KERS impact on electric bus transit systems efficiency

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Technology Evolution and Goals

Kinetic Energy Recovery Systems (KERS) have evolved significantly since their inception in the automotive industry, particularly in Formula 1 racing. The technology's application in electric bus transit systems represents a new frontier in urban transportation efficiency. The primary goal of KERS in this context is to harness and repurpose the kinetic energy typically lost during braking, converting it into usable electrical energy to power the bus's systems or assist in acceleration.

The evolution of KERS technology for electric buses has been driven by the increasing demand for sustainable and energy-efficient public transportation solutions. Initially, KERS was primarily mechanical, using flywheels to store energy. However, the trend has shifted towards electrical systems, which offer greater flexibility and integration with existing electric bus powertrains.

A key milestone in KERS development for electric buses was the transition from simple regenerative braking systems to more advanced, high-capacity energy storage solutions. This progression has enabled buses to capture and store larger amounts of energy, significantly extending their range and reducing overall energy consumption.

The current technological goals for KERS in electric bus transit systems focus on several key areas. Firstly, there is a push to improve energy conversion efficiency, aiming to recover and utilize a higher percentage of the kinetic energy generated during braking. This involves refining the energy capture mechanisms and minimizing losses in the conversion process.

Another critical objective is the development of more compact and lightweight KERS components. As space and weight are at a premium in bus design, creating systems that can be seamlessly integrated without compromising passenger capacity or vehicle performance is essential. This goal has led to innovations in materials science and system design, with a focus on high-density energy storage solutions.

Durability and longevity of KERS components are also paramount. Given the demanding nature of urban bus operations, with frequent stops and starts, the system must withstand continuous cycles of energy capture and release without degradation. This has spurred research into more robust materials and designs that can maintain high performance over extended periods.

Furthermore, there is an ongoing effort to enhance the control systems and algorithms that manage KERS operation. The aim is to optimize energy recovery and utilization in real-time, adapting to various driving conditions and route profiles. This involves the integration of advanced sensors and predictive analytics to anticipate braking events and maximize energy capture opportunities.

Looking ahead, the future goals for KERS in electric bus transit systems include achieving even higher energy recovery rates, potentially exceeding 70% of the available kinetic energy. There is also a focus on developing hybrid systems that combine different energy storage technologies, such as batteries and supercapacitors, to leverage the strengths of each and provide more flexible energy management options.

The evolution of KERS technology for electric buses has been driven by the increasing demand for sustainable and energy-efficient public transportation solutions. Initially, KERS was primarily mechanical, using flywheels to store energy. However, the trend has shifted towards electrical systems, which offer greater flexibility and integration with existing electric bus powertrains.

A key milestone in KERS development for electric buses was the transition from simple regenerative braking systems to more advanced, high-capacity energy storage solutions. This progression has enabled buses to capture and store larger amounts of energy, significantly extending their range and reducing overall energy consumption.

The current technological goals for KERS in electric bus transit systems focus on several key areas. Firstly, there is a push to improve energy conversion efficiency, aiming to recover and utilize a higher percentage of the kinetic energy generated during braking. This involves refining the energy capture mechanisms and minimizing losses in the conversion process.

Another critical objective is the development of more compact and lightweight KERS components. As space and weight are at a premium in bus design, creating systems that can be seamlessly integrated without compromising passenger capacity or vehicle performance is essential. This goal has led to innovations in materials science and system design, with a focus on high-density energy storage solutions.

Durability and longevity of KERS components are also paramount. Given the demanding nature of urban bus operations, with frequent stops and starts, the system must withstand continuous cycles of energy capture and release without degradation. This has spurred research into more robust materials and designs that can maintain high performance over extended periods.

Furthermore, there is an ongoing effort to enhance the control systems and algorithms that manage KERS operation. The aim is to optimize energy recovery and utilization in real-time, adapting to various driving conditions and route profiles. This involves the integration of advanced sensors and predictive analytics to anticipate braking events and maximize energy capture opportunities.

