Practices for Increasing PMMA's Mechanical Durability

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Durability Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries since its development in the 1930s. Its exceptional optical clarity, weather resistance, and lightweight properties have made it a preferred choice in applications ranging from automotive and aerospace to construction and medical devices. However, the inherent brittleness and limited mechanical durability of PMMA have long been recognized as significant drawbacks, limiting its potential in high-stress environments and impact-resistant applications.

The evolution of PMMA's mechanical properties has been a continuous focus of research and development efforts. Early improvements centered on optimizing polymerization techniques and molecular weight distribution to enhance basic mechanical properties. As the demand for more robust acrylic materials grew, attention shifted towards developing advanced formulations and composite structures to address the material's limitations.

In recent years, the push for sustainable and high-performance materials has further intensified the need for mechanically durable PMMA. This has led to a convergence of traditional polymer science with cutting-edge nanotechnology and materials engineering. The goal is to create PMMA-based materials that maintain the desirable characteristics of the base polymer while significantly improving its impact resistance, flexural strength, and overall toughness.

The objectives of enhancing PMMA's mechanical durability are multifaceted. Primarily, there is a drive to expand the material's applicability in high-impact and high-stress environments, potentially replacing heavier or more expensive materials in certain applications. Additionally, improving durability can lead to longer-lasting products, contributing to sustainability efforts by reducing material replacement frequency and waste.

Another critical objective is to maintain or improve upon PMMA's other desirable properties while enhancing its mechanical durability. This includes preserving its optical clarity, UV resistance, and processability, which are crucial for many of its current applications. The challenge lies in finding the right balance between improved mechanical properties and the retention of these essential characteristics.

Furthermore, the development of more durable PMMA variants aims to open new markets and applications. For instance, in the automotive industry, there is growing interest in using lightweight, durable plastics for glazing and structural components to improve fuel efficiency and safety. Similarly, in the construction sector, more robust PMMA could enable larger, more complex architectural designs while ensuring long-term structural integrity.

The evolution of PMMA's mechanical properties has been a continuous focus of research and development efforts. Early improvements centered on optimizing polymerization techniques and molecular weight distribution to enhance basic mechanical properties. As the demand for more robust acrylic materials grew, attention shifted towards developing advanced formulations and composite structures to address the material's limitations.

In recent years, the push for sustainable and high-performance materials has further intensified the need for mechanically durable PMMA. This has led to a convergence of traditional polymer science with cutting-edge nanotechnology and materials engineering. The goal is to create PMMA-based materials that maintain the desirable characteristics of the base polymer while significantly improving its impact resistance, flexural strength, and overall toughness.

The objectives of enhancing PMMA's mechanical durability are multifaceted. Primarily, there is a drive to expand the material's applicability in high-impact and high-stress environments, potentially replacing heavier or more expensive materials in certain applications. Additionally, improving durability can lead to longer-lasting products, contributing to sustainability efforts by reducing material replacement frequency and waste.

Another critical objective is to maintain or improve upon PMMA's other desirable properties while enhancing its mechanical durability. This includes preserving its optical clarity, UV resistance, and processability, which are crucial for many of its current applications. The challenge lies in finding the right balance between improved mechanical properties and the retention of these essential characteristics.

Furthermore, the development of more durable PMMA variants aims to open new markets and applications. For instance, in the automotive industry, there is growing interest in using lightweight, durable plastics for glazing and structural components to improve fuel efficiency and safety. Similarly, in the construction sector, more robust PMMA could enable larger, more complex architectural designs while ensuring long-term structural integrity.

Market Analysis for High-Strength PMMA

The market for high-strength PMMA (Polymethyl Methacrylate) has been experiencing significant growth due to the increasing demand for durable, lightweight materials across various industries. The global PMMA market size was valued at USD 4.67 billion in 2020 and is projected to reach USD 6.41 billion by 2028, growing at a CAGR of 4.2% during the forecast period.

The automotive sector is a key driver for high-strength PMMA demand, as manufacturers seek to reduce vehicle weight and improve fuel efficiency while maintaining safety standards. PMMA's excellent optical properties, combined with enhanced mechanical durability, make it an attractive alternative to traditional glass in automotive applications such as windshields, side windows, and rear lights.

