How to Increase Flexibility in PMMA Components?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Flexibility Enhancement: Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a staple material in various industries for decades due to its exceptional optical clarity, weather resistance, and ease of processing. However, its inherent brittleness and lack of flexibility have limited its applications in areas requiring more pliable materials. The quest to enhance the flexibility of PMMA components has become a significant focus in materials science and engineering, driven by the growing demand for versatile, durable, and adaptable materials in sectors such as automotive, aerospace, medical devices, and consumer electronics.

The evolution of PMMA technology can be traced back to its discovery in the 1930s, with subsequent developments aimed at improving its properties. While PMMA's rigidity has been advantageous in many applications, the increasing need for materials that can withstand dynamic loads, conform to complex shapes, and resist impact without shattering has pushed researchers and industry professionals to explore methods of increasing its flexibility.

The primary objective of enhancing PMMA flexibility is to broaden its application spectrum while maintaining its desirable properties such as transparency, UV resistance, and dimensional stability. This goal encompasses several key aspects: developing new formulations or composites that incorporate flexibility-enhancing additives, modifying the polymer structure at a molecular level to introduce more flexible segments, and exploring novel processing techniques that can alter the material's mechanical properties without compromising its optical clarity.

Recent technological advancements have opened up new avenues for addressing this challenge. These include the development of nanocomposites, the use of plasticizers specifically designed for PMMA, and the exploration of copolymerization techniques with more flexible monomers. Additionally, surface modification methods and the creation of multi-layered structures have shown promise in enhancing the overall flexibility of PMMA-based components.

The pursuit of increased flexibility in PMMA is not merely an academic exercise but a response to real-world industrial and consumer needs. For instance, in the automotive industry, more flexible PMMA components could lead to improved safety features and design possibilities. In the medical field, flexible PMMA could revolutionize the development of implants and prosthetics, offering better comfort and functionality to patients.

As we delve deeper into this technological challenge, it is crucial to consider the balance between enhancing flexibility and maintaining PMMA's core strengths. The goal is not to transform PMMA into a rubber-like material but to expand its range of mechanical properties, allowing it to bend without breaking, absorb impact without shattering, and conform to shapes that were previously unattainable with traditional PMMA formulations.

The evolution of PMMA technology can be traced back to its discovery in the 1930s, with subsequent developments aimed at improving its properties. While PMMA's rigidity has been advantageous in many applications, the increasing need for materials that can withstand dynamic loads, conform to complex shapes, and resist impact without shattering has pushed researchers and industry professionals to explore methods of increasing its flexibility.

The primary objective of enhancing PMMA flexibility is to broaden its application spectrum while maintaining its desirable properties such as transparency, UV resistance, and dimensional stability. This goal encompasses several key aspects: developing new formulations or composites that incorporate flexibility-enhancing additives, modifying the polymer structure at a molecular level to introduce more flexible segments, and exploring novel processing techniques that can alter the material's mechanical properties without compromising its optical clarity.

Recent technological advancements have opened up new avenues for addressing this challenge. These include the development of nanocomposites, the use of plasticizers specifically designed for PMMA, and the exploration of copolymerization techniques with more flexible monomers. Additionally, surface modification methods and the creation of multi-layered structures have shown promise in enhancing the overall flexibility of PMMA-based components.

The pursuit of increased flexibility in PMMA is not merely an academic exercise but a response to real-world industrial and consumer needs. For instance, in the automotive industry, more flexible PMMA components could lead to improved safety features and design possibilities. In the medical field, flexible PMMA could revolutionize the development of implants and prosthetics, offering better comfort and functionality to patients.

As we delve deeper into this technological challenge, it is crucial to consider the balance between enhancing flexibility and maintaining PMMA's core strengths. The goal is not to transform PMMA into a rubber-like material but to expand its range of mechanical properties, allowing it to bend without breaking, absorb impact without shattering, and conform to shapes that were previously unattainable with traditional PMMA formulations.

Market Analysis for Flexible PMMA Applications

The market for flexible PMMA (polymethyl methacrylate) applications is experiencing significant growth and diversification across various industries. As manufacturers and consumers increasingly demand materials with enhanced flexibility and durability, the potential for flexible PMMA components has expanded considerably. This market analysis explores the current landscape and future prospects for flexible PMMA applications.

