Integration of VR in submersible pump training programs.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VR Submersible Pump Training: Background and Objectives

Virtual Reality (VR) technology has been rapidly evolving over the past decade, revolutionizing various industries, including training and education. The integration of VR in submersible pump training programs represents a significant advancement in the field of industrial training. This technological convergence aims to enhance the effectiveness, safety, and efficiency of training processes for submersible pump operators and maintenance personnel.

The submersible pump industry has long faced challenges in providing comprehensive and realistic training experiences due to the nature of the equipment and its operating environments. Traditional training methods often fall short in simulating the complex underwater conditions and potential hazards associated with submersible pump operations. This limitation has led to a growing demand for more immersive and interactive training solutions.

VR technology offers a unique opportunity to address these challenges by creating virtual environments that closely mimic real-world scenarios. By leveraging VR, training programs can provide trainees with hands-on experience in a safe, controlled setting, allowing them to familiarize themselves with equipment, procedures, and potential issues without the risks associated with actual underwater operations.

The primary objective of integrating VR in submersible pump training programs is to improve the overall quality and effectiveness of training. This includes enhancing trainee engagement, increasing knowledge retention, and developing practical skills that can be directly applied in the field. Additionally, VR-based training aims to reduce the costs and logistical challenges associated with traditional on-site training methods.

Another key goal is to standardize training procedures across different locations and organizations within the industry. VR technology allows for the creation of consistent, replicable training experiences that can be easily updated and distributed globally. This standardization ensures that all trainees receive the same high-quality instruction, regardless of their geographical location or the specific equipment they will be working with.

Safety is a paramount concern in submersible pump operations, and VR training seeks to address this by allowing trainees to practice emergency procedures and troubleshooting in a risk-free environment. By simulating various fault scenarios and critical situations, VR training programs aim to better prepare operators for real-world challenges, ultimately reducing accidents and improving overall operational safety.

As the technology continues to advance, the integration of VR in submersible pump training is expected to evolve further. Future developments may include more sophisticated haptic feedback systems, improved graphics rendering for enhanced realism, and the incorporation of artificial intelligence to create adaptive learning experiences tailored to individual trainee needs.

The submersible pump industry has long faced challenges in providing comprehensive and realistic training experiences due to the nature of the equipment and its operating environments. Traditional training methods often fall short in simulating the complex underwater conditions and potential hazards associated with submersible pump operations. This limitation has led to a growing demand for more immersive and interactive training solutions.

VR technology offers a unique opportunity to address these challenges by creating virtual environments that closely mimic real-world scenarios. By leveraging VR, training programs can provide trainees with hands-on experience in a safe, controlled setting, allowing them to familiarize themselves with equipment, procedures, and potential issues without the risks associated with actual underwater operations.

The primary objective of integrating VR in submersible pump training programs is to improve the overall quality and effectiveness of training. This includes enhancing trainee engagement, increasing knowledge retention, and developing practical skills that can be directly applied in the field. Additionally, VR-based training aims to reduce the costs and logistical challenges associated with traditional on-site training methods.

Another key goal is to standardize training procedures across different locations and organizations within the industry. VR technology allows for the creation of consistent, replicable training experiences that can be easily updated and distributed globally. This standardization ensures that all trainees receive the same high-quality instruction, regardless of their geographical location or the specific equipment they will be working with.

Safety is a paramount concern in submersible pump operations, and VR training seeks to address this by allowing trainees to practice emergency procedures and troubleshooting in a risk-free environment. By simulating various fault scenarios and critical situations, VR training programs aim to better prepare operators for real-world challenges, ultimately reducing accidents and improving overall operational safety.

As the technology continues to advance, the integration of VR in submersible pump training is expected to evolve further. Future developments may include more sophisticated haptic feedback systems, improved graphics rendering for enhanced realism, and the incorporation of artificial intelligence to create adaptive learning experiences tailored to individual trainee needs.

Market Analysis for VR-Enhanced Pump Training

The market for VR-enhanced pump training programs is experiencing significant growth, driven by the increasing demand for skilled technicians in the submersible pump industry. As companies seek to improve the efficiency and safety of their operations, the integration of virtual reality technology in training programs has emerged as a promising solution. The global submersible pump market is projected to reach $12.2 billion by 2026, with a compound annual growth rate of 5.1% from 2021 to 2026. This growth is primarily attributed to the rising demand for water and wastewater management across various industries, including agriculture, construction, and oil & gas.

