Mechanical Enhancement Strategies for PMMA Products

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Mechanical Properties Evolution

The evolution of PMMA's mechanical properties has been a journey of continuous improvement and innovation since its discovery in the 1930s. Initially, PMMA was valued for its optical clarity and weather resistance, but its mechanical properties were limited compared to other engineering plastics. Over the decades, researchers and engineers have focused on enhancing its strength, impact resistance, and overall durability.

In the 1950s and 1960s, the focus was primarily on improving the basic formulation of PMMA. Scientists experimented with different polymerization techniques and additives to increase the molecular weight and cross-linking density of the polymer. These efforts resulted in PMMA grades with improved tensile strength and modulus of elasticity, making it more suitable for structural applications.

The 1970s and 1980s saw a shift towards developing impact-modified PMMA. By incorporating rubber particles into the PMMA matrix, researchers were able to significantly enhance the material's impact resistance without substantially compromising its optical properties. This breakthrough expanded PMMA's use in automotive and construction industries, where both clarity and toughness were required.

In the 1990s, the advent of nanotechnology opened new avenues for PMMA enhancement. Nanoparticle reinforcement became a key area of research, with materials such as silica, clay, and carbon nanotubes being incorporated into PMMA. These nanocomposites demonstrated remarkable improvements in mechanical properties, including increased tensile strength, modulus, and impact resistance.

The turn of the millennium brought about a focus on sustainable and bio-based approaches to PMMA modification. Researchers began exploring the use of natural fibers and bio-derived additives to enhance PMMA's properties while reducing its environmental footprint. This trend aligns with the growing demand for eco-friendly materials in various industries.

Recent years have seen advancements in surface modification techniques for PMMA. Plasma treatment, UV grafting, and other surface functionalization methods have been developed to improve the material's adhesion properties, wear resistance, and compatibility with other materials in composite structures.

The ongoing evolution of PMMA's mechanical properties continues to be driven by emerging technologies and changing market demands. Current research is exploring the potential of smart PMMA composites with self-healing capabilities and responsive mechanical properties. Additionally, there is a growing interest in developing PMMA formulations tailored for additive manufacturing processes, which require specific mechanical characteristics to ensure printability and final part performance.

In the 1950s and 1960s, the focus was primarily on improving the basic formulation of PMMA. Scientists experimented with different polymerization techniques and additives to increase the molecular weight and cross-linking density of the polymer. These efforts resulted in PMMA grades with improved tensile strength and modulus of elasticity, making it more suitable for structural applications.

The 1970s and 1980s saw a shift towards developing impact-modified PMMA. By incorporating rubber particles into the PMMA matrix, researchers were able to significantly enhance the material's impact resistance without substantially compromising its optical properties. This breakthrough expanded PMMA's use in automotive and construction industries, where both clarity and toughness were required.

In the 1990s, the advent of nanotechnology opened new avenues for PMMA enhancement. Nanoparticle reinforcement became a key area of research, with materials such as silica, clay, and carbon nanotubes being incorporated into PMMA. These nanocomposites demonstrated remarkable improvements in mechanical properties, including increased tensile strength, modulus, and impact resistance.

The turn of the millennium brought about a focus on sustainable and bio-based approaches to PMMA modification. Researchers began exploring the use of natural fibers and bio-derived additives to enhance PMMA's properties while reducing its environmental footprint. This trend aligns with the growing demand for eco-friendly materials in various industries.

Recent years have seen advancements in surface modification techniques for PMMA. Plasma treatment, UV grafting, and other surface functionalization methods have been developed to improve the material's adhesion properties, wear resistance, and compatibility with other materials in composite structures.

The ongoing evolution of PMMA's mechanical properties continues to be driven by emerging technologies and changing market demands. Current research is exploring the potential of smart PMMA composites with self-healing capabilities and responsive mechanical properties. Additionally, there is a growing interest in developing PMMA formulations tailored for additive manufacturing processes, which require specific mechanical characteristics to ensure printability and final part performance.

Market Demand for Enhanced PMMA

The market demand for enhanced PMMA (Polymethyl Methacrylate) products has been steadily growing across various industries due to the material's unique properties and versatility. PMMA, also known as acrylic, is valued for its optical clarity, weather resistance, and lightweight nature. However, its mechanical properties, particularly impact strength and scratch resistance, have been areas of concern for many applications.

