How to Test LS1 Engine Compression

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine Compression Testing Background and Objectives

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in the evolution of small-block V8 engines. This 5.7-liter aluminum powerplant became the heart of numerous high-performance vehicles, including the Chevrolet Corvette C5 and Camaro SS. Understanding compression testing for these engines has become increasingly important as these vehicles age and require maintenance or performance optimization.

Compression testing serves as a fundamental diagnostic procedure that measures the pressure generated within each cylinder during the compression stroke. This critical measurement provides valuable insights into the internal health of an engine, particularly regarding the sealing capabilities of piston rings, valves, and head gaskets. For the LS1 engine specifically, proper compression testing helps identify issues that could affect performance, fuel efficiency, and overall engine longevity.

The evolution of compression testing techniques has paralleled advancements in engine technology. Traditional mechanical gauges have been supplemented by digital tools that offer enhanced precision and data logging capabilities. For LS1 engines, which feature sequential fuel injection and coil-near-plug ignition systems, modern testing approaches must account for these technological characteristics to ensure accurate diagnostics.

Industry standards suggest that a healthy LS1 engine typically demonstrates compression readings between 150-185 PSI across all cylinders, with variations between cylinders not exceeding 10%. These benchmarks have been established through extensive testing and real-world application data collected since the engine's introduction. Understanding these parameters is essential for effective diagnosis and maintenance.

The primary objectives of LS1 compression testing include identifying cylinder-specific issues, evaluating overall engine condition, establishing baseline measurements for future reference, and determining the necessity for more invasive repairs. Additionally, compression testing serves as a valuable tool for performance enthusiasts seeking to optimize their engines, as it provides critical data for tuning and modification decisions.

Recent technological trends have introduced more sophisticated approaches to compression analysis, including relative compression testing using amperage draw measurements and dynamic compression testing during actual engine operation. These advanced methods complement traditional static compression testing and provide a more comprehensive picture of engine health.

For automotive professionals and enthusiasts alike, mastering LS1 compression testing techniques represents an essential skill in the broader context of engine diagnostics. As these engines continue to age, the importance of accurate compression testing will only increase, driving further innovation in testing methodologies and equipment.

Compression testing serves as a fundamental diagnostic procedure that measures the pressure generated within each cylinder during the compression stroke. This critical measurement provides valuable insights into the internal health of an engine, particularly regarding the sealing capabilities of piston rings, valves, and head gaskets. For the LS1 engine specifically, proper compression testing helps identify issues that could affect performance, fuel efficiency, and overall engine longevity.

The evolution of compression testing techniques has paralleled advancements in engine technology. Traditional mechanical gauges have been supplemented by digital tools that offer enhanced precision and data logging capabilities. For LS1 engines, which feature sequential fuel injection and coil-near-plug ignition systems, modern testing approaches must account for these technological characteristics to ensure accurate diagnostics.

Industry standards suggest that a healthy LS1 engine typically demonstrates compression readings between 150-185 PSI across all cylinders, with variations between cylinders not exceeding 10%. These benchmarks have been established through extensive testing and real-world application data collected since the engine's introduction. Understanding these parameters is essential for effective diagnosis and maintenance.

The primary objectives of LS1 compression testing include identifying cylinder-specific issues, evaluating overall engine condition, establishing baseline measurements for future reference, and determining the necessity for more invasive repairs. Additionally, compression testing serves as a valuable tool for performance enthusiasts seeking to optimize their engines, as it provides critical data for tuning and modification decisions.

Recent technological trends have introduced more sophisticated approaches to compression analysis, including relative compression testing using amperage draw measurements and dynamic compression testing during actual engine operation. These advanced methods complement traditional static compression testing and provide a more comprehensive picture of engine health.

For automotive professionals and enthusiasts alike, mastering LS1 compression testing techniques represents an essential skill in the broader context of engine diagnostics. As these engines continue to age, the importance of accurate compression testing will only increase, driving further innovation in testing methodologies and equipment.

Market Demand Analysis for LS1 Engine Diagnostics

The LS1 engine compression testing market has experienced significant growth over the past decade, driven primarily by the widespread adoption of GM's LS series engines in various vehicles and aftermarket applications. Market research indicates that the global automotive diagnostic equipment market, which includes compression testing tools, is valued at approximately $45 billion, with specialized engine diagnostic tools representing a substantial segment of this market.

The demand for LS1 engine compression testing equipment stems from multiple consumer segments. Professional automotive repair shops constitute the largest market segment, accounting for roughly 60% of total demand. These businesses require reliable, efficient diagnostic tools to quickly assess engine health and provide accurate service recommendations to customers. Independent mechanics and DIY enthusiasts form the second-largest segment, representing about 30% of the market, with racing teams and performance shops comprising the remaining 10%.

