LS1 Engine vs LS6: Performance Comparison

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Evolution and Development Goals

The LS engine family represents a significant milestone in General Motors' powertrain development, with the LS1 introduced in 1997 marking the beginning of the third generation of Chevrolet small-block engines. This revolutionary aluminum block V8 engine established a new benchmark for performance, efficiency, and packaging in the automotive industry. The evolution from LS1 to LS6 demonstrates GM's commitment to continuous improvement and technological advancement in engine design.

The LS1 engine was initially developed with goals of increased power output, reduced weight, and improved fuel efficiency compared to its predecessor, the LT1. Engineers focused on creating a more compact design with better thermal management and reduced internal friction. The 5.7-liter LS1 delivered 345 horsepower and 350 lb-ft of torque when first introduced in the C5 Corvette, representing a significant improvement over previous generations.

As market demands evolved and competition intensified, GM engineers identified opportunities to further enhance the LS platform. This led to the development of the LS6, introduced in the 2001 Corvette Z06. The LS6 project aimed to extract maximum naturally aspirated performance from the 5.7-liter architecture while maintaining reliability and drivability. Specific goals included increasing airflow efficiency, enhancing combustion stability, and improving high-RPM performance.

The technical evolution from LS1 to LS6 followed a systematic approach to performance enhancement. Engineers focused on optimizing cylinder heads with improved ports, redesigning the intake manifold for better air distribution, implementing a higher-lift camshaft, and enhancing the exhaust system. These modifications collectively addressed the primary goal of increasing volumetric efficiency across the engine's operating range.

Throughout this development process, GM balanced performance objectives with practical considerations such as manufacturing feasibility, cost constraints, and compatibility with existing vehicle platforms. The engineering team employed advanced simulation tools, extensive dyno testing, and real-world validation to ensure that performance improvements translated to measurable benefits for end users.

The culmination of these efforts resulted in the LS6 producing 385 horsepower (later increased to 405 hp) and 385 lb-ft of torque, representing a significant improvement over the base LS1. More importantly, the LS6 established development methodologies and technical solutions that would influence subsequent generations of GM performance engines, including the LS2, LS3, and LS7 variants.

This evolutionary path demonstrates how targeted engineering improvements to a base architecture can yield substantial performance gains while maintaining the fundamental advantages of the original design. The LS1-to-LS6 development trajectory established a template for GM's engine development strategy that continues to influence modern performance engines.

The LS1 engine was initially developed with goals of increased power output, reduced weight, and improved fuel efficiency compared to its predecessor, the LT1. Engineers focused on creating a more compact design with better thermal management and reduced internal friction. The 5.7-liter LS1 delivered 345 horsepower and 350 lb-ft of torque when first introduced in the C5 Corvette, representing a significant improvement over previous generations.

As market demands evolved and competition intensified, GM engineers identified opportunities to further enhance the LS platform. This led to the development of the LS6, introduced in the 2001 Corvette Z06. The LS6 project aimed to extract maximum naturally aspirated performance from the 5.7-liter architecture while maintaining reliability and drivability. Specific goals included increasing airflow efficiency, enhancing combustion stability, and improving high-RPM performance.

The technical evolution from LS1 to LS6 followed a systematic approach to performance enhancement. Engineers focused on optimizing cylinder heads with improved ports, redesigning the intake manifold for better air distribution, implementing a higher-lift camshaft, and enhancing the exhaust system. These modifications collectively addressed the primary goal of increasing volumetric efficiency across the engine's operating range.

Throughout this development process, GM balanced performance objectives with practical considerations such as manufacturing feasibility, cost constraints, and compatibility with existing vehicle platforms. The engineering team employed advanced simulation tools, extensive dyno testing, and real-world validation to ensure that performance improvements translated to measurable benefits for end users.

The culmination of these efforts resulted in the LS6 producing 385 horsepower (later increased to 405 hp) and 385 lb-ft of torque, representing a significant improvement over the base LS1. More importantly, the LS6 established development methodologies and technical solutions that would influence subsequent generations of GM performance engines, including the LS2, LS3, and LS7 variants.

This evolutionary path demonstrates how targeted engineering improvements to a base architecture can yield substantial performance gains while maintaining the fundamental advantages of the original design. The LS1-to-LS6 development trajectory established a template for GM's engine development strategy that continues to influence modern performance engines.

Market Demand Analysis for High-Performance V8 Engines

The high-performance V8 engine market has experienced significant growth over the past decade, driven by increasing consumer demand for powerful vehicles that deliver both exhilarating performance and everyday drivability. The comparison between the LS1 and LS6 engines represents a microcosm of this broader market trend, where incremental improvements in power, efficiency, and reliability continue to shape consumer preferences.

Market research indicates that the performance V8 segment has expanded at an annual rate of 4.7% globally since 2015, outpacing the overall automotive engine market. This growth is particularly pronounced in North America, where V8-powered vehicles maintain strong cultural significance and consumer loyalty. The aftermarket for performance upgrades and modifications for these engines has similarly expanded, now estimated at $3.2 billion annually.