In the automotive sector, there is a significant demand for enhanced PMMA products. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, PMMA is increasingly being used as a replacement for glass in windows, headlights, and interior components. The market requires PMMA with improved impact resistance to meet safety standards and enhanced scratch resistance to maintain clarity over time.

The construction industry represents another major market for enhanced PMMA products. The material is widely used in skylights, windows, and architectural panels. Builders and architects are seeking PMMA products with increased durability and weather resistance to withstand harsh environmental conditions and maintain aesthetic appeal for longer periods.

In the electronics and display industry, there is a growing demand for PMMA with enhanced mechanical properties. As consumer electronics become more portable and prone to drops and scratches, manufacturers are looking for PMMA formulations that can provide better protection for screens and device housings while maintaining optical clarity.

The medical device sector also presents a significant market opportunity for enhanced PMMA. The material is used in various medical applications, including implants, surgical instruments, and diagnostic equipment. There is a demand for PMMA products with improved biocompatibility, wear resistance, and mechanical strength to ensure long-term performance in the human body.

The aerospace industry is another sector driving demand for mechanically enhanced PMMA. The material is used in aircraft windows and cockpit displays, where impact resistance and optical clarity are critical. Enhanced PMMA products that can withstand high-altitude conditions and provide better protection against bird strikes are highly sought after.

Market research indicates that the global PMMA market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to the demand for enhanced mechanical properties. Manufacturers are investing in research and development to meet these market needs, focusing on strategies such as polymer blending, nanocomposite incorporation, and surface modification techniques.

As sustainability becomes increasingly important, there is also a growing demand for enhanced PMMA products that are recyclable or bio-based. This trend is driving innovation in the development of mechanically robust PMMA alternatives that have a reduced environmental impact.

In the automotive sector, there is a significant demand for enhanced PMMA products. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, PMMA is increasingly being used as a replacement for glass in windows, headlights, and interior components. The market requires PMMA with improved impact resistance to meet safety standards and enhanced scratch resistance to maintain clarity over time.

The construction industry represents another major market for enhanced PMMA products. The material is widely used in skylights, windows, and architectural panels. Builders and architects are seeking PMMA products with increased durability and weather resistance to withstand harsh environmental conditions and maintain aesthetic appeal for longer periods.

In the electronics and display industry, there is a growing demand for PMMA with enhanced mechanical properties. As consumer electronics become more portable and prone to drops and scratches, manufacturers are looking for PMMA formulations that can provide better protection for screens and device housings while maintaining optical clarity.

The medical device sector also presents a significant market opportunity for enhanced PMMA. The material is used in various medical applications, including implants, surgical instruments, and diagnostic equipment. There is a demand for PMMA products with improved biocompatibility, wear resistance, and mechanical strength to ensure long-term performance in the human body.

The aerospace industry is another sector driving demand for mechanically enhanced PMMA. The material is used in aircraft windows and cockpit displays, where impact resistance and optical clarity are critical. Enhanced PMMA products that can withstand high-altitude conditions and provide better protection against bird strikes are highly sought after.

Market research indicates that the global PMMA market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to the demand for enhanced mechanical properties. Manufacturers are investing in research and development to meet these market needs, focusing on strategies such as polymer blending, nanocomposite incorporation, and surface modification techniques.

As sustainability becomes increasingly important, there is also a growing demand for enhanced PMMA products that are recyclable or bio-based. This trend is driving innovation in the development of mechanically robust PMMA alternatives that have a reduced environmental impact.

Current Challenges in PMMA Strength

Despite its widespread use in various industries, Poly(methyl methacrylate) (PMMA) faces significant challenges in terms of mechanical strength, limiting its application in high-stress environments. One of the primary issues is its inherent brittleness, which makes PMMA products susceptible to cracking and fracturing under impact or sudden stress. This characteristic severely restricts its use in applications requiring high impact resistance or durability.

Another major challenge is PMMA's relatively low tensile strength compared to other engineering plastics. This limitation affects its performance in load-bearing applications and reduces its suitability for structural components. The material's low scratch resistance is also a concern, particularly in optical and aesthetic applications where surface quality is crucial.

PMMA's poor heat resistance poses challenges in high-temperature environments. The material tends to soften and deform at temperatures above its glass transition point, which is relatively low compared to other thermoplastics. This thermal sensitivity limits its use in applications exposed to elevated temperatures or thermal cycling.

