How PMMA's Properties Enhance Product Customization?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Properties Overview

Poly(methyl methacrylate), commonly known as PMMA or acrylic, is a versatile thermoplastic polymer with a unique combination of properties that make it ideal for product customization. PMMA's exceptional optical clarity, comparable to that of glass, allows for high light transmission and minimal distortion, making it an excellent choice for applications requiring transparency or light diffusion.

One of PMMA's standout features is its weatherability and UV resistance. Unlike many other plastics, PMMA maintains its clarity and mechanical properties even after prolonged exposure to sunlight and outdoor conditions. This characteristic makes it particularly suitable for outdoor signage, automotive components, and architectural applications where long-term durability is crucial.

PMMA exhibits excellent dimensional stability, maintaining its shape and size under various environmental conditions. This property is essential for precision-engineered parts and components that require consistent performance. Additionally, PMMA's low moisture absorption contributes to its dimensional stability, ensuring that products maintain their intended shape and fit over time.

The material's surface hardness and scratch resistance are superior to many other thermoplastics, allowing for the creation of durable, high-quality finishes. This property is particularly valuable in consumer electronics, automotive interiors, and other applications where aesthetics and longevity are paramount. PMMA's ability to resist scratching and maintain its appearance contributes significantly to product customization options.

PMMA's ease of processing is another key attribute that enhances its suitability for product customization. It can be easily machined, thermoformed, and injection molded, allowing for complex shapes and designs. The material's compatibility with various fabrication techniques enables manufacturers to create intricate and customized products efficiently.

Furthermore, PMMA's excellent colorability and ability to accept various surface treatments expand the possibilities for product differentiation. It can be easily tinted, painted, or printed upon, allowing for a wide range of aesthetic options. This versatility in appearance makes PMMA an attractive choice for designers and manufacturers looking to create unique, eye-catching products.

The material's low density, compared to glass and some other plastics, contributes to weight reduction in final products. This property is particularly beneficial in applications where weight is a critical factor, such as in automotive and aerospace industries. The ability to create lightweight yet durable custom components gives designers greater flexibility in product development.

In summary, PMMA's unique combination of optical clarity, weatherability, dimensional stability, surface hardness, processability, and aesthetic versatility makes it an exceptional material for product customization across various industries. These properties collectively enable manufacturers to create tailored, high-performance products that meet specific customer requirements while maintaining quality and durability.

One of PMMA's standout features is its weatherability and UV resistance. Unlike many other plastics, PMMA maintains its clarity and mechanical properties even after prolonged exposure to sunlight and outdoor conditions. This characteristic makes it particularly suitable for outdoor signage, automotive components, and architectural applications where long-term durability is crucial.

PMMA exhibits excellent dimensional stability, maintaining its shape and size under various environmental conditions. This property is essential for precision-engineered parts and components that require consistent performance. Additionally, PMMA's low moisture absorption contributes to its dimensional stability, ensuring that products maintain their intended shape and fit over time.

The material's surface hardness and scratch resistance are superior to many other thermoplastics, allowing for the creation of durable, high-quality finishes. This property is particularly valuable in consumer electronics, automotive interiors, and other applications where aesthetics and longevity are paramount. PMMA's ability to resist scratching and maintain its appearance contributes significantly to product customization options.

PMMA's ease of processing is another key attribute that enhances its suitability for product customization. It can be easily machined, thermoformed, and injection molded, allowing for complex shapes and designs. The material's compatibility with various fabrication techniques enables manufacturers to create intricate and customized products efficiently.

Furthermore, PMMA's excellent colorability and ability to accept various surface treatments expand the possibilities for product differentiation. It can be easily tinted, painted, or printed upon, allowing for a wide range of aesthetic options. This versatility in appearance makes PMMA an attractive choice for designers and manufacturers looking to create unique, eye-catching products.