Regional analysis reveals that North America dominates the market for LS1 diagnostic equipment, which aligns with the popularity of GM vehicles in this region. However, emerging markets in Eastern Europe, Australia, and parts of Asia are showing accelerated growth rates as LS engine swaps gain international popularity among automotive enthusiasts.

Consumer behavior studies indicate a growing preference for comprehensive diagnostic solutions rather than standalone compression testing tools. This trend is evidenced by the increasing sales of multi-function diagnostic equipment that can perform compression tests alongside other essential engine diagnostics. The average price point for professional-grade compression testing equipment ranges from $200 to $800, while consumer-grade options typically fall between $50 and $150.

Market forecasts project a compound annual growth rate of 5.7% for LS1 engine diagnostic equipment over the next five years. This growth is fueled by several factors, including the aging fleet of LS1-equipped vehicles now requiring more frequent maintenance, the continued popularity of LS engine swaps in custom builds, and the expanding aftermarket performance sector.

Customer pain points identified through market surveys include difficulties in accessing spark plug ports on certain LS1 configurations, time-consuming traditional testing methods, and challenges in interpreting results accurately. These pain points represent significant opportunities for innovation in compression testing methodologies and equipment design.

The subscription-based diagnostic software market is also emerging as a complementary segment, with annual revenues growing at approximately 12% as workshops and enthusiasts seek regularly updated diagnostic parameters and procedures specific to LS engines.

The demand for LS1 engine compression testing equipment stems from multiple consumer segments. Professional automotive repair shops constitute the largest market segment, accounting for roughly 60% of total demand. These businesses require reliable, efficient diagnostic tools to quickly assess engine health and provide accurate service recommendations to customers. Independent mechanics and DIY enthusiasts form the second-largest segment, representing about 30% of the market, with racing teams and performance shops comprising the remaining 10%.

Regional analysis reveals that North America dominates the market for LS1 diagnostic equipment, which aligns with the popularity of GM vehicles in this region. However, emerging markets in Eastern Europe, Australia, and parts of Asia are showing accelerated growth rates as LS engine swaps gain international popularity among automotive enthusiasts.

Consumer behavior studies indicate a growing preference for comprehensive diagnostic solutions rather than standalone compression testing tools. This trend is evidenced by the increasing sales of multi-function diagnostic equipment that can perform compression tests alongside other essential engine diagnostics. The average price point for professional-grade compression testing equipment ranges from $200 to $800, while consumer-grade options typically fall between $50 and $150.

Market forecasts project a compound annual growth rate of 5.7% for LS1 engine diagnostic equipment over the next five years. This growth is fueled by several factors, including the aging fleet of LS1-equipped vehicles now requiring more frequent maintenance, the continued popularity of LS engine swaps in custom builds, and the expanding aftermarket performance sector.

Customer pain points identified through market surveys include difficulties in accessing spark plug ports on certain LS1 configurations, time-consuming traditional testing methods, and challenges in interpreting results accurately. These pain points represent significant opportunities for innovation in compression testing methodologies and equipment design.

The subscription-based diagnostic software market is also emerging as a complementary segment, with annual revenues growing at approximately 12% as workshops and enthusiasts seek regularly updated diagnostic parameters and procedures specific to LS engines.

Current Compression Testing Technologies and Challenges

Compression testing is a critical diagnostic procedure for evaluating the mechanical health of an LS1 engine. Currently, several established technologies and methodologies are employed in the industry, each with specific applications and limitations. The conventional compression test remains the most widely utilized approach, involving the removal of all spark plugs, disabling the fuel and ignition systems, and measuring the pressure generated in each cylinder during cranking with a compression gauge. This method provides a straightforward comparative analysis of cylinder pressures, typically ranging from 150-185 PSI in healthy LS1 engines.

Wet compression testing represents an evolution of the standard method, incorporating the addition of small amounts of oil to cylinders before testing. This technique helps differentiate between ring and valve-related compression issues by temporarily sealing worn piston rings. A significant increase in pressure during wet testing compared to dry testing strongly indicates ring wear rather than valve problems.

Cylinder leakage testing (CLT) has emerged as a more sophisticated diagnostic tool, utilizing compressed air introduced into cylinders at TDC on the compression stroke. By measuring the percentage of air escaping, technicians can quantify compression loss and, importantly, identify the specific source of leakage by listening for escaping air at the intake, exhaust, or crankcase. This method provides more detailed diagnostic information than standard compression tests.

Despite technological advancements, several challenges persist in compression testing for LS1 engines. The deep-well spark plug design of LS1 heads creates accessibility issues, often requiring specialized tools and increasing testing time. Temperature-related variables significantly impact test results, with cold engines typically showing lower compression values than fully warmed engines, necessitating standardized testing conditions for accurate comparisons.

Modern LS1 engines incorporate variable valve timing and lift systems that can affect compression readings depending on their position during testing. This variability introduces complexity in result interpretation, particularly when comparing against standard specifications. Additionally, the high compression ratios in performance-modified LS1 engines often exceed the scale limits of standard compression gauges, requiring specialized high-pressure testing equipment.

