How to Mitigate Chemical Reaction Issues in PMMA?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Chemical Stability Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries since its development in the 1930s. Its exceptional optical clarity, weather resistance, and versatility have made it a preferred choice in applications ranging from automotive and aerospace to medical devices and consumer electronics. However, the chemical stability of PMMA has been a persistent concern, particularly in environments where it is exposed to harsh chemicals, UV radiation, or extreme temperatures.

The evolution of PMMA technology has been driven by the need to enhance its chemical resistance while maintaining its desirable properties. Early formulations of PMMA were susceptible to crazing, cracking, and degradation when exposed to certain solvents or under stress. This vulnerability limited its use in certain high-performance applications and necessitated the development of more robust variants.

Over the years, researchers and industry professionals have focused on understanding the molecular structure of PMMA and its interaction with various chemical agents. This has led to the identification of key degradation mechanisms, including chain scission, depolymerization, and oxidation. These insights have been crucial in guiding the development of strategies to mitigate chemical reaction issues in PMMA.

The primary objective in addressing PMMA's chemical stability is to enhance its resistance to a wide range of chemical agents without compromising its optical and mechanical properties. This involves modifying the polymer structure, developing new copolymers, and exploring innovative additives that can act as stabilizers or protective agents. Additionally, there is a growing emphasis on creating PMMA formulations that are not only chemically stable but also environmentally sustainable and recyclable.

Another critical goal is to improve PMMA's performance in extreme environments, such as those encountered in aerospace or deep-sea applications. This requires developing PMMA variants that can withstand exposure to aggressive chemicals, high pressures, and temperature fluctuations without degrading or losing their structural integrity.

As we look to the future, the objectives for PMMA chemical stability research extend beyond mere resistance to degradation. There is an increasing focus on developing "smart" PMMA materials that can actively respond to chemical threats, self-heal when damaged, or even change properties on demand. These advanced materials could revolutionize the use of PMMA in fields such as biomedical engineering, where controlled drug release or adaptive implants are highly desirable.

The evolution of PMMA technology has been driven by the need to enhance its chemical resistance while maintaining its desirable properties. Early formulations of PMMA were susceptible to crazing, cracking, and degradation when exposed to certain solvents or under stress. This vulnerability limited its use in certain high-performance applications and necessitated the development of more robust variants.

Over the years, researchers and industry professionals have focused on understanding the molecular structure of PMMA and its interaction with various chemical agents. This has led to the identification of key degradation mechanisms, including chain scission, depolymerization, and oxidation. These insights have been crucial in guiding the development of strategies to mitigate chemical reaction issues in PMMA.

The primary objective in addressing PMMA's chemical stability is to enhance its resistance to a wide range of chemical agents without compromising its optical and mechanical properties. This involves modifying the polymer structure, developing new copolymers, and exploring innovative additives that can act as stabilizers or protective agents. Additionally, there is a growing emphasis on creating PMMA formulations that are not only chemically stable but also environmentally sustainable and recyclable.

Another critical goal is to improve PMMA's performance in extreme environments, such as those encountered in aerospace or deep-sea applications. This requires developing PMMA variants that can withstand exposure to aggressive chemicals, high pressures, and temperature fluctuations without degrading or losing their structural integrity.

As we look to the future, the objectives for PMMA chemical stability research extend beyond mere resistance to degradation. There is an increasing focus on developing "smart" PMMA materials that can actively respond to chemical threats, self-heal when damaged, or even change properties on demand. These advanced materials could revolutionize the use of PMMA in fields such as biomedical engineering, where controlled drug release or adaptive implants are highly desirable.

Market Analysis for Chemically Resistant PMMA

The market for chemically resistant PMMA (Polymethyl methacrylate) has been experiencing steady growth due to increasing demand across various industries. This growth is primarily driven by the material's unique properties, including its exceptional resistance to chemical reactions, which makes it ideal for applications in harsh environments.

In the automotive sector, chemically resistant PMMA is gaining traction for use in fuel system components, where it must withstand exposure to various chemicals and solvents. The material's ability to maintain its structural integrity and optical clarity in these conditions has led to its increased adoption in fuel tanks, fuel lines, and other critical components.

The medical and laboratory equipment industry represents another significant market for chemically resistant PMMA. The material's resistance to harsh chemicals and sterilization processes makes it suitable for manufacturing laboratory apparatus, medical devices, and diagnostic equipment. As the healthcare sector continues to expand globally, the demand for chemically resistant PMMA in this segment is expected to grow substantially.

