Peltier Effect Standards and Test Methods: What Engineers Need to Reference

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Peltier Effect Technology Background and Objectives

The Peltier effect, discovered by Jean Charles Athanase Peltier in 1834, represents a thermoelectric phenomenon where heat transfer occurs at the junction of two different conductors when an electric current passes through them. This discovery laid the foundation for modern thermoelectric cooling technologies, which have evolved significantly over nearly two centuries. The progression from theoretical understanding to practical application accelerated in the mid-20th century with semiconductor advancements, enabling more efficient thermoelectric devices.

The technology has experienced three major evolutionary phases: initial discovery and theoretical development (1834-1950s), semiconductor implementation and efficiency improvements (1950s-1990s), and modern optimization with advanced materials and manufacturing techniques (1990s-present). Current research focuses on enhancing the figure of merit (ZT) of thermoelectric materials, with values exceeding 2.0 now achievable in laboratory settings compared to 0.7-1.0 in conventional commercial devices.

Despite widespread application across industries including electronics cooling, medical devices, automotive systems, and aerospace, standardized testing methodologies for Peltier devices remain fragmented. Engineers currently reference various standards from organizations such as IEEE, ASTM, and ISO, but a comprehensive unified framework specifically for thermoelectric cooling devices is lacking. This creates challenges in performance comparison, quality assurance, and design optimization.

The primary technical objectives for Peltier effect standardization include establishing uniform testing protocols for key performance parameters such as coefficient of performance (COP), maximum temperature differential (ΔTmax), and reliability metrics. Additionally, there is a critical need to develop standardized methodologies for measuring thermal resistance, electrical characteristics, and long-term stability under various operating conditions.

Emerging applications in energy harvesting, wearable technologies, and IoT devices further emphasize the importance of developing appropriate testing standards that address miniaturization, flexibility, and integration with other systems. The increasing demand for energy-efficient cooling solutions in data centers and electronic devices also drives the need for standardized performance metrics that accurately reflect real-world operating conditions.

The convergence of nanotechnology with thermoelectric materials presents promising avenues for efficiency improvements, but also introduces new challenges in characterization and testing. Quantum dot superlattices, nanowire arrays, and other nanostructured materials require specialized testing approaches that can accurately assess their unique thermoelectric properties while maintaining comparability with conventional devices.

The technology has experienced three major evolutionary phases: initial discovery and theoretical development (1834-1950s), semiconductor implementation and efficiency improvements (1950s-1990s), and modern optimization with advanced materials and manufacturing techniques (1990s-present). Current research focuses on enhancing the figure of merit (ZT) of thermoelectric materials, with values exceeding 2.0 now achievable in laboratory settings compared to 0.7-1.0 in conventional commercial devices.

Despite widespread application across industries including electronics cooling, medical devices, automotive systems, and aerospace, standardized testing methodologies for Peltier devices remain fragmented. Engineers currently reference various standards from organizations such as IEEE, ASTM, and ISO, but a comprehensive unified framework specifically for thermoelectric cooling devices is lacking. This creates challenges in performance comparison, quality assurance, and design optimization.

The primary technical objectives for Peltier effect standardization include establishing uniform testing protocols for key performance parameters such as coefficient of performance (COP), maximum temperature differential (ΔTmax), and reliability metrics. Additionally, there is a critical need to develop standardized methodologies for measuring thermal resistance, electrical characteristics, and long-term stability under various operating conditions.

Emerging applications in energy harvesting, wearable technologies, and IoT devices further emphasize the importance of developing appropriate testing standards that address miniaturization, flexibility, and integration with other systems. The increasing demand for energy-efficient cooling solutions in data centers and electronic devices also drives the need for standardized performance metrics that accurately reflect real-world operating conditions.

The convergence of nanotechnology with thermoelectric materials presents promising avenues for efficiency improvements, but also introduces new challenges in characterization and testing. Quantum dot superlattices, nanowire arrays, and other nanostructured materials require specialized testing approaches that can accurately assess their unique thermoelectric properties while maintaining comparability with conventional devices.

Market Applications and Demand Analysis

The global market for Peltier effect devices, also known as thermoelectric coolers (TECs), has experienced significant growth driven by increasing demand across multiple industries. The thermoelectric cooling market was valued at approximately $707 million in 2022 and is projected to reach $1.2 billion by 2028, growing at a CAGR of 9.2% during the forecast period. This growth trajectory underscores the expanding applications and market penetration of Peltier-based technologies.

Consumer electronics represents one of the largest application segments, with Peltier devices being integrated into portable coolers, temperature-controlled seats, and electronic component cooling systems. The automotive industry has emerged as a particularly dynamic market, incorporating thermoelectric modules in climate control systems, battery thermal management for electric vehicles, and seat cooling/heating applications. This sector's demand is expected to grow substantially as vehicle electrification accelerates globally.

