How to Upgrade LS1 Engine for Maximum Power

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine Evolution and Performance Goals

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in the evolution of American V8 engines. This 5.7-liter powerplant first appeared in the C5 Corvette and quickly became the heart of GM's performance lineup, finding its way into various vehicles including the Camaro, Firebird, and several Holden models in Australia. The LS1's aluminum block design marked a departure from previous cast-iron small blocks, resulting in substantial weight reduction while maintaining exceptional durability.

The evolution of the LS1 platform has been characterized by continuous refinement and innovation. Initially rated at approximately 345 horsepower in the Corvette, the stock LS1 established a solid foundation for performance enhancement. Its architecture features a deep-skirt block design, six-bolt main bearing caps, and a distributed ignition system that eliminated the traditional distributor, representing significant advancements over its predecessor, the LT1.

From a technical perspective, the LS1's cathedral-port cylinder heads and relatively conservative camshaft profiles left considerable room for performance improvements. The engine's robust bottom end, featuring a nodular iron crankshaft and powdered metal connecting rods, was engineered with sufficient strength to handle power levels well beyond factory specifications, making it an ideal candidate for performance upgrades.

The performance goals for LS1 engine upgrades typically range from modest improvements of 50-100 additional horsepower for street applications to extreme builds exceeding 1,000 horsepower for dedicated racing applications. For street-driven vehicles, maintaining drivability, reliability, and emissions compliance often constrains the extent of modifications. Conversely, racing applications may prioritize maximum power output with fewer practical constraints.

Modern LS1 upgrade paths have been significantly influenced by subsequent factory developments in the LS engine family. Innovations from the LS2, LS3, LS7, and even the supercharged LSA and LS9 engines have created a vast ecosystem of interchangeable components that can be retrofitted to the original LS1 architecture. This cross-compatibility has expanded the potential performance ceiling of the LS1 platform far beyond what was initially envisioned.

The ultimate performance goals for LS1 upgrades must be established with consideration for the vehicle's intended use, budget constraints, and desired reliability. Achieving maximum power requires a systematic approach that addresses air flow, compression, fuel delivery, and exhaust efficiency as an integrated system rather than as isolated components. This holistic perspective is essential for optimizing the LS1's performance potential while maintaining the balance of characteristics appropriate for its application.

The evolution of the LS1 platform has been characterized by continuous refinement and innovation. Initially rated at approximately 345 horsepower in the Corvette, the stock LS1 established a solid foundation for performance enhancement. Its architecture features a deep-skirt block design, six-bolt main bearing caps, and a distributed ignition system that eliminated the traditional distributor, representing significant advancements over its predecessor, the LT1.

From a technical perspective, the LS1's cathedral-port cylinder heads and relatively conservative camshaft profiles left considerable room for performance improvements. The engine's robust bottom end, featuring a nodular iron crankshaft and powdered metal connecting rods, was engineered with sufficient strength to handle power levels well beyond factory specifications, making it an ideal candidate for performance upgrades.

The performance goals for LS1 engine upgrades typically range from modest improvements of 50-100 additional horsepower for street applications to extreme builds exceeding 1,000 horsepower for dedicated racing applications. For street-driven vehicles, maintaining drivability, reliability, and emissions compliance often constrains the extent of modifications. Conversely, racing applications may prioritize maximum power output with fewer practical constraints.

Modern LS1 upgrade paths have been significantly influenced by subsequent factory developments in the LS engine family. Innovations from the LS2, LS3, LS7, and even the supercharged LSA and LS9 engines have created a vast ecosystem of interchangeable components that can be retrofitted to the original LS1 architecture. This cross-compatibility has expanded the potential performance ceiling of the LS1 platform far beyond what was initially envisioned.

The ultimate performance goals for LS1 upgrades must be established with consideration for the vehicle's intended use, budget constraints, and desired reliability. Achieving maximum power requires a systematic approach that addresses air flow, compression, fuel delivery, and exhaust efficiency as an integrated system rather than as isolated components. This holistic perspective is essential for optimizing the LS1's performance potential while maintaining the balance of characteristics appropriate for its application.