In the construction industry, high-strength PMMA is gaining traction for use in architectural glazing, skylights, and noise barriers. The material's improved impact resistance and weatherability contribute to its growing adoption in building facades and outdoor structures, particularly in regions prone to extreme weather conditions.

The electronics and consumer goods sectors also present significant opportunities for high-strength PMMA. As electronic devices become more sophisticated and portable, there is an increasing need for durable, scratch-resistant materials for screens and protective covers. High-strength PMMA meets these requirements while offering excellent optical clarity and UV resistance.

Geographically, Asia-Pacific is expected to dominate the high-strength PMMA market, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe are also significant markets, with a focus on innovative applications in aerospace, medical devices, and sustainable construction materials.

The market for high-strength PMMA faces competition from other advanced materials such as polycarbonate and high-performance plastics. However, PMMA's unique combination of optical clarity, UV resistance, and improved mechanical properties continues to give it a competitive edge in many applications.

Key market players are investing heavily in research and development to further enhance PMMA's mechanical durability and expand its application range. Collaborations between material suppliers, manufacturers, and end-users are driving innovation in high-strength PMMA formulations and processing techniques.

As sustainability becomes increasingly important, there is growing interest in bio-based and recyclable high-strength PMMA alternatives. This trend is likely to shape the market landscape in the coming years, with companies focusing on developing more environmentally friendly production methods and end-of-life solutions for PMMA products.

The automotive sector is a key driver for high-strength PMMA demand, as manufacturers seek to reduce vehicle weight and improve fuel efficiency while maintaining safety standards. PMMA's excellent optical properties, combined with enhanced mechanical durability, make it an attractive alternative to traditional glass in automotive applications such as windshields, side windows, and rear lights.

In the construction industry, high-strength PMMA is gaining traction for use in architectural glazing, skylights, and noise barriers. The material's improved impact resistance and weatherability contribute to its growing adoption in building facades and outdoor structures, particularly in regions prone to extreme weather conditions.

The electronics and consumer goods sectors also present significant opportunities for high-strength PMMA. As electronic devices become more sophisticated and portable, there is an increasing need for durable, scratch-resistant materials for screens and protective covers. High-strength PMMA meets these requirements while offering excellent optical clarity and UV resistance.

Geographically, Asia-Pacific is expected to dominate the high-strength PMMA market, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe are also significant markets, with a focus on innovative applications in aerospace, medical devices, and sustainable construction materials.

The market for high-strength PMMA faces competition from other advanced materials such as polycarbonate and high-performance plastics. However, PMMA's unique combination of optical clarity, UV resistance, and improved mechanical properties continues to give it a competitive edge in many applications.

Key market players are investing heavily in research and development to further enhance PMMA's mechanical durability and expand its application range. Collaborations between material suppliers, manufacturers, and end-users are driving innovation in high-strength PMMA formulations and processing techniques.

As sustainability becomes increasingly important, there is growing interest in bio-based and recyclable high-strength PMMA alternatives. This trend is likely to shape the market landscape in the coming years, with companies focusing on developing more environmentally friendly production methods and end-of-life solutions for PMMA products.

Current Challenges in PMMA Mechanical Properties

Poly(methyl methacrylate) (PMMA), widely known as acrylic or plexiglass, is a versatile thermoplastic with numerous applications across various industries. However, its mechanical properties, particularly its durability, present significant challenges that limit its use in certain high-performance applications.

One of the primary challenges faced by PMMA is its relatively low impact strength and toughness compared to other engineering plastics. This brittleness makes PMMA susceptible to cracking and shattering under sudden impacts or high stress conditions. The material's low resistance to crack propagation further exacerbates this issue, leading to premature failure in applications requiring high mechanical durability.

Another critical challenge is PMMA's poor scratch resistance. While the material offers excellent optical clarity, its surface is prone to scratching and marring, which can significantly degrade its appearance and optical properties over time. This susceptibility to surface damage limits PMMA's use in applications where maintaining a pristine surface is crucial, such as in automotive exteriors or high-traffic architectural installations.

PMMA also exhibits relatively low heat resistance compared to other engineering plastics. Its glass transition temperature (Tg) of around 105°C limits its use in high-temperature environments. This thermal sensitivity can lead to softening, deformation, and loss of mechanical properties when exposed to elevated temperatures, restricting its application in automotive and aerospace industries where heat resistance is critical.