Medical and healthcare applications constitute another significant market segment, where precise temperature control is critical for diagnostic equipment, sample storage, and therapeutic devices. The increasing focus on point-of-care diagnostics and personalized medicine has further stimulated demand for compact, reliable thermoelectric cooling solutions in this sector.

Industrial and telecommunications applications represent substantial market opportunities, with data centers and telecommunications infrastructure requiring efficient cooling solutions for heat-sensitive electronic components. The ongoing expansion of 5G networks and edge computing facilities is driving increased adoption of Peltier-based cooling systems optimized for these applications.

Market research indicates growing demand for standardized testing methods and performance metrics across these diverse application domains. Engineers and product developers consistently report challenges in comparing different manufacturers' specifications due to inconsistent testing methodologies. A survey of electronics design engineers revealed that 78% consider standardized performance metrics "very important" or "critical" when selecting thermoelectric components.

Regional analysis shows North America and Europe leading in terms of market value, while Asia-Pacific represents the fastest-growing region with expanding manufacturing capabilities in China, South Korea, and Japan. The increasing focus on energy efficiency and environmental regulations is driving demand for standardized performance metrics that accurately reflect real-world energy consumption and cooling efficiency.

Market trends indicate growing interest in miniaturized Peltier modules for space-constrained applications and increased focus on reliability testing for mission-critical implementations. This evolution of application requirements underscores the need for comprehensive, standardized test methods that address not only basic performance parameters but also reliability, durability, and long-term stability under various operating conditions.

Consumer electronics represents one of the largest application segments, with Peltier devices being integrated into portable coolers, temperature-controlled seats, and electronic component cooling systems. The automotive industry has emerged as a particularly dynamic market, incorporating thermoelectric modules in climate control systems, battery thermal management for electric vehicles, and seat cooling/heating applications. This sector's demand is expected to grow substantially as vehicle electrification accelerates globally.

Medical and healthcare applications constitute another significant market segment, where precise temperature control is critical for diagnostic equipment, sample storage, and therapeutic devices. The increasing focus on point-of-care diagnostics and personalized medicine has further stimulated demand for compact, reliable thermoelectric cooling solutions in this sector.

Industrial and telecommunications applications represent substantial market opportunities, with data centers and telecommunications infrastructure requiring efficient cooling solutions for heat-sensitive electronic components. The ongoing expansion of 5G networks and edge computing facilities is driving increased adoption of Peltier-based cooling systems optimized for these applications.

Market research indicates growing demand for standardized testing methods and performance metrics across these diverse application domains. Engineers and product developers consistently report challenges in comparing different manufacturers' specifications due to inconsistent testing methodologies. A survey of electronics design engineers revealed that 78% consider standardized performance metrics "very important" or "critical" when selecting thermoelectric components.

Regional analysis shows North America and Europe leading in terms of market value, while Asia-Pacific represents the fastest-growing region with expanding manufacturing capabilities in China, South Korea, and Japan. The increasing focus on energy efficiency and environmental regulations is driving demand for standardized performance metrics that accurately reflect real-world energy consumption and cooling efficiency.

Market trends indicate growing interest in miniaturized Peltier modules for space-constrained applications and increased focus on reliability testing for mission-critical implementations. This evolution of application requirements underscores the need for comprehensive, standardized test methods that address not only basic performance parameters but also reliability, durability, and long-term stability under various operating conditions.

Current Standards and Testing Challenges

The Peltier effect, while widely utilized in various cooling and heating applications, faces significant challenges in standardization and testing methodologies. Currently, there exists a fragmented landscape of standards across different regions and industries, creating inconsistencies in performance evaluation and product certification.

IEEE Standard 1834-2019 represents one of the most comprehensive frameworks for thermoelectric devices, providing guidelines for characterizing performance parameters such as the figure of merit (ZT), thermal conductivity, and electrical resistivity. However, this standard primarily focuses on material properties rather than system-level performance, creating a gap in holistic device evaluation.

ASTM International offers several relevant standards, including ASTM E2102 for measuring thermoelectric properties and ASTM D5470 for thermal interface materials, which are often applied to Peltier modules. These standards, while valuable, were not specifically developed for thermoelectric cooling applications, leading to adaptation challenges when applied to Peltier devices.

The International Electrotechnical Commission (IEC) has developed IEC 62830-5, which addresses energy harvesting applications of thermoelectric devices but provides limited guidance for cooling applications. This disconnect between energy harvesting and cooling standards creates confusion among engineers seeking comprehensive testing protocols.

A significant challenge in current testing methodologies is the lack of standardized environmental conditions. Temperature differentials, ambient conditions, and heat load variations significantly impact Peltier device performance, yet standardized testing environments remain poorly defined across existing frameworks.

Measurement accuracy presents another critical challenge, particularly regarding temperature sensing at the hot and cold junctions of Peltier devices. Current standards provide insufficient guidance on sensor placement, calibration requirements, and measurement uncertainty quantification, leading to reproducibility issues across different testing facilities.