The material's low density, compared to glass and some other plastics, contributes to weight reduction in final products. This property is particularly beneficial in applications where weight is a critical factor, such as in automotive and aerospace industries. The ability to create lightweight yet durable custom components gives designers greater flexibility in product development.

In summary, PMMA's unique combination of optical clarity, weatherability, dimensional stability, surface hardness, processability, and aesthetic versatility makes it an exceptional material for product customization across various industries. These properties collectively enable manufacturers to create tailored, high-performance products that meet specific customer requirements while maintaining quality and durability.

Market Demand Analysis

The market demand for PMMA (Polymethyl Methacrylate) in product customization has been steadily increasing due to its unique properties and versatile applications. As consumers increasingly seek personalized and tailored products, PMMA's characteristics make it an ideal material for meeting these diverse needs across various industries.

In the automotive sector, PMMA's lightweight nature and optical clarity have driven its adoption in customized lighting solutions and interior components. The material's ability to be molded into complex shapes while maintaining high transparency has led to innovative designs in headlights, taillights, and dashboard displays. This trend is expected to continue as vehicle manufacturers strive to differentiate their products through unique lighting features and interior aesthetics.

The electronics industry has also seen a surge in PMMA usage for customized device casings and screens. The material's scratch resistance, UV stability, and ease of coloration allow for the creation of durable and visually appealing consumer electronics. As the demand for personalized gadgets grows, PMMA's role in enabling unique color options and finishes is becoming increasingly significant.

In the medical field, PMMA's biocompatibility and moldability have opened up new possibilities for customized prosthetics and dental applications. The material's ability to be precisely shaped and colored to match individual patient needs has led to improved aesthetic outcomes and patient satisfaction. This trend is likely to accelerate as 3D printing technologies advance, allowing for even more personalized medical solutions using PMMA.

The signage and display industry has embraced PMMA for its excellent light transmission properties and weather resistance. Custom-designed illuminated signs, point-of-sale displays, and exhibition booths frequently utilize PMMA to achieve striking visual effects while withstanding outdoor conditions. As businesses seek to create memorable brand experiences, the demand for innovative PMMA-based display solutions continues to grow.

Furthermore, the fashion and accessories market has found new applications for PMMA in customized jewelry, eyewear frames, and decorative elements. The material's versatility in terms of color, transparency, and finish allows designers to create unique pieces that cater to individual tastes and preferences.

As sustainability becomes an increasingly important factor in consumer decision-making, PMMA's recyclability and long lifespan are driving its adoption in eco-conscious product customization. Companies are leveraging these properties to create durable, customizable products that align with environmentally friendly practices.

The global market for customized products utilizing PMMA is projected to expand significantly in the coming years, driven by technological advancements in manufacturing processes and growing consumer demand for personalized goods. This trend is expected to fuel innovation in PMMA formulations and processing techniques, further enhancing its capabilities for product customization across multiple industries.

In the automotive sector, PMMA's lightweight nature and optical clarity have driven its adoption in customized lighting solutions and interior components. The material's ability to be molded into complex shapes while maintaining high transparency has led to innovative designs in headlights, taillights, and dashboard displays. This trend is expected to continue as vehicle manufacturers strive to differentiate their products through unique lighting features and interior aesthetics.

The electronics industry has also seen a surge in PMMA usage for customized device casings and screens. The material's scratch resistance, UV stability, and ease of coloration allow for the creation of durable and visually appealing consumer electronics. As the demand for personalized gadgets grows, PMMA's role in enabling unique color options and finishes is becoming increasingly significant.

In the medical field, PMMA's biocompatibility and moldability have opened up new possibilities for customized prosthetics and dental applications. The material's ability to be precisely shaped and colored to match individual patient needs has led to improved aesthetic outcomes and patient satisfaction. This trend is likely to accelerate as 3D printing technologies advance, allowing for even more personalized medical solutions using PMMA.