The adoption of VR technology in training programs is expected to address several key challenges faced by the submersible pump industry. Traditional training methods often involve high costs, safety risks, and limited hands-on experience. VR-enhanced training offers a cost-effective, safe, and immersive learning environment that can significantly improve the skills and knowledge retention of trainees. This technology allows for realistic simulations of pump installation, maintenance, and troubleshooting scenarios, which are crucial for developing practical skills in a controlled environment.

The market for VR-enhanced pump training is segmented based on end-user industries, with oil & gas, water and wastewater treatment, and mining sectors showing the highest potential for adoption. The oil & gas industry, in particular, is expected to be a major driver of growth, as it faces increasing pressure to improve operational efficiency and reduce downtime. The water and wastewater treatment sector is also anticipated to contribute significantly to market growth, driven by the need for skilled technicians to manage complex pump systems in treatment plants.

Geographically, North America and Europe are currently leading the market for VR-enhanced pump training, owing to their advanced technological infrastructure and early adoption of innovative training methods. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing investments in water management infrastructure.

Key market players in the VR-enhanced pump training sector include both established pump manufacturers and specialized VR training solution providers. Companies such as Grundfos, Xylem, and Sulzer are investing in VR technology to enhance their training programs and maintain their competitive edge. Additionally, VR technology companies like EON Reality and Immerse are partnering with pump manufacturers to develop tailored training solutions for the industry.

The market analysis reveals several trends shaping the future of VR-enhanced pump training. These include the integration of artificial intelligence and machine learning to create adaptive learning experiences, the development of cloud-based VR training platforms for remote access, and the incorporation of haptic feedback technology to enhance the realism of simulations. As the technology continues to evolve and become more accessible, the market for VR-enhanced pump training is expected to expand rapidly, offering significant opportunities for both technology providers and pump manufacturers.

The adoption of VR technology in training programs is expected to address several key challenges faced by the submersible pump industry. Traditional training methods often involve high costs, safety risks, and limited hands-on experience. VR-enhanced training offers a cost-effective, safe, and immersive learning environment that can significantly improve the skills and knowledge retention of trainees. This technology allows for realistic simulations of pump installation, maintenance, and troubleshooting scenarios, which are crucial for developing practical skills in a controlled environment.

The market for VR-enhanced pump training is segmented based on end-user industries, with oil & gas, water and wastewater treatment, and mining sectors showing the highest potential for adoption. The oil & gas industry, in particular, is expected to be a major driver of growth, as it faces increasing pressure to improve operational efficiency and reduce downtime. The water and wastewater treatment sector is also anticipated to contribute significantly to market growth, driven by the need for skilled technicians to manage complex pump systems in treatment plants.

Geographically, North America and Europe are currently leading the market for VR-enhanced pump training, owing to their advanced technological infrastructure and early adoption of innovative training methods. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing investments in water management infrastructure.

Key market players in the VR-enhanced pump training sector include both established pump manufacturers and specialized VR training solution providers. Companies such as Grundfos, Xylem, and Sulzer are investing in VR technology to enhance their training programs and maintain their competitive edge. Additionally, VR technology companies like EON Reality and Immerse are partnering with pump manufacturers to develop tailored training solutions for the industry.

The market analysis reveals several trends shaping the future of VR-enhanced pump training. These include the integration of artificial intelligence and machine learning to create adaptive learning experiences, the development of cloud-based VR training platforms for remote access, and the incorporation of haptic feedback technology to enhance the realism of simulations. As the technology continues to evolve and become more accessible, the market for VR-enhanced pump training is expected to expand rapidly, offering significant opportunities for both technology providers and pump manufacturers.

Current VR Integration Challenges in Pump Training

The integration of Virtual Reality (VR) in submersible pump training programs faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the high initial cost associated with implementing VR technology. The expense of VR hardware, software development, and content creation can be prohibitive for many training facilities, especially smaller organizations or those with limited budgets.

Another challenge lies in the technical complexity of creating realistic and accurate VR simulations for submersible pump operations. Developing a virtual environment that accurately replicates the intricate mechanics, fluid dynamics, and operational nuances of submersible pumps requires extensive expertise in both pump technology and VR development. This specialized knowledge is often scarce, leading to a shortage of qualified professionals who can bridge the gap between these two domains.

