PMMA Additives: Improving Functional Properties

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Additives Overview and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries for decades. Its exceptional optical clarity, weather resistance, and ease of processing have made it a preferred choice in applications ranging from automotive to construction. However, as technological demands evolve, there is an increasing need to enhance PMMA's functional properties to meet more stringent requirements and expand its applicability.

The field of PMMA additives has emerged as a critical area of research and development, aimed at improving the material's performance characteristics without compromising its inherent advantages. These additives are designed to address specific limitations of PMMA, such as its brittleness, low impact resistance, and susceptibility to certain chemicals. By incorporating carefully selected additives, researchers and manufacturers seek to create PMMA formulations with enhanced mechanical strength, improved thermal stability, increased UV resistance, and even novel functionalities like antimicrobial properties.

The evolution of PMMA additives has been driven by a combination of market demands and technological advancements. Early efforts focused primarily on impact modifiers to improve toughness, but the scope has since expanded to include a wide array of functional improvements. Recent trends in the development of PMMA additives include the exploration of nanocomposites, the integration of smart materials for responsive properties, and the pursuit of more environmentally friendly formulations.

The objectives of current research in PMMA additives are multifaceted. Firstly, there is a push to develop additives that can significantly enhance PMMA's mechanical properties, particularly its impact resistance and flexural strength, without sacrificing optical clarity. Secondly, researchers are working on additives that can improve PMMA's thermal stability and fire resistance, expanding its use in more demanding environments. Thirdly, there is growing interest in additives that can impart new functionalities to PMMA, such as self-healing capabilities or enhanced electrical conductivity.

Another key objective is the development of sustainable PMMA additives. This includes bio-based additives derived from renewable resources and additives that improve the recyclability of PMMA products. The goal is to align the material's performance enhancements with increasing environmental concerns and regulations.

As we delve deeper into the world of PMMA additives, it becomes clear that this field represents a convergence of polymer science, materials engineering, and chemical innovation. The ongoing research and development in this area hold the promise of not only improving existing PMMA applications but also opening up entirely new markets and possibilities for this versatile material.

The field of PMMA additives has emerged as a critical area of research and development, aimed at improving the material's performance characteristics without compromising its inherent advantages. These additives are designed to address specific limitations of PMMA, such as its brittleness, low impact resistance, and susceptibility to certain chemicals. By incorporating carefully selected additives, researchers and manufacturers seek to create PMMA formulations with enhanced mechanical strength, improved thermal stability, increased UV resistance, and even novel functionalities like antimicrobial properties.

The evolution of PMMA additives has been driven by a combination of market demands and technological advancements. Early efforts focused primarily on impact modifiers to improve toughness, but the scope has since expanded to include a wide array of functional improvements. Recent trends in the development of PMMA additives include the exploration of nanocomposites, the integration of smart materials for responsive properties, and the pursuit of more environmentally friendly formulations.

The objectives of current research in PMMA additives are multifaceted. Firstly, there is a push to develop additives that can significantly enhance PMMA's mechanical properties, particularly its impact resistance and flexural strength, without sacrificing optical clarity. Secondly, researchers are working on additives that can improve PMMA's thermal stability and fire resistance, expanding its use in more demanding environments. Thirdly, there is growing interest in additives that can impart new functionalities to PMMA, such as self-healing capabilities or enhanced electrical conductivity.

Another key objective is the development of sustainable PMMA additives. This includes bio-based additives derived from renewable resources and additives that improve the recyclability of PMMA products. The goal is to align the material's performance enhancements with increasing environmental concerns and regulations.

As we delve deeper into the world of PMMA additives, it becomes clear that this field represents a convergence of polymer science, materials engineering, and chemical innovation. The ongoing research and development in this area hold the promise of not only improving existing PMMA applications but also opening up entirely new markets and possibilities for this versatile material.

Market Analysis for Enhanced PMMA Products

The global market for enhanced PMMA products is experiencing significant growth, driven by increasing demand across various industries. PMMA, or polymethyl methacrylate, is a versatile thermoplastic known for its optical clarity, weather resistance, and durability. The addition of functional additives to PMMA has opened up new opportunities and applications, expanding its market potential.

The automotive sector represents a key driver for enhanced PMMA products. As vehicle manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions, PMMA with improved impact resistance and weatherability is gaining traction for use in exterior components, lighting systems, and interior trim. The growing trend towards electric and autonomous vehicles is expected to further boost demand for advanced PMMA formulations with enhanced properties.