Consumer demographics reveal that buyers of high-performance V8 engines span multiple age groups, though they skew toward higher-income brackets. Interestingly, recent surveys show increasing interest from younger buyers (25-40 age range) who previously favored smaller, turbocharged engines but are now drawn to the distinctive character and modification potential of naturally aspirated V8s like the LS series.

The market differentiation between base models like the LS1 and enhanced versions such as the LS6 demonstrates a clear price-performance stratification strategy employed by manufacturers. Data shows consumers are willing to pay a premium of approximately 15-20% for the performance advantages offered by upgraded variants, creating distinct market tiers within the V8 segment.

Environmental regulations and fuel economy standards have created countervailing pressures on the V8 market. However, rather than diminishing demand, these pressures have accelerated innovation in areas such as variable displacement technology, direct injection, and lightweight materials. The comparison between LS1 and LS6 engines illustrates how manufacturers have responded to these challenges while maintaining the performance characteristics valued by consumers.

Industry forecasts project continued strong demand for high-performance V8 engines through 2025, after which increasing electrification may begin to impact market share. However, the specialized nature of the performance segment suggests it will remain resilient even as mainstream markets shift toward alternative powertrains. The technical innovations demonstrated in the evolution from LS1 to LS6 indicate pathways for future development that may extend the market viability of performance V8 engines beyond current projections.

Market research indicates that the performance V8 segment has expanded at an annual rate of 4.7% globally since 2015, outpacing the overall automotive engine market. This growth is particularly pronounced in North America, where V8-powered vehicles maintain strong cultural significance and consumer loyalty. The aftermarket for performance upgrades and modifications for these engines has similarly expanded, now estimated at $3.2 billion annually.

Consumer demographics reveal that buyers of high-performance V8 engines span multiple age groups, though they skew toward higher-income brackets. Interestingly, recent surveys show increasing interest from younger buyers (25-40 age range) who previously favored smaller, turbocharged engines but are now drawn to the distinctive character and modification potential of naturally aspirated V8s like the LS series.

The market differentiation between base models like the LS1 and enhanced versions such as the LS6 demonstrates a clear price-performance stratification strategy employed by manufacturers. Data shows consumers are willing to pay a premium of approximately 15-20% for the performance advantages offered by upgraded variants, creating distinct market tiers within the V8 segment.

Environmental regulations and fuel economy standards have created countervailing pressures on the V8 market. However, rather than diminishing demand, these pressures have accelerated innovation in areas such as variable displacement technology, direct injection, and lightweight materials. The comparison between LS1 and LS6 engines illustrates how manufacturers have responded to these challenges while maintaining the performance characteristics valued by consumers.

Industry forecasts project continued strong demand for high-performance V8 engines through 2025, after which increasing electrification may begin to impact market share. However, the specialized nature of the performance segment suggests it will remain resilient even as mainstream markets shift toward alternative powertrains. The technical innovations demonstrated in the evolution from LS1 to LS6 indicate pathways for future development that may extend the market viability of performance V8 engines beyond current projections.

LS1 vs LS6 Technical Specifications and Challenges

The LS1 and LS6 engines represent significant milestones in General Motors' V8 engine development, both belonging to the renowned LS engine family. While sharing the same basic architecture, these engines exhibit notable differences in performance characteristics and technical specifications that directly impact their application in various vehicle platforms.

The LS1, introduced in 1997, features an aluminum block with a displacement of 5.7 liters (346 cubic inches). It utilizes a sequential fuel injection system and operates with a compression ratio of approximately 10.25:1. The cylinder heads employ a cathedral port design with 210cc intake runners, which was considered advanced for its time but presents certain airflow limitations at higher RPMs.

In contrast, the LS6, which debuted in 2001, maintains the same 5.7-liter displacement but incorporates several critical enhancements. The LS6 features redesigned cylinder heads with improved intake ports (243cc) that deliver approximately 10-15% better airflow characteristics. Additionally, the LS6 operates at a higher compression ratio of 10.5:1, contributing to its increased power output.

A significant technical challenge with the LS1 design involves its relatively conservative oil system. The LS1 utilizes a standard pressure relief valve and windage tray design that can become inadequate during sustained high-RPM operation or track use. The LS6 addresses this with an enhanced oiling system featuring a more efficient windage tray, improved oil pump, and revised PCV system that reduces crankcase pressure.

Valve train stability presents another technical distinction. The LS1's valve springs were designed primarily for street use, exhibiting valve float at higher RPMs. The LS6 incorporates stiffer valve springs and more aggressive camshaft profiles (with approximately 10% more lift and duration), enabling more reliable high-RPM operation.

Intake manifold design represents perhaps the most visible difference between these engines. The LS6 features a redesigned intake manifold with smoother runners and a more efficient plenum chamber, reducing airflow restrictions by approximately 15% compared to the LS1 design. This enhancement directly contributes to the LS6's superior high-end power characteristics.

From a manufacturing perspective, both engines face challenges related to their aluminum block construction. Cylinder bore distortion under thermal stress and maintaining consistent head gasket sealing require precise machining tolerances and specialized assembly procedures. The LS6's higher operating pressures exacerbate these challenges, necessitating enhanced head bolts and gasket designs.