Looking ahead, the future goals for KERS in electric bus transit systems include achieving even higher energy recovery rates, potentially exceeding 70% of the available kinetic energy. There is also a focus on developing hybrid systems that combine different energy storage technologies, such as batteries and supercapacitors, to leverage the strengths of each and provide more flexible energy management options.

Electric Bus Market Demand Analysis

The electric bus market has experienced significant growth in recent years, driven by increasing environmental concerns and government initiatives to reduce carbon emissions in urban transportation. This trend is expected to continue, with the global electric bus market projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years.

Major metropolitan areas worldwide are leading the adoption of electric buses, with cities in China, Europe, and North America at the forefront. China, in particular, has been a dominant force in the market, accounting for a substantial portion of global electric bus sales. European cities are also rapidly transitioning their public transport fleets to electric vehicles, driven by stringent emission regulations and sustainability goals.

The demand for electric buses is further bolstered by advancements in battery technology, which have improved range and performance while reducing costs. This has made electric buses increasingly competitive with traditional diesel-powered vehicles in terms of total cost of ownership (TCO) over their lifecycle.

Public transit agencies are recognizing the benefits of electric buses, including lower operating costs, reduced maintenance requirements, and improved air quality in urban areas. These factors are driving the replacement of aging diesel fleets with electric alternatives, creating a steady demand for new electric buses.

The integration of Kinetic Energy Recovery Systems (KERS) in electric buses presents an opportunity to further enhance their efficiency and appeal. KERS technology can capture and store energy typically lost during braking, which can then be used to assist acceleration or power onboard systems. This has the potential to extend the range of electric buses, reduce energy consumption, and improve overall system efficiency.

Market demand analysis indicates that transit agencies are increasingly interested in technologies that can maximize the performance and efficiency of their electric bus fleets. KERS-equipped electric buses could offer a competitive advantage in this market, particularly in routes with frequent stops where the energy recovery potential is highest.

However, the adoption of KERS in electric buses also faces challenges. The additional cost of implementing KERS technology must be balanced against the potential energy savings and performance improvements. Transit agencies will need to carefully evaluate the return on investment, considering factors such as route characteristics, operational patterns, and local energy costs.

As cities continue to prioritize sustainable transportation solutions, the demand for advanced electric bus technologies is expected to grow. The market for KERS-equipped electric buses is likely to expand as transit agencies seek to optimize their fleet performance and reduce operational costs while meeting increasingly stringent environmental targets.

Major metropolitan areas worldwide are leading the adoption of electric buses, with cities in China, Europe, and North America at the forefront. China, in particular, has been a dominant force in the market, accounting for a substantial portion of global electric bus sales. European cities are also rapidly transitioning their public transport fleets to electric vehicles, driven by stringent emission regulations and sustainability goals.

The demand for electric buses is further bolstered by advancements in battery technology, which have improved range and performance while reducing costs. This has made electric buses increasingly competitive with traditional diesel-powered vehicles in terms of total cost of ownership (TCO) over their lifecycle.

Public transit agencies are recognizing the benefits of electric buses, including lower operating costs, reduced maintenance requirements, and improved air quality in urban areas. These factors are driving the replacement of aging diesel fleets with electric alternatives, creating a steady demand for new electric buses.

The integration of Kinetic Energy Recovery Systems (KERS) in electric buses presents an opportunity to further enhance their efficiency and appeal. KERS technology can capture and store energy typically lost during braking, which can then be used to assist acceleration or power onboard systems. This has the potential to extend the range of electric buses, reduce energy consumption, and improve overall system efficiency.

Market demand analysis indicates that transit agencies are increasingly interested in technologies that can maximize the performance and efficiency of their electric bus fleets. KERS-equipped electric buses could offer a competitive advantage in this market, particularly in routes with frequent stops where the energy recovery potential is highest.

However, the adoption of KERS in electric buses also faces challenges. The additional cost of implementing KERS technology must be balanced against the potential energy savings and performance improvements. Transit agencies will need to carefully evaluate the return on investment, considering factors such as route characteristics, operational patterns, and local energy costs.