In the construction industry, there is a rising demand for PMMA products with improved thermal insulation and UV resistance. These enhanced materials are increasingly used in windows, skylights, and architectural panels, offering better energy efficiency and longevity. The trend towards sustainable building practices is likely to accelerate the adoption of high-performance PMMA products in this sector.

The electronics and display market presents another significant opportunity for enhanced PMMA products. With the proliferation of smartphones, tablets, and other consumer electronics, there is a growing need for scratch-resistant, anti-glare, and optically clear PMMA formulations. The development of flexible displays and wearable devices is expected to drive further innovation in PMMA additives to meet the unique requirements of these applications.

Medical and healthcare applications are also contributing to the market growth of enhanced PMMA products. The material's biocompatibility and ability to be modified with antimicrobial additives make it attractive for use in medical devices, implants, and laboratory equipment. As the healthcare industry continues to evolve, the demand for specialized PMMA formulations with improved properties is likely to increase.

The packaging industry is another sector where enhanced PMMA products are gaining traction. PMMA with improved barrier properties and chemical resistance is being used in high-end cosmetic packaging, food containers, and pharmaceutical packaging. The trend towards sustainable and recyclable materials is driving research into bio-based additives for PMMA, potentially opening up new market segments.

Geographically, Asia-Pacific is expected to be the fastest-growing market for enhanced PMMA products, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on high-value applications in automotive, aerospace, and medical sectors.

The automotive sector represents a key driver for enhanced PMMA products. As vehicle manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions, PMMA with improved impact resistance and weatherability is gaining traction for use in exterior components, lighting systems, and interior trim. The growing trend towards electric and autonomous vehicles is expected to further boost demand for advanced PMMA formulations with enhanced properties.

In the construction industry, there is a rising demand for PMMA products with improved thermal insulation and UV resistance. These enhanced materials are increasingly used in windows, skylights, and architectural panels, offering better energy efficiency and longevity. The trend towards sustainable building practices is likely to accelerate the adoption of high-performance PMMA products in this sector.

The electronics and display market presents another significant opportunity for enhanced PMMA products. With the proliferation of smartphones, tablets, and other consumer electronics, there is a growing need for scratch-resistant, anti-glare, and optically clear PMMA formulations. The development of flexible displays and wearable devices is expected to drive further innovation in PMMA additives to meet the unique requirements of these applications.

Medical and healthcare applications are also contributing to the market growth of enhanced PMMA products. The material's biocompatibility and ability to be modified with antimicrobial additives make it attractive for use in medical devices, implants, and laboratory equipment. As the healthcare industry continues to evolve, the demand for specialized PMMA formulations with improved properties is likely to increase.

The packaging industry is another sector where enhanced PMMA products are gaining traction. PMMA with improved barrier properties and chemical resistance is being used in high-end cosmetic packaging, food containers, and pharmaceutical packaging. The trend towards sustainable and recyclable materials is driving research into bio-based additives for PMMA, potentially opening up new market segments.

Geographically, Asia-Pacific is expected to be the fastest-growing market for enhanced PMMA products, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on high-value applications in automotive, aerospace, and medical sectors.

Current PMMA Additive Technologies and Challenges

Poly(methyl methacrylate) (PMMA) is a versatile thermoplastic widely used in various industries due to its excellent optical properties, weatherability, and mechanical strength. However, to meet the ever-increasing demands of modern applications, researchers and manufacturers have been exploring various additive technologies to enhance PMMA's functional properties.

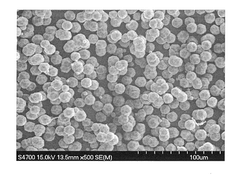

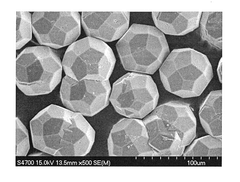

Currently, several additive technologies are employed to improve PMMA's performance. Impact modifiers, such as core-shell particles or acrylic-based elastomers, are commonly used to enhance the material's impact resistance and toughness. These additives create a network of stress-absorbing domains within the PMMA matrix, effectively dissipating impact energy and preventing crack propagation.

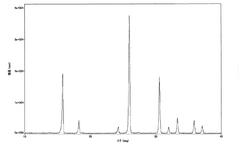

UV stabilizers and antioxidants are crucial additives for improving PMMA's weatherability and long-term durability. These compounds, including hindered amine light stabilizers (HALS) and benzotriazoles, protect the polymer from photo-oxidation and thermal degradation, extending its service life in outdoor applications.