The material's poor chemical resistance, particularly to organic solvents and some acids, presents another significant challenge. PMMA can be easily attacked by various chemicals, leading to crazing, cracking, or dissolution. This vulnerability limits its use in chemical processing equipment, laboratory apparatus, and other applications involving exposure to harsh chemical environments.

Weathering and UV resistance pose additional challenges for PMMA's long-term durability. While PMMA exhibits better UV resistance than many other plastics, prolonged exposure to sunlight and environmental factors can still lead to yellowing, embrittlement, and degradation of mechanical properties. This aging process affects the material's performance and aesthetics in outdoor applications, necessitating frequent replacement or additional protective measures.

Addressing these challenges requires innovative approaches in material science and engineering. Researchers and manufacturers are actively exploring various strategies to enhance PMMA's mechanical durability, including the development of impact-modified grades, surface treatments for improved scratch resistance, and the incorporation of nanofillers to enhance overall mechanical properties. However, balancing these improvements with PMMA's desirable characteristics, such as optical clarity and processability, remains a complex task that demands continued research and development efforts.

One of the primary challenges faced by PMMA is its relatively low impact strength and toughness compared to other engineering plastics. This brittleness makes PMMA susceptible to cracking and shattering under sudden impacts or high stress conditions. The material's low resistance to crack propagation further exacerbates this issue, leading to premature failure in applications requiring high mechanical durability.

Another critical challenge is PMMA's poor scratch resistance. While the material offers excellent optical clarity, its surface is prone to scratching and marring, which can significantly degrade its appearance and optical properties over time. This susceptibility to surface damage limits PMMA's use in applications where maintaining a pristine surface is crucial, such as in automotive exteriors or high-traffic architectural installations.

PMMA also exhibits relatively low heat resistance compared to other engineering plastics. Its glass transition temperature (Tg) of around 105°C limits its use in high-temperature environments. This thermal sensitivity can lead to softening, deformation, and loss of mechanical properties when exposed to elevated temperatures, restricting its application in automotive and aerospace industries where heat resistance is critical.

The material's poor chemical resistance, particularly to organic solvents and some acids, presents another significant challenge. PMMA can be easily attacked by various chemicals, leading to crazing, cracking, or dissolution. This vulnerability limits its use in chemical processing equipment, laboratory apparatus, and other applications involving exposure to harsh chemical environments.

Weathering and UV resistance pose additional challenges for PMMA's long-term durability. While PMMA exhibits better UV resistance than many other plastics, prolonged exposure to sunlight and environmental factors can still lead to yellowing, embrittlement, and degradation of mechanical properties. This aging process affects the material's performance and aesthetics in outdoor applications, necessitating frequent replacement or additional protective measures.

Addressing these challenges requires innovative approaches in material science and engineering. Researchers and manufacturers are actively exploring various strategies to enhance PMMA's mechanical durability, including the development of impact-modified grades, surface treatments for improved scratch resistance, and the incorporation of nanofillers to enhance overall mechanical properties. However, balancing these improvements with PMMA's desirable characteristics, such as optical clarity and processability, remains a complex task that demands continued research and development efforts.

Existing PMMA Reinforcement Techniques

01 Improving mechanical properties through polymer blending

Blending PMMA with other polymers or additives can enhance its mechanical durability. This approach can improve impact resistance, tensile strength, and overall toughness of the material while maintaining its optical properties.- Enhancing mechanical durability through polymer blending: PMMA's mechanical durability can be improved by blending it with other polymers or materials. This approach can enhance properties such as impact resistance, tensile strength, and overall toughness while maintaining PMMA's desirable optical characteristics.

- Surface modification techniques for improved durability: Various surface modification techniques can be applied to PMMA to enhance its mechanical durability. These may include plasma treatment, chemical etching, or the application of protective coatings, resulting in improved scratch resistance and overall longevity of PMMA-based products.

- Incorporation of nanoparticles or reinforcing agents: The addition of nanoparticles or other reinforcing agents to PMMA can significantly improve its mechanical properties. These additives can enhance the material's strength, stiffness, and wear resistance without compromising its transparency or other desirable characteristics.

- Optimizing polymerization and processing conditions: Careful control of polymerization and processing conditions during PMMA production can lead to improved mechanical durability. This may involve adjusting factors such as temperature, pressure, and curing time to achieve optimal molecular weight distribution and cross-linking.

