Innovations in ULED Energy Efficiency

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Efficiency Evolution

The evolution of ULED (Ultra Light Emitting Diode) efficiency has been a remarkable journey, characterized by continuous technological advancements and breakthroughs. This progression has been driven by the increasing demand for more energy-efficient lighting solutions across various industries and applications.

In the early stages of ULED development, the focus was primarily on improving the basic structure and materials of the diodes. Researchers experimented with different semiconductor compounds and layering techniques to enhance light output and reduce energy consumption. These initial efforts led to modest improvements in efficiency, typically in the range of 30-40 lumens per watt.

As the technology matured, significant strides were made in the optimization of the quantum well structure within ULEDs. By fine-tuning the thickness and composition of these layers, scientists were able to achieve better electron-hole recombination, resulting in higher light output with lower power input. This phase saw efficiency levels climb to 70-100 lumens per watt, marking a substantial leap forward in ULED performance.

The next major milestone in ULED efficiency evolution came with the introduction of advanced phosphor materials and color conversion techniques. These innovations allowed for better control over the spectral output of ULEDs, enabling the production of warmer, more natural light while maintaining high efficiency. Efficiency levels during this period reached 120-150 lumens per watt, making ULEDs competitive with other high-efficiency lighting technologies.

Recent years have witnessed the integration of nanotechnology into ULED design. Nanostructured materials and quantum dot technologies have been employed to further enhance light extraction and reduce energy losses. These cutting-edge approaches have pushed ULED efficiency to new heights, with some prototypes demonstrating efficiencies of over 200 lumens per watt.

The ongoing evolution of ULED efficiency has also been marked by improvements in thermal management and driver electronics. Advanced heat dissipation techniques and more efficient power supply designs have contributed to overall system efficiency gains, allowing ULEDs to maintain high performance over extended periods of operation.

Looking ahead, the trajectory of ULED efficiency evolution points towards even greater advancements. Researchers are exploring novel materials such as perovskites and organic-inorganic hybrids, which show promise for pushing efficiency boundaries further. Additionally, the integration of artificial intelligence and machine learning in ULED design and manufacturing processes is expected to unlock new optimization possibilities, potentially leading to efficiencies exceeding 300 lumens per watt in the near future.

In the early stages of ULED development, the focus was primarily on improving the basic structure and materials of the diodes. Researchers experimented with different semiconductor compounds and layering techniques to enhance light output and reduce energy consumption. These initial efforts led to modest improvements in efficiency, typically in the range of 30-40 lumens per watt.

As the technology matured, significant strides were made in the optimization of the quantum well structure within ULEDs. By fine-tuning the thickness and composition of these layers, scientists were able to achieve better electron-hole recombination, resulting in higher light output with lower power input. This phase saw efficiency levels climb to 70-100 lumens per watt, marking a substantial leap forward in ULED performance.

The next major milestone in ULED efficiency evolution came with the introduction of advanced phosphor materials and color conversion techniques. These innovations allowed for better control over the spectral output of ULEDs, enabling the production of warmer, more natural light while maintaining high efficiency. Efficiency levels during this period reached 120-150 lumens per watt, making ULEDs competitive with other high-efficiency lighting technologies.

Recent years have witnessed the integration of nanotechnology into ULED design. Nanostructured materials and quantum dot technologies have been employed to further enhance light extraction and reduce energy losses. These cutting-edge approaches have pushed ULED efficiency to new heights, with some prototypes demonstrating efficiencies of over 200 lumens per watt.

The ongoing evolution of ULED efficiency has also been marked by improvements in thermal management and driver electronics. Advanced heat dissipation techniques and more efficient power supply designs have contributed to overall system efficiency gains, allowing ULEDs to maintain high performance over extended periods of operation.

Looking ahead, the trajectory of ULED efficiency evolution points towards even greater advancements. Researchers are exploring novel materials such as perovskites and organic-inorganic hybrids, which show promise for pushing efficiency boundaries further. Additionally, the integration of artificial intelligence and machine learning in ULED design and manufacturing processes is expected to unlock new optimization possibilities, potentially leading to efficiencies exceeding 300 lumens per watt in the near future.

Market Demand Analysis

The market demand for innovations in ULED energy efficiency has been steadily growing, driven by increasing environmental concerns and the need for more sustainable lighting solutions. As consumers and businesses become more conscious of their energy consumption and carbon footprint, there is a rising demand for highly efficient lighting technologies that can significantly reduce energy usage while maintaining or improving light quality.