The material's susceptibility to environmental stress cracking (ESC) is another significant issue. When exposed to certain chemicals or under sustained stress, PMMA can develop microscopic cracks that propagate over time, leading to premature failure. This phenomenon is particularly problematic in outdoor applications or in environments where the material may come into contact with various solvents or cleaning agents.

PMMA's low wear resistance is a challenge in applications involving frequent friction or abrasion. This property limits its use in moving parts or in environments where surface degradation could compromise functionality or aesthetics. Additionally, the material's poor chemical resistance to certain solvents and acids restricts its application in chemical processing or laboratory environments.

The limited UV resistance of standard PMMA formulations is another area of concern, especially for outdoor applications. Prolonged exposure to sunlight can lead to yellowing, embrittlement, and degradation of mechanical properties, affecting both the appearance and performance of PMMA products over time.

Addressing these challenges requires innovative approaches in material science and engineering. Researchers and manufacturers are exploring various strategies to enhance PMMA's mechanical properties, including the development of composite materials, surface treatments, and novel polymerization techniques. The goal is to create PMMA-based products that maintain the material's desirable properties while overcoming its current limitations in strength and durability.

Another major challenge is PMMA's relatively low tensile strength compared to other engineering plastics. This limitation affects its performance in load-bearing applications and reduces its suitability for structural components. The material's low scratch resistance is also a concern, particularly in optical and aesthetic applications where surface quality is crucial.

PMMA's poor heat resistance poses challenges in high-temperature environments. The material tends to soften and deform at temperatures above its glass transition point, which is relatively low compared to other thermoplastics. This thermal sensitivity limits its use in applications exposed to elevated temperatures or thermal cycling.

The material's susceptibility to environmental stress cracking (ESC) is another significant issue. When exposed to certain chemicals or under sustained stress, PMMA can develop microscopic cracks that propagate over time, leading to premature failure. This phenomenon is particularly problematic in outdoor applications or in environments where the material may come into contact with various solvents or cleaning agents.

PMMA's low wear resistance is a challenge in applications involving frequent friction or abrasion. This property limits its use in moving parts or in environments where surface degradation could compromise functionality or aesthetics. Additionally, the material's poor chemical resistance to certain solvents and acids restricts its application in chemical processing or laboratory environments.

The limited UV resistance of standard PMMA formulations is another area of concern, especially for outdoor applications. Prolonged exposure to sunlight can lead to yellowing, embrittlement, and degradation of mechanical properties, affecting both the appearance and performance of PMMA products over time.

Addressing these challenges requires innovative approaches in material science and engineering. Researchers and manufacturers are exploring various strategies to enhance PMMA's mechanical properties, including the development of composite materials, surface treatments, and novel polymerization techniques. The goal is to create PMMA-based products that maintain the material's desirable properties while overcoming its current limitations in strength and durability.

Existing PMMA Reinforcement Methods

01 Improving mechanical properties of PMMA products

Various methods are employed to enhance the mechanical properties of PMMA products, including the incorporation of additives, modification of the polymer structure, and optimization of processing conditions. These techniques aim to improve strength, durability, and impact resistance of PMMA-based materials for diverse applications.- Improving mechanical properties of PMMA products: Various methods are employed to enhance the mechanical properties of PMMA products, including the incorporation of additives, modification of the polymer structure, and optimization of processing conditions. These techniques aim to improve strength, durability, and impact resistance of PMMA-based materials for diverse applications.

- PMMA composites for enhanced mechanical performance: PMMA composites are developed by combining PMMA with other materials such as nanoparticles, fibers, or other polymers. These composites often exhibit superior mechanical properties compared to pure PMMA, including improved tensile strength, flexural modulus, and impact resistance.

- Surface treatment and coating of PMMA products: Surface treatments and coatings are applied to PMMA products to enhance their mechanical properties, particularly scratch resistance and durability. These techniques can include chemical treatments, plasma treatments, or the application of protective coatings to improve the overall performance of PMMA surfaces.

- Optimization of PMMA processing techniques: Various processing techniques are optimized to improve the mechanical properties of PMMA products. These include modifications to injection molding, extrusion, and thermoforming processes, as well as the development of novel fabrication methods to enhance the structural integrity and performance of PMMA-based materials.

