How to Extend PMMA Applications in Biotechnology?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA in Biotech: Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a versatile material in various industries for decades. In recent years, its potential applications in biotechnology have garnered significant attention. The evolution of PMMA in biotechnology can be traced back to its initial use in medical devices and laboratory equipment due to its excellent optical properties and biocompatibility.

The primary objective of extending PMMA applications in biotechnology is to leverage its unique properties to develop innovative solutions for biomedical research, diagnostics, and therapeutic applications. PMMA's transparency, chemical resistance, and ease of fabrication make it an attractive material for microfluidic devices, biosensors, and cell culture platforms. These characteristics align well with the growing demand for miniaturized and high-throughput systems in biotechnology.

As the field of biotechnology continues to advance, there is an increasing need for materials that can meet the stringent requirements of biomedical applications. PMMA's potential to be functionalized and modified opens up new possibilities for creating tailored surfaces and structures suitable for specific biological interactions. This adaptability positions PMMA as a promising candidate for addressing various challenges in biotechnology, from drug delivery systems to tissue engineering scaffolds.

The current technological landscape shows a growing interest in PMMA-based solutions for point-of-care diagnostics, organ-on-a-chip devices, and bioprinting applications. These emerging trends highlight the material's versatility and its potential to contribute to the development of next-generation biotechnology tools and platforms. As researchers and industry professionals explore new ways to harness PMMA's properties, the material is poised to play a crucial role in advancing biotechnological innovations.

To fully realize the potential of PMMA in biotechnology, it is essential to address existing limitations and explore novel fabrication techniques. This includes improving the material's surface properties for enhanced cell adhesion, developing methods for precise micro- and nano-scale patterning, and investigating biocompatible modifications to expand its functionality. By overcoming these challenges, PMMA can become an even more valuable resource in the biotechnology sector, enabling the creation of sophisticated devices and materials that push the boundaries of current capabilities.

The primary objective of extending PMMA applications in biotechnology is to leverage its unique properties to develop innovative solutions for biomedical research, diagnostics, and therapeutic applications. PMMA's transparency, chemical resistance, and ease of fabrication make it an attractive material for microfluidic devices, biosensors, and cell culture platforms. These characteristics align well with the growing demand for miniaturized and high-throughput systems in biotechnology.

As the field of biotechnology continues to advance, there is an increasing need for materials that can meet the stringent requirements of biomedical applications. PMMA's potential to be functionalized and modified opens up new possibilities for creating tailored surfaces and structures suitable for specific biological interactions. This adaptability positions PMMA as a promising candidate for addressing various challenges in biotechnology, from drug delivery systems to tissue engineering scaffolds.

The current technological landscape shows a growing interest in PMMA-based solutions for point-of-care diagnostics, organ-on-a-chip devices, and bioprinting applications. These emerging trends highlight the material's versatility and its potential to contribute to the development of next-generation biotechnology tools and platforms. As researchers and industry professionals explore new ways to harness PMMA's properties, the material is poised to play a crucial role in advancing biotechnological innovations.

To fully realize the potential of PMMA in biotechnology, it is essential to address existing limitations and explore novel fabrication techniques. This includes improving the material's surface properties for enhanced cell adhesion, developing methods for precise micro- and nano-scale patterning, and investigating biocompatible modifications to expand its functionality. By overcoming these challenges, PMMA can become an even more valuable resource in the biotechnology sector, enabling the creation of sophisticated devices and materials that push the boundaries of current capabilities.

Biotech Market Demand for PMMA

The biotech market demand for PMMA (Poly(methyl methacrylate)) has been steadily growing due to its unique properties and versatile applications in the biotechnology sector. PMMA's excellent optical clarity, biocompatibility, and ease of fabrication make it an attractive material for various biotech applications.

In the field of medical devices and diagnostics, PMMA is widely used for the production of microfluidic devices, lab-on-a-chip systems, and biosensors. These applications leverage PMMA's transparency and ability to be precisely molded or machined to create intricate microstructures. The global microfluidics market, where PMMA plays a significant role, is experiencing rapid growth, driven by the increasing demand for point-of-care diagnostics and personalized medicine.

PMMA's biocompatibility and durability have also led to its extensive use in orthopedic implants, particularly in bone cements for joint replacements. As the global population ages and the incidence of osteoarthritis and other joint disorders rises, the demand for PMMA-based bone cements is expected to increase substantially.