- Development of PMMA-based composites: Creating composites that incorporate PMMA as a component can result in materials with enhanced mechanical durability. These composites may combine PMMA with other polymers, fibers, or inorganic materials to achieve a balance of properties suitable for specific applications.

02 Surface modification techniques

Various surface modification methods can be applied to PMMA to improve its mechanical durability. These techniques include plasma treatment, chemical etching, and coating applications, which can enhance scratch resistance and durability of the material's surface.Expand Specific Solutions03 Nanocomposite reinforcement

Incorporating nanoparticles or nanofibers into PMMA can significantly improve its mechanical properties. These nanocomposites can enhance strength, stiffness, and wear resistance of the material without compromising its transparency.Expand Specific Solutions04 Heat treatment and annealing processes

Applying specific heat treatment and annealing processes to PMMA can improve its mechanical durability. These thermal processes can reduce internal stresses, increase crystallinity, and enhance overall mechanical properties of the material.Expand Specific Solutions05 Crosslinking and copolymerization

Enhancing PMMA's mechanical durability through crosslinking or copolymerization with other monomers can create a more robust polymer structure. This approach can improve impact resistance, hardness, and overall durability of the material.Expand Specific Solutions

Key Players in PMMA Industry

The market for practices to increase PMMA's mechanical durability is in a growth phase, driven by increasing demand for high-performance materials across various industries. The global PMMA market size is projected to reach $5.9 billion by 2027, with a CAGR of 4.3%. Technologically, the field is moderately mature, with ongoing research focused on enhancing PMMA's properties. Key players like Röhm GmbH, Wanhua Chemical Group, and Kingfa Sci. & Tech. are investing in R&D to develop advanced PMMA formulations and composites. Academic institutions such as Zhejiang University and Beijing Institute of Technology are also contributing to innovation in this area, collaborating with industry partners to bridge the gap between research and commercial applications.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has made significant strides in improving PMMA's mechanical durability through their advanced polymer technology. They have developed a proprietary process for synthesizing high-molecular-weight PMMA with improved impact resistance and tensile strength[5]. Their approach involves carefully controlling the polymerization conditions to achieve a more uniform molecular weight distribution, resulting in enhanced mechanical properties. Wanhua has also introduced a novel copolymerization technique that incorporates flexible monomers into the PMMA backbone, increasing its overall toughness and flexibility[6]. Furthermore, they have developed a surface modification technology that applies a thin, highly cross-linked layer to PMMA products, significantly improving scratch resistance and weatherability[7].

Strengths: Strong expertise in polymer chemistry, large-scale production capabilities, and a diverse product portfolio. Weaknesses: Relatively new entrant in the PMMA market compared to established players, potential challenges in global market penetration.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has been at the forefront of PMMA research, focusing on molecular-level modifications to enhance its mechanical durability. They have developed a novel grafting technique that introduces flexible side chains onto the PMMA backbone, significantly improving its impact resistance and elongation at break[8]. Their research also includes the incorporation of nanofillers, such as graphene oxide and carbon nanotubes, which have shown remarkable improvements in the material's tensile strength and modulus[9]. Additionally, the institute has pioneered a new approach to creating interpenetrating polymer networks (IPNs) with PMMA, resulting in materials with superior mechanical properties and enhanced chemical resistance[10].

Strengths: Cutting-edge research capabilities, access to advanced characterization techniques, and collaboration with industry partners. Weaknesses: Potential challenges in scaling up laboratory discoveries to industrial production, longer time-to-market for new technologies.

Innovative Approaches to PMMA Toughening

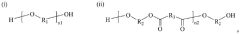

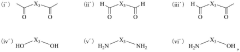

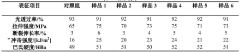

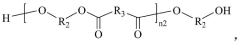

Reinforced and toughened PMMA (polymethyl methacrylate) material and preparation method thereof

PatentActiveCN116239781A

Innovation

- By forming a liquid phase system and adding polyol polymers and short-range connecting units, a connecting structure and a closed-loop structure interspersed between polymethyl methacrylate polymer chains are formed, thereby improving the toughness and strength of PMMA materials.