To enhance PMMA's thermal properties, flame retardants such as phosphorus-based compounds or halogenated additives are incorporated. These additives work by interfering with the combustion process, reducing heat release, and promoting char formation, thereby improving the material's fire resistance.

Surface modifiers, including silicone-based additives or fluoropolymers, are utilized to impart hydrophobic or oleophobic properties to PMMA surfaces. These additives migrate to the surface during processing, creating a thin protective layer that enhances the material's water and oil repellency.

Despite these advancements, several challenges persist in PMMA additive technologies. One major issue is maintaining optical clarity while incorporating additives. Many additives, particularly those used for impact modification or flame retardancy, can compromise PMMA's transparency, limiting its use in optical applications.

Another challenge lies in achieving a balance between different property enhancements. For instance, improving impact resistance often comes at the cost of reduced stiffness or heat resistance. Finding the right combination of additives that synergistically enhance multiple properties without significant trade-offs remains a complex task.

The long-term stability and compatibility of additives with PMMA is another area of concern. Some additives may leach out or degrade over time, leading to a loss of enhanced properties. Ensuring the durability of additive effects throughout the material's lifecycle is crucial for maintaining consistent performance.

Furthermore, the increasing focus on sustainability and environmental regulations poses challenges for certain additive technologies. Traditional halogenated flame retardants, for example, face scrutiny due to environmental concerns, necessitating the development of more eco-friendly alternatives.

As the demand for high-performance PMMA continues to grow, addressing these challenges and developing innovative additive technologies remains a key focus for researchers and manufacturers in the polymer industry.

Currently, several additive technologies are employed to improve PMMA's performance. Impact modifiers, such as core-shell particles or acrylic-based elastomers, are commonly used to enhance the material's impact resistance and toughness. These additives create a network of stress-absorbing domains within the PMMA matrix, effectively dissipating impact energy and preventing crack propagation.

UV stabilizers and antioxidants are crucial additives for improving PMMA's weatherability and long-term durability. These compounds, including hindered amine light stabilizers (HALS) and benzotriazoles, protect the polymer from photo-oxidation and thermal degradation, extending its service life in outdoor applications.

To enhance PMMA's thermal properties, flame retardants such as phosphorus-based compounds or halogenated additives are incorporated. These additives work by interfering with the combustion process, reducing heat release, and promoting char formation, thereby improving the material's fire resistance.

Surface modifiers, including silicone-based additives or fluoropolymers, are utilized to impart hydrophobic or oleophobic properties to PMMA surfaces. These additives migrate to the surface during processing, creating a thin protective layer that enhances the material's water and oil repellency.

Despite these advancements, several challenges persist in PMMA additive technologies. One major issue is maintaining optical clarity while incorporating additives. Many additives, particularly those used for impact modification or flame retardancy, can compromise PMMA's transparency, limiting its use in optical applications.

Another challenge lies in achieving a balance between different property enhancements. For instance, improving impact resistance often comes at the cost of reduced stiffness or heat resistance. Finding the right combination of additives that synergistically enhance multiple properties without significant trade-offs remains a complex task.

The long-term stability and compatibility of additives with PMMA is another area of concern. Some additives may leach out or degrade over time, leading to a loss of enhanced properties. Ensuring the durability of additive effects throughout the material's lifecycle is crucial for maintaining consistent performance.

Furthermore, the increasing focus on sustainability and environmental regulations poses challenges for certain additive technologies. Traditional halogenated flame retardants, for example, face scrutiny due to environmental concerns, necessitating the development of more eco-friendly alternatives.

As the demand for high-performance PMMA continues to grow, addressing these challenges and developing innovative additive technologies remains a key focus for researchers and manufacturers in the polymer industry.

Existing PMMA Functional Property Enhancement Methods

01 Impact modifiers for PMMA

Additives are used to improve the impact resistance of PMMA. These modifiers typically include elastomeric particles or core-shell structures that can absorb and dissipate energy from impacts, enhancing the toughness and durability of PMMA-based materials.- Impact modifiers for PMMA: Additives are used to improve the impact resistance of PMMA. These modifiers can be core-shell particles or other elastomeric materials that enhance the toughness and durability of PMMA without significantly affecting its optical properties. The incorporation of these additives can result in PMMA with improved impact strength for various applications.

- Optical enhancers for PMMA: Certain additives are used to enhance the optical properties of PMMA. These can include light diffusers, UV stabilizers, or fluorescent dyes. Such additives can improve light transmission, reduce glare, or add specific color effects to PMMA products, making them suitable for various lighting and display applications.