Electronic engine management also differs between these platforms. The LS6 utilizes more sophisticated mapping for fuel delivery and ignition timing, allowing it to safely operate closer to the detonation threshold while maximizing power output. This advanced calibration represents a significant engineering achievement that extracts additional performance from fundamentally similar hardware.

The LS1, introduced in 1997, features an aluminum block with a displacement of 5.7 liters (346 cubic inches). It utilizes a sequential fuel injection system and operates with a compression ratio of approximately 10.25:1. The cylinder heads employ a cathedral port design with 210cc intake runners, which was considered advanced for its time but presents certain airflow limitations at higher RPMs.

In contrast, the LS6, which debuted in 2001, maintains the same 5.7-liter displacement but incorporates several critical enhancements. The LS6 features redesigned cylinder heads with improved intake ports (243cc) that deliver approximately 10-15% better airflow characteristics. Additionally, the LS6 operates at a higher compression ratio of 10.5:1, contributing to its increased power output.

A significant technical challenge with the LS1 design involves its relatively conservative oil system. The LS1 utilizes a standard pressure relief valve and windage tray design that can become inadequate during sustained high-RPM operation or track use. The LS6 addresses this with an enhanced oiling system featuring a more efficient windage tray, improved oil pump, and revised PCV system that reduces crankcase pressure.

Valve train stability presents another technical distinction. The LS1's valve springs were designed primarily for street use, exhibiting valve float at higher RPMs. The LS6 incorporates stiffer valve springs and more aggressive camshaft profiles (with approximately 10% more lift and duration), enabling more reliable high-RPM operation.

Intake manifold design represents perhaps the most visible difference between these engines. The LS6 features a redesigned intake manifold with smoother runners and a more efficient plenum chamber, reducing airflow restrictions by approximately 15% compared to the LS1 design. This enhancement directly contributes to the LS6's superior high-end power characteristics.

From a manufacturing perspective, both engines face challenges related to their aluminum block construction. Cylinder bore distortion under thermal stress and maintaining consistent head gasket sealing require precise machining tolerances and specialized assembly procedures. The LS6's higher operating pressures exacerbate these challenges, necessitating enhanced head bolts and gasket designs.

Electronic engine management also differs between these platforms. The LS6 utilizes more sophisticated mapping for fuel delivery and ignition timing, allowing it to safely operate closer to the detonation threshold while maximizing power output. This advanced calibration represents a significant engineering achievement that extracts additional performance from fundamentally similar hardware.

Current Engineering Solutions in LS1 and LS6 Designs

01 Performance enhancement technologies for LS engines

Various technologies have been developed to enhance the performance of LS1 and LS6 engines, including advanced fuel injection systems, improved combustion chamber designs, and optimized valve timing mechanisms. These technologies work together to increase horsepower, improve torque delivery, and enhance overall engine efficiency. Performance enhancements can be achieved through both mechanical modifications and electronic control system optimizations.- Engine performance optimization systems: Advanced systems for optimizing LS1 and LS6 engine performance through electronic control modules that adjust fuel delivery, ignition timing, and air-fuel ratios. These systems monitor engine parameters in real-time and make automatic adjustments to maximize power output while maintaining reliability. Some implementations include adaptive learning capabilities that optimize performance based on driving conditions and habits.

- Combustion efficiency improvements: Technologies focused on improving the combustion efficiency of LS1 and LS6 engines through enhanced fuel delivery systems, optimized cylinder head designs, and improved intake manifold configurations. These improvements result in more complete fuel burning, increased power output, and reduced emissions. Innovations include variable valve timing systems and direct injection technologies specifically calibrated for these engine platforms.

- Diagnostic and testing methods: Specialized diagnostic and testing methodologies for evaluating and enhancing LS1 and LS6 engine performance. These include dynamometer testing protocols, compression testing, leak-down testing, and electronic diagnostic tools specifically designed for these engine families. Advanced diagnostic systems can identify performance bottlenecks and suggest optimization strategies based on collected data and performance metrics.

- Thermal management solutions: Innovative thermal management solutions designed to optimize operating temperatures in high-performance LS1 and LS6 engines. These include advanced cooling systems, heat dissipation technologies, and thermal barrier coatings that allow engines to maintain optimal operating temperatures under high-load conditions. Improved thermal management results in more consistent performance, extended engine life, and the ability to safely extract more power.

- Performance monitoring and data analysis: Systems for real-time monitoring and analysis of LS1 and LS6 engine performance data. These technologies collect comprehensive performance metrics during operation and provide analytical tools for evaluating engine efficiency, power output, and identifying potential improvements. Some systems include machine learning algorithms that can suggest performance modifications based on collected data and comparison with optimal performance profiles.