As cities continue to prioritize sustainable transportation solutions, the demand for advanced electric bus technologies is expected to grow. The market for KERS-equipped electric buses is likely to expand as transit agencies seek to optimize their fleet performance and reduce operational costs while meeting increasingly stringent environmental targets.

KERS Integration Challenges in Transit Systems

The integration of Kinetic Energy Recovery Systems (KERS) into electric bus transit systems presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the complexity of retrofitting existing electric buses with KERS technology. This process requires substantial modifications to the vehicle's powertrain and energy management systems, which can be both time-consuming and costly.

Another major challenge lies in the optimization of KERS for urban transit routes. Unlike personal vehicles or racing cars, where KERS has been more widely adopted, city buses operate on fixed routes with frequent stops and starts. This unique operational profile necessitates a carefully tailored KERS solution that can efficiently capture and utilize braking energy while maintaining the bus's overall performance and reliability.

The weight and space constraints of electric buses pose additional integration challenges. KERS components, including energy storage devices, power electronics, and mechanical systems, must be incorporated without significantly increasing the vehicle's weight or compromising passenger capacity. This requires innovative design solutions and the use of lightweight materials to minimize the impact on the bus's efficiency and range.

Furthermore, the integration of KERS with existing electric drivetrain systems presents technical hurdles. Ensuring seamless communication and coordination between the KERS and the bus's battery management system, motor controllers, and other electronic components is crucial for optimal energy recovery and utilization. This integration must be robust enough to handle the diverse operating conditions encountered in urban transit environments.

Durability and maintenance considerations also pose significant challenges. Transit buses operate for long hours under demanding conditions, and KERS components must be designed to withstand this rigorous use. The system needs to maintain its efficiency and reliability over the vehicle's lifespan, which typically spans several years. This requires the development of durable components and the implementation of effective maintenance strategies to minimize downtime and repair costs.

Safety is another critical aspect that must be addressed in KERS integration. The system must be designed with fail-safe mechanisms to prevent malfunctions that could compromise vehicle safety. Additionally, proper shielding and isolation of high-voltage components are essential to protect passengers and maintenance personnel from electrical hazards.

Lastly, the cost-effectiveness of KERS integration remains a significant challenge for transit agencies. While the technology promises improved energy efficiency, the initial investment and potential maintenance costs must be carefully weighed against the expected fuel savings and environmental benefits. Transit operators need to conduct thorough cost-benefit analyses to justify the adoption of KERS technology in their fleets.

Another major challenge lies in the optimization of KERS for urban transit routes. Unlike personal vehicles or racing cars, where KERS has been more widely adopted, city buses operate on fixed routes with frequent stops and starts. This unique operational profile necessitates a carefully tailored KERS solution that can efficiently capture and utilize braking energy while maintaining the bus's overall performance and reliability.

The weight and space constraints of electric buses pose additional integration challenges. KERS components, including energy storage devices, power electronics, and mechanical systems, must be incorporated without significantly increasing the vehicle's weight or compromising passenger capacity. This requires innovative design solutions and the use of lightweight materials to minimize the impact on the bus's efficiency and range.

Furthermore, the integration of KERS with existing electric drivetrain systems presents technical hurdles. Ensuring seamless communication and coordination between the KERS and the bus's battery management system, motor controllers, and other electronic components is crucial for optimal energy recovery and utilization. This integration must be robust enough to handle the diverse operating conditions encountered in urban transit environments.

Durability and maintenance considerations also pose significant challenges. Transit buses operate for long hours under demanding conditions, and KERS components must be designed to withstand this rigorous use. The system needs to maintain its efficiency and reliability over the vehicle's lifespan, which typically spans several years. This requires the development of durable components and the implementation of effective maintenance strategies to minimize downtime and repair costs.

Safety is another critical aspect that must be addressed in KERS integration. The system must be designed with fail-safe mechanisms to prevent malfunctions that could compromise vehicle safety. Additionally, proper shielding and isolation of high-voltage components are essential to protect passengers and maintenance personnel from electrical hazards.