The ULED (Ultra Light Emitting Diode) market has seen substantial growth in recent years, with a particular focus on energy efficiency improvements. This trend is expected to continue as governments worldwide implement stricter energy efficiency regulations and standards for lighting products. The push towards smart cities and smart buildings has also contributed to the increased demand for advanced lighting solutions that can integrate seamlessly with IoT systems and offer enhanced control and energy management capabilities.

In the residential sector, homeowners are increasingly seeking energy-efficient lighting options to reduce their electricity bills and minimize their environmental impact. The commercial and industrial sectors, which account for a significant portion of global energy consumption, are also driving demand for high-efficiency ULED lighting solutions. These sectors are particularly interested in lighting systems that can offer long-term cost savings through reduced energy consumption and maintenance requirements.

The automotive industry represents another significant market for ULED energy efficiency innovations. As electric vehicles gain popularity and manufacturers strive to extend battery range, there is a growing need for ultra-efficient lighting solutions that can minimize power consumption without compromising safety or aesthetics.

Market research indicates that the global ULED market is projected to experience robust growth in the coming years, with energy efficiency being a key factor driving this expansion. The Asia-Pacific region, particularly China, is expected to lead in terms of market share and growth rate, followed by North America and Europe. This growth is attributed to rapid urbanization, increasing adoption of smart lighting systems, and government initiatives promoting energy-efficient technologies.

Despite the positive market outlook, there are challenges that need to be addressed to fully capitalize on the demand for ULED energy efficiency innovations. These include the higher initial costs associated with advanced ULED technologies, which can be a barrier to adoption, especially in price-sensitive markets. Additionally, there is a need for increased consumer education regarding the long-term benefits and energy savings potential of ULED lighting solutions.

In conclusion, the market demand for innovations in ULED energy efficiency is robust and multifaceted, spanning various sectors and geographical regions. As technology continues to advance and awareness of environmental issues grows, this demand is expected to intensify, creating significant opportunities for companies investing in research and development of ultra-efficient lighting solutions.

The ULED (Ultra Light Emitting Diode) market has seen substantial growth in recent years, with a particular focus on energy efficiency improvements. This trend is expected to continue as governments worldwide implement stricter energy efficiency regulations and standards for lighting products. The push towards smart cities and smart buildings has also contributed to the increased demand for advanced lighting solutions that can integrate seamlessly with IoT systems and offer enhanced control and energy management capabilities.

In the residential sector, homeowners are increasingly seeking energy-efficient lighting options to reduce their electricity bills and minimize their environmental impact. The commercial and industrial sectors, which account for a significant portion of global energy consumption, are also driving demand for high-efficiency ULED lighting solutions. These sectors are particularly interested in lighting systems that can offer long-term cost savings through reduced energy consumption and maintenance requirements.

The automotive industry represents another significant market for ULED energy efficiency innovations. As electric vehicles gain popularity and manufacturers strive to extend battery range, there is a growing need for ultra-efficient lighting solutions that can minimize power consumption without compromising safety or aesthetics.

Market research indicates that the global ULED market is projected to experience robust growth in the coming years, with energy efficiency being a key factor driving this expansion. The Asia-Pacific region, particularly China, is expected to lead in terms of market share and growth rate, followed by North America and Europe. This growth is attributed to rapid urbanization, increasing adoption of smart lighting systems, and government initiatives promoting energy-efficient technologies.

Despite the positive market outlook, there are challenges that need to be addressed to fully capitalize on the demand for ULED energy efficiency innovations. These include the higher initial costs associated with advanced ULED technologies, which can be a barrier to adoption, especially in price-sensitive markets. Additionally, there is a need for increased consumer education regarding the long-term benefits and energy savings potential of ULED lighting solutions.

In conclusion, the market demand for innovations in ULED energy efficiency is robust and multifaceted, spanning various sectors and geographical regions. As technology continues to advance and awareness of environmental issues grows, this demand is expected to intensify, creating significant opportunities for companies investing in research and development of ultra-efficient lighting solutions.

ULED Tech Challenges

Ultra-LED (ULED) technology has made significant strides in recent years, yet it still faces several critical challenges in achieving optimal energy efficiency. One of the primary obstacles is the issue of light extraction efficiency. Despite improvements in internal quantum efficiency, a substantial portion of light generated within the LED structure is trapped due to total internal reflection at the semiconductor-air interface. This phenomenon results in a significant loss of potential luminous output and, consequently, reduced overall energy efficiency.