Digital compression analyzers represent the cutting edge of current technology, offering real-time cylinder pressure waveform analysis and automated diagnostic capabilities. While these systems provide unprecedented insight into engine condition, their high cost and complexity limit widespread adoption, particularly in smaller service facilities. The integration of these advanced diagnostic tools with comprehensive engine management system data remains an ongoing challenge in the industry.

Wet compression testing represents an evolution of the standard method, incorporating the addition of small amounts of oil to cylinders before testing. This technique helps differentiate between ring and valve-related compression issues by temporarily sealing worn piston rings. A significant increase in pressure during wet testing compared to dry testing strongly indicates ring wear rather than valve problems.

Cylinder leakage testing (CLT) has emerged as a more sophisticated diagnostic tool, utilizing compressed air introduced into cylinders at TDC on the compression stroke. By measuring the percentage of air escaping, technicians can quantify compression loss and, importantly, identify the specific source of leakage by listening for escaping air at the intake, exhaust, or crankcase. This method provides more detailed diagnostic information than standard compression tests.

Despite technological advancements, several challenges persist in compression testing for LS1 engines. The deep-well spark plug design of LS1 heads creates accessibility issues, often requiring specialized tools and increasing testing time. Temperature-related variables significantly impact test results, with cold engines typically showing lower compression values than fully warmed engines, necessitating standardized testing conditions for accurate comparisons.

Modern LS1 engines incorporate variable valve timing and lift systems that can affect compression readings depending on their position during testing. This variability introduces complexity in result interpretation, particularly when comparing against standard specifications. Additionally, the high compression ratios in performance-modified LS1 engines often exceed the scale limits of standard compression gauges, requiring specialized high-pressure testing equipment.

Digital compression analyzers represent the cutting edge of current technology, offering real-time cylinder pressure waveform analysis and automated diagnostic capabilities. While these systems provide unprecedented insight into engine condition, their high cost and complexity limit widespread adoption, particularly in smaller service facilities. The integration of these advanced diagnostic tools with comprehensive engine management system data remains an ongoing challenge in the industry.