Lastly, the cost-effectiveness of KERS integration remains a significant challenge for transit agencies. While the technology promises improved energy efficiency, the initial investment and potential maintenance costs must be carefully weighed against the expected fuel savings and environmental benefits. Transit operators need to conduct thorough cost-benefit analyses to justify the adoption of KERS technology in their fleets.

Current KERS Solutions for Electric Buses

01 Energy storage and conversion efficiency

KERS efficiency is largely dependent on the system's ability to store and convert kinetic energy. This involves optimizing energy capture during braking, minimizing losses during storage, and maximizing the conversion back to usable energy. Advanced storage technologies and improved power electronics play crucial roles in enhancing overall system efficiency.- Improved energy recovery mechanisms: Advanced KERS designs focus on enhancing energy recovery mechanisms to increase overall system efficiency. This includes optimizing the conversion of kinetic energy to electrical energy during braking, and improving energy storage and release processes. Innovations in this area aim to maximize the amount of energy that can be captured and reused, thereby increasing the system's overall efficiency.

- Integration with hybrid and electric vehicle systems: KERS efficiency is enhanced through better integration with hybrid and electric vehicle powertrains. This involves optimizing the interaction between KERS and other vehicle systems, such as regenerative braking and electric motors. Improved integration allows for more seamless energy transfer and utilization, contributing to higher overall vehicle efficiency and performance.

- Advanced energy storage technologies: The development of more efficient energy storage technologies is crucial for improving KERS efficiency. This includes the use of advanced batteries, supercapacitors, or flywheels that can quickly store and release large amounts of energy. These technologies aim to reduce energy losses during storage and retrieval, thereby increasing the overall efficiency of the KERS.

- Intelligent control systems and algorithms: Sophisticated control systems and algorithms are being developed to optimize KERS operation. These systems manage energy flow, predict energy demands, and adjust system parameters in real-time to maximize efficiency. Machine learning and AI techniques are increasingly used to enhance the decision-making capabilities of KERS control systems, leading to improved overall performance.

- Lightweight and compact designs: Efforts are being made to develop lighter and more compact KERS components. This includes the use of advanced materials and innovative design approaches to reduce the weight and size of energy recovery, storage, and conversion components. Lightweight designs contribute to overall vehicle efficiency by reducing the energy required for acceleration and improving the power-to-weight ratio of the KERS.

02 Hybrid and electric vehicle integration

Integrating KERS with hybrid and electric vehicle powertrains can significantly improve overall vehicle efficiency. This integration involves optimizing the interplay between the KERS, electric motors, and conventional engines to maximize energy recovery and utilization across various driving conditions.Expand Specific Solutions03 Flywheel-based KERS optimization

Flywheel-based KERS systems offer high power density and efficiency. Improving these systems involves enhancing flywheel design, reducing friction losses, and optimizing the transmission system between the flywheel and the drivetrain. Advanced materials and bearing technologies contribute to increased efficiency and energy storage capacity.Expand Specific Solutions04 Control strategies for KERS

Sophisticated control strategies are crucial for maximizing KERS efficiency. These strategies involve real-time optimization of energy recovery, storage, and deployment based on driving conditions, vehicle state, and driver inputs. Machine learning and predictive algorithms can enhance the system's ability to manage energy flow effectively.Expand Specific Solutions05 Thermal management in KERS

Effective thermal management is essential for maintaining KERS efficiency, particularly in high-performance applications. This involves developing cooling systems for energy storage components, power electronics, and mechanical interfaces. Improved thermal management helps reduce energy losses and extends the system's operational life.Expand Specific Solutions

Key Players in KERS and Electric Bus Industry

The KERS (Kinetic Energy Recovery System) impact on electric bus transit systems efficiency is in an early development stage, with a growing market potential as urban areas seek sustainable transportation solutions. The technology's maturity varies among key players, with companies like Volvo Lastvagnar AB, Siemens AG, and Robert Bosch GmbH leading in research and development. While established automotive giants are investing heavily, innovative startups like Punch Flybrid Ltd and Flybrid Automotive Ltd are also making significant contributions. The market is characterized by a mix of traditional vehicle manufacturers and specialized technology firms, indicating a competitive and evolving landscape with potential for rapid advancements in KERS efficiency for electric bus applications.