The issue of user adaptation and acceptance also presents a significant hurdle. Many trainees, particularly those from older generations or with limited exposure to technology, may find it challenging to adapt to VR interfaces. This resistance can lead to reduced engagement and effectiveness of the training programs, potentially undermining the benefits of VR integration.

Ensuring the fidelity and relevance of VR simulations to real-world pump operations is another critical challenge. While VR can provide immersive experiences, replicating the tactile feedback and physical sensations associated with handling submersible pumps remains difficult. This limitation can potentially create a disconnect between virtual training and practical application, raising concerns about the transferability of skills learned in VR to actual pump maintenance and operation scenarios.

Furthermore, the rapid pace of technological advancement in both VR and pump technologies poses a continuous challenge. Training programs must regularly update their VR content and systems to keep pace with evolving pump designs and operational procedures. This need for constant updates can strain resources and require ongoing investment, which may be unsustainable for some organizations.

Lastly, there are concerns regarding the health and safety implications of prolonged VR use in training environments. Issues such as motion sickness, eye strain, and potential long-term effects of immersive VR experiences on trainees' well-being need to be carefully addressed. Developing protocols for safe and comfortable VR usage in pump training programs adds another layer of complexity to the integration process.

Another challenge lies in the technical complexity of creating realistic and accurate VR simulations for submersible pump operations. Developing a virtual environment that accurately replicates the intricate mechanics, fluid dynamics, and operational nuances of submersible pumps requires extensive expertise in both pump technology and VR development. This specialized knowledge is often scarce, leading to a shortage of qualified professionals who can bridge the gap between these two domains.

The issue of user adaptation and acceptance also presents a significant hurdle. Many trainees, particularly those from older generations or with limited exposure to technology, may find it challenging to adapt to VR interfaces. This resistance can lead to reduced engagement and effectiveness of the training programs, potentially undermining the benefits of VR integration.

Ensuring the fidelity and relevance of VR simulations to real-world pump operations is another critical challenge. While VR can provide immersive experiences, replicating the tactile feedback and physical sensations associated with handling submersible pumps remains difficult. This limitation can potentially create a disconnect between virtual training and practical application, raising concerns about the transferability of skills learned in VR to actual pump maintenance and operation scenarios.

Furthermore, the rapid pace of technological advancement in both VR and pump technologies poses a continuous challenge. Training programs must regularly update their VR content and systems to keep pace with evolving pump designs and operational procedures. This need for constant updates can strain resources and require ongoing investment, which may be unsustainable for some organizations.

Lastly, there are concerns regarding the health and safety implications of prolonged VR use in training environments. Issues such as motion sickness, eye strain, and potential long-term effects of immersive VR experiences on trainees' well-being need to be carefully addressed. Developing protocols for safe and comfortable VR usage in pump training programs adds another layer of complexity to the integration process.

Existing VR Solutions for Pump Training Programs

01 VR Display and Rendering Technologies

Advancements in display and rendering technologies for virtual reality systems, including improvements in image quality, frame rates, and field of view. These technologies aim to enhance the immersive experience and reduce motion sickness in VR applications.- VR Display and Rendering Technologies: Advancements in display and rendering technologies for virtual reality systems, including improvements in image quality, frame rates, and field of view. These technologies aim to enhance the immersive experience and reduce motion sickness for users.

- VR Input and Interaction Methods: Development of novel input devices and interaction methods for virtual reality environments, such as gesture recognition, haptic feedback, and eye-tracking technologies. These innovations allow for more natural and intuitive user interactions within virtual spaces.

- VR Content Creation and Management: Tools and platforms for creating, managing, and distributing virtual reality content, including 3D modeling software, 360-degree video production techniques, and content management systems specifically designed for VR applications.

- VR Network and Cloud Infrastructure: Infrastructure solutions for supporting virtual reality applications, including cloud-based rendering, low-latency networking protocols, and distributed computing architectures. These technologies aim to improve performance and scalability of VR systems.

- VR Applications in Various Industries: Implementation of virtual reality technologies in diverse fields such as healthcare, education, entertainment, and industrial training. These applications leverage VR to provide immersive experiences, simulate real-world scenarios, and enhance learning and productivity.