In the construction and architectural sectors, chemically resistant PMMA is finding applications in areas exposed to harsh environmental conditions or chemical pollutants. Its use in outdoor signage, protective barriers, and architectural panels is increasing due to its ability to withstand weathering and chemical exposure while maintaining optical clarity.

The electronics industry is another key market for chemically resistant PMMA. As electronic devices become more compact and exposed to various environmental factors, the need for materials that can protect sensitive components from chemical reactions is growing. PMMA's chemical resistance, combined with its electrical insulation properties, makes it an attractive option for encapsulation and protection of electronic components.

The water treatment and chemical processing industries are also driving demand for chemically resistant PMMA. The material's ability to withstand exposure to various chemicals and maintain its properties in aggressive environments makes it suitable for use in pipes, tanks, and other equipment used in these industries.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for chemically resistant PMMA, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes. North America and Europe remain significant markets, with steady demand from established industries and ongoing research and development activities.

As environmental regulations become more stringent, there is a growing emphasis on developing PMMA formulations with enhanced chemical resistance while maintaining recyclability and sustainability. This trend is likely to shape the future of the chemically resistant PMMA market, with manufacturers focusing on eco-friendly solutions that do not compromise on performance.

In the automotive sector, chemically resistant PMMA is gaining traction for use in fuel system components, where it must withstand exposure to various chemicals and solvents. The material's ability to maintain its structural integrity and optical clarity in these conditions has led to its increased adoption in fuel tanks, fuel lines, and other critical components.

The medical and laboratory equipment industry represents another significant market for chemically resistant PMMA. The material's resistance to harsh chemicals and sterilization processes makes it suitable for manufacturing laboratory apparatus, medical devices, and diagnostic equipment. As the healthcare sector continues to expand globally, the demand for chemically resistant PMMA in this segment is expected to grow substantially.

In the construction and architectural sectors, chemically resistant PMMA is finding applications in areas exposed to harsh environmental conditions or chemical pollutants. Its use in outdoor signage, protective barriers, and architectural panels is increasing due to its ability to withstand weathering and chemical exposure while maintaining optical clarity.

The electronics industry is another key market for chemically resistant PMMA. As electronic devices become more compact and exposed to various environmental factors, the need for materials that can protect sensitive components from chemical reactions is growing. PMMA's chemical resistance, combined with its electrical insulation properties, makes it an attractive option for encapsulation and protection of electronic components.

The water treatment and chemical processing industries are also driving demand for chemically resistant PMMA. The material's ability to withstand exposure to various chemicals and maintain its properties in aggressive environments makes it suitable for use in pipes, tanks, and other equipment used in these industries.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for chemically resistant PMMA, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes. North America and Europe remain significant markets, with steady demand from established industries and ongoing research and development activities.

As environmental regulations become more stringent, there is a growing emphasis on developing PMMA formulations with enhanced chemical resistance while maintaining recyclability and sustainability. This trend is likely to shape the future of the chemically resistant PMMA market, with manufacturers focusing on eco-friendly solutions that do not compromise on performance.

Current Challenges in PMMA Chemical Resistance

Poly(methyl methacrylate) (PMMA), widely known as acrylic or plexiglass, is a versatile thermoplastic with numerous applications across various industries. However, its susceptibility to chemical reactions poses significant challenges in maintaining its integrity and performance. One of the primary issues is the material's vulnerability to certain solvents and chemicals, which can lead to crazing, cracking, or dissolution of the polymer structure.

The chemical resistance of PMMA is particularly problematic when exposed to organic solvents such as acetone, chloroform, and various alcohols. These substances can rapidly degrade the material, causing surface damage or complete structural failure. Additionally, PMMA exhibits poor resistance to strong acids and bases, limiting its use in certain chemical processing environments.

Another challenge lies in the material's tendency to undergo stress cracking when exposed to certain chemicals, even at low concentrations. This phenomenon occurs when the chemical agent penetrates the polymer matrix, causing localized swelling and inducing internal stresses that lead to crack formation and propagation. Such stress cracking can significantly compromise the mechanical properties and optical clarity of PMMA components.

The hydrolysis of PMMA in aqueous environments presents a further challenge, especially in applications involving prolonged exposure to water or high humidity. This process can lead to the degradation of the polymer chains, resulting in a loss of mechanical strength and optical properties over time. The rate of hydrolysis is accelerated in the presence of acids or bases, further complicating the use of PMMA in certain environments.