- Thermal stability improvers for PMMA: Additives are incorporated into PMMA to enhance its thermal stability. These can include heat stabilizers, antioxidants, or inorganic fillers. Such additives help to prevent degradation of PMMA at elevated temperatures, extending the material's usable temperature range and improving its long-term performance in high-temperature environments.

- Surface property modifiers for PMMA: Various additives are used to modify the surface properties of PMMA. These can include anti-static agents, slip additives, or hydrophobic coatings. Such additives can improve the material's resistance to dust attraction, enhance its scratch resistance, or modify its wettability, making PMMA suitable for a wider range of applications.

- Flame retardants for PMMA: Specific additives are incorporated into PMMA to improve its flame retardancy. These can include halogenated compounds, phosphorus-based additives, or inorganic fillers. Such additives help to reduce the flammability of PMMA, improve its self-extinguishing properties, and enhance its overall fire safety performance in various applications.

02 Optical property enhancers

Certain additives are incorporated into PMMA to improve its optical properties. These can include light stabilizers to prevent yellowing, UV absorbers to protect against degradation, and colorants for specific visual effects. Such additives help maintain clarity and enhance the material's performance in optical applications.Expand Specific Solutions03 Thermal stability improvers

Additives are used to enhance the thermal stability of PMMA. These can include antioxidants, heat stabilizers, and other compounds that prevent degradation at elevated temperatures. Such additives extend the usable temperature range of PMMA and improve its long-term performance in high-temperature environments.Expand Specific Solutions04 Surface property modifiers

Various additives are employed to modify the surface properties of PMMA. These can include slip agents to reduce friction, anti-static agents to prevent dust accumulation, and hydrophobic or hydrophilic additives to alter wetting characteristics. Such modifications enhance the material's performance in specific applications.Expand Specific Solutions05 Flame retardants for PMMA

Flame retardant additives are incorporated into PMMA to improve its fire resistance. These additives work by various mechanisms such as char formation, gas dilution, or endothermic decomposition to suppress combustion. The use of flame retardants expands the application range of PMMA in areas where fire safety is critical.Expand Specific Solutions

Key PMMA Additive Manufacturers and Suppliers

The PMMA additives market is in a growth phase, driven by increasing demand for enhanced functional properties in various industries. The market size is expanding, with a projected CAGR of around 5-6% over the next few years. Technologically, the field is advancing rapidly, with companies like DuPont de Nemours, Kingfa Sci. & Tech., and Röhm GmbH leading innovation. These players are focusing on developing additives that improve impact resistance, thermal stability, and weatherability of PMMA. Emerging players such as Shanghai Kumho Sunny Plastics and Weihai Jinhass Chemical are also contributing to market competitiveness, particularly in the Asian region. The industry is characterized by ongoing R&D efforts to meet evolving customer demands for high-performance PMMA materials.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has made significant strides in PMMA additive technology, focusing on enhancing mechanical and thermal properties. They have developed a proprietary blend of impact modifiers that increase PMMA's impact strength by up to 30% without significant loss in transparency[9]. Kingfa's research has also yielded heat-resistant additives that elevate PMMA's heat deflection temperature, making it suitable for high-temperature applications[10]. Their innovative approach includes the use of functionalized graphene as a reinforcing additive, which has shown to improve both mechanical strength and thermal conductivity of PMMA composites[11].

Strengths: Strong focus on high-performance additives, innovative use of nanomaterials, growing presence in international markets. Weaknesses: Relatively newer to the global PMMA market compared to established players, potential challenges in scaling up production of advanced additives.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced PMMA additives to enhance functional properties. Their approach includes the use of nano-sized silica particles as additives, which significantly improve scratch resistance and durability of PMMA surfaces[1]. They have also introduced impact modifiers that increase the toughness of PMMA without compromising its optical clarity[2]. DuPont's research has led to the development of UV stabilizers specifically designed for PMMA, extending the material's outdoor lifespan and preventing yellowing[3]. Additionally, they have created flame-retardant additives that improve PMMA's fire resistance while maintaining its transparency, crucial for applications in construction and automotive industries[4].

Strengths: Extensive R&D capabilities, wide range of specialized additives, proven track record in material science. Weaknesses: Higher cost of additives compared to generic alternatives, potential for over-engineering solutions for simpler applications.