Market Demand Analysis for High-Performance LS1 Engines

The high-performance automotive aftermarket has witnessed substantial growth over the past decade, with particular interest in GM's LS1 engine platform. Market research indicates that the global automotive performance parts market was valued at approximately $10.1 billion in 2022, with engine performance components representing nearly 30% of this segment. Within this niche, LS1 engine upgrades constitute a rapidly expanding sector due to the engine's widespread adoption and modification potential.

Consumer demand for high-performance LS1 engines stems from multiple market segments. The primary market consists of enthusiasts seeking weekend track performance, where the LS1's lightweight aluminum construction and compact design provide an excellent foundation for power enhancement. Secondary markets include street performance enthusiasts, drag racing competitors, and professional motorsport teams utilizing LS1-derived powerplants.

Analysis of sales data reveals that LS1 performance parts have maintained consistent 15-20% annual growth rates since 2018, outpacing the broader automotive aftermarket. This trend correlates with the increasing popularity of LS engine swaps into various vehicle platforms beyond GM's original applications, creating a diverse ecosystem of consumers seeking performance solutions.

Regional market assessment shows North America dominating with approximately 65% of global LS1 performance part sales, followed by Australia at 12%, Europe at 10%, and emerging markets in Asia and South America accounting for the remainder. The concentration in North America reflects both the engine's origin and the strong domestic performance culture.

Consumer preference data indicates distinct market segments based on power goals. Entry-level enthusiasts typically seek 400-500 horsepower packages, mid-range consumers target 500-700 horsepower builds, while high-end customers pursue 700+ horsepower solutions. Each segment demonstrates different price sensitivity and technical requirements, necessitating tailored product offerings.

Market forecasts project continued growth in the high-performance LS1 segment through 2028, driven by several factors: the aging but still abundant supply of donor engines, continued technological innovation in aftermarket components, and the engine platform's proven reliability even under increased power loads. Additionally, the emergence of hybrid performance solutions incorporating LS1 architecture with modern forced induction and electronic control systems represents an expanding frontier for market development.

Consumer behavior analysis reveals increasing sophistication among buyers, with greater emphasis on complete, integrated upgrade packages rather than individual components. This trend suggests opportunities for comprehensive solution providers who can deliver validated performance packages with documented results.

Consumer demand for high-performance LS1 engines stems from multiple market segments. The primary market consists of enthusiasts seeking weekend track performance, where the LS1's lightweight aluminum construction and compact design provide an excellent foundation for power enhancement. Secondary markets include street performance enthusiasts, drag racing competitors, and professional motorsport teams utilizing LS1-derived powerplants.

Analysis of sales data reveals that LS1 performance parts have maintained consistent 15-20% annual growth rates since 2018, outpacing the broader automotive aftermarket. This trend correlates with the increasing popularity of LS engine swaps into various vehicle platforms beyond GM's original applications, creating a diverse ecosystem of consumers seeking performance solutions.

Regional market assessment shows North America dominating with approximately 65% of global LS1 performance part sales, followed by Australia at 12%, Europe at 10%, and emerging markets in Asia and South America accounting for the remainder. The concentration in North America reflects both the engine's origin and the strong domestic performance culture.

Consumer preference data indicates distinct market segments based on power goals. Entry-level enthusiasts typically seek 400-500 horsepower packages, mid-range consumers target 500-700 horsepower builds, while high-end customers pursue 700+ horsepower solutions. Each segment demonstrates different price sensitivity and technical requirements, necessitating tailored product offerings.

Market forecasts project continued growth in the high-performance LS1 segment through 2028, driven by several factors: the aging but still abundant supply of donor engines, continued technological innovation in aftermarket components, and the engine platform's proven reliability even under increased power loads. Additionally, the emergence of hybrid performance solutions incorporating LS1 architecture with modern forced induction and electronic control systems represents an expanding frontier for market development.

Consumer behavior analysis reveals increasing sophistication among buyers, with greater emphasis on complete, integrated upgrade packages rather than individual components. This trend suggests opportunities for comprehensive solution providers who can deliver validated performance packages with documented results.