In the realm of cell culture and tissue engineering, PMMA is utilized for the fabrication of cell culture dishes, scaffolds, and bioreactors. Its optical clarity allows for easy observation of cell growth and behavior, while its surface can be modified to enhance cell adhesion and proliferation. The growing interest in regenerative medicine and 3D cell culture systems is likely to drive further demand for PMMA in these applications.

The dental industry represents another significant market for PMMA, where it is used in the production of dentures, temporary crowns, and orthodontic appliances. The rising prevalence of dental disorders and the increasing adoption of cosmetic dentistry procedures contribute to the growing demand for PMMA in this sector.

PMMA's potential in drug delivery systems is also gaining attention. Its ability to be formulated into nanoparticles or microspheres for controlled release of therapeutic agents opens up new possibilities in targeted drug delivery and sustained-release formulations. This application area is expected to see significant growth as pharmaceutical companies seek more efficient drug delivery methods.

The biotechnology research sector continues to be a steady consumer of PMMA products, including laboratory equipment, optical components for microscopy, and disposable labware. As research activities in genomics, proteomics, and other biotechnology fields expand, the demand for PMMA-based research tools is likely to increase.

While PMMA faces competition from other polymers and materials in some applications, its overall market demand in biotechnology remains robust. The material's versatility, coupled with ongoing research into surface modifications and composite formulations, suggests that PMMA will continue to find new applications and maintain its importance in the biotech industry.

In the field of medical devices and diagnostics, PMMA is widely used for the production of microfluidic devices, lab-on-a-chip systems, and biosensors. These applications leverage PMMA's transparency and ability to be precisely molded or machined to create intricate microstructures. The global microfluidics market, where PMMA plays a significant role, is experiencing rapid growth, driven by the increasing demand for point-of-care diagnostics and personalized medicine.

PMMA's biocompatibility and durability have also led to its extensive use in orthopedic implants, particularly in bone cements for joint replacements. As the global population ages and the incidence of osteoarthritis and other joint disorders rises, the demand for PMMA-based bone cements is expected to increase substantially.

In the realm of cell culture and tissue engineering, PMMA is utilized for the fabrication of cell culture dishes, scaffolds, and bioreactors. Its optical clarity allows for easy observation of cell growth and behavior, while its surface can be modified to enhance cell adhesion and proliferation. The growing interest in regenerative medicine and 3D cell culture systems is likely to drive further demand for PMMA in these applications.

The dental industry represents another significant market for PMMA, where it is used in the production of dentures, temporary crowns, and orthodontic appliances. The rising prevalence of dental disorders and the increasing adoption of cosmetic dentistry procedures contribute to the growing demand for PMMA in this sector.

PMMA's potential in drug delivery systems is also gaining attention. Its ability to be formulated into nanoparticles or microspheres for controlled release of therapeutic agents opens up new possibilities in targeted drug delivery and sustained-release formulations. This application area is expected to see significant growth as pharmaceutical companies seek more efficient drug delivery methods.

The biotechnology research sector continues to be a steady consumer of PMMA products, including laboratory equipment, optical components for microscopy, and disposable labware. As research activities in genomics, proteomics, and other biotechnology fields expand, the demand for PMMA-based research tools is likely to increase.

While PMMA faces competition from other polymers and materials in some applications, its overall market demand in biotechnology remains robust. The material's versatility, coupled with ongoing research into surface modifications and composite formulations, suggests that PMMA will continue to find new applications and maintain its importance in the biotech industry.

PMMA in Biotech: Current Status and Challenges

Poly(methyl methacrylate) (PMMA) has been widely used in various biomedical applications due to its excellent biocompatibility, optical clarity, and mechanical properties. However, the current status of PMMA in biotechnology faces several challenges that limit its broader adoption and potential applications.

One of the primary challenges is the limited surface functionality of PMMA. While it possesses good biocompatibility, its hydrophobic nature can hinder cell adhesion and protein adsorption, which are crucial for many biotechnological applications. This limitation has led researchers to explore various surface modification techniques to enhance PMMA's functionality in biological environments.

Another significant challenge is the need for improved mechanical properties in certain biotech applications. Although PMMA exhibits good rigidity and optical clarity, it may lack the necessary flexibility or strength required for specific biomedical devices or tissue engineering scaffolds. This has prompted investigations into PMMA-based composites or copolymers to enhance its mechanical performance while maintaining its desirable characteristics.