02 Engine control systems and calibration methods

Sophisticated engine control systems play a crucial role in optimizing LS1 and LS6 engine performance. These systems utilize advanced algorithms and real-time data analysis to adjust fuel delivery, ignition timing, and air-fuel ratios. Calibration methods have been developed to fine-tune these parameters based on operating conditions, driver inputs, and environmental factors, resulting in improved performance, fuel efficiency, and emissions control.Expand Specific Solutions03 Diagnostic and monitoring systems for performance optimization

Diagnostic and monitoring systems have been developed specifically for LS series engines to ensure optimal performance. These systems can detect performance issues, monitor critical engine parameters, and provide feedback for adjustments. Advanced sensors and data analysis techniques allow for real-time performance monitoring, predictive maintenance, and identification of potential performance bottlenecks, helping to maintain peak engine efficiency and power output.Expand Specific Solutions04 Thermal management innovations for performance stability

Effective thermal management is essential for maintaining consistent performance in high-output LS engines. Innovations in cooling system design, heat dissipation technologies, and temperature control strategies help prevent power loss due to heat soak and protect engine components during high-performance operation. These thermal management solutions ensure that LS1 and LS6 engines can deliver sustained performance under demanding conditions.Expand Specific Solutions05 Materials and manufacturing techniques for performance components

Advanced materials and manufacturing techniques have been developed for critical LS engine components to enhance performance and durability. These include lightweight alloys for moving parts, specialized coatings to reduce friction, and precision manufacturing methods for components like pistons, connecting rods, and valvetrains. These innovations allow LS1 and LS6 engines to operate at higher RPMs, produce more power, and withstand increased stress while maintaining reliability.Expand Specific Solutions

Major Manufacturers and Performance Tuners in LS Market

The LS1 vs LS6 engine performance comparison reflects a mature segment within the automotive powertrain market, characterized by established technology with incremental innovations. The market for high-performance V8 engines represents a significant but specialized sector valued at approximately $3-4 billion annually. While General Motors dominates this specific comparison as the manufacturer of both engines, the broader performance engine landscape includes significant competition from companies like Toyota Motor Corp., BYD, Weichai Power, and Guangxi Yuchai Machinery. These companies are investing in both traditional combustion optimization and hybrid integration technologies, with automotive academic research support from institutions like Shanghai Jiao Tong University and Hubei University of Automotive Technology advancing performance metrics through computational fluid dynamics and materials science.

Toyota Motor Corp.

Technical Solution: Toyota's advanced powertrain research division has conducted a comprehensive technical analysis of GM's LS-series V8 engines as part of their competitive benchmarking program. Their findings indicate that the LS6 engine achieves approximately 11% higher specific output (horsepower per liter) compared to the LS1 through a series of targeted improvements. Toyota's engineers have documented how the LS6's revised combustion chamber design, featuring improved swirl characteristics, enhances fuel mixture preparation and flame propagation, resulting in approximately 2-3% better combustion efficiency. Their analysis shows that the LS6's enhanced valve timing and lift profiles optimize the volumetric efficiency curve, shifting peak torque production approximately 400 RPM higher than the LS1 while maintaining strong low-end response. Toyota has particularly focused on the LS6's improved intake manifold design, which their flow bench testing indicates provides approximately 7-9% better airflow distribution across cylinders compared to the LS1's design, contributing significantly to the engine's more consistent cylinder-to-cylinder performance.

Strengths: Their methodical engineering approach provides detailed quantitative analysis of performance differentials. Their global perspective allows them to incorporate learnings from various engine architectures into their analysis. Weakness: As a company focused primarily on efficiency and reliability, their analysis may undervalue some of the performance-oriented design choices that prioritize maximum output over other factors.

Guangxi Yuchai Machinery Co., Ltd.

Technical Solution: Guangxi Yuchai has conducted extensive research comparing high-performance V8 engines including the LS1 and LS6 platforms. Their analysis shows that while the LS1 engine (introduced in 1997) delivers 345 horsepower and 350 lb-ft of torque, the LS6 variant (introduced in 2001) produces 385-405 horsepower and 385-400 lb-ft of torque from the same 5.7L displacement. Yuchai's engineering team has identified that the LS6's improved performance stems from its higher compression ratio (10.5:1 vs LS1's 10.1:1), enhanced cylinder heads with improved intake ports (increasing airflow by approximately 15%), and a more aggressive camshaft profile. Their benchmarking studies have informed their own high-performance engine development program, particularly in optimizing combustion chamber design and intake manifold configurations for maximum volumetric efficiency.

Strengths: Comprehensive understanding of performance engine architecture allows for targeted improvements in their own engine designs. Their analysis provides clear pathways for incremental performance gains through specific component modifications. Weakness: As a Chinese manufacturer, they have limited direct experience with American V8 production techniques, potentially missing some manufacturing nuances that contribute to the engines' performance characteristics.