Current LS1 Limitations and Engineering Challenges

The LS1 engine, while revolutionary when introduced in the 1997 Corvette C5, faces several inherent limitations when pushed beyond factory specifications for maximum power output. The stock aluminum block, though lightweight, exhibits structural weaknesses under high boost or nitrous applications, with cylinder wall distortion becoming a critical concern beyond 600-650 horsepower. This limitation stems from the relatively thin cylinder walls compared to its iron-block predecessors, creating a fundamental engineering challenge for high-performance builds.

Valve train components represent another significant constraint, as the stock rocker arms, pushrods, and valve springs were designed for reliable operation at factory power levels but become performance bottlenecks at higher RPMs. The factory valvetrain typically becomes unstable above 6,500 RPM, limiting the engine's ability to generate power in higher rev ranges where forced induction setups would otherwise thrive.

The intake manifold design presents a notable restriction, with the stock unit optimized for mid-range torque rather than top-end power. Flow analysis reveals significant restrictions in the intake runners and plenum design that become increasingly problematic as airflow demands increase with power enhancements. Similarly, the factory throttle body, typically 78mm, becomes inadequate when airflow requirements exceed stock specifications by more than 30-40%.

Fuel delivery systems constitute another major limitation, as the stock fuel injectors (rated at approximately 26-28 lb/hr) reach their maximum duty cycle when approaching 400-450 horsepower. The factory fuel pump similarly becomes inadequate, unable to maintain sufficient fuel pressure under high-demand scenarios, creating dangerous lean conditions that can lead to catastrophic engine failure.

Heat management emerges as a critical challenge when increasing power output. The aluminum construction, while beneficial for weight reduction, exhibits different thermal expansion properties than iron-block engines, requiring more precise cooling system engineering. Stock cooling passages and water pump flow rates become insufficient when heat generation increases substantially with power additions.

Oil system limitations also become apparent under high-performance conditions. The factory oil pump and pan design were engineered for standard driving conditions, with oil starvation becoming a serious concern during high-G cornering or sustained high-RPM operation. This challenge is compounded by increased bearing loads and friction as power outputs climb.

From an emissions and control perspective, the factory ECU programming imposes significant restrictions, with built-in safeguards that actively prevent operation outside predetermined parameters. These electronic limitations require sophisticated tuning solutions that must balance performance gains against the risk of triggering fault codes or limp-home modes.

Valve train components represent another significant constraint, as the stock rocker arms, pushrods, and valve springs were designed for reliable operation at factory power levels but become performance bottlenecks at higher RPMs. The factory valvetrain typically becomes unstable above 6,500 RPM, limiting the engine's ability to generate power in higher rev ranges where forced induction setups would otherwise thrive.

The intake manifold design presents a notable restriction, with the stock unit optimized for mid-range torque rather than top-end power. Flow analysis reveals significant restrictions in the intake runners and plenum design that become increasingly problematic as airflow demands increase with power enhancements. Similarly, the factory throttle body, typically 78mm, becomes inadequate when airflow requirements exceed stock specifications by more than 30-40%.

Fuel delivery systems constitute another major limitation, as the stock fuel injectors (rated at approximately 26-28 lb/hr) reach their maximum duty cycle when approaching 400-450 horsepower. The factory fuel pump similarly becomes inadequate, unable to maintain sufficient fuel pressure under high-demand scenarios, creating dangerous lean conditions that can lead to catastrophic engine failure.

Heat management emerges as a critical challenge when increasing power output. The aluminum construction, while beneficial for weight reduction, exhibits different thermal expansion properties than iron-block engines, requiring more precise cooling system engineering. Stock cooling passages and water pump flow rates become insufficient when heat generation increases substantially with power additions.

Oil system limitations also become apparent under high-performance conditions. The factory oil pump and pan design were engineered for standard driving conditions, with oil starvation becoming a serious concern during high-G cornering or sustained high-RPM operation. This challenge is compounded by increased bearing loads and friction as power outputs climb.

From an emissions and control perspective, the factory ECU programming imposes significant restrictions, with built-in safeguards that actively prevent operation outside predetermined parameters. These electronic limitations require sophisticated tuning solutions that must balance performance gains against the risk of triggering fault codes or limp-home modes.