The biocompatibility of PMMA, while generally good, still presents challenges in long-term implantation scenarios. Extended exposure to biological fluids can lead to degradation and potential release of monomers or additives, raising concerns about long-term safety and performance. Addressing these issues requires the development of more stable PMMA formulations or surface treatments that can withstand prolonged biological exposure.

In the realm of drug delivery, PMMA faces limitations in terms of drug loading capacity and controlled release profiles. Its relatively dense structure and hydrophobicity can restrict the incorporation and release of certain therapeutic agents, particularly hydrophilic drugs. Overcoming these barriers is essential for expanding PMMA's role in advanced drug delivery systems and personalized medicine applications.

The processing and fabrication of PMMA for complex biotech applications also present challenges. While PMMA is amenable to various manufacturing techniques, achieving precise micro- and nanostructures with high reproducibility remains difficult. This is particularly crucial for applications in microfluidics, biosensors, and organ-on-chip devices, where precise control over surface topography and channel dimensions is essential.

Lastly, the integration of PMMA with other materials and technologies in biotechnology poses challenges. Ensuring strong and stable interfaces between PMMA and other biomaterials, electronics, or sensing elements is critical for developing advanced biomedical devices and diagnostic platforms. Overcoming these integration challenges is key to realizing the full potential of PMMA in next-generation biotechnological applications.

One of the primary challenges is the limited surface functionality of PMMA. While it possesses good biocompatibility, its hydrophobic nature can hinder cell adhesion and protein adsorption, which are crucial for many biotechnological applications. This limitation has led researchers to explore various surface modification techniques to enhance PMMA's functionality in biological environments.

Another significant challenge is the need for improved mechanical properties in certain biotech applications. Although PMMA exhibits good rigidity and optical clarity, it may lack the necessary flexibility or strength required for specific biomedical devices or tissue engineering scaffolds. This has prompted investigations into PMMA-based composites or copolymers to enhance its mechanical performance while maintaining its desirable characteristics.

The biocompatibility of PMMA, while generally good, still presents challenges in long-term implantation scenarios. Extended exposure to biological fluids can lead to degradation and potential release of monomers or additives, raising concerns about long-term safety and performance. Addressing these issues requires the development of more stable PMMA formulations or surface treatments that can withstand prolonged biological exposure.

In the realm of drug delivery, PMMA faces limitations in terms of drug loading capacity and controlled release profiles. Its relatively dense structure and hydrophobicity can restrict the incorporation and release of certain therapeutic agents, particularly hydrophilic drugs. Overcoming these barriers is essential for expanding PMMA's role in advanced drug delivery systems and personalized medicine applications.

The processing and fabrication of PMMA for complex biotech applications also present challenges. While PMMA is amenable to various manufacturing techniques, achieving precise micro- and nanostructures with high reproducibility remains difficult. This is particularly crucial for applications in microfluidics, biosensors, and organ-on-chip devices, where precise control over surface topography and channel dimensions is essential.

Lastly, the integration of PMMA with other materials and technologies in biotechnology poses challenges. Ensuring strong and stable interfaces between PMMA and other biomaterials, electronics, or sensing elements is critical for developing advanced biomedical devices and diagnostic platforms. Overcoming these integration challenges is key to realizing the full potential of PMMA in next-generation biotechnological applications.

Current PMMA Biotech Solutions

01 PMMA-based composite materials

PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and functionality. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for applications in industries such as automotive, construction, and electronics.- PMMA-based composite materials: PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for different applications.

- PMMA in optical and electronic applications: PMMA is widely used in optical and electronic applications due to its excellent light transmission properties and ease of processing. It is utilized in the production of lenses, displays, light guides, and other optical components for various devices and systems.

- PMMA-based coatings and surface treatments: PMMA is employed in the development of coatings and surface treatments to improve the properties of various substrates. These coatings can enhance scratch resistance, weatherability, and aesthetic appearance of materials used in automotive, construction, and consumer goods industries.

- PMMA in medical and dental applications: PMMA is extensively used in medical and dental fields for applications such as bone cements, dental prosthetics, and implants. Its biocompatibility and mechanical properties make it suitable for various medical devices and materials that come into contact with the human body.