Surface degradation due to chemical interactions is another significant issue. Many chemicals can cause etching, discoloration, or loss of surface gloss, affecting both the aesthetic and functional properties of PMMA products. This is particularly problematic in applications where optical clarity and surface quality are critical, such as in display screens or medical devices.

The challenges in PMMA's chemical resistance also extend to its compatibility with adhesives and coatings. Many common adhesives and surface treatments can react adversely with PMMA, leading to poor bonding, surface defects, or long-term degradation of the material. This complicates manufacturing processes and limits design options in multi-material assemblies.

Addressing these chemical resistance issues in PMMA requires a multifaceted approach. Ongoing research focuses on developing modified PMMA formulations with enhanced chemical resistance, exploring surface treatment techniques to improve barrier properties, and investigating protective coatings that can shield the material from aggressive chemical environments. The development of effective mitigation strategies is crucial for expanding the application range of PMMA and ensuring its long-term performance in challenging chemical environments.

The chemical resistance of PMMA is particularly problematic when exposed to organic solvents such as acetone, chloroform, and various alcohols. These substances can rapidly degrade the material, causing surface damage or complete structural failure. Additionally, PMMA exhibits poor resistance to strong acids and bases, limiting its use in certain chemical processing environments.

Another challenge lies in the material's tendency to undergo stress cracking when exposed to certain chemicals, even at low concentrations. This phenomenon occurs when the chemical agent penetrates the polymer matrix, causing localized swelling and inducing internal stresses that lead to crack formation and propagation. Such stress cracking can significantly compromise the mechanical properties and optical clarity of PMMA components.

The hydrolysis of PMMA in aqueous environments presents a further challenge, especially in applications involving prolonged exposure to water or high humidity. This process can lead to the degradation of the polymer chains, resulting in a loss of mechanical strength and optical properties over time. The rate of hydrolysis is accelerated in the presence of acids or bases, further complicating the use of PMMA in certain environments.

Surface degradation due to chemical interactions is another significant issue. Many chemicals can cause etching, discoloration, or loss of surface gloss, affecting both the aesthetic and functional properties of PMMA products. This is particularly problematic in applications where optical clarity and surface quality are critical, such as in display screens or medical devices.

The challenges in PMMA's chemical resistance also extend to its compatibility with adhesives and coatings. Many common adhesives and surface treatments can react adversely with PMMA, leading to poor bonding, surface defects, or long-term degradation of the material. This complicates manufacturing processes and limits design options in multi-material assemblies.

Addressing these chemical resistance issues in PMMA requires a multifaceted approach. Ongoing research focuses on developing modified PMMA formulations with enhanced chemical resistance, exploring surface treatment techniques to improve barrier properties, and investigating protective coatings that can shield the material from aggressive chemical environments. The development of effective mitigation strategies is crucial for expanding the application range of PMMA and ensuring its long-term performance in challenging chemical environments.

Existing Mitigation Strategies for PMMA Chemical Reactions

01 Polymerization of methyl methacrylate

The chemical reaction to produce PMMA involves the polymerization of methyl methacrylate monomers. This process typically uses free radical polymerization techniques, often initiated by heat or light, to create long chains of PMMA molecules. The reaction conditions and catalysts used can significantly affect the properties of the resulting polymer.- Polymerization of methyl methacrylate: The chemical reaction to produce PMMA involves the polymerization of methyl methacrylate monomers. This process typically uses free radical polymerization techniques, often initiated by heat or light, to create long chains of PMMA molecules. The reaction conditions and catalysts used can significantly affect the properties of the resulting polymer.

- PMMA synthesis for specific applications: Different synthesis methods and reaction conditions are employed to create PMMA with specific properties for various applications. This includes controlling molecular weight, tacticity, and incorporating additives during the polymerization process to enhance certain characteristics such as impact resistance or optical clarity.

- Surface modification of PMMA: Chemical reactions are used to modify the surface of PMMA for improved adhesion, biocompatibility, or other functional properties. These reactions may include plasma treatment, grafting of functional groups, or chemical etching to alter the surface chemistry and topography of PMMA materials.

- PMMA degradation and recycling: Chemical reactions are employed in the degradation and recycling of PMMA. This includes depolymerization processes to break down PMMA into its monomer components, which can then be purified and repolymerized. Various catalysts and reaction conditions are used to optimize the efficiency and yield of these recycling processes.