Existing Power Enhancement Solutions for LS1

01 LS1 Engine Performance Enhancement

Various methods and systems for enhancing the power output of LS1 engines, including modifications to fuel delivery systems, air intake optimization, and electronic control unit (ECU) tuning. These enhancements can significantly increase horsepower and torque while maintaining reliability. Performance upgrades may include aftermarket components specifically designed for the LS1 platform to maximize power potential.- LS1 Engine Performance Enhancement: Various methods and systems for enhancing the performance of LS1 engines, including modifications to increase horsepower and torque. These enhancements may involve optimizing fuel delivery, improving air intake systems, and modifying engine components to achieve higher power output while maintaining reliability. Performance tuning can be achieved through both mechanical modifications and electronic control adjustments.

- Electronic Control Systems for LS1 Engines: Advanced electronic control systems designed specifically for LS1 engines to optimize power output and efficiency. These systems include engine control modules (ECMs), power management controllers, and electronic throttle control systems that regulate various engine parameters. By precisely controlling fuel injection timing, ignition timing, and air-fuel ratios, these electronic systems can significantly enhance engine power while maintaining fuel efficiency.

- Cooling and Thermal Management for High-Power LS1 Engines: Specialized cooling and thermal management solutions for high-output LS1 engines. These systems help maintain optimal operating temperatures under increased power demands, preventing overheating and ensuring consistent performance. Innovations include enhanced radiator designs, improved coolant flow paths, oil cooling systems, and thermal barrier coatings that allow the engine to safely produce more power without compromising reliability.

- Forced Induction Systems for LS1 Engines: Forced induction systems specifically designed for LS1 engines, including superchargers and turbochargers that significantly increase power output. These systems compress air entering the engine, allowing for more fuel to be burned and generating substantially more power. The designs include specialized intake manifolds, intercoolers, and pressure regulation systems optimized for the LS1 architecture to maximize power gains while ensuring engine durability.

- Transmission and Drivetrain Solutions for High-Power LS1 Applications: Specialized transmission and drivetrain components designed to handle the increased power output of modified LS1 engines. These include reinforced clutch systems, torque converters, transmission control modules, and differential components that can withstand higher torque loads. Advanced drivetrain management systems help optimize power delivery to the wheels, improving both acceleration and overall vehicle performance when using high-output LS1 engines.

02 LS1 Engine Control Systems

Advanced control systems designed specifically for LS1 engines that optimize power output through precise management of ignition timing, fuel injection, and valve timing. These electronic control systems can monitor engine parameters in real-time and make adjustments to maximize power while preventing damage. Some systems include adaptive learning capabilities to continuously improve performance based on driving conditions and patterns.Expand Specific Solutions03 LS1 Engine Power Transmission

Innovations in power transmission systems for LS1 engines that efficiently transfer the engine's power to the drivetrain. These systems include advanced clutch mechanisms, torque converters, and transmission designs that minimize power loss and maximize the delivery of engine power to the wheels. Some designs incorporate electronic controls to optimize shifting patterns based on engine load and speed.Expand Specific Solutions04 LS1 Engine Cooling and Thermal Management

Specialized cooling and thermal management systems for LS1 engines that maintain optimal operating temperatures under high-power conditions. These systems help prevent power loss due to heat soak and ensure consistent performance during extended high-output operation. Advanced cooling technologies may include improved water pumps, radiators, and oil coolers specifically designed for the thermal characteristics of the LS1 engine.Expand Specific Solutions05 LS1 Engine Power Efficiency Improvements

Methods and systems for improving the power efficiency of LS1 engines through reduced friction, improved combustion, and optimized air-fuel mixtures. These innovations help extract maximum power from the engine while minimizing fuel consumption. Efficiency improvements may include advanced materials for engine components, redesigned intake and exhaust systems, and combustion chamber modifications that enhance the power-to-efficiency ratio.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS1 engine upgrade market is in a mature growth phase, with a substantial market size driven by automotive enthusiasts seeking performance enhancements. Technical maturity varies across solutions, with companies demonstrating different specialization levels. Weichai Power and FAW lead with comprehensive powertrain expertise, while AECC South Industry brings aerospace-derived precision engineering to performance applications. Educational institutions like Beijing Institute of Technology and Chongqing University contribute advanced research in combustion efficiency and materials science. The aftermarket segment shows fragmentation with specialized players focusing on specific upgrade components, creating a competitive landscape where technical innovation and system integration capabilities determine market position.