Another major challenge lies in the thermal management of ULED devices. As the power density of these devices increases to meet higher brightness demands, heat dissipation becomes a critical factor. Excessive heat not only reduces the lifespan of the LED but also negatively impacts its efficiency. Current thermal management solutions often add bulk and cost to the overall system, presenting a trade-off between performance and practicality.

The color quality and consistency of ULED lighting also present ongoing challenges. While advancements have been made in phosphor technology and color mixing techniques, achieving a high color rendering index (CRI) while maintaining energy efficiency remains a delicate balance. The pursuit of warmer color temperatures, which are often preferred in residential and hospitality settings, can lead to reduced efficacy compared to cooler color temperatures.

Droop, the phenomenon where LED efficiency decreases at higher current densities, continues to be a significant hurdle in ULED development. This effect is particularly pronounced in the blue and green spectral regions, limiting the overall efficiency of white light LEDs. Overcoming droop without compromising other performance aspects is crucial for pushing the boundaries of ULED energy efficiency.

The integration of smart control systems and dimming capabilities into ULED technology presents another set of challenges. While these features offer potential for energy savings through adaptive lighting, they also introduce complexity in driver design and can impact the overall efficiency of the lighting system. Ensuring that ULEDs maintain high efficiency across a wide range of dimming levels and operating conditions is an ongoing area of research and development.

Lastly, the manufacturing processes for high-efficiency ULEDs often involve complex and costly techniques. Achieving uniformity in large-scale production while maintaining the high-performance characteristics of laboratory prototypes remains a significant challenge. This impacts not only the energy efficiency of the final product but also its economic viability in the competitive lighting market.

Another major challenge lies in the thermal management of ULED devices. As the power density of these devices increases to meet higher brightness demands, heat dissipation becomes a critical factor. Excessive heat not only reduces the lifespan of the LED but also negatively impacts its efficiency. Current thermal management solutions often add bulk and cost to the overall system, presenting a trade-off between performance and practicality.

The color quality and consistency of ULED lighting also present ongoing challenges. While advancements have been made in phosphor technology and color mixing techniques, achieving a high color rendering index (CRI) while maintaining energy efficiency remains a delicate balance. The pursuit of warmer color temperatures, which are often preferred in residential and hospitality settings, can lead to reduced efficacy compared to cooler color temperatures.

Droop, the phenomenon where LED efficiency decreases at higher current densities, continues to be a significant hurdle in ULED development. This effect is particularly pronounced in the blue and green spectral regions, limiting the overall efficiency of white light LEDs. Overcoming droop without compromising other performance aspects is crucial for pushing the boundaries of ULED energy efficiency.

The integration of smart control systems and dimming capabilities into ULED technology presents another set of challenges. While these features offer potential for energy savings through adaptive lighting, they also introduce complexity in driver design and can impact the overall efficiency of the lighting system. Ensuring that ULEDs maintain high efficiency across a wide range of dimming levels and operating conditions is an ongoing area of research and development.

Lastly, the manufacturing processes for high-efficiency ULEDs often involve complex and costly techniques. Achieving uniformity in large-scale production while maintaining the high-performance characteristics of laboratory prototypes remains a significant challenge. This impacts not only the energy efficiency of the final product but also its economic viability in the competitive lighting market.

Current ULED Solutions

01 Improved LED structure for enhanced energy efficiency

Ultra Light Emitting Diodes (ULEDs) utilize advanced structural designs to improve energy efficiency. These designs may include optimized quantum well structures, novel electrode configurations, or improved light extraction techniques. Such enhancements result in higher luminous efficacy and reduced power consumption compared to traditional LEDs.- Improved LED structure for enhanced energy efficiency: Advanced LED structures are designed to improve energy efficiency. These include optimized chip designs, novel electrode configurations, and improved light extraction techniques. Such structures aim to reduce energy loss and increase light output, resulting in more efficient ULED devices.

- Novel materials for ULED fabrication: The use of innovative materials in ULED fabrication contributes to enhanced energy efficiency. This includes the development of new semiconductor compounds, phosphor materials, and substrate materials that improve light emission and reduce energy consumption. These materials can lead to higher luminous efficacy and lower power requirements.

- Thermal management techniques for ULEDs: Effective thermal management is crucial for maintaining ULED energy efficiency. Various techniques are employed, such as advanced heat sink designs, thermal interface materials, and active cooling systems. These methods help dissipate heat more efficiently, preventing performance degradation and extending the lifespan of ULED devices.