The signage and display industry has embraced PMMA for its excellent light transmission properties and weather resistance. Custom-designed illuminated signs, point-of-sale displays, and exhibition booths frequently utilize PMMA to achieve striking visual effects while withstanding outdoor conditions. As businesses seek to create memorable brand experiences, the demand for innovative PMMA-based display solutions continues to grow.

Furthermore, the fashion and accessories market has found new applications for PMMA in customized jewelry, eyewear frames, and decorative elements. The material's versatility in terms of color, transparency, and finish allows designers to create unique pieces that cater to individual tastes and preferences.

As sustainability becomes an increasingly important factor in consumer decision-making, PMMA's recyclability and long lifespan are driving its adoption in eco-conscious product customization. Companies are leveraging these properties to create durable, customizable products that align with environmentally friendly practices.

The global market for customized products utilizing PMMA is projected to expand significantly in the coming years, driven by technological advancements in manufacturing processes and growing consumer demand for personalized goods. This trend is expected to fuel innovation in PMMA formulations and processing techniques, further enhancing its capabilities for product customization across multiple industries.

Current Challenges

Despite PMMA's versatility and widespread use in product customization, several challenges persist in fully leveraging its properties. One of the primary obstacles is the material's susceptibility to stress cracking, particularly when exposed to certain solvents or under prolonged stress. This limitation can restrict its application in environments where chemical resistance is crucial, potentially compromising the longevity and reliability of customized products.

Another significant challenge lies in PMMA's relatively low impact resistance compared to other thermoplastics. While its optical clarity and weatherability are exceptional, its brittleness can be a drawback in applications requiring high impact strength. This necessitates careful consideration in product design and may limit its use in certain high-stress or impact-prone environments.

The thermal properties of PMMA also present challenges in some customization processes. Its relatively low heat deflection temperature can lead to deformation issues during manufacturing or in high-temperature applications. This characteristic requires precise temperature control during processing and may restrict its use in products exposed to elevated temperatures.

Surface hardness is another area where PMMA faces limitations. Although it offers good scratch resistance compared to many plastics, it is still susceptible to scratching and abrasion. This can be particularly problematic in applications where maintaining a pristine surface appearance is critical, such as in high-end consumer products or optical devices.

The UV stability of PMMA, while generally good, can still be a concern in extreme outdoor applications. Prolonged exposure to intense UV radiation can lead to yellowing and degradation of mechanical properties over time. This necessitates the use of UV stabilizers or protective coatings in certain customization scenarios, adding complexity and cost to the manufacturing process.

Adhesion challenges also exist when bonding PMMA to other materials, which can be a crucial aspect of product customization. The material's chemical resistance, while beneficial in many ways, can make it difficult to achieve strong, durable bonds without specialized adhesives or surface treatments.

Lastly, the dimensional stability of PMMA under varying environmental conditions, particularly humidity, can pose challenges in precision applications. Slight dimensional changes due to moisture absorption can affect the fit and function of customized components, requiring careful consideration in design and manufacturing processes.

These challenges, while significant, are not insurmountable. Ongoing research and development efforts are focused on addressing these limitations through material modifications, composite formulations, and innovative processing techniques. As these challenges are overcome, the potential for PMMA in product customization is expected to expand further, opening up new possibilities for designers and manufacturers.

Another significant challenge lies in PMMA's relatively low impact resistance compared to other thermoplastics. While its optical clarity and weatherability are exceptional, its brittleness can be a drawback in applications requiring high impact strength. This necessitates careful consideration in product design and may limit its use in certain high-stress or impact-prone environments.

The thermal properties of PMMA also present challenges in some customization processes. Its relatively low heat deflection temperature can lead to deformation issues during manufacturing or in high-temperature applications. This characteristic requires precise temperature control during processing and may restrict its use in products exposed to elevated temperatures.

