power consumption constraints. The calculation workbook demonstrates that power requirements increase non-linearly with the desired temperature differential, with significant energy penalties observed when attempting to achieve temperature differentials exceeding 30°C. This relationship necessitates careful optimization to avoid oversizing, which would result in unnecessary energy expenditure.

From a sustainability perspective, the direct energy consumption of Peltier-based systems must be evaluated within a broader lifecycle assessment framework. While operational efficiency remains lower than conventional cooling technologies, thermoelectric systems offer advantages including the absence of refrigerants with high global warming potential (GWP), longer operational lifespans due to no moving parts, and reduced maintenance requirements. These factors can partially offset the higher energy consumption when conducting comprehensive environmental impact analyses.

Material considerations also factor prominently in sustainability assessments. Peltier elements typically contain bismuth telluride semiconductor materials, which present resource scarcity and extraction impact concerns. The manufacturing process energy intensity and end-of-life recyclability of these materials must be factored into holistic sustainability evaluations. Current research indicates that the embodied energy in Peltier element production represents a significant portion of their lifetime environmental footprint.

Application-specific energy optimization strategies can substantially improve the sustainability profile of Peltier-based cooling systems. The calculation workbook demonstrates that implementing variable power control based on dynamic cooling needs, optimizing thermal insulation to reduce heat leakage, and employing heat sink designs that maximize heat dissipation efficiency can collectively reduce energy consumption by 15-30% compared to basic implementations. These optimizations are particularly valuable in battery-powered or renewable energy applications where energy efficiency directly impacts system viability.

Emerging research directions in this field include the development of segmented thermoelectric materials with improved efficiency across wider temperature ranges, hybrid cooling systems that combine Peltier elements with passive cooling techniques, and advanced control algorithms that continuously optimize power delivery based on real-time cooling demands and ambient conditions.

Thermal Management System Integration Guidelines

Thermal Management System Integration Guidelines

Effective integration of Peltier elements into small-scale refrigeration systems requires comprehensive thermal management strategies. When designing such systems, engineers must consider the entire thermal path from the cold side to the ambient environment. The thermal resistance of each component in this path significantly impacts overall system performance and efficiency.

Heat sink selection represents a critical decision point in the integration process. For optimal performance, heat sinks should be sized according to the total heat load, which includes both the heat being pumped from the cold side and the electrical power input to the Peltier element. Copper or aluminum heat sinks with appropriate fin designs are typically recommended, with forced convection cooling often necessary to manage the substantial heat rejection requirements.

Thermal interface materials (TIMs) play an essential role in minimizing contact resistance between the Peltier element and adjacent components. High-quality thermal greases, phase change materials, or graphite pads should be selected based on the specific application requirements, temperature range, and expected operational lifetime. Proper application techniques are crucial to avoid air gaps that can significantly degrade thermal performance.

System insulation strategies must be implemented to minimize parasitic heat loads. The cold side of the system should be thermally isolated from the ambient environment using appropriate insulation materials such as closed-cell foam or vacuum insulation panels. Special attention must be paid to thermal bridges that can bypass insulation and reduce system efficiency.

Condensation management represents another integration challenge, particularly when operating below the dew point. Proper sealing and moisture barriers should be incorporated into the design to prevent water ingress into electrical components. In some applications, condensate collection and removal systems may be necessary.

Control system integration is vital for optimizing Peltier element performance across varying conditions. Temperature sensors should be strategically placed to monitor both hot and cold side temperatures, with feedback loops implemented to adjust power input based on cooling demand. Advanced control algorithms can significantly improve energy efficiency by preventing overcooling and optimizing the coefficient of performance.

Mechanical mounting considerations must address both thermal and structural requirements. Mounting hardware should provide adequate pressure for good thermal contact while accommodating thermal expansion differences between materials. Vibration isolation may be necessary in certain applications to prevent mechanical fatigue of the thermoelectric modules.

Effective integration of Peltier elements into small-scale refrigeration systems requires comprehensive thermal management strategies. When designing such systems, engineers must consider the entire thermal path from the cold side to the ambient environment. The thermal resistance of each component in this path significantly impacts overall system performance and efficiency.

Heat sink selection represents a critical decision point in the integration process. For optimal performance, heat sinks should be sized according to the total heat load, which includes both the heat being pumped from the cold side and the electrical power input to the Peltier element. Copper or aluminum heat sinks with appropriate fin designs are typically recommended, with forced convection cooling often necessary to manage the substantial heat rejection requirements.

Thermal interface materials (TIMs) play an essential role in minimizing contact resistance between the Peltier element and adjacent components. High-quality thermal greases, phase change materials, or graphite pads should be selected based on the specific application requirements, temperature range, and expected operational lifetime. Proper application techniques are crucial to avoid air gaps that can significantly degrade thermal performance.

System insulation strategies must be implemented to minimize parasitic heat loads. The cold side of the system should be thermally isolated from the ambient environment using appropriate insulation materials such as closed-cell foam or vacuum insulation panels. Special attention must be paid to thermal bridges that can bypass insulation and reduce system efficiency.

Condensation management represents another integration challenge, particularly when operating below the dew point. Proper sealing and moisture barriers should be incorporated into the design to prevent water ingress into electrical components. In some applications, condensate collection and removal systems may be necessary.

Control system integration is vital for optimizing Peltier element performance across varying conditions. Temperature sensors should be strategically placed to monitor both hot and cold side temperatures, with feedback loops implemented to adjust power input based on cooling demand. Advanced control algorithms can significantly improve energy efficiency by preventing overcooling and optimizing the coefficient of performance.

Mechanical mounting considerations must address both thermal and structural requirements. Mounting hardware should provide adequate pressure for good thermal contact while accommodating thermal expansion differences between materials. Vibration isolation may be necessary in certain applications to prevent mechanical fatigue of the thermoelectric modules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!