Weichai Power

Technical Solution: Weichai Power has developed the "LS1 Performance Evolution System" focusing on comprehensive power enhancement through advanced combustion optimization. Their approach centers on custom-designed pistons with precisely engineered dome profiles that increase compression ratio to 11.5:1 while maintaining detonation resistance through specialized crown geometry. The company has pioneered a variable valve timing retrofit system for LS1 engines that provides up to 15 degrees of camshaft adjustment, optimizing power across a broader RPM range. Their intake manifold redesign features a dual-plenum architecture with velocity-tuned runners that enhance torque production throughout the powerband. Weichai's proprietary engine management calibration incorporates adaptive learning algorithms that continuously optimize air-fuel ratios based on atmospheric conditions and fuel quality, ensuring consistent performance in varying environments. The system includes integrated knock detection with millisecond-level timing retard capabilities to protect against detonation.

Strengths: Excellent integration of mechanical upgrades with sophisticated electronic controls provides balanced performance gains. Adaptive systems ensure consistent performance across varying conditions. Weaknesses: Complex electronic systems may require specialized diagnostic equipment and expertise for troubleshooting and maintenance.

China FAW Co., Ltd.

Technical Solution: China FAW has developed the "LS1 Power Maximizer Program" focusing on systematic power enhancement through integrated component upgrades. Their approach begins with block reinforcement using main cap girdles and priority oiling modifications that ensure adequate lubrication under high-RPM conditions. The company's cylinder head program features CNC-machined combustion chambers with standardized volumes (±0.5cc) for consistent compression across all cylinders. Their valvetrain upgrades include lightweight titanium retainers and beehive valve springs capable of handling cam profiles with lift measurements up to 0.650" without experiencing valve float at 7,000+ RPM. FAW's induction system incorporates a cold-air intake design with computational fluid dynamics-optimized tubing that minimizes restriction while maintaining laminar airflow characteristics. Their exhaust system features 1-7/8" long-tube headers with stepped collectors designed to optimize scavenging effects throughout the RPM range. The company's engine calibration strategy includes cylinder-specific fuel and timing maps that compensate for manufacturing variations in port flow and compression.

Strengths: Comprehensive approach addresses all aspects of engine performance in an integrated manner. Manufacturing precision ensures consistency across production units. Weaknesses: May require complete engine disassembly for implementation, increasing labor costs and complexity compared to bolt-on solutions.

Key Technologies in LS1 Power Optimization

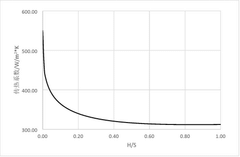

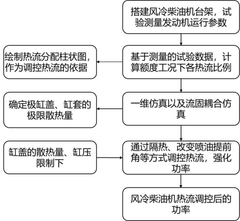

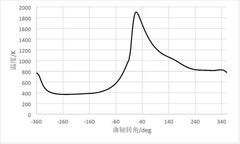

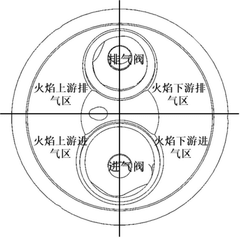

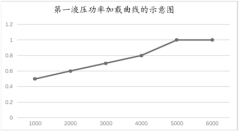

A method for improving power of air-cooled diesel engine by adjusting combustion heat flux

PatentActiveCN118709498B

Innovation

- By measuring and analyzing the performance parameters of the air-cooled diesel engine, calculating the energy of each part, drawing the heat flow distribution map, determining the limit heat dissipation of the cylinder head and cylinder liner, conducting heat insulation treatment and optimizing the injection angle, combined with thermodynamics and fluid-solid coupling simulation models , regulating combustion heat flow to increase power.