Siemens AG

Technical Solution: Siemens has engineered a sophisticated KERS solution for electric bus transit systems, focusing on maximizing energy efficiency and reducing overall operational costs. Their system employs a dual-mode approach, combining both electrical and mechanical energy storage methods. The electrical component uses high-capacity supercapacitors for rapid energy absorption and release, while the mechanical system utilizes a high-speed flywheel for longer-term energy storage. This hybrid approach allows for optimal energy management across various driving conditions. Siemens' KERS can recover up to 30% of the energy typically lost during braking[3], potentially extending the range of electric buses by up to 20%[4]. The system also incorporates advanced power electronics and control algorithms to seamlessly integrate with the bus's existing electrical systems, ensuring smooth operation and minimal driver intervention.

Strengths: Versatile energy storage, high efficiency in various driving conditions, and seamless integration. Weaknesses: Higher complexity due to dual-mode system, potentially higher maintenance requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Kinetic Energy Recovery System (KERS) for electric buses that significantly improves transit system efficiency. Their system utilizes a high-power electric motor-generator coupled with an advanced energy storage system, typically a high-performance lithium-ion battery pack or ultracapacitors. The KERS captures kinetic energy during braking, converting it into electrical energy, which is then stored for later use. This stored energy can be used to assist acceleration, reducing the load on the main propulsion system. Bosch's KERS for electric buses can recover up to 70% of braking energy[1], which can lead to energy savings of 20-30% in urban driving conditions[2]. The system is designed to be compact and lightweight, minimizing the impact on vehicle payload capacity.

Strengths: High energy recovery efficiency, significant fuel savings, and reduced emissions. Weaknesses: Initial installation costs and complexity in integration with existing bus systems.

Core KERS Innovations for Transit Efficiency

Kinetic energy recovery system

PatentPendingCN118722205A

Innovation

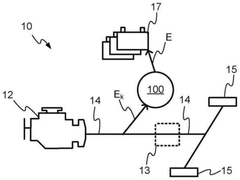

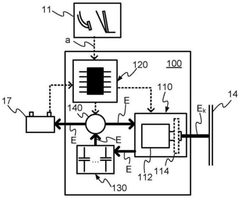

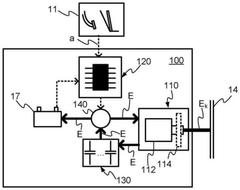

- Employs a kinetic energy recovery system (KERS) connected to the vehicle's propulsion shaft, which converts energy from the propulsion shaft into electrical energy through internal energy storage and processing circuitry, and distributes it to non-propulsion batteries or propulsion shafts when appropriate, in lieu of generator charging and provide motivation.

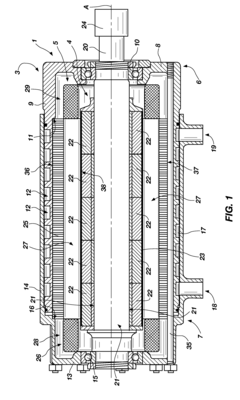

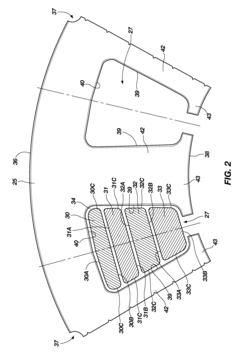

Electric motor with bar winding and connection plates

PatentActiveUS8076817B2

Innovation

- A compact, high-power-density multiphase synchronous electrical machine with a rotor and stator design featuring axial connection plates that extend the stator pack, providing large joining surfaces and efficient heat exchange, allowing for a high power-to-weight and power-to-volume ratio.

Environmental Impact of KERS in Urban Transit

The implementation of Kinetic Energy Recovery Systems (KERS) in urban transit, particularly in electric bus systems, has significant environmental implications. By capturing and reusing kinetic energy that would otherwise be lost during braking, KERS technology contributes to improved energy efficiency and reduced environmental impact in urban transportation.