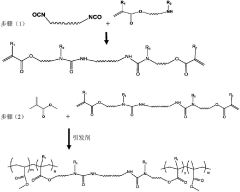

Preparation method of partially crosslinked PMMA (polymethyl methacrylate) and composite material thereof

PatentActiveCN115785328A

Innovation

- Using the preparation method of partially cross-linked PMMA, an intermediate product is generated through the polyurea reaction of diisocyanate and hindered amine acrylate, and then undergoes free radical copolymerization with MMA monomer to form partially cross-linked PMMA, thereby enhancing the cross-linking degree of its molecular chain. , thereby improving tensile strength and toughness.

Environmental Impact of PMMA Reinforcement

The environmental impact of PMMA reinforcement is a crucial consideration in the pursuit of enhancing its mechanical durability. As efforts to improve PMMA's strength and resilience intensify, it is essential to evaluate the ecological consequences of these practices. The reinforcement processes often involve the incorporation of additional materials or chemical treatments, which can alter the environmental footprint of the resulting product.

One significant aspect to consider is the potential increase in energy consumption during the manufacturing process. Reinforcement techniques such as copolymerization or the addition of nanoparticles may require higher temperatures or longer processing times, leading to increased energy usage and associated greenhouse gas emissions. This energy-intensive production could offset some of the environmental benefits gained from the improved durability and longevity of reinforced PMMA products.

The introduction of reinforcing agents into PMMA also raises concerns about the material's end-of-life management. While PMMA itself is recyclable, the addition of reinforcing materials may complicate the recycling process or render the composite unrecyclable through conventional means. This could lead to increased waste and potentially negate the environmental advantages of using a more durable material.

Water pollution is another environmental factor to consider. Some reinforcement techniques may involve the use of solvents or chemical additives that, if not properly managed, could contaminate water sources. Implementing robust waste management systems and closed-loop manufacturing processes becomes crucial to mitigate these risks.

On the positive side, the enhanced durability of reinforced PMMA can lead to longer-lasting products, potentially reducing the overall demand for raw materials and the frequency of replacement. This extended lifespan could result in a net positive environmental impact by decreasing the total amount of plastic waste generated over time.

The choice of reinforcing agents also plays a significant role in the environmental impact. Bio-based additives or naturally occurring minerals may offer more sustainable alternatives to synthetic reinforcements, potentially reducing the carbon footprint of the reinforced PMMA. However, the sourcing and processing of these natural materials must also be carefully evaluated to ensure a truly positive environmental outcome.

In conclusion, while reinforcing PMMA can offer significant benefits in terms of mechanical durability, it is crucial to carefully balance these improvements against their environmental costs. A holistic approach that considers the entire lifecycle of reinforced PMMA products is necessary to ensure that efforts to enhance durability do not come at an unacceptable environmental price.

One significant aspect to consider is the potential increase in energy consumption during the manufacturing process. Reinforcement techniques such as copolymerization or the addition of nanoparticles may require higher temperatures or longer processing times, leading to increased energy usage and associated greenhouse gas emissions. This energy-intensive production could offset some of the environmental benefits gained from the improved durability and longevity of reinforced PMMA products.

The introduction of reinforcing agents into PMMA also raises concerns about the material's end-of-life management. While PMMA itself is recyclable, the addition of reinforcing materials may complicate the recycling process or render the composite unrecyclable through conventional means. This could lead to increased waste and potentially negate the environmental advantages of using a more durable material.

Water pollution is another environmental factor to consider. Some reinforcement techniques may involve the use of solvents or chemical additives that, if not properly managed, could contaminate water sources. Implementing robust waste management systems and closed-loop manufacturing processes becomes crucial to mitigate these risks.

On the positive side, the enhanced durability of reinforced PMMA can lead to longer-lasting products, potentially reducing the overall demand for raw materials and the frequency of replacement. This extended lifespan could result in a net positive environmental impact by decreasing the total amount of plastic waste generated over time.

The choice of reinforcing agents also plays a significant role in the environmental impact. Bio-based additives or naturally occurring minerals may offer more sustainable alternatives to synthetic reinforcements, potentially reducing the carbon footprint of the reinforced PMMA. However, the sourcing and processing of these natural materials must also be carefully evaluated to ensure a truly positive environmental outcome.

In conclusion, while reinforcing PMMA can offer significant benefits in terms of mechanical durability, it is crucial to carefully balance these improvements against their environmental costs. A holistic approach that considers the entire lifecycle of reinforced PMMA products is necessary to ensure that efforts to enhance durability do not come at an unacceptable environmental price.