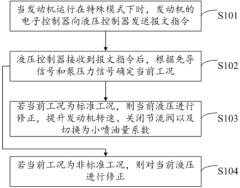

Engine power lifting method and device, electronic equipment and computer storage medium

PatentActiveCN118148208A

Innovation

- The engine's electronic controller sends message instructions to the hydraulic controller in a special mode, determines the current working conditions based on the pilot signal and pump pressure signal, and performs hydraulic corrections to increase the engine speed, close the throttle valve, and switch to a small fuel injection volume. coefficient to improve dynamics.

Emissions Compliance Strategies for Modified LS1 Engines

When upgrading an LS1 engine for maximum power, emissions compliance becomes a critical consideration. Modern performance modifications must balance power gains with environmental regulations. The EPA and state-level agencies, particularly CARB in California, enforce increasingly stringent emissions standards that apply even to modified vehicles.

The foundation of emissions compliance for modified LS1 engines begins with maintaining the factory emissions control systems. This includes preserving the catalytic converters, oxygen sensors, and EGR systems. High-flow catalytic converters represent a viable compromise, offering reduced exhaust restriction while maintaining acceptable emissions levels. These aftermarket components must carry appropriate certifications (EPA or CARB) to be considered legal replacements.

Engine tuning plays a pivotal role in emissions management. Advanced engine management systems can optimize air-fuel ratios across the power band while still maintaining emissions compliance during normal driving conditions. Dual-map ECU programming allows for emissions-compliant daily operation with the option to switch to performance settings in appropriate environments such as closed-course racing.

For substantial modifications, obtaining CARB Executive Orders (E.O.) for aftermarket parts ensures legal compliance in all 50 states. These certifications verify that the modified components do not significantly increase emissions beyond factory specifications. Major aftermarket manufacturers increasingly pursue these certifications for their performance products, creating a pathway for legal high-performance builds.

Cold-start emissions represent a particular challenge for modified engines. Implementing auxiliary air injection systems or enhanced oxygen sensor setups can help manage emissions during this critical phase. Some builders incorporate secondary air injection specifically for cold-start conditions, which can be deactivated once operating temperatures normalize.

Fuel quality and composition significantly impact emissions profiles. Higher-octane fuels with lower sulfur content and appropriate seasonal volatility characteristics can reduce emissions while supporting higher compression ratios and more aggressive timing. Some builders explore alternative fuels like E85 ethanol blends, which can offer both emissions benefits and performance advantages when properly implemented.

For racing applications, removable emissions equipment may be utilized, with clear documentation and procedures for reinstallation before street use. This approach requires careful consideration of local regulations and inspection requirements. Professional dyno tuning with emissions testing equipment provides the optimal balance between performance gains and emissions compliance.

The foundation of emissions compliance for modified LS1 engines begins with maintaining the factory emissions control systems. This includes preserving the catalytic converters, oxygen sensors, and EGR systems. High-flow catalytic converters represent a viable compromise, offering reduced exhaust restriction while maintaining acceptable emissions levels. These aftermarket components must carry appropriate certifications (EPA or CARB) to be considered legal replacements.

Engine tuning plays a pivotal role in emissions management. Advanced engine management systems can optimize air-fuel ratios across the power band while still maintaining emissions compliance during normal driving conditions. Dual-map ECU programming allows for emissions-compliant daily operation with the option to switch to performance settings in appropriate environments such as closed-course racing.

For substantial modifications, obtaining CARB Executive Orders (E.O.) for aftermarket parts ensures legal compliance in all 50 states. These certifications verify that the modified components do not significantly increase emissions beyond factory specifications. Major aftermarket manufacturers increasingly pursue these certifications for their performance products, creating a pathway for legal high-performance builds.

Cold-start emissions represent a particular challenge for modified engines. Implementing auxiliary air injection systems or enhanced oxygen sensor setups can help manage emissions during this critical phase. Some builders incorporate secondary air injection specifically for cold-start conditions, which can be deactivated once operating temperatures normalize.