- Driving circuit optimization for ULEDs: Optimized driving circuits play a significant role in improving ULED energy efficiency. This includes the development of advanced power supply designs, current regulation techniques, and intelligent control systems. These innovations help minimize power losses in the driving circuitry and ensure optimal operation of ULED devices.

- Integration of ULEDs with energy-saving technologies: ULEDs are being integrated with various energy-saving technologies to further enhance their efficiency. This includes the incorporation of smart lighting controls, sensors for adaptive brightness adjustment, and integration with renewable energy sources. Such combinations lead to overall energy savings in lighting systems and contribute to sustainable lighting solutions.

02 Novel materials for ULED fabrication

The use of innovative materials in ULED fabrication contributes to improved energy efficiency. These materials may include advanced semiconductor compounds, nanostructures, or novel dopants that enhance charge carrier mobility and light emission properties. The incorporation of these materials results in ULEDs with higher quantum efficiency and lower energy losses.Expand Specific Solutions03 Thermal management techniques for ULEDs

Effective thermal management is crucial for maintaining ULED energy efficiency. Advanced heat dissipation methods, such as improved package designs, novel heat sink materials, or active cooling systems, help to reduce thermal resistance and maintain optimal operating temperatures. This results in sustained high performance and extended lifespan of ULEDs.Expand Specific Solutions04 Driving circuit optimization for ULEDs

Optimized driving circuits play a significant role in enhancing ULED energy efficiency. These circuits may incorporate advanced power management techniques, precise current control mechanisms, or intelligent dimming capabilities. Such optimizations ensure that ULEDs operate at their most efficient points, minimizing energy waste and maximizing light output.Expand Specific Solutions05 Integration of ULEDs with smart control systems

The integration of ULEDs with smart control systems further enhances their energy efficiency. These systems may include sensors for ambient light detection, occupancy sensing, or color temperature adjustment. By dynamically adapting ULED output to environmental conditions and user needs, these smart systems optimize energy consumption while maintaining desired lighting conditions.Expand Specific Solutions

Key ULED Manufacturers

The ULED energy efficiency market is in a growth phase, driven by increasing demand for high-performance, low-energy displays. The market size is expanding rapidly, with major players like Universal Display Corp., BOE Technology Group, and LG Display Co., Ltd. leading innovation. Technological maturity varies, with established companies like Samsung Display Co., Ltd. and emerging players such as eLux, Inc. pushing boundaries. Companies like Lumileds LLC and Bridgelux, Inc. are focusing on LED advancements, while others like Micledi Microdisplays BV are exploring micro-LED technologies. The competitive landscape is diverse, with both traditional display manufacturers and specialized ULED companies vying for market share and technological breakthroughs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced ULED (Ultra LED) technology, which incorporates quantum dot and mini-LED backlighting to enhance energy efficiency. Their ULED panels use a combination of local dimming zones and quantum dot color conversion to achieve higher brightness and contrast while reducing power consumption. BOE's latest ULED displays can achieve up to 2000 nits of peak brightness while maintaining energy efficiency through precise control of LED zones and advanced thermal management systems.

Strengths: High brightness and contrast, improved color gamut, and reduced power consumption. Weaknesses: Higher production costs and complexity in manufacturing process.

LG Display Co., Ltd.

Technical Solution: LG Display has introduced OLED.EX technology, which stands for 'Evolution' and 'eXperience'. This innovation uses deuterium compounds and personalized algorithms to enhance OLED's energy efficiency. The technology allows for up to 30% brighter images compared to conventional OLED displays while maintaining or even reducing power consumption. LG's OLED.EX also incorporates advanced heat dissipation techniques and improved pixel structures to maximize energy efficiency without compromising on picture quality.

Strengths: Significant brightness increase without proportional power increase, improved color accuracy. Weaknesses: Limited to OLED displays, potentially higher initial costs.

Core ULED Innovations

UV-led and display

PatentActiveUS20200098832A1

Innovation

- A UV-LED with a quadrate planar shape and a patterned sapphire substrate, featuring a buffer layer, contact layer, and an InGaN light emitting layer, optimized for smaller chip sizes (50 μm or less) to enhance luminous efficiency and reduce power output decrease, incorporating a superlattice structure and specific layer compositions for improved emission recombination and extraction efficiency.