The absence of accelerated life testing standards specifically designed for Peltier devices hampers reliability assessment. While general reliability standards exist for electronic components, the unique thermal cycling and electrical stresses experienced by thermoelectric devices require specialized testing protocols that current standards fail to address adequately.

Cross-compatibility between standards remains problematic, with engineers often forced to reference multiple, sometimes contradictory standards to fully characterize device performance. This fragmentation increases testing complexity and costs while reducing result comparability across different manufacturers and applications.

IEEE Standard 1834-2019 represents one of the most comprehensive frameworks for thermoelectric devices, providing guidelines for characterizing performance parameters such as the figure of merit (ZT), thermal conductivity, and electrical resistivity. However, this standard primarily focuses on material properties rather than system-level performance, creating a gap in holistic device evaluation.

ASTM International offers several relevant standards, including ASTM E2102 for measuring thermoelectric properties and ASTM D5470 for thermal interface materials, which are often applied to Peltier modules. These standards, while valuable, were not specifically developed for thermoelectric cooling applications, leading to adaptation challenges when applied to Peltier devices.

The International Electrotechnical Commission (IEC) has developed IEC 62830-5, which addresses energy harvesting applications of thermoelectric devices but provides limited guidance for cooling applications. This disconnect between energy harvesting and cooling standards creates confusion among engineers seeking comprehensive testing protocols.

A significant challenge in current testing methodologies is the lack of standardized environmental conditions. Temperature differentials, ambient conditions, and heat load variations significantly impact Peltier device performance, yet standardized testing environments remain poorly defined across existing frameworks.

Measurement accuracy presents another critical challenge, particularly regarding temperature sensing at the hot and cold junctions of Peltier devices. Current standards provide insufficient guidance on sensor placement, calibration requirements, and measurement uncertainty quantification, leading to reproducibility issues across different testing facilities.

The absence of accelerated life testing standards specifically designed for Peltier devices hampers reliability assessment. While general reliability standards exist for electronic components, the unique thermal cycling and electrical stresses experienced by thermoelectric devices require specialized testing protocols that current standards fail to address adequately.

Cross-compatibility between standards remains problematic, with engineers often forced to reference multiple, sometimes contradictory standards to fully characterize device performance. This fragmentation increases testing complexity and costs while reducing result comparability across different manufacturers and applications.

Established Test Methods and Measurement Protocols

01 Testing methods for Peltier devices

Various testing methods have been developed to evaluate the performance and characteristics of Peltier devices. These methods include measuring thermal conductivity, electrical resistance, and temperature differentials across the device. Standardized testing procedures help ensure consistent evaluation of Peltier effect devices under controlled conditions, allowing for accurate comparison between different devices and manufacturers.- Standardized testing methods for Peltier devices: Various standardized methods have been developed for testing Peltier effect devices to ensure consistent performance evaluation. These methods include procedures for measuring thermal conductivity, electrical resistance, and temperature differentials across thermoelectric modules. The testing protocols often involve specialized equipment and controlled environmental conditions to obtain accurate and reproducible results. These standards help manufacturers and researchers compare different Peltier devices and ensure they meet specific performance requirements.

- Performance measurement techniques for thermoelectric cooling systems: Specific techniques have been developed to measure the performance of thermoelectric cooling systems that utilize the Peltier effect. These techniques include methods for determining coefficient of performance (COP), cooling capacity, and power consumption under various operating conditions. The measurement approaches often involve temperature sensors, heat flux meters, and electrical measurement tools to characterize the efficiency and effectiveness of Peltier-based cooling systems. These techniques help optimize the design and operation of thermoelectric cooling applications.

- Quality control and reliability testing for Peltier modules: Quality control and reliability testing methods have been established for Peltier modules to ensure long-term performance and durability. These methods include accelerated aging tests, thermal cycling, mechanical stress testing, and failure analysis procedures. The testing protocols help identify potential defects, estimate service life, and verify the robustness of thermoelectric modules under various environmental conditions. These quality assurance measures are essential for applications requiring high reliability and consistent performance over extended periods.

- Calibration standards for Peltier effect measurement equipment: Calibration standards and procedures have been developed for equipment used to measure Peltier effect parameters. These standards ensure the accuracy and traceability of measurements related to thermoelectric phenomena. The calibration methods typically involve reference materials with known thermoelectric properties, temperature calibration devices, and electrical calibration standards. Proper calibration is crucial for research, development, and quality control activities involving Peltier effect devices, as it enables reliable comparison of results across different laboratories and testing facilities.

- Characterization methods for thermoelectric materials: Specialized characterization methods have been developed for evaluating the properties of thermoelectric materials used in Peltier devices. These methods include techniques for measuring Seebeck coefficient, electrical conductivity, thermal conductivity, and figure of merit (ZT). The characterization approaches often involve specialized equipment such as laser flash apparatus, four-probe electrical measurements, and Hall effect measurements. These methods help researchers develop and optimize new thermoelectric materials with improved efficiency and performance for various applications.