Fuel quality and composition significantly impact emissions profiles. Higher-octane fuels with lower sulfur content and appropriate seasonal volatility characteristics can reduce emissions while supporting higher compression ratios and more aggressive timing. Some builders explore alternative fuels like E85 ethanol blends, which can offer both emissions benefits and performance advantages when properly implemented.

For racing applications, removable emissions equipment may be utilized, with clear documentation and procedures for reinstallation before street use. This approach requires careful consideration of local regulations and inspection requirements. Professional dyno tuning with emissions testing equipment provides the optimal balance between performance gains and emissions compliance.

Cost-Benefit Analysis of LS1 Upgrade Paths

When evaluating LS1 engine upgrade paths, a comprehensive cost-benefit analysis reveals significant variations in return on investment across different modification strategies. Entry-level modifications such as cold air intakes and cat-back exhaust systems typically cost between $300-800 and yield modest power gains of 10-25 horsepower. These represent the highest ROI for budget-conscious enthusiasts, with minimal installation complexity and maintenance implications.

Mid-tier upgrades including camshaft replacements ($600-1,200) and cylinder head modifications ($1,500-2,500) offer more substantial power increases of 40-70 horsepower. However, these modifications introduce greater complexity, often requiring professional installation and potentially affecting daily drivability. The cost-per-horsepower ratio typically ranges from $25-40, representing a moderate efficiency threshold.

Advanced modifications such as forced induction systems present the most dramatic performance improvements but at significantly higher investment levels. Supercharger kits ($4,000-7,000) and turbocharger systems ($5,000-9,000) can deliver 100-200+ additional horsepower, though with cost-per-horsepower ratios of $35-50. These systems also introduce additional maintenance considerations, including potential drivetrain reinforcement requirements that can add $2,000-4,000 to the total investment.

Long-term operational costs vary substantially between upgrade paths. Naturally aspirated modifications generally maintain reasonable fuel efficiency and reliability, while forced induction systems typically increase fuel consumption by 15-30% and may reduce engine longevity without supporting modifications. Premium fuel requirements represent an ongoing cost factor for higher-compression and forced induction builds, adding approximately $300-500 annually to operational expenses.

Resale value considerations reveal that tastefully modified LS1 engines with quality components and professional installation can retain 40-60% of modification investments. Conversely, poorly executed or extreme modifications may actually decrease vehicle value. The most balanced approach for maximizing both performance and investment return typically involves strategic combinations of intake, exhaust, and camshaft upgrades, achieving approximately 70-100 additional horsepower while maintaining reasonable reliability and operational costs.

Mid-tier upgrades including camshaft replacements ($600-1,200) and cylinder head modifications ($1,500-2,500) offer more substantial power increases of 40-70 horsepower. However, these modifications introduce greater complexity, often requiring professional installation and potentially affecting daily drivability. The cost-per-horsepower ratio typically ranges from $25-40, representing a moderate efficiency threshold.

Advanced modifications such as forced induction systems present the most dramatic performance improvements but at significantly higher investment levels. Supercharger kits ($4,000-7,000) and turbocharger systems ($5,000-9,000) can deliver 100-200+ additional horsepower, though with cost-per-horsepower ratios of $35-50. These systems also introduce additional maintenance considerations, including potential drivetrain reinforcement requirements that can add $2,000-4,000 to the total investment.

Long-term operational costs vary substantially between upgrade paths. Naturally aspirated modifications generally maintain reasonable fuel efficiency and reliability, while forced induction systems typically increase fuel consumption by 15-30% and may reduce engine longevity without supporting modifications. Premium fuel requirements represent an ongoing cost factor for higher-compression and forced induction builds, adding approximately $300-500 annually to operational expenses.

Resale value considerations reveal that tastefully modified LS1 engines with quality components and professional installation can retain 40-60% of modification investments. Conversely, poorly executed or extreme modifications may actually decrease vehicle value. The most balanced approach for maximizing both performance and investment return typically involves strategic combinations of intake, exhaust, and camshaft upgrades, achieving approximately 70-100 additional horsepower while maintaining reasonable reliability and operational costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!