Innovative PMMA Additive Formulations

Additive for PMMA, and PMMA resin composition

PatentWO2020158064A1

Innovation

- Incorporating synthetic analcyme particles with specific particle size distribution and shape as an additive to PMMA resin, which maintains transparency and durability while improving surface hardness.

Patent

Innovation

- Incorporation of core-shell structured nanoparticles to enhance impact resistance and thermal stability of PMMA.

- Development of surface-modified silica nanoparticles to improve scratch resistance and transparency of PMMA.

- Introduction of flame retardant additives that maintain PMMA's optical clarity while improving fire resistance.

Environmental Impact of PMMA Additives

The environmental impact of PMMA additives is a critical consideration in the development and application of improved functional properties for PMMA materials. These additives, while enhancing performance characteristics, can have significant implications for ecosystems and human health throughout their lifecycle.

During the production phase, many PMMA additives require energy-intensive manufacturing processes, contributing to greenhouse gas emissions and resource depletion. Some additives may involve the use of hazardous chemicals or solvents, posing potential risks of environmental contamination if not properly managed. The synthesis of certain additives can also generate toxic by-products, necessitating careful waste management and disposal practices.

In the use phase, PMMA products with additives may exhibit improved durability and longevity, potentially reducing the need for frequent replacements and thereby minimizing overall material consumption. However, some additives can leach from PMMA products over time, especially when exposed to environmental stressors such as UV radiation or moisture. This leaching can lead to the release of potentially harmful substances into soil, water, or air, affecting local ecosystems and potentially entering the food chain.

End-of-life considerations for PMMA products with additives present additional environmental challenges. The presence of certain additives can complicate recycling processes, as they may interfere with the material's ability to be effectively reprocessed or degrade the quality of recycled PMMA. Some additives may also render the material unsuitable for conventional recycling methods, necessitating specialized treatment or disposal techniques.

Biodegradability is another important factor to consider. While PMMA itself is not biodegradable, some additives may enhance or impede the material's ability to break down in natural environments. Additives that improve UV resistance, for instance, may prolong the persistence of PMMA products in ecosystems, potentially contributing to long-term environmental accumulation and microplastic pollution.

The environmental impact of PMMA additives also extends to their potential effects on aquatic ecosystems. Leached additives can accumulate in water bodies, potentially affecting aquatic organisms through direct toxicity or bioaccumulation. This can lead to disruptions in aquatic food webs and long-term ecological imbalances.

To address these environmental concerns, researchers and manufacturers are increasingly focusing on developing more sustainable PMMA additives. This includes exploring bio-based alternatives, designing additives for easier recyclability, and improving the overall lifecycle assessment of PMMA products. Additionally, regulatory frameworks are evolving to address the environmental implications of these additives, driving innovation towards more eco-friendly solutions in the PMMA industry.

During the production phase, many PMMA additives require energy-intensive manufacturing processes, contributing to greenhouse gas emissions and resource depletion. Some additives may involve the use of hazardous chemicals or solvents, posing potential risks of environmental contamination if not properly managed. The synthesis of certain additives can also generate toxic by-products, necessitating careful waste management and disposal practices.

In the use phase, PMMA products with additives may exhibit improved durability and longevity, potentially reducing the need for frequent replacements and thereby minimizing overall material consumption. However, some additives can leach from PMMA products over time, especially when exposed to environmental stressors such as UV radiation or moisture. This leaching can lead to the release of potentially harmful substances into soil, water, or air, affecting local ecosystems and potentially entering the food chain.

End-of-life considerations for PMMA products with additives present additional environmental challenges. The presence of certain additives can complicate recycling processes, as they may interfere with the material's ability to be effectively reprocessed or degrade the quality of recycled PMMA. Some additives may also render the material unsuitable for conventional recycling methods, necessitating specialized treatment or disposal techniques.

Biodegradability is another important factor to consider. While PMMA itself is not biodegradable, some additives may enhance or impede the material's ability to break down in natural environments. Additives that improve UV resistance, for instance, may prolong the persistence of PMMA products in ecosystems, potentially contributing to long-term environmental accumulation and microplastic pollution.

The environmental impact of PMMA additives also extends to their potential effects on aquatic ecosystems. Leached additives can accumulate in water bodies, potentially affecting aquatic organisms through direct toxicity or bioaccumulation. This can lead to disruptions in aquatic food webs and long-term ecological imbalances.