02 Calibration standards for thermoelectric systems

Calibration standards are essential for ensuring the accuracy and reliability of Peltier effect measurements. These standards define reference points and procedures for calibrating instruments used in thermoelectric testing. Proper calibration helps minimize measurement errors and ensures that test results are comparable across different laboratories and testing environments.Expand Specific Solutions03 Performance evaluation metrics for Peltier devices

Specific metrics have been established to evaluate the performance of Peltier effect devices. These include coefficient of performance (COP), figure of merit (ZT), power consumption, heat transfer capacity, and temperature stability. These standardized metrics allow for objective comparison of different thermoelectric cooling and heating systems and help in selecting appropriate devices for specific applications.Expand Specific Solutions04 Quality control methods for thermoelectric materials

Quality control methods have been developed to ensure the consistency and reliability of thermoelectric materials used in Peltier devices. These methods include testing for material purity, homogeneity, and thermoelectric properties. Standardized quality control procedures help manufacturers maintain consistent production quality and ensure that the final devices meet performance specifications.Expand Specific Solutions05 Environmental testing standards for Peltier applications

Environmental testing standards have been established to evaluate the performance of Peltier devices under various environmental conditions. These standards include testing for temperature extremes, humidity, vibration, and long-term reliability. Environmental testing helps ensure that Peltier devices can operate reliably in their intended applications and environments, from consumer electronics to industrial and aerospace applications.Expand Specific Solutions

Leading Organizations and Manufacturers in Thermoelectric Industry

The Peltier Effect standards and test methods landscape is currently in a growth phase, with increasing market demand driven by thermoelectric applications across multiple industries. The technology has reached moderate maturity, with established players like State Grid Corporation of China and its research institutes leading standardization efforts in power applications. Companies such as BASF Coatings, F. Hoffmann-La Roche, and Carl Zeiss are advancing precision testing methodologies in their respective sectors. Academic institutions including Xi'an Jiaotong University and Shandong University contribute significant research to improve measurement accuracy. The competitive environment features collaboration between industry giants and specialized research organizations to develop internationally recognized standards, with particular focus on improving efficiency and reliability metrics.

Centro Sviluppo Materiali SpA

Technical Solution: Centro Sviluppo Materiali (CSM) has established comprehensive test methodologies for Peltier devices used in industrial process control and metallurgical applications. Their approach focuses on high-temperature performance characterization, with standardized protocols for evaluating thermoelectric modules operating in harsh industrial environments. CSM has developed specialized test rigs that can simultaneously measure electrical, thermal, and mechanical properties of Peltier devices under controlled conditions. Their test methods incorporate precise thermal imaging techniques to map temperature distributions across module surfaces, identifying non-uniformities that affect performance. The company has established reference standards for comparing device performance across different manufacturers, with particular attention to long-term stability under thermal cycling. Their methodology includes accelerated aging tests that correlate with field performance data, enabling more accurate lifetime predictions. Additionally, CSM has contributed to international standardization efforts by developing test procedures that address the challenges of measuring thermoelectric properties at elevated temperatures where traditional methods often fail.

Strengths: Specialized expertise in high-temperature applications and industrial environments, with robust test methods that address both performance and reliability aspects. Weaknesses: Focus on industrial applications may limit relevance to consumer electronics or medical device sectors, and their test methods may require expensive specialized equipment.

Imra Europe SAS

Technical Solution: Imra Europe SAS has developed advanced characterization techniques for Peltier devices focused on automotive and industrial applications. Their approach includes high-precision measurement systems for thermoelectric parameters across wide temperature ranges (-40°C to 150°C) relevant to automotive environments. The company has established standardized test protocols that evaluate both steady-state performance and transient response characteristics critical for dynamic thermal management applications. Their methodology incorporates automated test sequences that measure the Seebeck coefficient, electrical resistivity, and thermal conductivity while accounting for temperature-dependent variations in these parameters. Imra's test systems feature calibrated reference materials that ensure measurement traceability to international standards. They have also developed specialized fixtures that minimize parasitic heat flows and contact resistances during measurement, addressing key sources of error in Peltier device characterization. Their comprehensive approach includes performance mapping under various electrical input conditions and thermal boundary constraints, providing engineers with detailed performance envelopes for design optimization.

Strengths: Industry-focused test methods with direct applicability to automotive and industrial applications, with particular expertise in dynamic performance characterization under varying operating conditions. Weaknesses: Proprietary nature of some test methodologies may limit widespread adoption, and their specialized equipment requirements could present barriers to implementation in smaller organizations.