Standard LS1 Compression Testing Procedures and Tools

01 Compression ratio optimization in LS1 engines

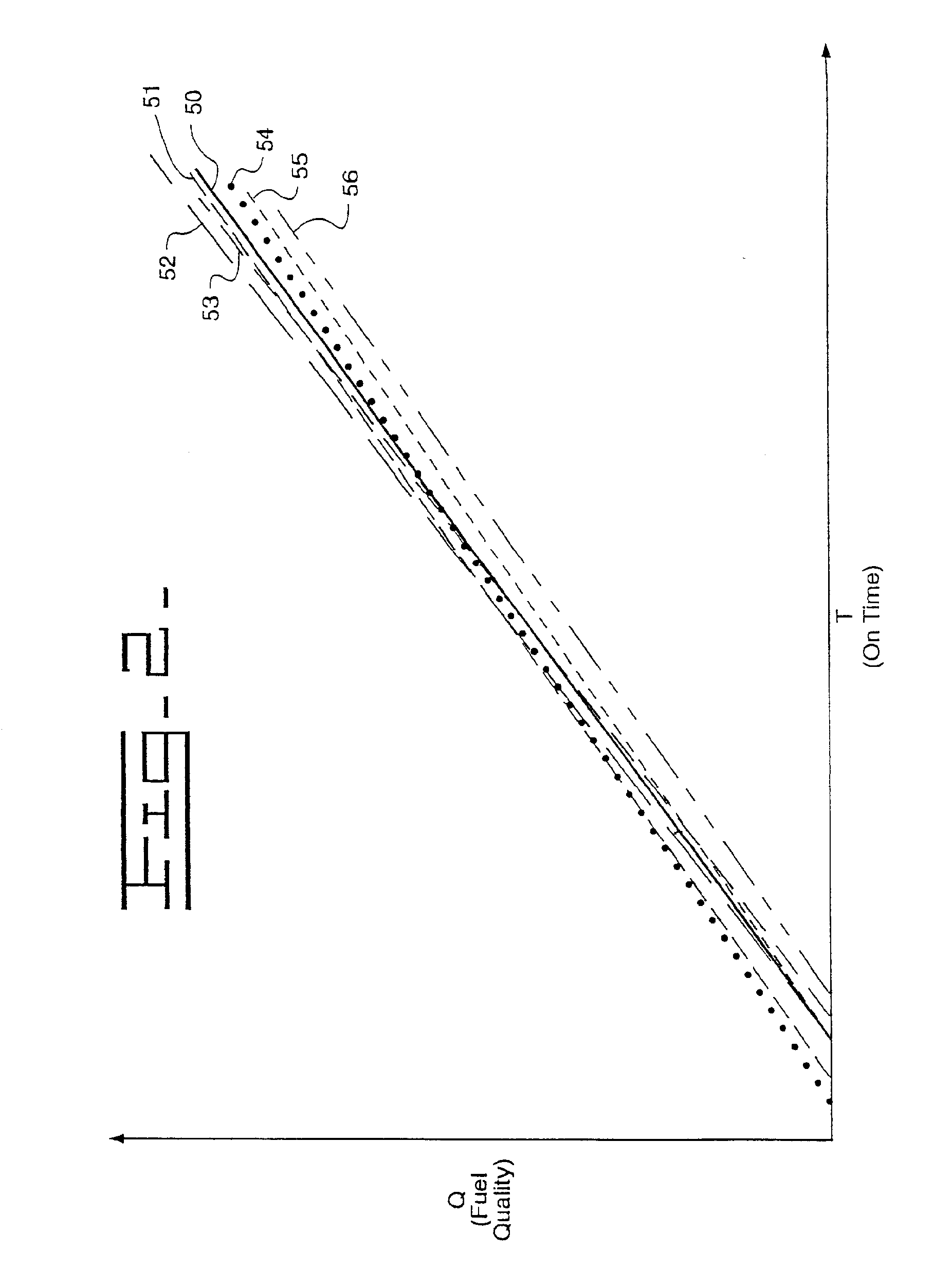

Optimizing the compression ratio in LS1 engines is crucial for performance enhancement. This involves precise engineering of the combustion chamber geometry, piston design, and cylinder head configuration to achieve the ideal compression ratio. Higher compression ratios generally lead to improved thermal efficiency and power output, while maintaining reliability and preventing detonation issues. Various techniques can be employed to adjust compression ratios, including modified piston designs and cylinder head modifications.- Compression ratio optimization in LS1 engines: Optimizing the compression ratio in LS1 engines is crucial for performance enhancement. This involves precise engineering of the combustion chamber geometry, piston design, and cylinder head configuration to achieve the ideal compression ratio. Higher compression ratios generally improve engine efficiency and power output, but must be balanced with fuel quality requirements and thermal management considerations.