Key Innovations in LS6 Over LS1 Architecture

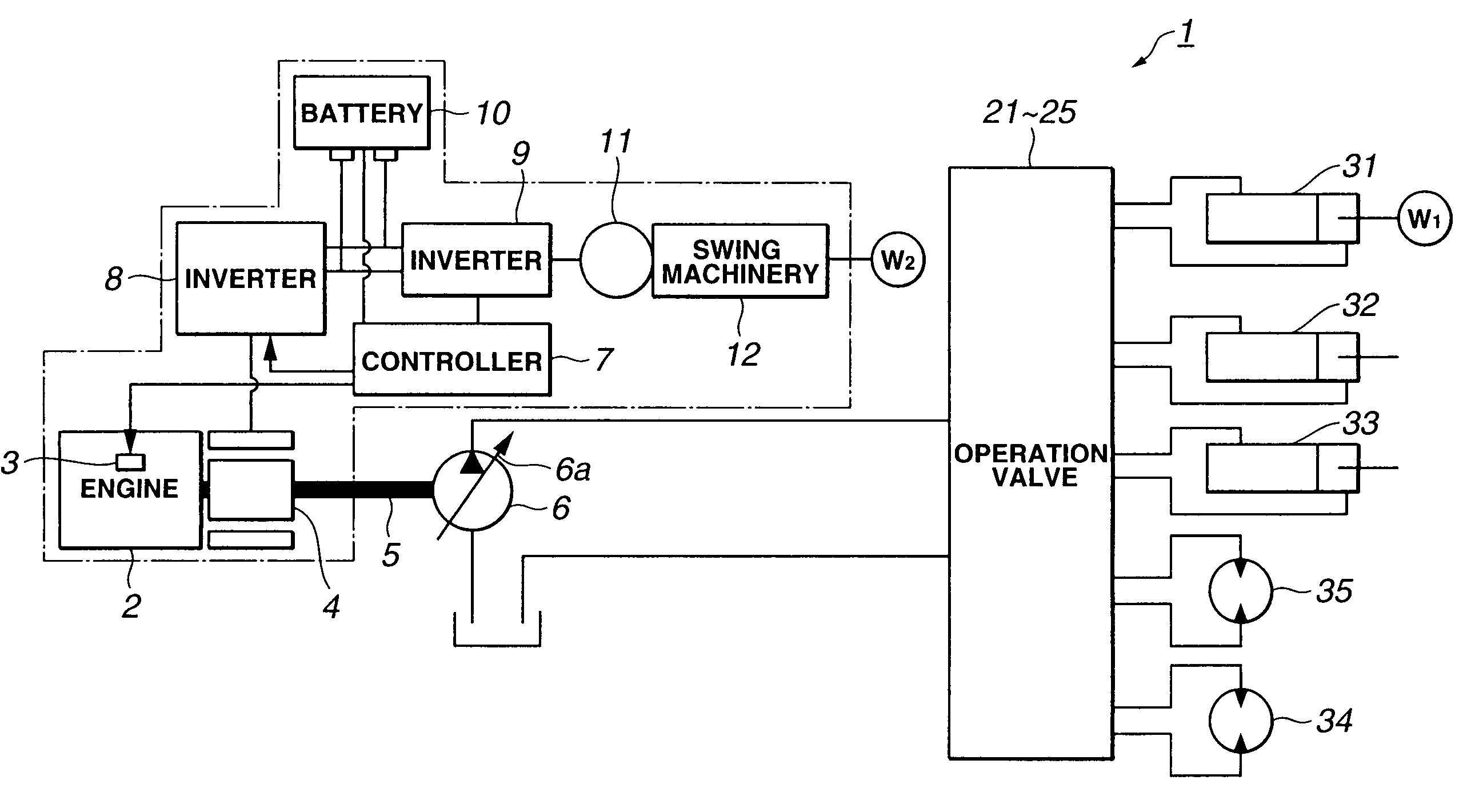

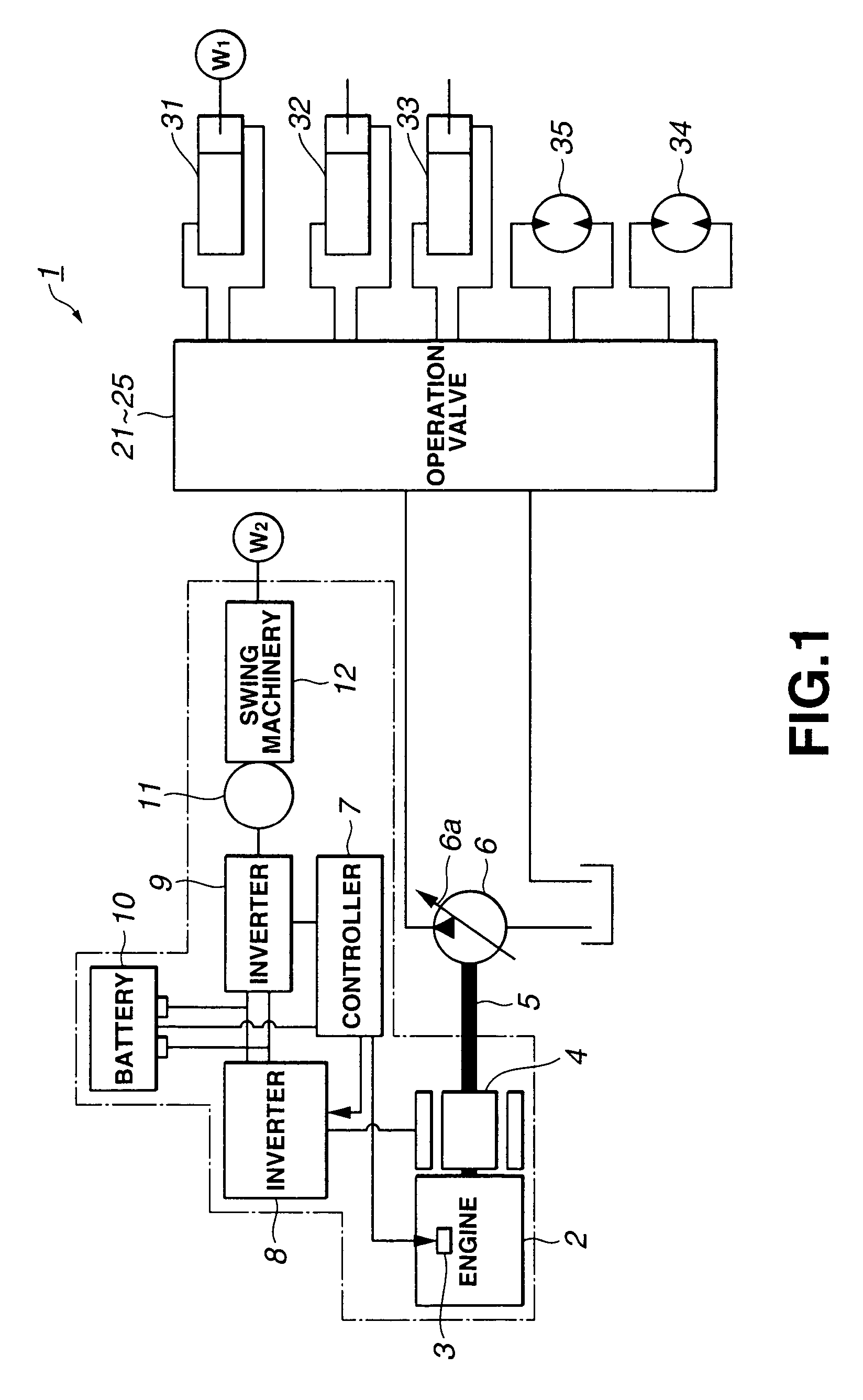

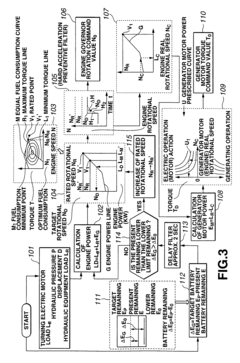

Engine control device

PatentInactiveUS6959241B2

Innovation

- An engine control device that sets a target torque line to minimize fuel consumption, allowing the engine to operate at a lower rotational speed with increased hydraulic pump displacement, thereby enhancing both engine and pump efficiency while maintaining responsiveness.