- PMMA copolymerization and blending: Chemical reactions involving PMMA copolymerization with other monomers or blending with different polymers are used to create materials with enhanced properties. These reactions can produce materials with improved thermal stability, impact resistance, or specific optical characteristics by combining the properties of PMMA with those of other polymers.

02 PMMA synthesis for specific applications

Different synthesis methods and reaction conditions are employed to create PMMA with specific properties for various applications. This includes controlling molecular weight, tacticity, and incorporating additives during the polymerization process to enhance certain characteristics such as impact resistance or optical clarity.Expand Specific Solutions03 Surface modification of PMMA

Chemical reactions are used to modify the surface of PMMA for improved adhesion, biocompatibility, or other functional properties. These reactions may include plasma treatment, grafting of functional groups, or chemical etching to alter the surface chemistry and topography of PMMA materials.Expand Specific Solutions04 PMMA degradation and recycling

Chemical reactions involved in the degradation and recycling of PMMA are studied to develop more sustainable practices. This includes depolymerization reactions to recover methyl methacrylate monomers, as well as chemical processes to break down PMMA into other useful compounds for reuse in various industries.Expand Specific Solutions05 PMMA-based composite materials

Chemical reactions are employed to create PMMA-based composite materials by incorporating other substances during or after polymerization. This can include the addition of nanoparticles, other polymers, or reactive compounds to enhance mechanical, thermal, or optical properties of the resulting material.Expand Specific Solutions

Key Players in PMMA Manufacturing and Research

The mitigation of chemical reaction issues in PMMA is a complex technical challenge in an evolving industry. The market is in a growth phase, driven by increasing demand in various sectors such as automotive, electronics, and construction. The global PMMA market size is projected to expand significantly in the coming years. Technologically, the field is advancing, with companies like Röhm GmbH, BASF Corp., and Wanhua Chemical Group Co., Ltd. leading innovation efforts. These firms are developing new formulations and processing techniques to enhance PMMA's chemical stability and performance. Academic institutions such as Zhejiang University of Technology and Fudan University are also contributing to research in this area, focusing on molecular-level modifications and novel additives to improve PMMA's resistance to chemical reactions.

Zhejiang University of Technology

Technical Solution: Researchers at Zhejiang University of Technology have developed several innovative approaches to mitigate chemical reaction issues in PMMA. One of their key strategies involves the use of nanocomposites to enhance the chemical resistance of PMMA. By incorporating carefully selected nanoparticles into the PMMA matrix, they have achieved significant improvements in the material's resistance to various chemical agents[1]. The team has also explored the use of plasma surface modification techniques to create a protective layer on PMMA surfaces, enhancing their resistance to chemical attack and environmental stress cracking[2]. Additionally, they have developed a novel copolymerization method that introduces specific functional groups into the PMMA structure, resulting in improved resistance to hydrolysis and oxidation[3]. Their research also includes the development of new stabilizer systems that provide long-term protection against UV-induced degradation and thermal decomposition.

Strengths: Cutting-edge research in nanocomposites and surface modification techniques, strong focus on fundamental polymer science. Weaknesses: Potential challenges in scaling up laboratory techniques to industrial production.

Röhm GmbH

Technical Solution: Röhm GmbH has developed advanced stabilization techniques for PMMA to mitigate chemical reaction issues. Their approach includes the use of specialized additives and UV stabilizers to enhance the material's resistance to degradation. They have implemented a proprietary process called ACRYLITE® which involves careful control of polymerization conditions and the addition of specific stabilizers[1]. This process significantly reduces the likelihood of unwanted chemical reactions, particularly those caused by UV exposure and thermal stress. Additionally, Röhm has developed a surface treatment method that creates a protective layer on PMMA products, further enhancing their chemical resistance[2]. The company also employs advanced testing methods to simulate long-term environmental exposure, allowing for continuous improvement of their stabilization techniques[3].

Strengths: Extensive experience in PMMA production, proprietary stabilization techniques, and comprehensive testing methods. Weaknesses: Potential higher production costs due to specialized additives and processes.