- PMMA processing and manufacturing techniques: Various processing and manufacturing techniques are employed to produce PMMA-based products, including extrusion, injection molding, and 3D printing. These methods allow for the creation of complex shapes and structures, as well as the incorporation of additives to enhance specific properties of the final product.

02 PMMA in optical applications

PMMA is widely used in optical applications due to its excellent light transmission properties and ease of processing. It is employed in the manufacture of lenses, light guides, displays, and other optical components. Modifications to PMMA for optical uses often focus on improving clarity, UV resistance, and scratch resistance.Expand Specific Solutions03 PMMA in medical and dental applications

PMMA finds extensive use in medical and dental fields due to its biocompatibility and versatility. It is used in the production of dental prosthetics, bone cements, contact lenses, and various medical devices. Research in this area often focuses on improving biocompatibility, antimicrobial properties, and integration with biological tissues.Expand Specific Solutions04 PMMA processing and manufacturing techniques

Innovations in PMMA processing and manufacturing techniques aim to improve production efficiency, reduce costs, and enhance material properties. These advancements include new polymerization methods, extrusion techniques, molding processes, and surface treatments to tailor PMMA for specific applications.Expand Specific Solutions05 PMMA modifications for enhanced properties

Research focuses on modifying PMMA to enhance its properties such as impact resistance, thermal stability, and chemical resistance. This includes the development of PMMA copolymers, blends with other polymers, and the incorporation of additives to achieve desired characteristics for specific industrial applications.Expand Specific Solutions

Key Players in PMMA Biotech Industry

The biotechnology applications of PMMA are in a growth phase, with increasing market size and evolving technological maturity. The competitive landscape is characterized by a mix of academic institutions, established chemical companies, and specialized biotech firms. Universities like Tianjin University, Duke University, and Zhejiang University are driving fundamental research, while companies such as DuPont, Kingfa Sci. & Tech., and Bioretec are developing commercial applications. The market is seeing advancements in areas like biomedical materials, drug delivery systems, and tissue engineering. As the technology matures, collaborations between academia and industry are becoming more prevalent, accelerating innovation and commercialization in this promising field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel PMMA-based biocompatible material called Delrin® acetal homopolymer for medical applications. This material combines the durability of PMMA with enhanced biocompatibility, making it suitable for long-term implants and medical devices. The company has also introduced PMMA-based bone cements with improved mechanical properties and antibiotic-releasing capabilities for orthopedic applications[1][3]. Additionally, DuPont has explored the use of PMMA in microfluidic devices for biotechnology research, leveraging its optical clarity and ease of fabrication[5].

Strengths: Extensive R&D capabilities, diverse product portfolio, and established presence in the medical industry. Weaknesses: High production costs and potential regulatory challenges for new biomaterials.

Tecres SpA

Technical Solution: Tecres SpA has developed a proprietary PMMA-based bone cement technology called Cemex®. This technology incorporates antibiotics into the PMMA matrix, allowing for controlled release of antimicrobial agents to prevent post-operative infections in orthopedic surgeries. The company has also introduced a novel PMMA-based vertebroplasty cement with enhanced injectability and radiopacity for minimally invasive spine procedures[2]. Tecres has further expanded PMMA applications by developing custom-made PMMA spacers for two-stage revision surgeries in cases of prosthetic joint infections[4].

Strengths: Specialized expertise in orthopedic applications of PMMA, innovative drug delivery systems. Weaknesses: Limited diversification beyond orthopedic applications, potential for market saturation in niche areas.

Innovative PMMA Biotech Patents and Research

A method for the production of poly(methyl methacrylate) (PMMA) membranes and uses thereof

PatentInactiveEP3359285A1

Innovation

- A method for producing highly porous, symmetric reticulated PMMA membranes using a thin film casting and solvent removal process, combined with hydrophilization techniques, to create a composite membrane with enhanced capillary flow and protein binding capacity, overcoming the limitations of previous PMMA membrane production methods.