- Characterization and testing of PMMA mechanical properties: Advanced characterization and testing methods are employed to assess and analyze the mechanical properties of PMMA products. These techniques include various stress tests, impact resistance evaluations, and microscopic analyses to understand and improve the performance of PMMA materials in different applications.

02 PMMA composites for enhanced performance

PMMA composites are developed by combining PMMA with other materials such as nanoparticles, fibers, or other polymers. These composites often exhibit superior mechanical properties compared to pure PMMA, including improved tensile strength, flexural modulus, and impact resistance.Expand Specific Solutions03 Surface treatment and coating of PMMA products

Surface treatments and coatings are applied to PMMA products to enhance their mechanical properties. These processes can improve scratch resistance, hardness, and durability of the surface while maintaining the optical clarity and other desirable properties of PMMA.Expand Specific Solutions04 PMMA blends for tailored mechanical properties

PMMA is blended with other polymers to create materials with customized mechanical properties. These blends can combine the advantageous properties of multiple polymers, resulting in products with improved impact resistance, flexibility, or heat resistance while retaining PMMA's optical clarity.Expand Specific Solutions05 Processing techniques for optimized PMMA properties

Advanced processing techniques are developed to optimize the mechanical properties of PMMA products. These may include specialized molding processes, heat treatments, or orientation techniques that enhance the material's strength, toughness, and dimensional stability.Expand Specific Solutions

Key Players in PMMA Industry

The mechanical enhancement of PMMA products is in a mature development stage, with a significant market size due to PMMA's widespread applications in various industries. The technology's maturity is evident from the involvement of established players like Röhm GmbH, a leading PMMA manufacturer, and Wanhua Chemical Group, known for its chemical innovations. Companies such as Shanghai PRET Composites and Zhejiang Pret Advanced Materials are actively developing advanced polymer composites, indicating ongoing research to improve PMMA's mechanical properties. The presence of academic institutions like Zhejiang University and Sichuan University in this field suggests a strong focus on research and development, driving further advancements in PMMA enhancement strategies.

Röhm GmbH

Technical Solution: Röhm GmbH, a global leader in PMMA production, has developed advanced mechanical enhancement strategies for PMMA products. Their approach includes the incorporation of nanoparticles to improve impact resistance and scratch resistance[1]. They have also implemented a proprietary cross-linking technology that enhances the material's heat resistance and dimensional stability[2]. Additionally, Röhm has developed a surface modification technique that improves the adhesion properties of PMMA, making it more suitable for composite applications[3]. Their research has also focused on optimizing the molecular weight distribution of PMMA to achieve a balance between processability and mechanical strength[4].

Strengths: Extensive experience in PMMA production, strong R&D capabilities, and a wide range of enhancement techniques. Weaknesses: Potential higher costs associated with advanced technologies and the need for specialized equipment for some enhancement processes.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed innovative strategies for enhancing PMMA products. Their research focuses on the development of advanced processing techniques, including reactive extrusion and in-situ polymerization, to create PMMA-based nanocomposites with improved mechanical properties[16]. They have also explored the use of supercritical fluid technology for the production of PMMA microspheres with controlled morphology and enhanced mechanical strength[17]. Additionally, the institute has made significant progress in the development of PMMA-based shape memory polymers, incorporating novel cross-linking agents and nanofillers to achieve improved shape recovery and mechanical properties[18]. Their work also extends to the modification of PMMA surfaces using plasma treatment and grafting techniques to enhance adhesion and biocompatibility[19].

Strengths: Strong focus on advanced processing techniques, expertise in nanocomposite development, and access to state-of-the-art research facilities. Weaknesses: Potential challenges in scaling up laboratory-scale processes to industrial production and navigating intellectual property issues in international collaborations.

Innovative PMMA Strengthening Techniques

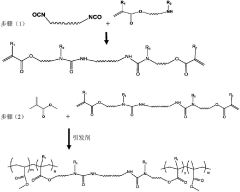

Preparation method of partially crosslinked PMMA (polymethyl methacrylate) and composite material thereof

PatentActiveCN115785328A

Innovation

- Using the preparation method of partially cross-linked PMMA, an intermediate product is generated through the polyurea reaction of diisocyanate and hindered amine acrylate, and then undergoes free radical copolymerization with MMA monomer to form partially cross-linked PMMA, thereby enhancing the cross-linking degree of its molecular chain. , thereby improving tensile strength and toughness.