Innovative Approaches to Enhance PMMA Chemical Stability

Moulding compositions resistant to stress cracks based on PMMA/SAN-blends

PatentInactiveEP0627461A1

Innovation

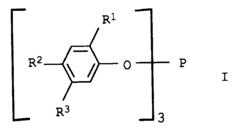

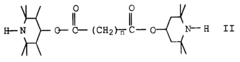

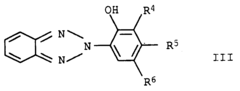

- A molding composition comprising 49-99% of a polymer from C₁-C₂₀ alkyl esters of methacrylic or acrylic acid, 0.95-50% of a vinyl aromatic monomer copolymer with acrylonitrile, and 0.05-1% of a mixture containing triaryl phosphite, amine, and benzotriazole, which are combined to enhance stress cracking resistance and weathering stability.

Method for manufacturing methacrylic polymer

PatentWO2013099670A1

Innovation

- A method involving continuous bulk polymerization using a complete mixing reactor and plug flow reactor, with specific conditions for adding radical polymerization initiators and controlling temperatures and half-lives to stabilize the polymerization process, ensuring high productivity and thermal decomposition resistance.

Environmental Impact of PMMA Chemical Stabilization Methods

The environmental impact of PMMA chemical stabilization methods is a critical consideration in the ongoing efforts to mitigate chemical reaction issues in this widely used polymer. PMMA, or polymethyl methacrylate, is known for its versatility and optical clarity, but its susceptibility to degradation necessitates the use of stabilizers to enhance its longevity and performance.

Traditional stabilization methods often involve the incorporation of additives such as hindered amine light stabilizers (HALS) and UV absorbers. While effective in protecting PMMA from photo-oxidation and thermal degradation, these additives can have significant environmental implications. The production of these chemical stabilizers often requires energy-intensive processes and may involve the use of hazardous substances, contributing to increased carbon footprints and potential environmental contamination.

Moreover, the presence of these stabilizers in PMMA can complicate recycling efforts. As PMMA products reach the end of their lifecycle, the additives may leach into the environment during disposal or recycling processes. This leaching can lead to soil and water pollution, potentially affecting ecosystems and human health. The persistence of some stabilizers in the environment is particularly concerning, as they may bioaccumulate in food chains.

Recent research has focused on developing more environmentally friendly stabilization methods. Bio-based additives derived from natural sources, such as lignin and plant extracts, show promise in reducing the environmental impact of PMMA stabilization. These alternatives often exhibit lower toxicity and improved biodegradability compared to their synthetic counterparts. However, their long-term effectiveness and compatibility with PMMA processing techniques require further investigation.

Another approach gaining traction is the development of intrinsically stable PMMA formulations. By modifying the polymer structure at the molecular level, researchers aim to enhance its inherent resistance to degradation without relying heavily on additional stabilizers. This strategy could significantly reduce the need for potentially harmful additives, thereby minimizing environmental concerns associated with their production and disposal.

The environmental impact of PMMA stabilization methods extends beyond the immediate effects of additives. The improved durability of stabilized PMMA can lead to longer product lifespans, potentially reducing overall plastic waste. However, this benefit must be weighed against the environmental costs of producing and disposing of the stabilizers themselves.

As regulatory frameworks evolve to address environmental concerns, the PMMA industry faces increasing pressure to adopt more sustainable stabilization practices. Life cycle assessments are becoming crucial tools in evaluating the overall environmental impact of different stabilization methods, considering factors such as resource depletion, energy consumption, and emissions throughout the product lifecycle.

Traditional stabilization methods often involve the incorporation of additives such as hindered amine light stabilizers (HALS) and UV absorbers. While effective in protecting PMMA from photo-oxidation and thermal degradation, these additives can have significant environmental implications. The production of these chemical stabilizers often requires energy-intensive processes and may involve the use of hazardous substances, contributing to increased carbon footprints and potential environmental contamination.

Moreover, the presence of these stabilizers in PMMA can complicate recycling efforts. As PMMA products reach the end of their lifecycle, the additives may leach into the environment during disposal or recycling processes. This leaching can lead to soil and water pollution, potentially affecting ecosystems and human health. The persistence of some stabilizers in the environment is particularly concerning, as they may bioaccumulate in food chains.

Recent research has focused on developing more environmentally friendly stabilization methods. Bio-based additives derived from natural sources, such as lignin and plant extracts, show promise in reducing the environmental impact of PMMA stabilization. These alternatives often exhibit lower toxicity and improved biodegradability compared to their synthetic counterparts. However, their long-term effectiveness and compatibility with PMMA processing techniques require further investigation.

Another approach gaining traction is the development of intrinsically stable PMMA formulations. By modifying the polymer structure at the molecular level, researchers aim to enhance its inherent resistance to degradation without relying heavily on additional stabilizers. This strategy could significantly reduce the need for potentially harmful additives, thereby minimizing environmental concerns associated with their production and disposal.