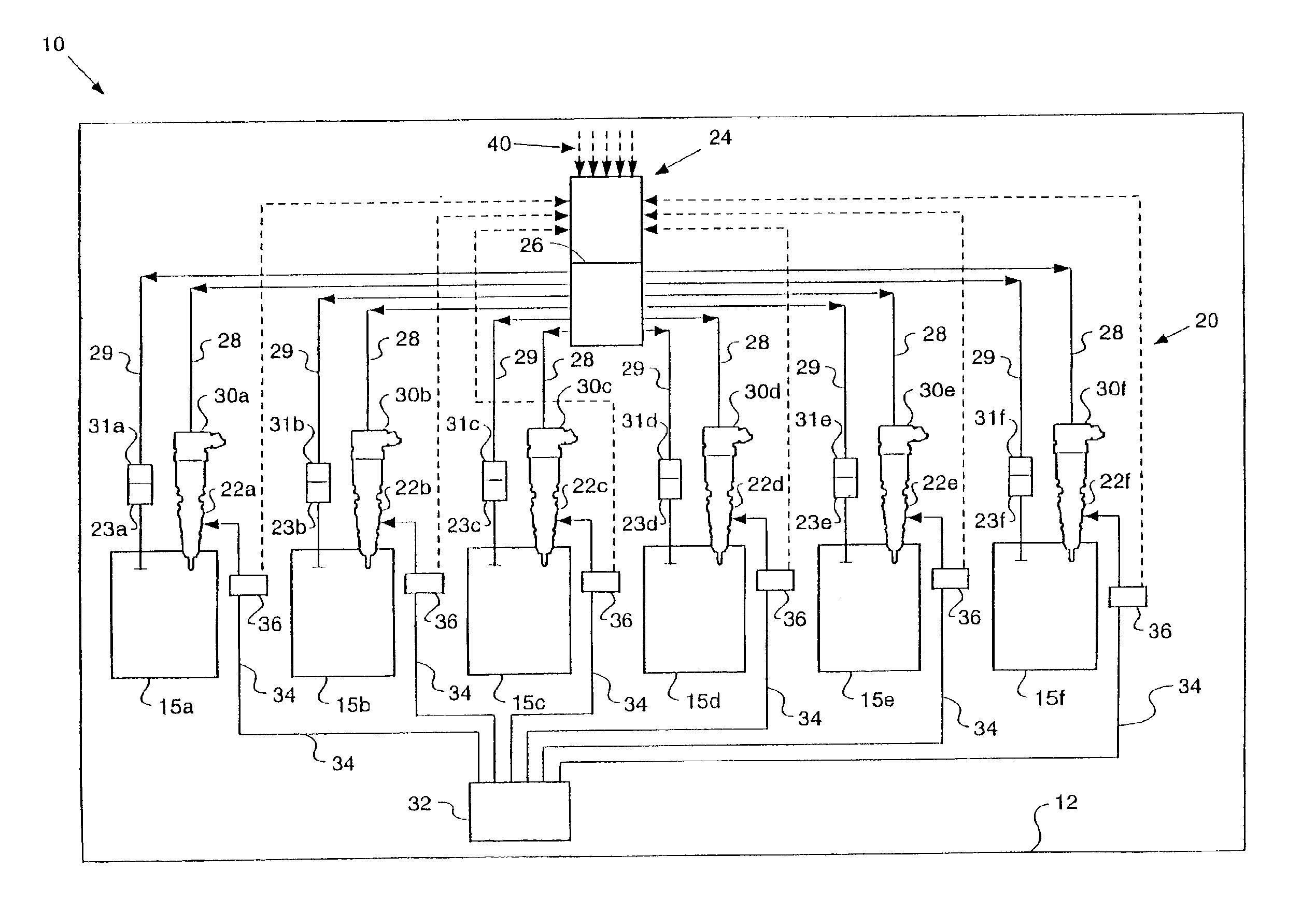

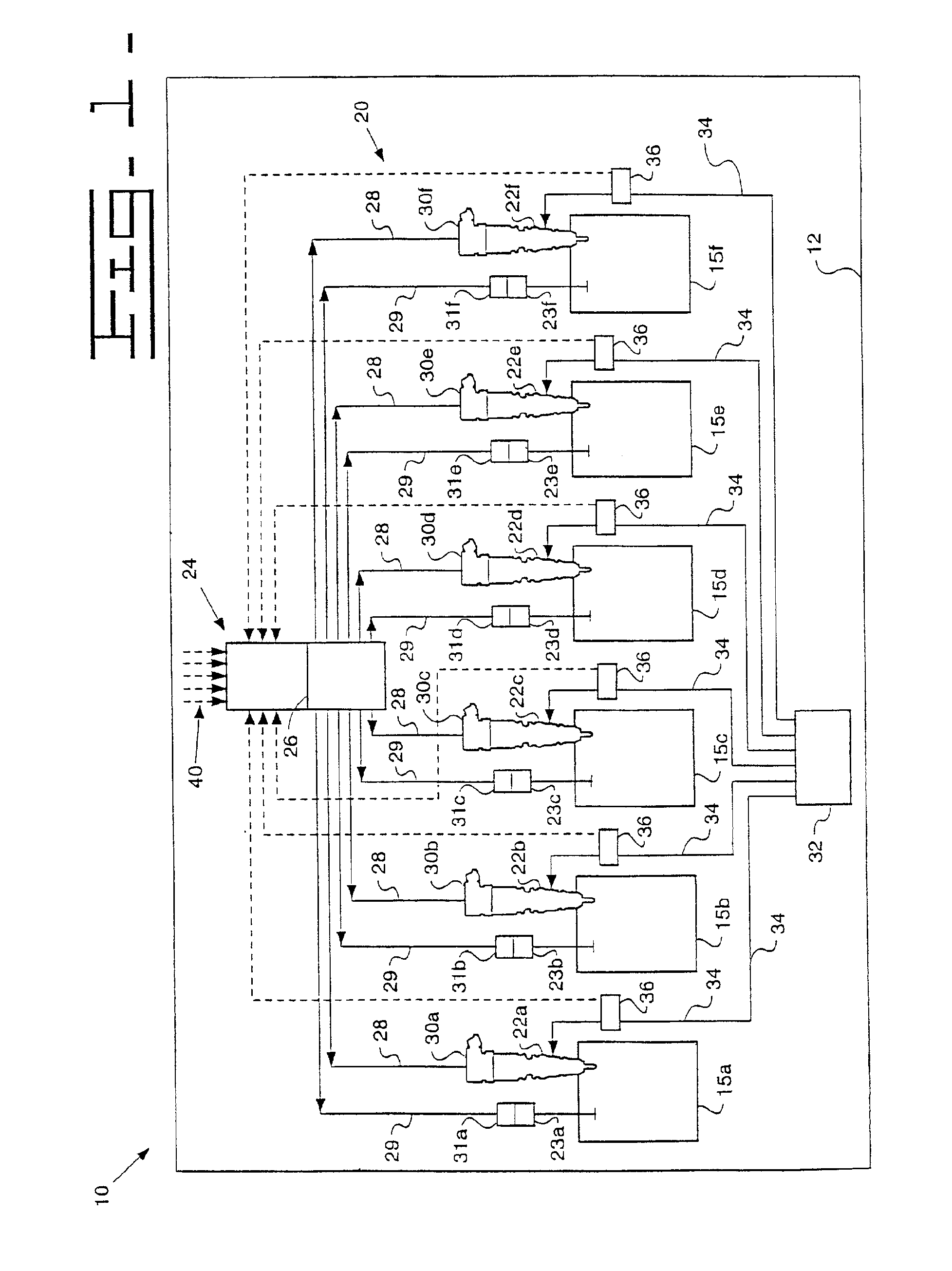

- Compression monitoring and control systems: Advanced monitoring and control systems are implemented in LS1 engines to maintain optimal compression performance. These systems utilize sensors to measure compression parameters in real-time and adjust engine operation accordingly. Electronic control units process this data to optimize fuel injection timing, ignition timing, and valve operation, ensuring consistent compression across all cylinders under varying operating conditions.