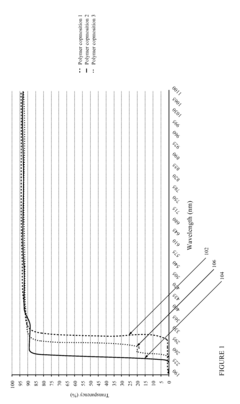

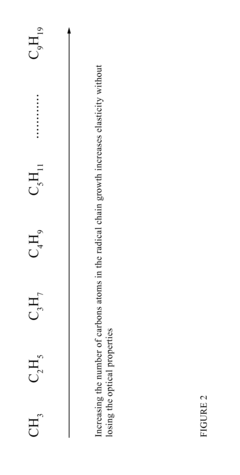

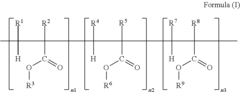

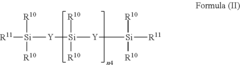

High-transparent, thermoplastically processible polymer compositions

PatentActiveUS20160168293A1

Innovation

- A high-transparent, thermoplastically processable polymer composition is developed, comprising acrylate copolymers blended with C1-C20 alcyl methacrylate, polysilicon, polycarbonate, and polyvinyl polymers, which allows for modification of properties through copolymerization, enhancing optical and mechanical characteristics without compromising transparency.

Regulatory Considerations for PMMA in Biotech

The regulatory landscape for PMMA applications in biotechnology is complex and multifaceted, requiring careful consideration of various guidelines and standards. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of PMMA in biomedical applications. The FDA categorizes PMMA-based products under different regulatory pathways depending on their intended use and risk profile.

For medical devices incorporating PMMA, manufacturers must comply with the FDA's Quality System Regulation (QSR) and obtain premarket approval (PMA) or 510(k) clearance, depending on the device classification. Class III devices, which pose the highest risk, typically require PMA, while Class II devices may be eligible for the less stringent 510(k) pathway.

In the European Union, PMMA-based products must adhere to the Medical Device Regulation (MDR) or In Vitro Diagnostic Regulation (IVDR), depending on their intended use. These regulations mandate comprehensive clinical evaluation, risk management, and post-market surveillance for PMMA-containing devices.

Biocompatibility testing is a critical aspect of regulatory compliance for PMMA in biotechnology. ISO 10993 series of standards provide guidelines for evaluating the biocompatibility of medical devices, including those containing PMMA. Manufacturers must conduct appropriate tests to assess cytotoxicity, sensitization, and irritation potential of PMMA-based products.

Environmental considerations also play a role in PMMA regulation. The disposal and recycling of PMMA products must comply with local and international environmental regulations. In some jurisdictions, there may be specific requirements for the handling and disposal of PMMA waste generated during manufacturing or clinical use.

As PMMA finds new applications in biotechnology, such as in microfluidic devices or biosensors, regulatory bodies may need to adapt their frameworks to address novel risks and benefits. Companies developing innovative PMMA-based technologies should engage early with regulatory authorities to navigate the evolving landscape and ensure compliance throughout the product lifecycle.

Intellectual property considerations are also crucial when extending PMMA applications in biotechnology. Manufacturers must conduct thorough patent searches and freedom-to-operate analyses to avoid infringing on existing patents while protecting their own innovations through strategic patent filings.

For medical devices incorporating PMMA, manufacturers must comply with the FDA's Quality System Regulation (QSR) and obtain premarket approval (PMA) or 510(k) clearance, depending on the device classification. Class III devices, which pose the highest risk, typically require PMA, while Class II devices may be eligible for the less stringent 510(k) pathway.

In the European Union, PMMA-based products must adhere to the Medical Device Regulation (MDR) or In Vitro Diagnostic Regulation (IVDR), depending on their intended use. These regulations mandate comprehensive clinical evaluation, risk management, and post-market surveillance for PMMA-containing devices.

Biocompatibility testing is a critical aspect of regulatory compliance for PMMA in biotechnology. ISO 10993 series of standards provide guidelines for evaluating the biocompatibility of medical devices, including those containing PMMA. Manufacturers must conduct appropriate tests to assess cytotoxicity, sensitization, and irritation potential of PMMA-based products.

Environmental considerations also play a role in PMMA regulation. The disposal and recycling of PMMA products must comply with local and international environmental regulations. In some jurisdictions, there may be specific requirements for the handling and disposal of PMMA waste generated during manufacturing or clinical use.

As PMMA finds new applications in biotechnology, such as in microfluidic devices or biosensors, regulatory bodies may need to adapt their frameworks to address novel risks and benefits. Companies developing innovative PMMA-based technologies should engage early with regulatory authorities to navigate the evolving landscape and ensure compliance throughout the product lifecycle.