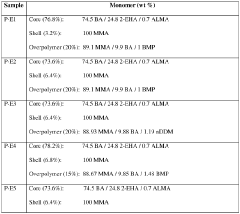

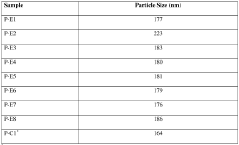

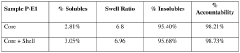

Poly(methyl methacrylate) resin composition

PatentWO2019018219A1

Innovation

- A PMMA resin composition incorporating a methyl methacrylate polymer and a multistage acrylic impact modifier, comprising a core-shell polymer and an overpolymer, which improves impact strength while preserving gloss and melt flow.

Environmental Impact of PMMA Enhancements

The environmental impact of mechanical enhancement strategies for PMMA products is a critical consideration in the development and implementation of these techniques. As PMMA (polymethyl methacrylate) is widely used in various industries, including automotive, construction, and electronics, the environmental consequences of its enhancement processes must be carefully evaluated.

One of the primary environmental concerns associated with PMMA enhancement is the potential release of volatile organic compounds (VOCs) during manufacturing and processing. Many mechanical enhancement techniques involve the use of solvents or chemical additives, which can contribute to air pollution and pose health risks to workers and surrounding communities. Efforts to mitigate these impacts have led to the development of low-VOC and water-based enhancement methods, which significantly reduce emissions while maintaining product performance.

Energy consumption is another crucial factor in assessing the environmental impact of PMMA enhancements. Some mechanical enhancement processes, such as heat treatment or precision machining, require substantial energy inputs. This increased energy demand can lead to higher greenhouse gas emissions if the energy source is not renewable. However, advancements in energy-efficient manufacturing technologies and the adoption of renewable energy sources in production facilities are helping to address this concern.

The disposal and recyclability of enhanced PMMA products also play a significant role in their overall environmental footprint. While PMMA is generally recyclable, certain enhancement techniques may introduce additives or modify the material structure in ways that complicate the recycling process. Research is ongoing to develop enhancement strategies that maintain or improve the recyclability of PMMA, ensuring that these products can be effectively reprocessed at the end of their lifecycle.

Water usage and potential water pollution are additional environmental considerations in PMMA enhancement processes. Some techniques may require significant amounts of water for cooling or cleaning, and there is a risk of contaminating water sources with chemical residues. Implementing closed-loop water systems and developing water-efficient enhancement methods are key strategies for minimizing these impacts.

The durability and lifespan of enhanced PMMA products also have indirect environmental implications. By improving the mechanical properties and resistance to wear and degradation, these enhancements can extend the useful life of PMMA products. This longevity reduces the need for frequent replacements, potentially decreasing overall material consumption and waste generation in the long term.

As sustainability becomes an increasingly important factor in product development and consumer choice, the environmental impact of PMMA enhancements is likely to drive innovation in this field. Future research and development efforts are expected to focus on creating enhancement strategies that not only improve mechanical properties but also minimize environmental footprint throughout the product lifecycle.

One of the primary environmental concerns associated with PMMA enhancement is the potential release of volatile organic compounds (VOCs) during manufacturing and processing. Many mechanical enhancement techniques involve the use of solvents or chemical additives, which can contribute to air pollution and pose health risks to workers and surrounding communities. Efforts to mitigate these impacts have led to the development of low-VOC and water-based enhancement methods, which significantly reduce emissions while maintaining product performance.

Energy consumption is another crucial factor in assessing the environmental impact of PMMA enhancements. Some mechanical enhancement processes, such as heat treatment or precision machining, require substantial energy inputs. This increased energy demand can lead to higher greenhouse gas emissions if the energy source is not renewable. However, advancements in energy-efficient manufacturing technologies and the adoption of renewable energy sources in production facilities are helping to address this concern.

The disposal and recyclability of enhanced PMMA products also play a significant role in their overall environmental footprint. While PMMA is generally recyclable, certain enhancement techniques may introduce additives or modify the material structure in ways that complicate the recycling process. Research is ongoing to develop enhancement strategies that maintain or improve the recyclability of PMMA, ensuring that these products can be effectively reprocessed at the end of their lifecycle.

Water usage and potential water pollution are additional environmental considerations in PMMA enhancement processes. Some techniques may require significant amounts of water for cooling or cleaning, and there is a risk of contaminating water sources with chemical residues. Implementing closed-loop water systems and developing water-efficient enhancement methods are key strategies for minimizing these impacts.