- Variable compression technology for LS1 engines: Variable compression technology allows LS1 engines to dynamically adjust compression ratios during operation. This adaptive capability optimizes engine performance across different load conditions and driving scenarios. The technology typically employs mechanical or hydraulic systems to alter the effective volume of the combustion chamber or the position of the piston at top dead center, providing improved efficiency and power output.

- Compression enhancement through component design: Specialized component designs are employed to enhance compression in LS1 engines. This includes advanced piston profiles, cylinder head modifications, and gasket technologies that improve sealing and maintain consistent compression. Materials with superior thermal properties are selected to minimize distortion under high-temperature conditions, while precision machining ensures optimal component fit and compression stability.

- Compression diagnostics and maintenance procedures: Specific diagnostic methods and maintenance procedures are developed for evaluating and maintaining proper compression in LS1 engines. These include compression testing protocols, leak-down testing, and specialized tools for assessing cylinder condition. Regular maintenance practices such as valve adjustments, carbon deposit removal, and ring replacement help preserve optimal compression ratios throughout the engine's service life.

02 Compression monitoring and control systems

Advanced monitoring and control systems are implemented in LS1 engines to maintain optimal compression performance. These systems utilize sensors to measure compression parameters in real-time, allowing for adjustments to fuel delivery, ignition timing, and valve operation. Electronic control units process this data to ensure the engine operates within designed compression specifications across various operating conditions, helping to prevent damage from abnormal compression events while maximizing performance and efficiency.Expand Specific Solutions03 Variable compression technology for LS1 engines

Variable compression technology allows LS1 engines to dynamically adjust compression ratios during operation. This adaptive system can modify the effective compression ratio based on driving conditions, load requirements, and fuel quality. The technology typically employs mechanical or hydraulic systems to alter piston positions or combustion chamber volumes, enabling the engine to optimize for power when needed or for efficiency during cruising conditions, resulting in improved overall performance and fuel economy.Expand Specific Solutions04 Compression-related components and materials

Specialized components and materials are utilized in LS1 engines to withstand and optimize compression forces. These include high-strength pistons, connecting rods, and crankshafts designed to handle the stresses of high compression ratios. Advanced materials such as forged alloys and composite materials provide durability while reducing weight. Cylinder head gaskets and sealing technologies are engineered to maintain compression integrity under extreme conditions, preventing compression loss and ensuring consistent engine performance throughout the operational lifespan.Expand Specific Solutions05 Compression diagnostics and maintenance procedures

Diagnostic methods and maintenance procedures are essential for maintaining proper compression in LS1 engines. These include compression testing techniques to identify issues such as worn piston rings, valve problems, or head gasket failures. Regular maintenance protocols help preserve optimal compression characteristics, including valve adjustments, carbon deposit removal, and cylinder wall maintenance. Advanced diagnostic equipment can detect subtle compression variations that might indicate developing problems, allowing for preventive maintenance before major failures occur.Expand Specific Solutions

Major Players in Automotive Diagnostic Equipment Industry

The LS1 engine compression testing market is in a mature phase, characterized by established diagnostic procedures and specialized equipment. The market size is moderate but stable, driven by the large installed base of LS1 engines in vehicles worldwide. From a technical maturity perspective, compression testing technology has evolved significantly with companies like Robert Bosch GmbH and BMW leading innovation in diagnostic equipment. Automotive specialists such as Honda Motor and Volkswagen AG have integrated advanced compression testing into their service protocols, while specialized tool manufacturers like A&E, Inc. provide dedicated testing equipment. The aftermarket is well-served by companies including Stratio and Moon Environment Technology, who are incorporating digital diagnostics and data analytics into traditional compression testing methods, signaling a gradual shift toward more sophisticated diagnostic capabilities.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced LS1 engine compression testing solution as part of their comprehensive engine diagnostic portfolio. Their system utilizes precision-calibrated pressure sensors that can be installed in place of spark plugs or fuel injectors to measure compression directly within each cylinder. Bosch's technology captures both static compression readings and dynamic pressure curves during engine operation, providing insights into valve timing, ring sealing, and combustion efficiency. Their diagnostic platform incorporates comparative analysis algorithms that evaluate cylinder-to-cylinder variations against manufacturer specifications, automatically flagging deviations that exceed acceptable thresholds. The Bosch system also features integration with their KTS diagnostic series, allowing technicians to correlate compression test results with other engine parameters such as fuel trim, ignition timing, and exhaust gas composition for comprehensive troubleshooting.