Regulatory Considerations for Enhanced PMMA

Regulatory considerations play a crucial role in the development and implementation of enhanced PMMA materials with improved mechanical durability. As manufacturers and researchers explore new techniques to increase PMMA's strength and resilience, they must navigate a complex landscape of regulations and standards to ensure compliance and safety.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PMMA-based products used in medical applications, such as intraocular lenses and bone cement. Any modifications to PMMA's composition or manufacturing process that aim to enhance its mechanical properties must undergo rigorous testing and evaluation to meet FDA requirements. This includes demonstrating the safety and efficacy of the enhanced material through pre-market approval processes or 510(k) clearance, depending on the specific application and the extent of the modifications.

The European Union's regulatory framework, governed by the European Medicines Agency (EMA) and the Medical Device Regulation (MDR), imposes similar stringent requirements for PMMA-based medical devices. Manufacturers must comply with the Essential Requirements outlined in the MDR, which include demonstrating the mechanical stability and durability of the enhanced PMMA materials throughout their intended lifecycle.

Environmental regulations also come into play when considering practices for increasing PMMA's mechanical durability. The use of certain additives or processing techniques may be subject to restrictions under regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the EU or the Toxic Substances Control Act (TSCA) in the US. Manufacturers must ensure that any new formulations or treatments used to enhance PMMA's properties do not introduce harmful substances or pose environmental risks.

In the construction and automotive industries, enhanced PMMA materials must meet specific building codes and safety standards. For instance, the American Society for Testing and Materials (ASTM) provides guidelines for testing the mechanical properties of plastics, including PMMA. Any new practices for increasing PMMA's durability must be validated against these standards to ensure compliance and market acceptance.

Intellectual property considerations are another important aspect of regulatory compliance. As companies develop novel techniques for enhancing PMMA's mechanical properties, they must navigate patent landscapes and ensure that their innovations do not infringe on existing intellectual property rights. This may involve conducting thorough patent searches and potentially seeking patent protection for new methods or compositions.

Lastly, regulatory bodies are increasingly focusing on sustainability and circular economy principles. As such, any new practices for enhancing PMMA's durability should also consider end-of-life scenarios, recyclability, and overall environmental impact. This may influence the choice of additives, processing methods, and even the fundamental approach to improving PMMA's mechanical properties.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PMMA-based products used in medical applications, such as intraocular lenses and bone cement. Any modifications to PMMA's composition or manufacturing process that aim to enhance its mechanical properties must undergo rigorous testing and evaluation to meet FDA requirements. This includes demonstrating the safety and efficacy of the enhanced material through pre-market approval processes or 510(k) clearance, depending on the specific application and the extent of the modifications.

The European Union's regulatory framework, governed by the European Medicines Agency (EMA) and the Medical Device Regulation (MDR), imposes similar stringent requirements for PMMA-based medical devices. Manufacturers must comply with the Essential Requirements outlined in the MDR, which include demonstrating the mechanical stability and durability of the enhanced PMMA materials throughout their intended lifecycle.

Environmental regulations also come into play when considering practices for increasing PMMA's mechanical durability. The use of certain additives or processing techniques may be subject to restrictions under regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the EU or the Toxic Substances Control Act (TSCA) in the US. Manufacturers must ensure that any new formulations or treatments used to enhance PMMA's properties do not introduce harmful substances or pose environmental risks.

In the construction and automotive industries, enhanced PMMA materials must meet specific building codes and safety standards. For instance, the American Society for Testing and Materials (ASTM) provides guidelines for testing the mechanical properties of plastics, including PMMA. Any new practices for increasing PMMA's durability must be validated against these standards to ensure compliance and market acceptance.

Intellectual property considerations are another important aspect of regulatory compliance. As companies develop novel techniques for enhancing PMMA's mechanical properties, they must navigate patent landscapes and ensure that their innovations do not infringe on existing intellectual property rights. This may involve conducting thorough patent searches and potentially seeking patent protection for new methods or compositions.

Lastly, regulatory bodies are increasingly focusing on sustainability and circular economy principles. As such, any new practices for enhancing PMMA's durability should also consider end-of-life scenarios, recyclability, and overall environmental impact. This may influence the choice of additives, processing methods, and even the fundamental approach to improving PMMA's mechanical properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!