The durability and lifespan of enhanced PMMA products also have indirect environmental implications. By improving the mechanical properties and resistance to wear and degradation, these enhancements can extend the useful life of PMMA products. This longevity reduces the need for frequent replacements, potentially decreasing overall material consumption and waste generation in the long term.

As sustainability becomes an increasingly important factor in product development and consumer choice, the environmental impact of PMMA enhancements is likely to drive innovation in this field. Future research and development efforts are expected to focus on creating enhancement strategies that not only improve mechanical properties but also minimize environmental footprint throughout the product lifecycle.

PMMA Standards and Regulations

The regulatory landscape for PMMA (Polymethyl Methacrylate) products is complex and multifaceted, encompassing various standards and regulations across different regions and applications. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PMMA products used in medical applications, such as intraocular lenses and bone cement. The FDA's 21 CFR Part 888 specifically addresses orthopedic devices, including PMMA-based bone cement, outlining requirements for safety and effectiveness.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to PMMA products. ISO 527 series standards are particularly important for determining the tensile properties of plastics, including PMMA. These standards provide guidelines for test specimen preparation, testing conditions, and data interpretation, ensuring consistency in mechanical property evaluation across different manufacturers and laboratories.

In the European Union, PMMA products must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. This comprehensive framework aims to protect human health and the environment from the risks posed by chemicals. Manufacturers and importers of PMMA products must register their substances with the European Chemicals Agency (ECHA) and provide safety information.

For construction applications, the European Standard EN 16240 specifically addresses light transmitting flat solid polycarbonate (PC) sheets for internal and external use in roofs, walls, and ceilings. While this standard primarily focuses on PC, it also includes provisions for PMMA sheets, setting requirements for optical, mechanical, and thermal properties.

In the automotive industry, PMMA products must meet stringent safety and performance standards. The United Nations Economic Commission for Europe (UNECE) Regulation No. 43 sets requirements for safety glazing materials, including those made from PMMA. This regulation specifies tests for optical properties, impact resistance, and environmental durability.

The American Society for Testing and Materials (ASTM) has developed several standards relevant to PMMA products. ASTM D638 is widely used for testing the tensile properties of plastics, including PMMA. Additionally, ASTM D790 provides a standard test method for flexural properties, which is crucial for assessing the mechanical performance of PMMA products under bending loads.

Compliance with these standards and regulations is essential for manufacturers seeking to enhance the mechanical properties of PMMA products. Adherence ensures product safety, reliability, and market acceptance across various industries and geographical regions. As mechanical enhancement strategies are developed, they must be evaluated and validated within the framework of these established standards to ensure regulatory compliance and product performance.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to PMMA products. ISO 527 series standards are particularly important for determining the tensile properties of plastics, including PMMA. These standards provide guidelines for test specimen preparation, testing conditions, and data interpretation, ensuring consistency in mechanical property evaluation across different manufacturers and laboratories.

In the European Union, PMMA products must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. This comprehensive framework aims to protect human health and the environment from the risks posed by chemicals. Manufacturers and importers of PMMA products must register their substances with the European Chemicals Agency (ECHA) and provide safety information.

For construction applications, the European Standard EN 16240 specifically addresses light transmitting flat solid polycarbonate (PC) sheets for internal and external use in roofs, walls, and ceilings. While this standard primarily focuses on PC, it also includes provisions for PMMA sheets, setting requirements for optical, mechanical, and thermal properties.

In the automotive industry, PMMA products must meet stringent safety and performance standards. The United Nations Economic Commission for Europe (UNECE) Regulation No. 43 sets requirements for safety glazing materials, including those made from PMMA. This regulation specifies tests for optical properties, impact resistance, and environmental durability.

The American Society for Testing and Materials (ASTM) has developed several standards relevant to PMMA products. ASTM D638 is widely used for testing the tensile properties of plastics, including PMMA. Additionally, ASTM D790 provides a standard test method for flexural properties, which is crucial for assessing the mechanical performance of PMMA products under bending loads.

Compliance with these standards and regulations is essential for manufacturers seeking to enhance the mechanical properties of PMMA products. Adherence ensures product safety, reliability, and market acceptance across various industries and geographical regions. As mechanical enhancement strategies are developed, they must be evaluated and validated within the framework of these established standards to ensure regulatory compliance and product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!