Strengths: Bosch's solution offers exceptional integration with their broader diagnostic ecosystem, providing context-rich analysis that correlates compression data with other engine parameters. Their equipment is widely available through their global distribution network. Weaknesses: The comprehensive nature of their testing equipment requires significant investment, and proper interpretation of the advanced data requires specialized training beyond basic mechanical knowledge.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a comprehensive LS1 engine compression testing methodology that integrates both traditional and advanced diagnostic techniques. Their approach utilizes specialized pressure transducers connected to each cylinder through spark plug ports to measure compression values with precision. Honda's system incorporates real-time data acquisition that captures compression readings across multiple engine cycles, allowing for trend analysis and detection of intermittent issues. The technology includes comparative analysis against factory specifications, with automated software that can identify deviations indicating valve timing issues, ring wear, or head gasket failures. Honda's testing protocol also incorporates relative compression testing using amperage draw analysis during cranking, providing a supplementary diagnostic method that can be performed without removing spark plugs.

Strengths: Honda's system offers exceptional diagnostic accuracy with digital precision measurements and comprehensive data logging capabilities. Their dual-method approach (direct pressure measurement and amperage analysis) provides redundant verification. Weaknesses: The system requires specialized Honda-specific diagnostic equipment and training, making it less accessible for independent repair facilities without Honda certification.

Technical Analysis of Advanced Compression Testing Solutions

In-chassis engine compression release brake diagnostic test and electronic control module using the same

PatentInactiveUS6892569B2

Innovation

- An in-chassis diagnostic test method using an electronic control module to operate engine cylinders in power and braking modes, determining trial fuel injector and engine responses, and comparing them to expected responses to adjust fuel injector on-times and engine brake performance.

Engine simulation test device capable of realizing ultrahigh compression temperature and pressure

PatentActiveUS11959826B2

Innovation

- An engine simulation test device comprising a compressed air inlet mechanism, nitrogen gas inlet mechanism, pressure stabilizing mechanism, cyclic heating mechanism, and fast compressor mechanism, which includes air and nitrogen gas introduction, pressure stabilization, heating, and adjustable gas composition to achieve ultrahigh compression temperatures and pressures, with the ability to control temperature and pressure up to 893 K and 150 bar.

Cost-Benefit Analysis of Different Testing Approaches

When evaluating different approaches for testing LS1 engine compression, a comprehensive cost-benefit analysis reveals significant variations in financial investment, time requirements, accuracy levels, and diagnostic capabilities across methods.

The standard compression test using a compression gauge represents the most economical option, typically costing between $20-50 for the gauge plus minimal labor costs if performed independently. This method requires approximately 30-45 minutes to complete and provides adequate baseline measurements for general diagnostic purposes. However, its accuracy can be compromised by variables such as cranking speed inconsistencies and potential gauge reading errors.

Cylinder leakage testing presents a moderate investment option, with professional-grade leakage testers ranging from $100-300. This approach demands approximately 60-90 minutes for thorough testing but delivers superior diagnostic information by identifying specific failure points such as valve sealing issues, head gasket failures, or ring problems. The enhanced diagnostic precision often translates to more targeted repairs, potentially reducing overall maintenance costs by 15-30% compared to exploratory repairs based on standard compression tests.

Professional diagnostic services utilizing advanced equipment represent the highest initial cost option, typically ranging from $150-300 per service. These services employ specialized tools including digital compression analyzers and sometimes borescopes for visual cylinder inspection. While outsourcing testing increases immediate expenses, the superior accuracy (typically within ±2% variance) can prevent misdiagnosis and unnecessary parts replacement, potentially saving $500-1,500 in avoided repairs.

The return on investment calculation varies significantly based on the engine's application. For high-performance or racing applications where optimal compression is critical, the precision of professional or leakage testing justifies the additional expense through improved engine performance and reduced risk of catastrophic failure. For standard street applications, the basic compression test often provides sufficient diagnostic value relative to its cost.

Long-term considerations favor more comprehensive testing approaches, as early detection of specific issues through methods like leakage testing can prevent cascading failures. This preventive aspect represents a significant hidden value proposition, particularly for engines with higher replacement costs such as the LS1 platform where complete engine rebuilds can exceed $4,000.

The standard compression test using a compression gauge represents the most economical option, typically costing between $20-50 for the gauge plus minimal labor costs if performed independently. This method requires approximately 30-45 minutes to complete and provides adequate baseline measurements for general diagnostic purposes. However, its accuracy can be compromised by variables such as cranking speed inconsistencies and potential gauge reading errors.