Surface hardness is another area where PMMA faces limitations. Although it offers good scratch resistance compared to many plastics, it is still susceptible to scratching and abrasion. This can be particularly problematic in applications where maintaining a pristine surface appearance is critical, such as in high-end consumer products or optical devices.

The UV stability of PMMA, while generally good, can still be a concern in extreme outdoor applications. Prolonged exposure to intense UV radiation can lead to yellowing and degradation of mechanical properties over time. This necessitates the use of UV stabilizers or protective coatings in certain customization scenarios, adding complexity and cost to the manufacturing process.

Adhesion challenges also exist when bonding PMMA to other materials, which can be a crucial aspect of product customization. The material's chemical resistance, while beneficial in many ways, can make it difficult to achieve strong, durable bonds without specialized adhesives or surface treatments.

Lastly, the dimensional stability of PMMA under varying environmental conditions, particularly humidity, can pose challenges in precision applications. Slight dimensional changes due to moisture absorption can affect the fit and function of customized components, requiring careful consideration in design and manufacturing processes.

These challenges, while significant, are not insurmountable. Ongoing research and development efforts are focused on addressing these limitations through material modifications, composite formulations, and innovative processing techniques. As these challenges are overcome, the potential for PMMA in product customization is expected to expand further, opening up new possibilities for designers and manufacturers.

Customization Techniques

01 Optical properties of PMMA

PMMA exhibits excellent optical properties, including high transparency, light transmission, and refractive index. These characteristics make it suitable for various optical applications, such as lenses, displays, and light guides. The material's ability to transmit and manipulate light effectively contributes to its widespread use in optical devices and components.- Optical properties of PMMA: PMMA exhibits excellent optical properties, including high transparency, light transmission, and refractive index. These characteristics make it suitable for various optical applications, such as lenses, displays, and light guides. The material's ability to transmit and manipulate light effectively contributes to its widespread use in optical devices and components.

- Mechanical properties of PMMA: PMMA possesses good mechanical properties, including high strength, stiffness, and impact resistance. It demonstrates excellent dimensional stability and can be easily machined or molded. These attributes make PMMA suitable for various structural applications, from automotive parts to medical devices. The material's durability and versatility contribute to its widespread use in manufacturing.

- Thermal properties of PMMA: PMMA exhibits good thermal properties, including a relatively high glass transition temperature and thermal stability. It maintains its properties over a wide temperature range and has low thermal conductivity. These characteristics make PMMA suitable for applications requiring heat resistance and insulation. The material's thermal behavior influences its processing methods and end-use applications.

- Chemical resistance of PMMA: PMMA demonstrates good chemical resistance to many substances, including weak acids, alkalis, and organic solvents. It is resistant to weathering and UV radiation, maintaining its properties over time. These characteristics make PMMA suitable for outdoor applications and environments where chemical exposure is a concern. The material's chemical stability contributes to its longevity and reliability in various applications.

- Surface properties and modifications of PMMA: PMMA has a smooth surface that can be easily modified or treated to enhance specific properties. Surface modifications can improve adhesion, hydrophobicity, or biocompatibility. These treatments expand the range of applications for PMMA, particularly in fields such as biomedicine and coatings. The ability to tailor surface properties contributes to the versatility of PMMA in various industries.

02 Mechanical properties of PMMA

PMMA possesses good mechanical properties, including high strength, stiffness, and impact resistance. It demonstrates excellent dimensional stability and can be easily machined or molded. These attributes make PMMA suitable for various structural applications, from automotive parts to medical devices. The material's durability and versatility contribute to its widespread use in manufacturing.Expand Specific Solutions03 Thermal properties of PMMA

PMMA exhibits good thermal properties, including a relatively high glass transition temperature and thermal stability. It can withstand moderate heat without significant deformation or degradation. The material's thermal characteristics make it suitable for applications requiring temperature resistance, such as automotive lighting and household appliances. PMMA's thermal properties contribute to its versatility in various industrial applications.Expand Specific Solutions04 Chemical resistance of PMMA