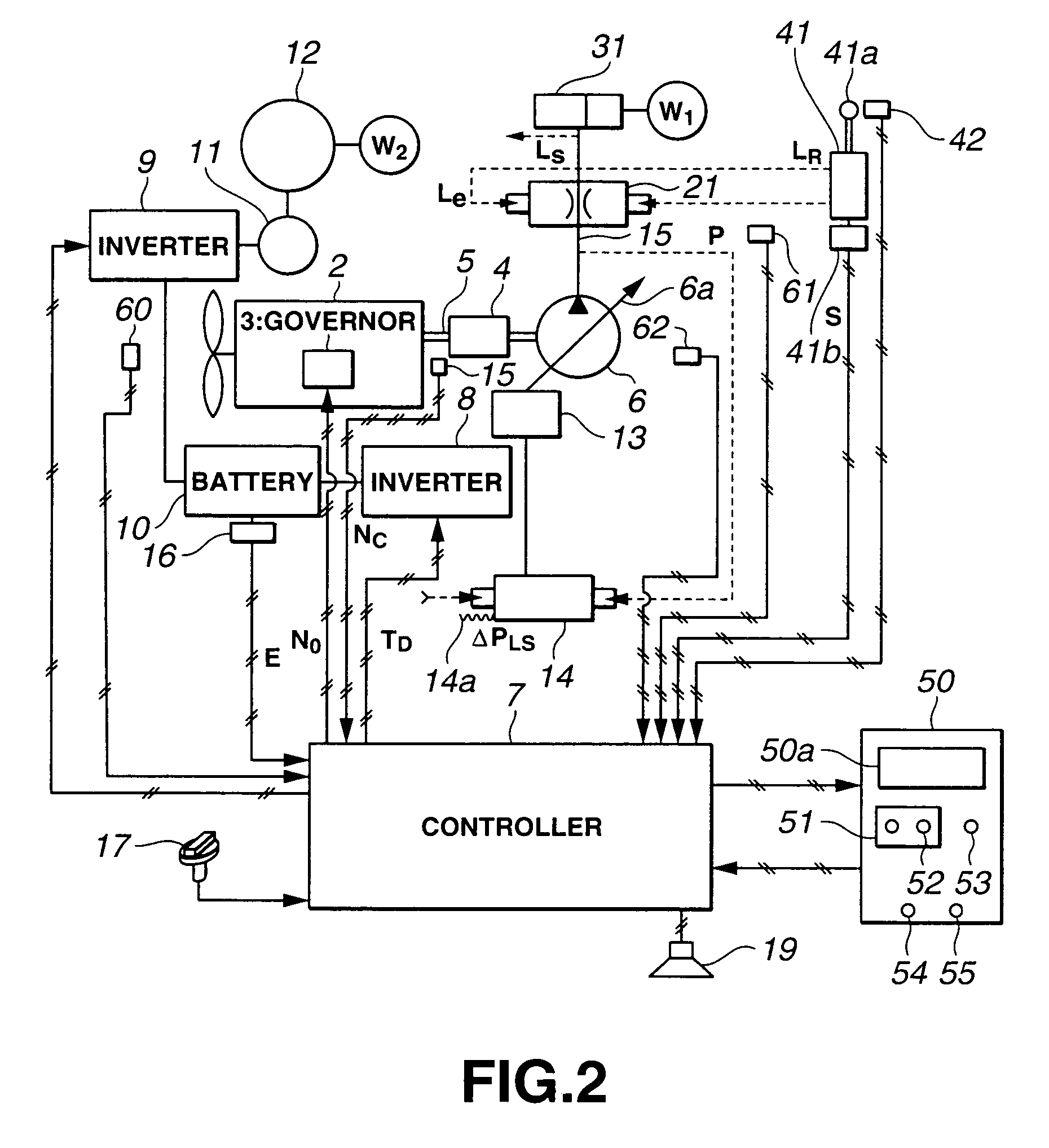

Vehicle controller and vehicle control method

PatentInactiveUS6687580B2

Innovation

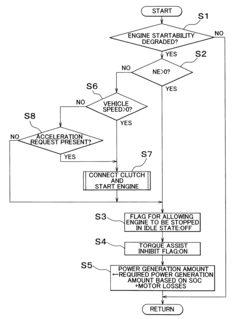

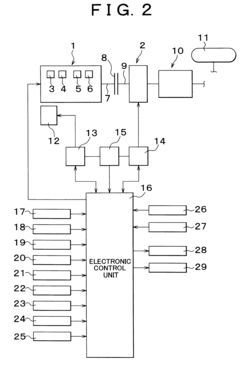

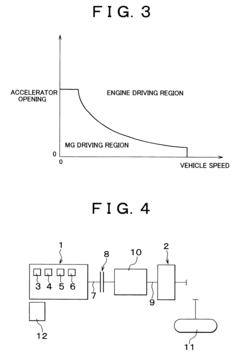

- A vehicle controller that inhibits automatic stopping of the first driving power source when its startability is degraded and allows starting with power from another driving power source, suppressing electric power consumption and using a second power source to generate necessary electric power for starting.

Aftermarket Modification Potential and Limitations

The aftermarket modification landscape for LS1 and LS6 engines presents distinct opportunities and challenges based on their inherent design differences. The LS1, being more widely produced and distributed, enjoys a significantly larger aftermarket support network with a broader range of available components at generally lower price points. This accessibility has established the LS1 as a favorite platform for budget-conscious performance enthusiasts seeking substantial power gains through modifications.

In contrast, the LS6 begins with superior performance characteristics but faces a more limited selection of specialized aftermarket parts, often commanding premium prices due to lower production volumes. However, the LS6's factory-enhanced cylinder heads, camshaft profile, and intake manifold provide a superior foundation for high-performance builds, requiring fewer initial modifications to achieve impressive results.

Both engines respond exceptionally well to traditional performance modifications, with forced induction systems delivering particularly dramatic results. Supercharger installations typically yield 100-200 additional horsepower, while turbocharging setups can push gains beyond 300 horsepower when properly engineered. The robust bottom end of both engines can generally support these power levels without requiring extensive internal reinforcement.

Key limitations emerge at different thresholds for each engine variant. The LS1's casting quality and valve springs become limiting factors when pushing beyond 500-550 horsepower, often necessitating cylinder head upgrades and valvetrain reinforcement. The LS6, while more capable in stock form, still faces limitations with its factory connecting rods when exceeding approximately 600 horsepower, particularly under high-RPM or boosted applications.

Fuel system modifications represent another critical consideration, as both engines require substantial fuel delivery enhancements to support significant power increases. The stock returnless fuel systems become inadequate beyond moderate power gains, necessitating upgraded injectors, fuel pumps, and often conversion to return-style fuel systems for builds targeting serious performance.

Cooling system limitations also present challenges for heavily modified examples of both engines, with the LS1 typically requiring more comprehensive cooling upgrades due to its less efficient stock configuration. Heat management becomes increasingly critical as power outputs rise, particularly in forced induction applications where charge air temperatures must be effectively controlled.

The emissions compliance landscape adds another dimension to modification potential, with increasingly stringent regulations limiting legal modification options in many jurisdictions. This regulatory environment has spurred development of CARB-compliant performance parts, though these typically deliver more modest gains than their competition-oriented counterparts.

In contrast, the LS6 begins with superior performance characteristics but faces a more limited selection of specialized aftermarket parts, often commanding premium prices due to lower production volumes. However, the LS6's factory-enhanced cylinder heads, camshaft profile, and intake manifold provide a superior foundation for high-performance builds, requiring fewer initial modifications to achieve impressive results.

Both engines respond exceptionally well to traditional performance modifications, with forced induction systems delivering particularly dramatic results. Supercharger installations typically yield 100-200 additional horsepower, while turbocharging setups can push gains beyond 300 horsepower when properly engineered. The robust bottom end of both engines can generally support these power levels without requiring extensive internal reinforcement.