Cylinder leakage testing presents a moderate investment option, with professional-grade leakage testers ranging from $100-300. This approach demands approximately 60-90 minutes for thorough testing but delivers superior diagnostic information by identifying specific failure points such as valve sealing issues, head gasket failures, or ring problems. The enhanced diagnostic precision often translates to more targeted repairs, potentially reducing overall maintenance costs by 15-30% compared to exploratory repairs based on standard compression tests.

Professional diagnostic services utilizing advanced equipment represent the highest initial cost option, typically ranging from $150-300 per service. These services employ specialized tools including digital compression analyzers and sometimes borescopes for visual cylinder inspection. While outsourcing testing increases immediate expenses, the superior accuracy (typically within ±2% variance) can prevent misdiagnosis and unnecessary parts replacement, potentially saving $500-1,500 in avoided repairs.

The return on investment calculation varies significantly based on the engine's application. For high-performance or racing applications where optimal compression is critical, the precision of professional or leakage testing justifies the additional expense through improved engine performance and reduced risk of catastrophic failure. For standard street applications, the basic compression test often provides sufficient diagnostic value relative to its cost.

Long-term considerations favor more comprehensive testing approaches, as early detection of specific issues through methods like leakage testing can prevent cascading failures. This preventive aspect represents a significant hidden value proposition, particularly for engines with higher replacement costs such as the LS1 platform where complete engine rebuilds can exceed $4,000.

Environmental Impact of Engine Compression Testing Methods

Engine compression testing, while essential for vehicle maintenance and performance optimization, carries significant environmental implications that warrant careful consideration. Traditional compression testing methods often involve the release of unburned hydrocarbons, carbon monoxide, and other pollutants directly into the atmosphere during the testing process. When testing LS1 engines specifically, these emissions can be substantial due to the engine's displacement and performance characteristics.

The conventional wet and dry compression tests require the engine to be cranked multiple times, consuming fuel and generating emissions without the benefit of complete combustion or exhaust treatment systems. This is particularly concerning in enclosed workshop environments where technicians may be exposed to these pollutants, creating both environmental and occupational health concerns.

Modern testing equipment has evolved to address some of these issues. Closed-loop compression testing systems can now capture and contain the gases released during testing, significantly reducing atmospheric emissions. Additionally, electronic compression testers that require minimal engine operation reduce the overall carbon footprint of the diagnostic process compared to traditional methods.

Waste products generated during compression testing also present environmental challenges. Used oil, coolant, and cleaning solvents employed in the testing process contain contaminants that can harm ecosystems if improperly disposed of. Proper collection and recycling of these materials is essential to minimize environmental impact.

Energy consumption represents another environmental consideration. The electricity required to power testing equipment and the fuel consumed during engine operation contribute to the overall carbon footprint of compression testing. More efficient testing protocols that minimize test duration and engine runtime can substantially reduce this impact.

Regulatory frameworks increasingly address these environmental concerns. Many jurisdictions now mandate specific disposal procedures for automotive fluids and emissions control during testing procedures. Workshops conducting LS1 engine compression tests must navigate these regulations to ensure compliance and environmental responsibility.

The industry is responding with greener alternatives, including non-invasive testing methods that utilize ultrasonic technology to evaluate engine compression without requiring the engine to run. These emerging technologies promise to dramatically reduce the environmental impact of engine diagnostics while maintaining or even improving diagnostic accuracy for high-performance engines like the LS1.

The conventional wet and dry compression tests require the engine to be cranked multiple times, consuming fuel and generating emissions without the benefit of complete combustion or exhaust treatment systems. This is particularly concerning in enclosed workshop environments where technicians may be exposed to these pollutants, creating both environmental and occupational health concerns.

Modern testing equipment has evolved to address some of these issues. Closed-loop compression testing systems can now capture and contain the gases released during testing, significantly reducing atmospheric emissions. Additionally, electronic compression testers that require minimal engine operation reduce the overall carbon footprint of the diagnostic process compared to traditional methods.

Waste products generated during compression testing also present environmental challenges. Used oil, coolant, and cleaning solvents employed in the testing process contain contaminants that can harm ecosystems if improperly disposed of. Proper collection and recycling of these materials is essential to minimize environmental impact.

Energy consumption represents another environmental consideration. The electricity required to power testing equipment and the fuel consumed during engine operation contribute to the overall carbon footprint of compression testing. More efficient testing protocols that minimize test duration and engine runtime can substantially reduce this impact.

Regulatory frameworks increasingly address these environmental concerns. Many jurisdictions now mandate specific disposal procedures for automotive fluids and emissions control during testing procedures. Workshops conducting LS1 engine compression tests must navigate these regulations to ensure compliance and environmental responsibility.

The industry is responding with greener alternatives, including non-invasive testing methods that utilize ultrasonic technology to evaluate engine compression without requiring the engine to run. These emerging technologies promise to dramatically reduce the environmental impact of engine diagnostics while maintaining or even improving diagnostic accuracy for high-performance engines like the LS1.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!