Critical Standards and Reference Materials Analysis

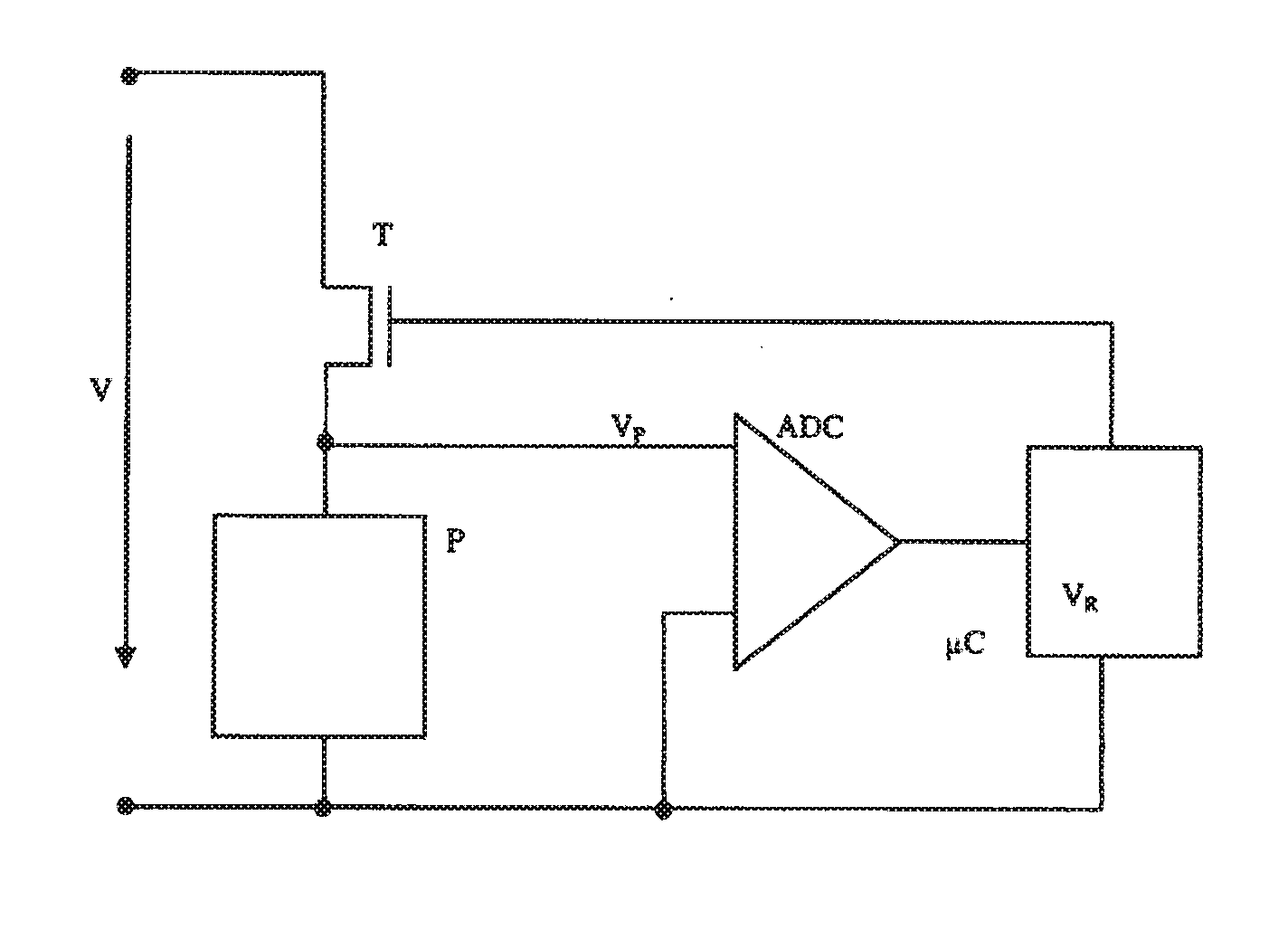

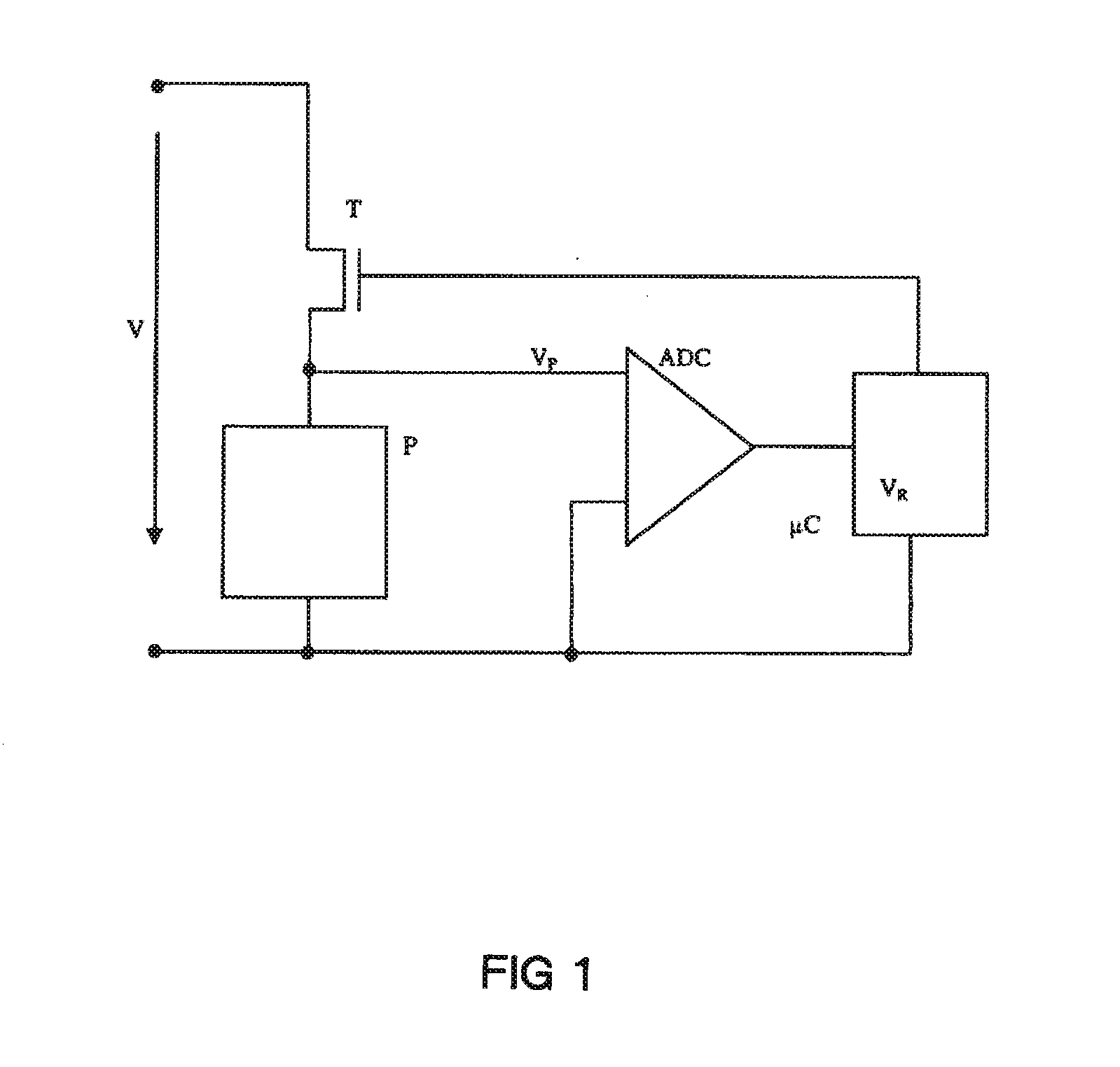

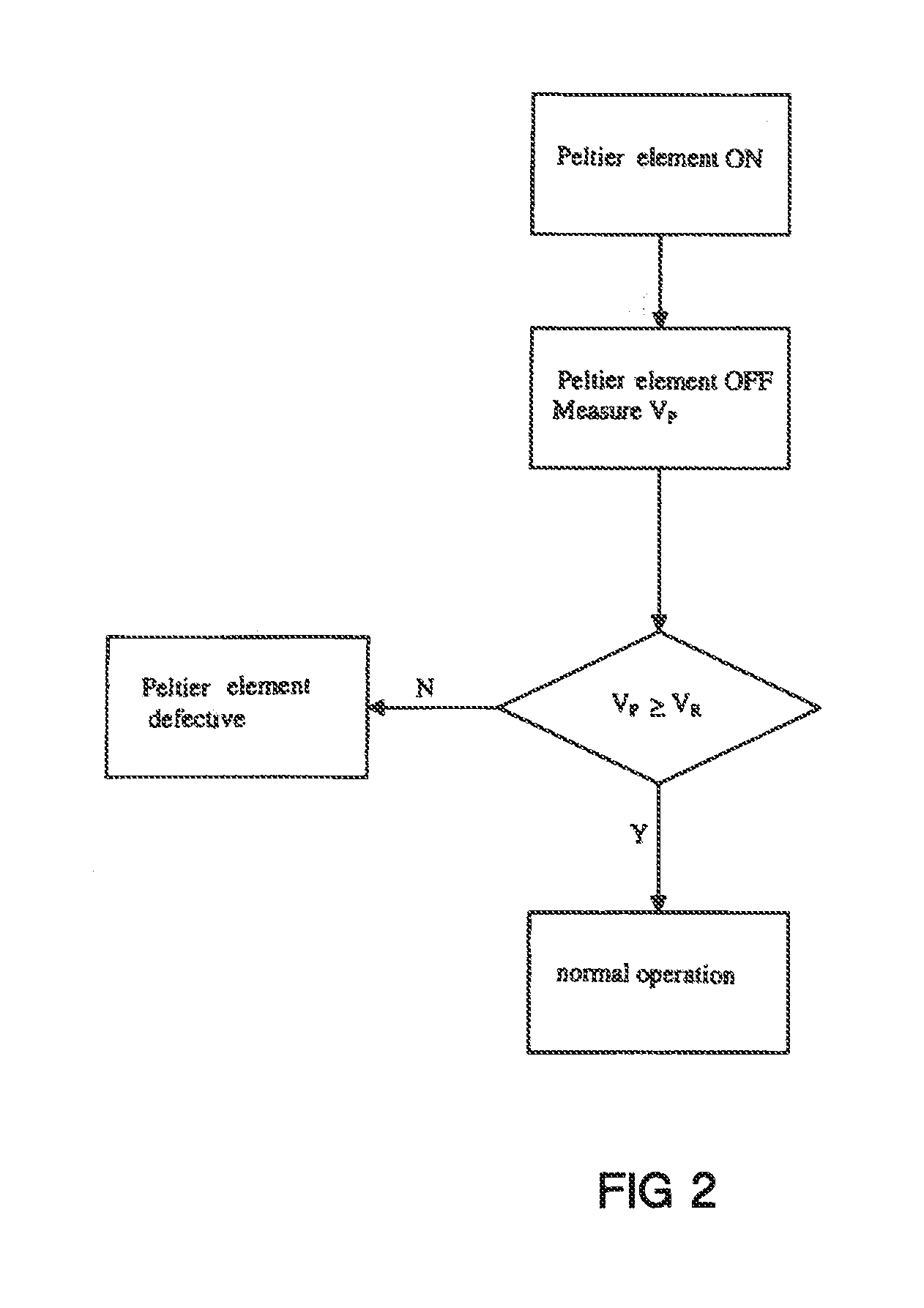

Method for testing a peltier element as well as a small electrical appliance with a peltier element and a safety device

PatentInactiveUS20120234022A1

Innovation

- A method involving applying voltage to the Peltier element for a period, measuring the resulting thermoelectric voltage after switching off, and comparing it to a reference value to determine integrity, with a safety device using a microcontroller and switch to prevent unsafe operation if defective, and optionally including a temperature sensor for additional safety measures.

Peltier effect temperature control device

PatentInactiveGB2112565B

Innovation

- A temperature control device with a substrate and conductors forming thermocouple junctions on the same surface as circuit elements, allowing for efficient heat transfer and integration within the hybrid circuit, using semiconductor layers and dissimilar metals with insulating materials to facilitate heat exchange.

International Compliance and Certification Requirements

Compliance with international standards and certifications is crucial for manufacturers and integrators of Peltier effect devices. The global nature of thermoelectric technology markets necessitates adherence to various regional and international regulatory frameworks. The International Electrotechnical Commission (IEC) provides several standards relevant to thermoelectric cooling devices, including IEC 62108 