To address these environmental concerns, researchers and manufacturers are increasingly focusing on developing more sustainable PMMA additives. This includes exploring bio-based alternatives, designing additives for easier recyclability, and improving the overall lifecycle assessment of PMMA products. Additionally, regulatory frameworks are evolving to address the environmental implications of these additives, driving innovation towards more eco-friendly solutions in the PMMA industry.

Regulatory Compliance for PMMA Additives

Regulatory compliance is a critical aspect of developing and implementing PMMA additives to improve functional properties. As the use of these additives becomes more widespread in various industries, manufacturers and suppliers must navigate a complex landscape of regulations to ensure product safety, environmental protection, and consumer confidence.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PMMA additives used in food contact materials and medical devices. Manufacturers must comply with FDA regulations, including 21 CFR 177.1010 for acrylic and modified acrylic plastics, to ensure the safety of PMMA additives in these applications. The FDA also requires thorough testing and documentation to demonstrate the safety and efficacy of PMMA additives in medical devices.

The European Union (EU) has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. PMMA additive manufacturers and importers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, which may impact the selection of PMMA additives for these applications.

Environmental regulations also play a significant role in the development and use of PMMA additives. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which can affect the formulation of certain PMMA additives. Manufacturers must ensure their products comply with these regulations, such as the EU's Paints Directive and the U.S. Environmental Protection Agency's (EPA) regulations on VOC content in coatings and adhesives.

The global nature of the PMMA additives market necessitates compliance with international standards and regulations. The International Organization for Standardization (ISO) provides guidelines for quality management (ISO 9001) and environmental management (ISO 14001) that are relevant to PMMA additive manufacturers. Adherence to these standards can help ensure consistent product quality and environmental responsibility across different markets.

As sustainability becomes an increasingly important consideration, regulations surrounding the recyclability and end-of-life management of PMMA products are evolving. Manufacturers must stay informed about emerging regulations related to circular economy initiatives, such as the EU's Circular Economy Action Plan, which may impact the design and selection of PMMA additives to improve recyclability and reduce environmental impact.

Compliance with workplace safety regulations is also crucial for manufacturers and users of PMMA additives. Occupational safety and health administrations, such as OSHA in the United States and EU-OSHA in Europe, set standards for handling and processing these materials to protect workers from potential hazards.

To navigate this complex regulatory landscape, companies involved in PMMA additive development and application must implement robust compliance management systems. This includes staying up-to-date with changing regulations, conducting regular audits, and maintaining comprehensive documentation of safety data and testing results. Collaboration with regulatory experts and participation in industry associations can also help ensure ongoing compliance and anticipate future regulatory trends in the PMMA additives sector.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PMMA additives used in food contact materials and medical devices. Manufacturers must comply with FDA regulations, including 21 CFR 177.1010 for acrylic and modified acrylic plastics, to ensure the safety of PMMA additives in these applications. The FDA also requires thorough testing and documentation to demonstrate the safety and efficacy of PMMA additives in medical devices.

The European Union (EU) has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. PMMA additive manufacturers and importers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, which may impact the selection of PMMA additives for these applications.

Environmental regulations also play a significant role in the development and use of PMMA additives. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which can affect the formulation of certain PMMA additives. Manufacturers must ensure their products comply with these regulations, such as the EU's Paints Directive and the U.S. Environmental Protection Agency's (EPA) regulations on VOC content in coatings and adhesives.

The global nature of the PMMA additives market necessitates compliance with international standards and regulations. The International Organization for Standardization (ISO) provides guidelines for quality management (ISO 9001) and environmental management (ISO 14001) that are relevant to PMMA additive manufacturers. Adherence to these standards can help ensure consistent product quality and environmental responsibility across different markets.

As sustainability becomes an increasingly important consideration, regulations surrounding the recyclability and end-of-life management of PMMA products are evolving. Manufacturers must stay informed about emerging regulations related to circular economy initiatives, such as the EU's Circular Economy Action Plan, which may impact the design and selection of PMMA additives to improve recyclability and reduce environmental impact.

Compliance with workplace safety regulations is also crucial for manufacturers and users of PMMA additives. Occupational safety and health administrations, such as OSHA in the United States and EU-OSHA in Europe, set standards for handling and processing these materials to protect workers from potential hazards.

To navigate this complex regulatory landscape, companies involved in PMMA additive development and application must implement robust compliance management systems. This includes staying up-to-date with changing regulations, conducting regular audits, and maintaining comprehensive documentation of safety data and testing results. Collaboration with regulatory experts and participation in industry associations can also help ensure ongoing compliance and anticipate future regulatory trends in the PMMA additives sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!