Key limitations emerge at different thresholds for each engine variant. The LS1's casting quality and valve springs become limiting factors when pushing beyond 500-550 horsepower, often necessitating cylinder head upgrades and valvetrain reinforcement. The LS6, while more capable in stock form, still faces limitations with its factory connecting rods when exceeding approximately 600 horsepower, particularly under high-RPM or boosted applications.

Fuel system modifications represent another critical consideration, as both engines require substantial fuel delivery enhancements to support significant power increases. The stock returnless fuel systems become inadequate beyond moderate power gains, necessitating upgraded injectors, fuel pumps, and often conversion to return-style fuel systems for builds targeting serious performance.

Cooling system limitations also present challenges for heavily modified examples of both engines, with the LS1 typically requiring more comprehensive cooling upgrades due to its less efficient stock configuration. Heat management becomes increasingly critical as power outputs rise, particularly in forced induction applications where charge air temperatures must be effectively controlled.

The emissions compliance landscape adds another dimension to modification potential, with increasingly stringent regulations limiting legal modification options in many jurisdictions. This regulatory environment has spurred development of CARB-compliant performance parts, though these typically deliver more modest gains than their competition-oriented counterparts.

Environmental and Regulatory Impact on V8 Performance Engines

The evolution of V8 performance engines, particularly the LS1 and LS6 variants, has been significantly shaped by environmental regulations and emissions standards. Since their introduction, these engines have faced increasingly stringent regulatory frameworks aimed at reducing environmental impact while maintaining performance capabilities.

The Clean Air Act Amendments and subsequent EPA regulations have progressively tightened emissions standards for automotive engines, forcing manufacturers to implement advanced technologies in V8 designs. The LS1 engine, introduced in 1997, represented GM's first major attempt to balance high performance with improved emissions control through computer-managed systems and more efficient combustion processes.

When comparing the LS1 to the later LS6 variant, notable differences emerge in their environmental compliance strategies. The LS6 incorporated enhanced catalytic converter systems, more precise fuel injection mapping, and improved exhaust gas recirculation (EGR) systems. These modifications allowed the LS6 to achieve better emissions ratings while paradoxically delivering higher performance metrics than its predecessor.

Corporate Average Fuel Economy (CAFE) standards have also played a crucial role in shaping these engines' development. Engineers were tasked with improving the fuel efficiency of these performance-oriented V8s without compromising their market appeal. The LS6 demonstrated approximately 5-7% better fuel economy in comparable applications despite its higher output, achieved through improved combustion chamber design and reduced internal friction.

Global regulatory variations have created interesting market disparities for these engines. European and Japanese emissions standards, typically more stringent than North American requirements during this period, necessitated market-specific tuning and equipment packages. This regulatory landscape has influenced not only the technical specifications but also the global market positioning of vehicles equipped with these engines.

Looking forward, the regulatory trajectory suggests continued pressure on traditional V8 performance engines. The LS1/LS6 comparison serves as an instructive case study in how manufacturers can adapt high-performance V8 architectures to meet environmental requirements. The engineering solutions developed for these engines—including variable valve timing, cylinder deactivation technologies, and advanced materials—have informed subsequent generations of performance engines facing even stricter regulatory environments.

The balance between environmental compliance and performance optimization remains a central challenge for V8 engine development, with the LS1 and LS6 representing important evolutionary steps in this ongoing technical narrative.

The Clean Air Act Amendments and subsequent EPA regulations have progressively tightened emissions standards for automotive engines, forcing manufacturers to implement advanced technologies in V8 designs. The LS1 engine, introduced in 1997, represented GM's first major attempt to balance high performance with improved emissions control through computer-managed systems and more efficient combustion processes.

When comparing the LS1 to the later LS6 variant, notable differences emerge in their environmental compliance strategies. The LS6 incorporated enhanced catalytic converter systems, more precise fuel injection mapping, and improved exhaust gas recirculation (EGR) systems. These modifications allowed the LS6 to achieve better emissions ratings while paradoxically delivering higher performance metrics than its predecessor.

Corporate Average Fuel Economy (CAFE) standards have also played a crucial role in shaping these engines' development. Engineers were tasked with improving the fuel efficiency of these performance-oriented V8s without compromising their market appeal. The LS6 demonstrated approximately 5-7% better fuel economy in comparable applications despite its higher output, achieved through improved combustion chamber design and reduced internal friction.

Global regulatory variations have created interesting market disparities for these engines. European and Japanese emissions standards, typically more stringent than North American requirements during this period, necessitated market-specific tuning and equipment packages. This regulatory landscape has influenced not only the technical specifications but also the global market positioning of vehicles equipped with these engines.

Looking forward, the regulatory trajectory suggests continued pressure on traditional V8 performance engines. The LS1/LS6 comparison serves as an instructive case study in how manufacturers can adapt high-performance V8 architectures to meet environmental requirements. The engineering solutions developed for these engines—including variable valve timing, cylinder deactivation technologies, and advanced materials—have informed subsequent generations of performance engines facing even stricter regulatory environments.

The balance between environmental compliance and performance optimization remains a central challenge for V8 engine development, with the LS1 and LS6 representing important evolutionary steps in this ongoing technical narrative.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!