One of the primary environmental benefits of KERS in electric bus transit systems is the reduction in overall energy consumption. As buses frequently stop and start in urban environments, the energy recovered during braking can be substantial. This recovered energy is then used to assist in acceleration, reducing the demand on the main power source. Consequently, this leads to a decrease in electricity consumption from the grid, which in turn reduces the indirect emissions associated with power generation.

The implementation of KERS also contributes to the reduction of particulate matter emissions in urban areas. Traditional braking systems release brake dust and other particulates into the air, contributing to urban air pollution. By reducing the reliance on friction brakes, KERS helps mitigate this source of pollution, leading to improved air quality in cities.

Furthermore, the use of KERS in electric buses can extend the overall lifespan of the vehicle's battery system. By reducing the strain on the main battery during acceleration phases, KERS helps to slow down battery degradation. This has positive environmental implications as it reduces the frequency of battery replacements, thereby decreasing the environmental impact associated with battery production and disposal.

The noise reduction aspect of KERS is another environmental benefit worth noting. Electric buses equipped with KERS tend to operate more quietly during acceleration phases, as the energy recovery system provides a smoother power delivery compared to traditional propulsion methods. This contributes to a reduction in noise pollution in urban areas, improving the quality of life for city residents.

However, it is important to consider the full lifecycle environmental impact of KERS implementation. The production of KERS components, such as high-capacity capacitors or flywheels, involves resource extraction and manufacturing processes that have their own environmental footprint. A comprehensive environmental assessment should take into account these factors to provide a balanced view of the overall impact.

In conclusion, while the implementation of KERS in electric bus transit systems offers significant environmental benefits in terms of energy efficiency, emissions reduction, and noise pollution mitigation, a holistic approach is necessary to fully understand its environmental impact. As urban areas continue to prioritize sustainable transportation solutions, the role of KERS in improving the environmental performance of public transit systems is likely to grow in importance.

One of the primary environmental benefits of KERS in electric bus transit systems is the reduction in overall energy consumption. As buses frequently stop and start in urban environments, the energy recovered during braking can be substantial. This recovered energy is then used to assist in acceleration, reducing the demand on the main power source. Consequently, this leads to a decrease in electricity consumption from the grid, which in turn reduces the indirect emissions associated with power generation.

The implementation of KERS also contributes to the reduction of particulate matter emissions in urban areas. Traditional braking systems release brake dust and other particulates into the air, contributing to urban air pollution. By reducing the reliance on friction brakes, KERS helps mitigate this source of pollution, leading to improved air quality in cities.

Furthermore, the use of KERS in electric buses can extend the overall lifespan of the vehicle's battery system. By reducing the strain on the main battery during acceleration phases, KERS helps to slow down battery degradation. This has positive environmental implications as it reduces the frequency of battery replacements, thereby decreasing the environmental impact associated with battery production and disposal.

The noise reduction aspect of KERS is another environmental benefit worth noting. Electric buses equipped with KERS tend to operate more quietly during acceleration phases, as the energy recovery system provides a smoother power delivery compared to traditional propulsion methods. This contributes to a reduction in noise pollution in urban areas, improving the quality of life for city residents.

However, it is important to consider the full lifecycle environmental impact of KERS implementation. The production of KERS components, such as high-capacity capacitors or flywheels, involves resource extraction and manufacturing processes that have their own environmental footprint. A comprehensive environmental assessment should take into account these factors to provide a balanced view of the overall impact.

In conclusion, while the implementation of KERS in electric bus transit systems offers significant environmental benefits in terms of energy efficiency, emissions reduction, and noise pollution mitigation, a holistic approach is necessary to fully understand its environmental impact. As urban areas continue to prioritize sustainable transportation solutions, the role of KERS in improving the environmental performance of public transit systems is likely to grow in importance.

Cost-Benefit Analysis of KERS Implementation

The implementation of Kinetic Energy Recovery Systems (KERS) in electric bus transit systems requires a comprehensive cost-benefit analysis to determine its economic viability and potential efficiency gains. This analysis must consider both the initial investment costs and the long-term operational benefits.