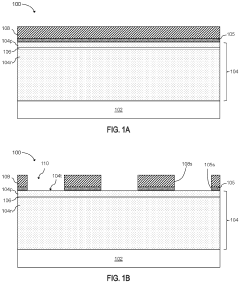

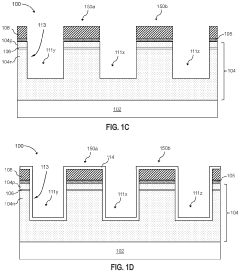

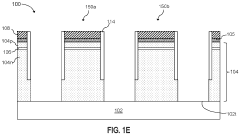

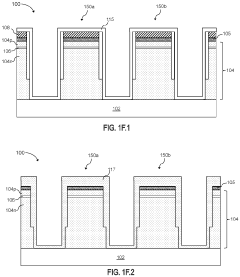

Flip chip micro light emitting diodes

PatentActiveUS11955583B2

Innovation

- A thin film flip-chip (TFFC) design for micro-LEDs with a mesa structure that includes a p-contact layer contacting the p-type layer, a cathode contacting the n-type layer's sidewall, and an anode contacting the p-contact layer's top surface, with dielectric materials isolating these components to enhance light extraction and handling efficiency.

ULED Environmental Impact

The environmental impact of Ultra-Light Emitting Diodes (ULEDs) is a crucial consideration in the context of innovations in ULED energy efficiency. As these advanced lighting technologies continue to evolve, their potential to reduce energy consumption and minimize environmental footprint becomes increasingly significant.

ULEDs demonstrate remarkable energy efficiency compared to traditional lighting solutions. By consuming less electricity to produce the same amount of light, they contribute to reduced power plant emissions and lower overall carbon footprints. This efficiency translates into substantial energy savings over the lifetime of ULED devices, potentially leading to decreased reliance on fossil fuels for electricity generation.

The manufacturing process of ULEDs also plays a role in their environmental impact. While the production of these devices requires certain rare earth elements and specialized materials, ongoing research aims to optimize manufacturing techniques and explore alternative materials. These efforts focus on reducing the environmental burden associated with resource extraction and processing.

ULEDs' long lifespan further enhances their environmental benefits. With extended operational hours compared to conventional lighting technologies, ULEDs require less frequent replacement. This longevity results in reduced waste generation and diminished need for raw materials in the production of replacement units, contributing to overall resource conservation.

The compact size and lightweight nature of ULEDs offer additional environmental advantages. Their smaller form factor allows for more efficient transportation and packaging, potentially reducing the carbon emissions associated with logistics and distribution. Moreover, the reduced material requirements for ULED production can lead to lower environmental impacts in terms of resource extraction and processing.

Heat generation is another aspect where ULEDs excel in environmental performance. Unlike traditional lighting solutions that emit significant amounts of heat, ULEDs operate at lower temperatures. This characteristic not only improves energy efficiency but also reduces the cooling requirements in buildings, potentially leading to further energy savings and decreased environmental impact from air conditioning systems.

As innovations in ULED energy efficiency continue to progress, the potential for positive environmental impact grows. Ongoing research focuses on improving light output per unit of energy consumed, enhancing color rendering capabilities, and developing more sustainable manufacturing processes. These advancements promise to further reduce the environmental footprint of lighting technologies, contributing to global efforts in energy conservation and climate change mitigation.

ULEDs demonstrate remarkable energy efficiency compared to traditional lighting solutions. By consuming less electricity to produce the same amount of light, they contribute to reduced power plant emissions and lower overall carbon footprints. This efficiency translates into substantial energy savings over the lifetime of ULED devices, potentially leading to decreased reliance on fossil fuels for electricity generation.

The manufacturing process of ULEDs also plays a role in their environmental impact. While the production of these devices requires certain rare earth elements and specialized materials, ongoing research aims to optimize manufacturing techniques and explore alternative materials. These efforts focus on reducing the environmental burden associated with resource extraction and processing.

ULEDs' long lifespan further enhances their environmental benefits. With extended operational hours compared to conventional lighting technologies, ULEDs require less frequent replacement. This longevity results in reduced waste generation and diminished need for raw materials in the production of replacement units, contributing to overall resource conservation.

The compact size and lightweight nature of ULEDs offer additional environmental advantages. Their smaller form factor allows for more efficient transportation and packaging, potentially reducing the carbon emissions associated with logistics and distribution. Moreover, the reduced material requirements for ULED production can lead to lower environmental impacts in terms of resource extraction and processing.

Heat generation is another aspect where ULEDs excel in environmental performance. Unlike traditional lighting solutions that emit significant amounts of heat, ULEDs operate at lower temperatures. This characteristic not only improves energy efficiency but also reduces the cooling requirements in buildings, potentially leading to further energy savings and decreased environmental impact from air conditioning systems.