02 VR Input and Interaction Methods

Development of novel input devices and interaction methods for VR environments, such as hand tracking, gesture recognition, and haptic feedback systems. These innovations allow for more natural and intuitive user interactions within virtual spaces.Expand Specific Solutions03 VR Content Creation and Management

Tools and platforms for creating, managing, and distributing VR content, including 3D modeling software, 360-degree video production, and content management systems specifically designed for virtual reality applications.Expand Specific Solutions04 VR Networking and Multiplayer Experiences

Technologies for enabling networked and multiplayer VR experiences, including synchronization methods, latency reduction techniques, and social interaction features within virtual environments.Expand Specific Solutions05 VR Integration with Other Technologies

Integration of VR with other emerging technologies such as artificial intelligence, blockchain, and Internet of Things (IoT) to create more sophisticated and interconnected virtual experiences across various domains like education, healthcare, and entertainment.Expand Specific Solutions

Key Players in VR and Submersible Pump Industries

The integration of VR in submersible pump training programs is in its early stages, with the market showing significant growth potential. The technology's maturity varies across companies, with major players like China National Offshore Oil Corp. and CNOOC Energy Technology & Services Ltd. likely leading in adoption due to their extensive offshore operations. Smaller firms such as Beijing Huaru Technology Co., Ltd. are also contributing to the field's advancement. The market size is expected to expand as the oil and gas industry increasingly recognizes the benefits of VR training for complex underwater operations. As the technology evolves, we anticipate a competitive landscape with diverse players from both the energy and technology sectors collaborating to enhance training effectiveness and safety in submersible pump operations.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corp. (CNOOC) has developed an advanced VR-based submersible pump training program. The system utilizes high-fidelity 3D models of offshore platforms and submersible pumps, allowing trainees to interact with virtual equipment in a realistic offshore environment. The VR program incorporates real-time physics simulations for pump operations, fluid dynamics, and equipment failures. Trainees can practice installation, maintenance, and troubleshooting procedures in a safe, controlled virtual space. The system also features multi-user capabilities, enabling collaborative training sessions and instructor-led exercises[1][3].

Strengths: Realistic simulation of offshore environments, safe training for high-risk scenarios, and collaborative learning capabilities. Weaknesses: High initial investment costs and potential technical limitations in simulating complex fluid dynamics.

Beijing Huaru Technology Co., Ltd.

Technical Solution: Beijing Huaru Technology has developed a comprehensive VR-based submersible pump training solution. Their system employs advanced haptic feedback technology, allowing trainees to feel realistic tactile sensations when interacting with virtual pump components. The VR environment accurately replicates various submersible pump models and their operating conditions. The training program includes modules for assembly, disassembly, maintenance, and fault diagnosis. A unique feature is the integration of AI-driven scenarios that adapt to each trainee's performance, providing personalized learning experiences. The system also incorporates a detailed analytics dashboard for trainers to track progress and identify areas for improvement[2][5].

Strengths: Advanced haptic feedback for enhanced realism, AI-driven personalized training, and comprehensive performance analytics. Weaknesses: May require specialized hardware for haptic feedback, potentially limiting widespread adoption.

Innovative VR Techniques for Pump Simulation

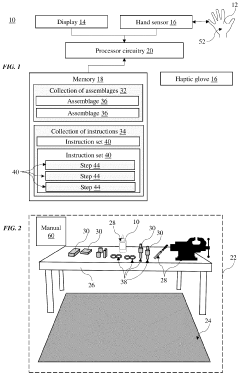

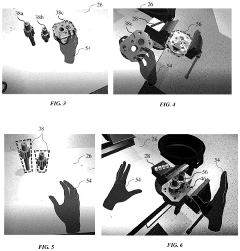

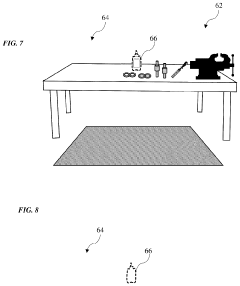

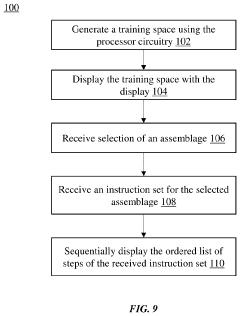

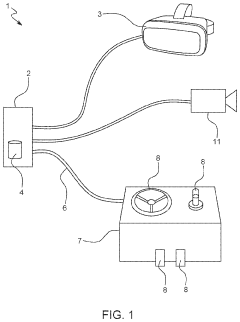

Virtual reality training simulator

PatentPendingUS20240078930A1

Innovation

- A virtual reality system that guides users through a sequential list of assembly steps by highlighting tools and locations in a virtual work area, utilizing a haptic glove for tactile feedback to simulate surface finishes and detect issues like burrs during assembly.