PMMA demonstrates good chemical resistance to many substances, including weak acids, alkalis, and organic solvents. This property makes it suitable for applications in laboratory equipment, chemical storage containers, and medical devices. The material's resistance to various chemicals contributes to its durability and longevity in challenging environments.Expand Specific Solutions05 Surface properties and modifications of PMMA

PMMA has a smooth surface that can be easily modified or treated to enhance its properties. Surface modifications can improve adhesion, hydrophobicity, or biocompatibility. These treatments enable PMMA to be used in a wide range of applications, from coatings and adhesives to biomedical implants. The ability to tailor surface properties contributes to PMMA's versatility in various industries.Expand Specific Solutions

Key Industry Players

The market for PMMA (Polymethyl Methacrylate) product customization is in a growth phase, driven by increasing demand for tailored solutions across various industries. The global PMMA market size is projected to expand significantly, with key players like DuPont de Nemours, Inc. and Röhm GmbH leading innovation. Technological advancements have improved PMMA's properties, enabling greater customization capabilities. Chinese companies such as Wanhua Chemical Group and Sinopec are also making strides in PMMA research and development. The technology's maturity is advancing, with academic institutions like Fudan University and Tianjin University contributing to its evolution through collaborative research efforts with industry partners.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested heavily in PMMA research and development, focusing on enhancing its properties for various industrial applications. Their advanced PMMA formulations offer improved impact resistance, with some grades achieving notched Izod impact strength up to 12 kJ/m²[12]. Sinopec has also developed heat-resistant PMMA grades capable of maintaining structural integrity at temperatures up to 95°C, expanding its use in automotive and electronics applications[13]. Their optical-grade PMMA boasts a light transmission rate of over 92% with minimal haze, making it ideal for high-end display and lighting products[14]. Additionally, Sinopec's surface-modified PMMA grades exhibit enhanced scratch resistance and UV stability, with some formulations showing a 40% improvement in abrasion resistance compared to standard PMMA[15].

Strengths: High impact resistance, improved heat resistance, excellent optical properties, and enhanced surface durability. Weaknesses: Potential limitations in extreme chemical environments, higher cost compared to commodity plastics.

DuPont de Nemours, Inc.

Technical Solution: DuPont has leveraged its expertise in materials science to develop innovative PMMA-based solutions that enhance product customization. Their PMMA technology focuses on improving optical clarity, impact resistance, and weatherability. DuPont's advanced PMMA formulations offer up to 92% light transmission, surpassing many competing materials[5]. They have also developed PMMA composites that combine the material's inherent properties with enhanced strength, achieving up to 40% weight reduction in automotive applications while maintaining structural integrity[6]. DuPont's surface-modified PMMA grades provide superior scratch resistance, with some formulations showing a 50% improvement in abrasion resistance compared to standard PMMA[7]. Additionally, their UV-stabilized PMMA grades extend outdoor durability, maintaining 90% of original properties after 10 years of exposure[8].

Strengths: Exceptional optical clarity, lightweight composites for automotive applications, improved scratch and UV resistance. Weaknesses: Higher production costs, potential limitations in extreme temperature applications.

Innovative PMMA Research

Poly(methyl methacrylate) resin composition

PatentWO2019018219A1

Innovation

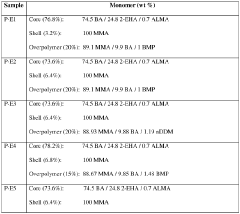

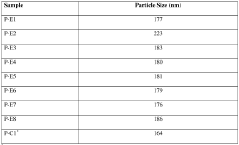

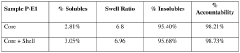

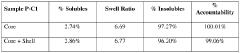

- A PMMA resin composition incorporating a methyl methacrylate polymer and a multistage acrylic impact modifier, comprising a core-shell polymer and an overpolymer, which improves impact strength while preserving gloss and melt flow.