As innovations in ULED energy efficiency continue to progress, the potential for positive environmental impact grows. Ongoing research focuses on improving light output per unit of energy consumed, enhancing color rendering capabilities, and developing more sustainable manufacturing processes. These advancements promise to further reduce the environmental footprint of lighting technologies, contributing to global efforts in energy conservation and climate change mitigation.

ULED Industry Standards

The ULED (Ultra Light Emitting Diode) industry has been rapidly evolving, necessitating the development and implementation of comprehensive standards to ensure quality, safety, and interoperability across the sector. These standards play a crucial role in driving innovation, particularly in the realm of energy efficiency.

One of the primary focuses of ULED industry standards is the establishment of minimum energy efficiency requirements. These standards typically set thresholds for luminous efficacy, measured in lumens per watt, which manufacturers must meet or exceed. As technology advances, these thresholds are periodically revised upwards, encouraging continuous improvement in energy efficiency.

Color rendering and color consistency are also key aspects addressed by ULED standards. The Color Rendering Index (CRI) and correlated color temperature (CCT) are commonly used metrics to ensure that ULEDs produce light that accurately represents colors and maintains consistency across different products and manufacturers.

Longevity and reliability standards are equally important in the ULED industry. These standards often specify minimum lifespans for ULED products, typically measured in hours of operation, and define acceptable rates of lumen depreciation over time. Such standards help ensure that energy-efficient ULEDs maintain their performance throughout their expected lifespan.

Thermal management is another critical area covered by industry standards. Proper heat dissipation is essential for maintaining ULED efficiency and longevity. Standards in this area may specify maximum operating temperatures and thermal resistance requirements for ULED packages and fixtures.

Environmental considerations are increasingly being incorporated into ULED industry standards. This includes guidelines for the use of environmentally friendly materials, restrictions on hazardous substances, and requirements for recyclability and disposal of ULED products at the end of their life cycle.

Standardization of ULED driver electronics is also a key focus area. These standards aim to ensure compatibility between different ULED products and control systems, as well as to promote energy-efficient power supply and dimming capabilities.

Compliance with these industry standards is often verified through rigorous testing and certification processes. Many regions have established accredited laboratories and certification bodies to conduct these tests and issue certifications, providing assurance to consumers and regulators alike.

As the ULED industry continues to innovate, particularly in the area of energy efficiency, these standards are regularly reviewed and updated. This ongoing process ensures that industry standards remain relevant and continue to drive technological advancements in the field of ultra-efficient lighting.

One of the primary focuses of ULED industry standards is the establishment of minimum energy efficiency requirements. These standards typically set thresholds for luminous efficacy, measured in lumens per watt, which manufacturers must meet or exceed. As technology advances, these thresholds are periodically revised upwards, encouraging continuous improvement in energy efficiency.

Color rendering and color consistency are also key aspects addressed by ULED standards. The Color Rendering Index (CRI) and correlated color temperature (CCT) are commonly used metrics to ensure that ULEDs produce light that accurately represents colors and maintains consistency across different products and manufacturers.

Longevity and reliability standards are equally important in the ULED industry. These standards often specify minimum lifespans for ULED products, typically measured in hours of operation, and define acceptable rates of lumen depreciation over time. Such standards help ensure that energy-efficient ULEDs maintain their performance throughout their expected lifespan.

Thermal management is another critical area covered by industry standards. Proper heat dissipation is essential for maintaining ULED efficiency and longevity. Standards in this area may specify maximum operating temperatures and thermal resistance requirements for ULED packages and fixtures.

Environmental considerations are increasingly being incorporated into ULED industry standards. This includes guidelines for the use of environmentally friendly materials, restrictions on hazardous substances, and requirements for recyclability and disposal of ULED products at the end of their life cycle.

Standardization of ULED driver electronics is also a key focus area. These standards aim to ensure compatibility between different ULED products and control systems, as well as to promote energy-efficient power supply and dimming capabilities.

Compliance with these industry standards is often verified through rigorous testing and certification processes. Many regions have established accredited laboratories and certification bodies to conduct these tests and issue certifications, providing assurance to consumers and regulators alike.

As the ULED industry continues to innovate, particularly in the area of energy efficiency, these standards are regularly reviewed and updated. This ongoing process ensures that industry standards remain relevant and continue to drive technological advancements in the field of ultra-efficient lighting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!