The environmental impact of PMMA stabilization methods extends beyond the immediate effects of additives. The improved durability of stabilized PMMA can lead to longer product lifespans, potentially reducing overall plastic waste. However, this benefit must be weighed against the environmental costs of producing and disposing of the stabilizers themselves.

As regulatory frameworks evolve to address environmental concerns, the PMMA industry faces increasing pressure to adopt more sustainable stabilization practices. Life cycle assessments are becoming crucial tools in evaluating the overall environmental impact of different stabilization methods, considering factors such as resource depletion, energy consumption, and emissions throughout the product lifecycle.

Regulatory Considerations for Modified PMMA Materials

When considering the modification of PMMA materials to mitigate chemical reaction issues, it is crucial to address the regulatory landscape that governs these changes. The regulatory framework for modified PMMA materials encompasses various aspects, including safety standards, environmental impact, and product performance requirements.

One of the primary regulatory considerations is compliance with food contact regulations. Modified PMMA materials used in food packaging or containers must adhere to strict guidelines set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations typically require extensive testing to ensure that the modified materials do not leach harmful substances into food or beverages.

Environmental regulations also play a significant role in the development and use of modified PMMA materials. Many countries have implemented regulations aimed at reducing plastic waste and promoting recyclability. As such, any modifications to PMMA must take into account the material's end-of-life disposal or recycling potential. This may include considerations for biodegradability or the ability to separate and recycle the modified components.

In the medical and healthcare sectors, modified PMMA materials used in implants, prosthetics, or medical devices are subject to rigorous regulatory scrutiny. Regulatory bodies such as the FDA in the United States and the European Medicines Agency (EMA) in Europe require extensive clinical trials and safety assessments before approving modified PMMA materials for medical applications.

The construction industry also imposes regulatory requirements on modified PMMA materials used in building components. These regulations often focus on fire safety, structural integrity, and long-term durability. Modified PMMA materials must meet specific standards for flame retardancy and smoke emission, as well as demonstrate resistance to weathering and environmental stressors.

Occupational health and safety regulations are another critical consideration for manufacturers and users of modified PMMA materials. These regulations may mandate specific handling procedures, personal protective equipment, and workplace exposure limits for any new additives or modifications introduced to mitigate chemical reaction issues in PMMA.

As the field of nanotechnology advances, regulatory bodies are increasingly focusing on the potential risks associated with nanomaterials. If nanoparticles or nanostructures are incorporated into PMMA to address chemical reaction issues, manufacturers must navigate the evolving regulatory landscape surrounding nanomaterials, including potential requirements for specialized risk assessments and labeling.

One of the primary regulatory considerations is compliance with food contact regulations. Modified PMMA materials used in food packaging or containers must adhere to strict guidelines set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations typically require extensive testing to ensure that the modified materials do not leach harmful substances into food or beverages.

Environmental regulations also play a significant role in the development and use of modified PMMA materials. Many countries have implemented regulations aimed at reducing plastic waste and promoting recyclability. As such, any modifications to PMMA must take into account the material's end-of-life disposal or recycling potential. This may include considerations for biodegradability or the ability to separate and recycle the modified components.

In the medical and healthcare sectors, modified PMMA materials used in implants, prosthetics, or medical devices are subject to rigorous regulatory scrutiny. Regulatory bodies such as the FDA in the United States and the European Medicines Agency (EMA) in Europe require extensive clinical trials and safety assessments before approving modified PMMA materials for medical applications.

The construction industry also imposes regulatory requirements on modified PMMA materials used in building components. These regulations often focus on fire safety, structural integrity, and long-term durability. Modified PMMA materials must meet specific standards for flame retardancy and smoke emission, as well as demonstrate resistance to weathering and environmental stressors.

Occupational health and safety regulations are another critical consideration for manufacturers and users of modified PMMA materials. These regulations may mandate specific handling procedures, personal protective equipment, and workplace exposure limits for any new additives or modifications introduced to mitigate chemical reaction issues in PMMA.

As the field of nanotechnology advances, regulatory bodies are increasingly focusing on the potential risks associated with nanomaterials. If nanoparticles or nanostructures are incorporated into PMMA to address chemical reaction issues, manufacturers must navigate the evolving regulatory landscape surrounding nanomaterials, including potential requirements for specialized risk assessments and labeling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!