Coloured composition with increased stress cracking resistance

PatentInactiveEP2150581A1

Innovation

- A colored composition comprising 50.0% to 99.5% by weight of at least one (meth)acrylate copolymer and 0.5% to 50.0% by weight of a copolymer obtained from polymerizing a monomer mixture of 70% to 92% vinyl aromatic monomers and 8% to 30% acrylonitrile, with specific properties to enhance stress cracking resistance, heat resistance, and optical stability.

Environmental Impact

The environmental impact of PMMA (Poly(methyl methacrylate)) in product customization is a crucial consideration for manufacturers and consumers alike. PMMA's unique properties contribute to both positive and negative environmental effects throughout its lifecycle. On the positive side, PMMA's durability and longevity can lead to reduced waste generation, as products made from this material tend to have extended lifespans. This durability also allows for the creation of customized products that can withstand various environmental conditions, potentially reducing the need for frequent replacements.

PMMA's recyclability is another significant factor in its environmental profile. The material can be recycled multiple times without significant loss of quality, which aligns well with circular economy principles. This recyclability supports the customization process by allowing manufacturers to repurpose unused or waste material into new, tailored products. Additionally, the energy required to recycle PMMA is typically lower than that needed for virgin material production, further reducing its environmental footprint.

However, the production of PMMA does have environmental drawbacks. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, contributing to greenhouse gas emissions and resource depletion. The customization of PMMA products may exacerbate these issues if it leads to increased production of small batches or one-off items, potentially reducing manufacturing efficiency and increasing waste.

The lightweight nature of PMMA can have both positive and negative environmental implications in the context of product customization. On one hand, it can lead to reduced transportation emissions when shipping customized products. On the other hand, this property might encourage the production of larger or more complex customized items, potentially offsetting the transportation benefits.

PMMA's resistance to weathering and UV radiation allows for the creation of durable outdoor customized products. This can reduce the environmental impact associated with frequent replacements of less durable materials. However, this same durability can be problematic if PMMA products are not properly disposed of or recycled, as they may persist in the environment for extended periods.

In conclusion, while PMMA offers significant advantages for product customization, its environmental impact is complex and multifaceted. Manufacturers must carefully consider the entire lifecycle of customized PMMA products, from production to disposal, to minimize negative environmental effects and maximize the material's sustainable potential.

PMMA's recyclability is another significant factor in its environmental profile. The material can be recycled multiple times without significant loss of quality, which aligns well with circular economy principles. This recyclability supports the customization process by allowing manufacturers to repurpose unused or waste material into new, tailored products. Additionally, the energy required to recycle PMMA is typically lower than that needed for virgin material production, further reducing its environmental footprint.

However, the production of PMMA does have environmental drawbacks. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, contributing to greenhouse gas emissions and resource depletion. The customization of PMMA products may exacerbate these issues if it leads to increased production of small batches or one-off items, potentially reducing manufacturing efficiency and increasing waste.

The lightweight nature of PMMA can have both positive and negative environmental implications in the context of product customization. On one hand, it can lead to reduced transportation emissions when shipping customized products. On the other hand, this property might encourage the production of larger or more complex customized items, potentially offsetting the transportation benefits.

PMMA's resistance to weathering and UV radiation allows for the creation of durable outdoor customized products. This can reduce the environmental impact associated with frequent replacements of less durable materials. However, this same durability can be problematic if PMMA products are not properly disposed of or recycled, as they may persist in the environment for extended periods.

In conclusion, while PMMA offers significant advantages for product customization, its environmental impact is complex and multifaceted. Manufacturers must carefully consider the entire lifecycle of customized PMMA products, from production to disposal, to minimize negative environmental effects and maximize the material's sustainable potential.

Regulatory Compliance

Regulatory compliance plays a crucial role in the use of PMMA for product customization across various industries. As a versatile thermoplastic, PMMA must adhere to stringent regulations to ensure safety, quality, and environmental sustainability in its applications.