for concentrated photovoltaic modules and assemblies, which includes testing procedures for thermoelectric components. Additionally, IEC 61215 outlines design qualification and type approval for photovoltaic modules, with sections applicable to thermoelectric cooling systems used in conjunction with PV technology.

In North America, Underwriters Laboratories (UL) certification is often required, with UL 1995 covering heating and cooling equipment that may incorporate Peltier devices. The European market demands CE marking compliance, requiring manufacturers to meet the Low Voltage Directive (2014/35/EU), Electromagnetic Compatibility Directive (2014/30/EU), and RoHS Directive (2011/65/EU) for restriction of hazardous substances. The European Committee for Standardization (CEN) has developed EN 62108, which harmonizes with the IEC standard but includes specific European requirements.

For energy efficiency certification, the U.S. Environmental Protection Agency's ENERGY STAR program includes specifications for products that may incorporate thermoelectric cooling technology. Similarly, the European Union's Energy-related Products (ErP) Directive establishes eco-design requirements for energy-related products, including those utilizing Peltier effect technology.

In Asia, Japan's JIS C 8954 provides standards for thermoelectric conversion modules, while China's GB/T standards include GB/T 17814 for thermoelectric coolers. These standards specify performance metrics, safety requirements, and testing methodologies specific to the regional markets.

The IEEE Standards Association has developed IEEE 1834-2019, which establishes standard test methods for thermoelectric materials, providing a framework for consistent evaluation of material properties critical to Peltier effect devices. This standard is particularly valuable for research and development teams working on new thermoelectric materials.

For medical applications of Peltier technology, compliance with ISO 13485 for medical device quality management systems and IEC 60601 for medical electrical equipment safety is mandatory. Similarly, aerospace applications must meet standards such as DO-160 for environmental conditions and test procedures for airborne equipment, which includes thermal management systems utilizing thermoelectric cooling.

Engineers must also consider environmental compliance standards such as WEEE (Waste Electrical and Electronic Equipment) for end-of-life disposal and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) for chemical substance management in products sold in the European market.

In North America, Underwriters Laboratories (UL) certification is often required, with UL 1995 covering heating and cooling equipment that may incorporate Peltier devices. The European market demands CE marking compliance, requiring manufacturers to meet the Low Voltage Directive (2014/35/EU), Electromagnetic Compatibility Directive (2014/30/EU), and RoHS Directive (2011/65/EU) for restriction of hazardous substances. The European Committee for Standardization (CEN) has developed EN 62108, which harmonizes with the IEC standard but includes specific European requirements.