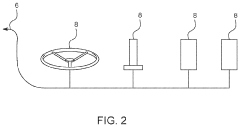

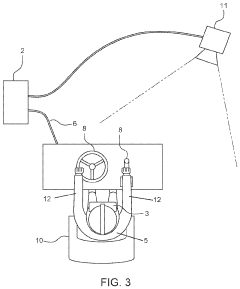

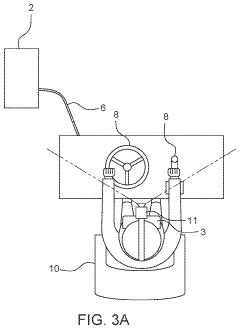

Integrating Tactile Nonvirtual Controls in a Virtual Reality (VR) Training Simulator

PatentActiveUS20220276709A1

Innovation

- A virtual reality training system that integrates nonvirtual tactile controls with a computer system and video camera to capture and render the operator's limb movements, allowing for physical interaction with controls that translate into the virtual environment, providing a more immersive and cost-effective training experience.

Safety Regulations in VR Industrial Training

The integration of Virtual Reality (VR) in submersible pump training programs necessitates a comprehensive understanding of safety regulations in VR industrial training. These regulations are crucial to ensure the well-being of trainees and the effectiveness of the training programs.

Safety regulations in VR industrial training for submersible pump operations typically encompass both physical and virtual safety considerations. Physical safety measures include ensuring proper setup of VR equipment, adequate space for movement, and prevention of trip hazards. Virtual safety protocols focus on minimizing motion sickness, preventing eye strain, and managing cognitive load during simulations.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the International Organization for Standardization (ISO) have begun to address VR-specific safety concerns in industrial training. These organizations emphasize the importance of risk assessment, user comfort, and the prevention of cybersickness.

Key safety regulations for VR submersible pump training include guidelines for session duration, breaks between VR experiences, and the proper use of haptic feedback devices. Additionally, regulations often mandate clear communication protocols between trainees and instructors during VR sessions to ensure immediate assistance if needed.

Environmental considerations are also critical in VR safety regulations. Training facilities must maintain appropriate temperature, lighting, and ventilation to support comfortable and safe VR experiences. Regulations may specify minimum room dimensions and the use of non-slip flooring to prevent accidents during VR-guided physical movements.

Data privacy and security regulations play a significant role in VR industrial training. Safety protocols must address the protection of personal information collected during training sessions, as well as the secure storage and transmission of performance data.

Ergonomic regulations for VR equipment used in submersible pump training are essential to prevent musculoskeletal issues. These may include specifications for headset weight, adjustability of straps, and the design of handheld controllers to minimize strain during extended use.

Emergency procedures form a critical component of VR safety regulations. Training programs must include protocols for quickly removing VR equipment in case of physical discomfort or technical malfunctions. Clear guidelines for emergency exits and the presence of trained personnel to assist in such situations are typically mandated.

As the field of VR industrial training evolves, safety regulations continue to adapt. Ongoing research into the long-term effects of VR exposure informs the development of new safety standards, ensuring that submersible pump training programs remain both effective and safe for all participants.

Safety regulations in VR industrial training for submersible pump operations typically encompass both physical and virtual safety considerations. Physical safety measures include ensuring proper setup of VR equipment, adequate space for movement, and prevention of trip hazards. Virtual safety protocols focus on minimizing motion sickness, preventing eye strain, and managing cognitive load during simulations.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the International Organization for Standardization (ISO) have begun to address VR-specific safety concerns in industrial training. These organizations emphasize the importance of risk assessment, user comfort, and the prevention of cybersickness.

Key safety regulations for VR submersible pump training include guidelines for session duration, breaks between VR experiences, and the proper use of haptic feedback devices. Additionally, regulations often mandate clear communication protocols between trainees and instructors during VR sessions to ensure immediate assistance if needed.

Environmental considerations are also critical in VR safety regulations. Training facilities must maintain appropriate temperature, lighting, and ventilation to support comfortable and safe VR experiences. Regulations may specify minimum room dimensions and the use of non-slip flooring to prevent accidents during VR-guided physical movements.

Data privacy and security regulations play a significant role in VR industrial training. Safety protocols must address the protection of personal information collected during training sessions, as well as the secure storage and transmission of performance data.

Ergonomic regulations for VR equipment used in submersible pump training are essential to prevent musculoskeletal issues. These may include specifications for headset weight, adjustability of straps, and the design of handheld controllers to minimize strain during extended use.