The primary costs associated with KERS implementation include the purchase and installation of the system components, such as the energy storage device, power electronics, and control systems. These upfront costs can be substantial, often ranging from $20,000 to $50,000 per bus, depending on the system's complexity and capacity. Additionally, there are costs related to staff training, maintenance, and potential vehicle downtime during installation.

On the benefit side, KERS offers significant potential for energy savings and reduced operational costs. Studies have shown that KERS can recover up to 25-30% of the energy typically lost during braking, translating to a 10-15% reduction in overall energy consumption. This energy recovery leads to extended battery life and increased range for electric buses, potentially reducing the need for frequent charging stops and improving route efficiency.

The financial benefits of KERS implementation can be substantial over time. Reduced energy consumption directly correlates to lower electricity costs, which can amount to savings of $3,000 to $5,000 per bus annually, depending on local electricity rates and route characteristics. Moreover, the extended battery life can delay the need for battery replacement, saving an additional $20,000 to $30,000 per bus over its operational lifespan.

Improved operational efficiency is another key benefit. KERS-equipped buses can maintain more consistent speeds and acceleration profiles, leading to smoother rides and potentially reducing wear on other vehicle components. This can result in lower maintenance costs and increased vehicle uptime, further enhancing the system's cost-effectiveness.

Environmental benefits, while not directly financial, should also be considered in the analysis. The reduced energy consumption leads to lower greenhouse gas emissions, aligning with sustainability goals and potentially qualifying transit agencies for environmental incentives or grants.

The payback period for KERS implementation typically ranges from 3 to 5 years, depending on factors such as route characteristics, energy prices, and system efficiency. Transit agencies must consider their specific operational context, including route topography, stop frequency, and climate conditions, to accurately assess the potential benefits and determine the most suitable KERS configuration.

In conclusion, while the initial investment in KERS technology is significant, the long-term benefits in terms of energy savings, operational efficiency, and environmental impact make it a compelling option for many electric bus transit systems. A detailed, context-specific analysis is crucial for transit agencies to make informed decisions about KERS implementation and maximize its potential benefits.

The primary costs associated with KERS implementation include the purchase and installation of the system components, such as the energy storage device, power electronics, and control systems. These upfront costs can be substantial, often ranging from $20,000 to $50,000 per bus, depending on the system's complexity and capacity. Additionally, there are costs related to staff training, maintenance, and potential vehicle downtime during installation.

On the benefit side, KERS offers significant potential for energy savings and reduced operational costs. Studies have shown that KERS can recover up to 25-30% of the energy typically lost during braking, translating to a 10-15% reduction in overall energy consumption. This energy recovery leads to extended battery life and increased range for electric buses, potentially reducing the need for frequent charging stops and improving route efficiency.

The financial benefits of KERS implementation can be substantial over time. Reduced energy consumption directly correlates to lower electricity costs, which can amount to savings of $3,000 to $5,000 per bus annually, depending on local electricity rates and route characteristics. Moreover, the extended battery life can delay the need for battery replacement, saving an additional $20,000 to $30,000 per bus over its operational lifespan.

Improved operational efficiency is another key benefit. KERS-equipped buses can maintain more consistent speeds and acceleration profiles, leading to smoother rides and potentially reducing wear on other vehicle components. This can result in lower maintenance costs and increased vehicle uptime, further enhancing the system's cost-effectiveness.

Environmental benefits, while not directly financial, should also be considered in the analysis. The reduced energy consumption leads to lower greenhouse gas emissions, aligning with sustainability goals and potentially qualifying transit agencies for environmental incentives or grants.

The payback period for KERS implementation typically ranges from 3 to 5 years, depending on factors such as route characteristics, energy prices, and system efficiency. Transit agencies must consider their specific operational context, including route topography, stop frequency, and climate conditions, to accurately assess the potential benefits and determine the most suitable KERS configuration.

In conclusion, while the initial investment in KERS technology is significant, the long-term benefits in terms of energy savings, operational efficiency, and environmental impact make it a compelling option for many electric bus transit systems. A detailed, context-specific analysis is crucial for transit agencies to make informed decisions about KERS implementation and maximize its potential benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!