For energy efficiency certification, the U.S. Environmental Protection Agency's ENERGY STAR program includes specifications for products that may incorporate thermoelectric cooling technology. Similarly, the European Union's Energy-related Products (ErP) Directive establishes eco-design requirements for energy-related products, including those utilizing Peltier effect technology.

In Asia, Japan's JIS C 8954 provides standards for thermoelectric conversion modules, while China's GB/T standards include GB/T 17814 for thermoelectric coolers. These standards specify performance metrics, safety requirements, and testing methodologies specific to the regional markets.

The IEEE Standards Association has developed IEEE 1834-2019, which establishes standard test methods for thermoelectric materials, providing a framework for consistent evaluation of material properties critical to Peltier effect devices. This standard is particularly valuable for research and development teams working on new thermoelectric materials.

For medical applications of Peltier technology, compliance with ISO 13485 for medical device quality management systems and IEC 60601 for medical electrical equipment safety is mandatory. Similarly, aerospace applications must meet standards such as DO-160 for environmental conditions and test procedures for airborne equipment, which includes thermal management systems utilizing thermoelectric cooling.

Engineers must also consider environmental compliance standards such as WEEE (Waste Electrical and Electronic Equipment) for end-of-life disposal and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) for chemical substance management in products sold in the European market.

Environmental Impact and Sustainability Considerations

The environmental impact of Peltier effect devices presents a significant consideration for engineers and manufacturers in today's sustainability-focused landscape. These thermoelectric devices, while offering advantages in precise temperature control without moving parts, carry notable environmental implications throughout their lifecycle. The manufacturing process involves several rare earth elements and semiconductor materials that require energy-intensive mining and processing operations, contributing to habitat disruption and potential pollution when not properly managed.

Energy efficiency remains a primary environmental concern with Peltier devices. Traditional thermoelectric coolers typically operate at only 5-10% efficiency, resulting in substantial energy consumption relative to their cooling capacity. This inefficiency translates directly to increased carbon emissions when powered by non-renewable energy sources. Recent advancements in material science have improved this efficiency, but the technology still lags behind conventional vapor-compression cooling systems in terms of energy performance.

Waste management considerations are equally important, as Peltier devices contain bismuth telluride and other materials that require specialized disposal procedures. Improper disposal can lead to soil and water contamination, highlighting the need for comprehensive end-of-life management strategies. Several countries have implemented regulations requiring manufacturers to establish take-back programs for thermoelectric devices, promoting responsible recycling and material recovery.

The sustainability profile of Peltier technology can be significantly improved through several approaches. Extending device lifespan through improved design and manufacturing standards reduces replacement frequency and associated resource consumption. Additionally, integrating these devices with renewable energy sources such as solar power can substantially reduce their operational carbon footprint, particularly in remote applications where grid power is unavailable.

Emerging test methods now incorporate environmental impact assessments alongside traditional performance metrics. The Environmental Product Declaration (EPD) framework provides standardized methodology for evaluating the lifecycle environmental impact of thermoelectric devices. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) offers certification standards that engineers can reference when designing more sustainable Peltier-based systems.

Industry standards organizations have begun developing specific guidelines for sustainable thermoelectric applications. The International Electrotechnical Commission (IEC) has established working groups focused on environmental considerations for thermoelectric devices, while the IEEE Standards Association is developing frameworks for assessing the environmental performance of cooling technologies, including Peltier-based systems.

Energy efficiency remains a primary environmental concern with Peltier devices. Traditional thermoelectric coolers typically operate at only 5-10% efficiency, resulting in substantial energy consumption relative to their cooling capacity. This inefficiency translates directly to increased carbon emissions when powered by non-renewable energy sources. Recent advancements in material science have improved this efficiency, but the technology still lags behind conventional vapor-compression cooling systems in terms of energy performance.

Waste management considerations are equally important, as Peltier devices contain bismuth telluride and other materials that require specialized disposal procedures. Improper disposal can lead to soil and water contamination, highlighting the need for comprehensive end-of-life management strategies. Several countries have implemented regulations requiring manufacturers to establish take-back programs for thermoelectric devices, promoting responsible recycling and material recovery.

The sustainability profile of Peltier technology can be significantly improved through several approaches. Extending device lifespan through improved design and manufacturing standards reduces replacement frequency and associated resource consumption. Additionally, integrating these devices with renewable energy sources such as solar power can substantially reduce their operational carbon footprint, particularly in remote applications where grid power is unavailable.

Emerging test methods now incorporate environmental impact assessments alongside traditional performance metrics. The Environmental Product Declaration (EPD) framework provides standardized methodology for evaluating the lifecycle environmental impact of thermoelectric devices. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) offers certification standards that engineers can reference when designing more sustainable Peltier-based systems.

Industry standards organizations have begun developing specific guidelines for sustainable thermoelectric applications. The International Electrotechnical Commission (IEC) has established working groups focused on environmental considerations for thermoelectric devices, while the IEEE Standards Association is developing frameworks for assessing the environmental performance of cooling technologies, including Peltier-based systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!