Intellectual property considerations are also crucial when extending PMMA applications in biotechnology. Manufacturers must conduct thorough patent searches and freedom-to-operate analyses to avoid infringing on existing patents while protecting their own innovations through strategic patent filings.

Environmental Impact of PMMA in Biotech Applications

The environmental impact of PMMA (Polymethyl methacrylate) in biotechnology applications is a crucial consideration as the material's usage expands in this field. PMMA, known for its optical clarity and biocompatibility, has found increasing applications in biotech, from lab equipment to medical devices. However, its widespread use raises concerns about its environmental footprint throughout its lifecycle.

During production, PMMA manufacturing processes involve the use of petrochemicals and energy-intensive methods, contributing to carbon emissions and resource depletion. The polymerization of methyl methacrylate monomers requires careful handling of potentially hazardous chemicals, necessitating stringent safety measures to prevent environmental contamination.

In its use phase, PMMA demonstrates excellent durability and chemical resistance, which can be both an advantage and a drawback from an environmental perspective. While its longevity reduces the need for frequent replacements, it also means that PMMA products persist in the environment for extended periods when discarded improperly.

The disposal of PMMA-based biotech products presents significant challenges. Unlike some other plastics, PMMA is not biodegradable, leading to long-term accumulation in landfills or natural environments if not properly managed. Incineration of PMMA waste can release toxic substances, including methyl methacrylate monomers, potentially harming air quality and human health.

Recycling offers a potential solution to mitigate PMMA's environmental impact. The material can be depolymerized back into its monomer form, allowing for the production of new PMMA products. However, the recycling process for PMMA used in biotech applications faces unique challenges due to potential contamination with biological materials or hazardous substances.

To address these environmental concerns, the biotech industry is exploring several strategies. These include developing more sustainable production methods for PMMA, such as using renewable resources or improving energy efficiency in manufacturing processes. Additionally, there is a growing focus on designing PMMA-based products for easier disassembly and recycling at the end of their life cycle.

Research into biodegradable alternatives that mimic PMMA's desirable properties is also gaining traction. These efforts aim to create materials that maintain the optical and mechanical characteristics of PMMA while reducing its environmental persistence. However, ensuring these alternatives meet the stringent requirements for biotech applications remains a significant challenge.

As the biotech sector continues to expand its use of PMMA, implementing comprehensive lifecycle assessments becomes crucial. These assessments can help identify hotspots of environmental impact and guide the development of more sustainable practices throughout the material's lifecycle, from production to disposal or recycling.

During production, PMMA manufacturing processes involve the use of petrochemicals and energy-intensive methods, contributing to carbon emissions and resource depletion. The polymerization of methyl methacrylate monomers requires careful handling of potentially hazardous chemicals, necessitating stringent safety measures to prevent environmental contamination.

In its use phase, PMMA demonstrates excellent durability and chemical resistance, which can be both an advantage and a drawback from an environmental perspective. While its longevity reduces the need for frequent replacements, it also means that PMMA products persist in the environment for extended periods when discarded improperly.

The disposal of PMMA-based biotech products presents significant challenges. Unlike some other plastics, PMMA is not biodegradable, leading to long-term accumulation in landfills or natural environments if not properly managed. Incineration of PMMA waste can release toxic substances, including methyl methacrylate monomers, potentially harming air quality and human health.

Recycling offers a potential solution to mitigate PMMA's environmental impact. The material can be depolymerized back into its monomer form, allowing for the production of new PMMA products. However, the recycling process for PMMA used in biotech applications faces unique challenges due to potential contamination with biological materials or hazardous substances.

To address these environmental concerns, the biotech industry is exploring several strategies. These include developing more sustainable production methods for PMMA, such as using renewable resources or improving energy efficiency in manufacturing processes. Additionally, there is a growing focus on designing PMMA-based products for easier disassembly and recycling at the end of their life cycle.

Research into biodegradable alternatives that mimic PMMA's desirable properties is also gaining traction. These efforts aim to create materials that maintain the optical and mechanical characteristics of PMMA while reducing its environmental persistence. However, ensuring these alternatives meet the stringent requirements for biotech applications remains a significant challenge.

As the biotech sector continues to expand its use of PMMA, implementing comprehensive lifecycle assessments becomes crucial. These assessments can help identify hotspots of environmental impact and guide the development of more sustainable practices throughout the material's lifecycle, from production to disposal or recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!