In the medical and healthcare sector, PMMA-based products must comply with FDA regulations in the United States and similar regulatory bodies worldwide. These regulations cover aspects such as biocompatibility, sterilization processes, and material purity. For instance, PMMA used in dental implants or intraocular lenses must meet specific standards to ensure patient safety and product efficacy.

The automotive industry utilizes PMMA in various components, including lighting systems and interior parts. Regulatory compliance in this sector focuses on safety standards, such as impact resistance and light transmission properties. PMMA products must meet regulations like FMVSS (Federal Motor Vehicle Safety Standards) in the US or ECE regulations in Europe.

In the construction and architecture field, PMMA is subject to building codes and fire safety regulations. These regulations often specify requirements for flame retardancy, smoke emission, and structural integrity. Compliance with standards like ASTM International or European EN standards is essential for PMMA products used in windows, skylights, or decorative panels.

The food packaging industry employs PMMA in various applications, necessitating compliance with food contact material regulations. In the EU, for example, PMMA must adhere to Regulation (EC) No 1935/2004 and specific migration limits for monomers and additives. Similar regulations exist in other regions, ensuring the safety of PMMA-based food packaging.

Environmental regulations also impact PMMA product customization. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, affecting the manufacturing processes and formulations of PMMA products. Additionally, regulations promoting recycling and waste reduction influence the design and end-of-life considerations for PMMA-based items.

As product customization often involves unique designs and manufacturing processes, companies must ensure that their PMMA products comply with relevant regulations throughout the entire product lifecycle. This includes considerations for raw material sourcing, production methods, quality control, and disposal or recycling.

To maintain regulatory compliance while leveraging PMMA's properties for product customization, manufacturers must stay informed about evolving regulations across different markets and industries. Implementing robust quality management systems and conducting regular compliance audits are essential practices to ensure adherence to regulatory requirements while maximizing the potential for product innovation and customization using PMMA.

In the medical and healthcare sector, PMMA-based products must comply with FDA regulations in the United States and similar regulatory bodies worldwide. These regulations cover aspects such as biocompatibility, sterilization processes, and material purity. For instance, PMMA used in dental implants or intraocular lenses must meet specific standards to ensure patient safety and product efficacy.

The automotive industry utilizes PMMA in various components, including lighting systems and interior parts. Regulatory compliance in this sector focuses on safety standards, such as impact resistance and light transmission properties. PMMA products must meet regulations like FMVSS (Federal Motor Vehicle Safety Standards) in the US or ECE regulations in Europe.

In the construction and architecture field, PMMA is subject to building codes and fire safety regulations. These regulations often specify requirements for flame retardancy, smoke emission, and structural integrity. Compliance with standards like ASTM International or European EN standards is essential for PMMA products used in windows, skylights, or decorative panels.

The food packaging industry employs PMMA in various applications, necessitating compliance with food contact material regulations. In the EU, for example, PMMA must adhere to Regulation (EC) No 1935/2004 and specific migration limits for monomers and additives. Similar regulations exist in other regions, ensuring the safety of PMMA-based food packaging.

Environmental regulations also impact PMMA product customization. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, affecting the manufacturing processes and formulations of PMMA products. Additionally, regulations promoting recycling and waste reduction influence the design and end-of-life considerations for PMMA-based items.

As product customization often involves unique designs and manufacturing processes, companies must ensure that their PMMA products comply with relevant regulations throughout the entire product lifecycle. This includes considerations for raw material sourcing, production methods, quality control, and disposal or recycling.

To maintain regulatory compliance while leveraging PMMA's properties for product customization, manufacturers must stay informed about evolving regulations across different markets and industries. Implementing robust quality management systems and conducting regular compliance audits are essential practices to ensure adherence to regulatory requirements while maximizing the potential for product innovation and customization using PMMA.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!