Emergency procedures form a critical component of VR safety regulations. Training programs must include protocols for quickly removing VR equipment in case of physical discomfort or technical malfunctions. Clear guidelines for emergency exits and the presence of trained personnel to assist in such situations are typically mandated.

As the field of VR industrial training evolves, safety regulations continue to adapt. Ongoing research into the long-term effects of VR exposure informs the development of new safety standards, ensuring that submersible pump training programs remain both effective and safe for all participants.

Cost-Benefit Analysis of VR Pump Training Integration

The integration of Virtual Reality (VR) in submersible pump training programs represents a significant investment for companies in the water and wastewater industry. A comprehensive cost-benefit analysis is crucial to determine the financial viability and long-term value of implementing VR technology in pump training.

Initial costs for VR integration include hardware purchases, such as VR headsets, high-performance computers, and motion tracking systems. Software development or licensing fees for creating realistic pump simulations also contribute to upfront expenses. Additionally, companies must consider the cost of training instructors to effectively utilize VR technology in their teaching methods.

However, these initial investments can be offset by substantial long-term benefits. VR training programs significantly reduce the need for physical training equipment, which can be expensive to purchase, maintain, and replace. Virtual simulations eliminate the risk of damage to actual pumps during training exercises, potentially saving thousands of dollars in repair or replacement costs.

Travel expenses for on-site training can be drastically reduced or eliminated, as VR allows for remote training sessions. This not only cuts costs but also increases accessibility to training for employees in various locations. Furthermore, VR training can be conducted more frequently and with greater flexibility, reducing downtime and increasing overall productivity.

The efficiency of VR training is another key benefit. Trainees can practice complex procedures repeatedly in a safe, virtual environment, leading to faster skill acquisition and improved retention. This accelerated learning curve translates to reduced training time and quicker deployment of skilled workers, ultimately improving operational efficiency.

Safety improvements represent a significant, albeit less quantifiable, benefit. VR training allows employees to practice hazardous scenarios without real-world risks, potentially reducing workplace accidents and associated costs, including medical expenses, legal fees, and lost productivity.

Long-term cost savings can also be realized through reduced equipment wear and tear. By conducting initial training and practice sessions in VR, companies can preserve their physical pumps for actual operations, extending their lifespan and reducing maintenance costs.

While the initial investment in VR technology may be substantial, the potential for long-term cost savings, improved training outcomes, and enhanced safety makes a compelling case for its integration into submersible pump training programs. Companies must carefully weigh these factors against their specific operational needs and financial constraints to determine the overall value proposition of VR implementation.

Initial costs for VR integration include hardware purchases, such as VR headsets, high-performance computers, and motion tracking systems. Software development or licensing fees for creating realistic pump simulations also contribute to upfront expenses. Additionally, companies must consider the cost of training instructors to effectively utilize VR technology in their teaching methods.

However, these initial investments can be offset by substantial long-term benefits. VR training programs significantly reduce the need for physical training equipment, which can be expensive to purchase, maintain, and replace. Virtual simulations eliminate the risk of damage to actual pumps during training exercises, potentially saving thousands of dollars in repair or replacement costs.

Travel expenses for on-site training can be drastically reduced or eliminated, as VR allows for remote training sessions. This not only cuts costs but also increases accessibility to training for employees in various locations. Furthermore, VR training can be conducted more frequently and with greater flexibility, reducing downtime and increasing overall productivity.

The efficiency of VR training is another key benefit. Trainees can practice complex procedures repeatedly in a safe, virtual environment, leading to faster skill acquisition and improved retention. This accelerated learning curve translates to reduced training time and quicker deployment of skilled workers, ultimately improving operational efficiency.

Safety improvements represent a significant, albeit less quantifiable, benefit. VR training allows employees to practice hazardous scenarios without real-world risks, potentially reducing workplace accidents and associated costs, including medical expenses, legal fees, and lost productivity.

Long-term cost savings can also be realized through reduced equipment wear and tear. By conducting initial training and practice sessions in VR, companies can preserve their physical pumps for actual operations, extending their lifespan and reducing maintenance costs.

While the initial investment in VR technology may be substantial, the potential for long-term cost savings, improved training outcomes, and enhanced safety makes a compelling case for its integration into submersible pump training programs. Companies must carefully weigh these factors against their specific operational needs and financial constraints to determine the overall value proposition of VR implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!