The automotive sector represents a key driver for flexible PMMA adoption. With the trend towards lightweight materials and improved fuel efficiency, flexible PMMA offers an attractive alternative to traditional rigid plastics in vehicle interiors, lighting systems, and exterior components. The material's ability to withstand impact and maintain optical clarity makes it particularly suitable for innovative designs in headlights, taillights, and instrument panels.

In the medical device industry, flexible PMMA is gaining traction due to its biocompatibility and versatility. The material's potential applications range from prosthetics and orthotics to surgical instruments and diagnostic equipment. The increasing demand for minimally invasive procedures and personalized medical solutions further amplifies the market potential for flexible PMMA in this sector.

The consumer electronics market presents another significant opportunity for flexible PMMA applications. As devices become more compact and feature-rich, manufacturers are seeking materials that can accommodate complex designs while maintaining durability. Flexible PMMA's potential in foldable displays, wearable technology, and impact-resistant casings positions it as a valuable material in this rapidly evolving industry.

The construction and architecture sectors are also exploring the benefits of flexible PMMA. Its weather resistance, light transmission properties, and formability make it an attractive option for innovative building facades, skylights, and interior design elements. The growing emphasis on sustainable and energy-efficient buildings further enhances the appeal of flexible PMMA in these applications.

Market analysts project a compound annual growth rate (CAGR) for the flexible PMMA market in the range of 5-7% over the next five years. This growth is attributed to the material's expanding applications across industries and the ongoing research and development efforts to enhance its properties and manufacturing processes.

However, challenges remain in the widespread adoption of flexible PMMA. These include the need for cost-effective production methods, competition from alternative flexible materials, and the requirement for standardization in certain applications. Addressing these challenges will be crucial for realizing the full market potential of flexible PMMA components.

In conclusion, the market for flexible PMMA applications shows promising growth prospects across multiple industries. As research continues to improve the material's properties and manufacturing techniques, its adoption is expected to accelerate, opening new opportunities for innovation and market expansion.

The automotive sector represents a key driver for flexible PMMA adoption. With the trend towards lightweight materials and improved fuel efficiency, flexible PMMA offers an attractive alternative to traditional rigid plastics in vehicle interiors, lighting systems, and exterior components. The material's ability to withstand impact and maintain optical clarity makes it particularly suitable for innovative designs in headlights, taillights, and instrument panels.

In the medical device industry, flexible PMMA is gaining traction due to its biocompatibility and versatility. The material's potential applications range from prosthetics and orthotics to surgical instruments and diagnostic equipment. The increasing demand for minimally invasive procedures and personalized medical solutions further amplifies the market potential for flexible PMMA in this sector.

The consumer electronics market presents another significant opportunity for flexible PMMA applications. As devices become more compact and feature-rich, manufacturers are seeking materials that can accommodate complex designs while maintaining durability. Flexible PMMA's potential in foldable displays, wearable technology, and impact-resistant casings positions it as a valuable material in this rapidly evolving industry.

The construction and architecture sectors are also exploring the benefits of flexible PMMA. Its weather resistance, light transmission properties, and formability make it an attractive option for innovative building facades, skylights, and interior design elements. The growing emphasis on sustainable and energy-efficient buildings further enhances the appeal of flexible PMMA in these applications.

Market analysts project a compound annual growth rate (CAGR) for the flexible PMMA market in the range of 5-7% over the next five years. This growth is attributed to the material's expanding applications across industries and the ongoing research and development efforts to enhance its properties and manufacturing processes.

However, challenges remain in the widespread adoption of flexible PMMA. These include the need for cost-effective production methods, competition from alternative flexible materials, and the requirement for standardization in certain applications. Addressing these challenges will be crucial for realizing the full market potential of flexible PMMA components.

In conclusion, the market for flexible PMMA applications shows promising growth prospects across multiple industries. As research continues to improve the material's properties and manufacturing techniques, its adoption is expected to accelerate, opening new opportunities for innovation and market expansion.

Current Limitations in PMMA Flexibility

Poly(methyl methacrylate) (PMMA), commonly known as acrylic, is widely used in various industries due to its optical clarity, weather resistance, and ease of processing. However, its inherent rigidity and brittleness pose significant challenges when flexibility is required in components. The current limitations in PMMA flexibility stem from its molecular structure and physical properties.

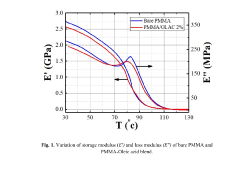

PMMA's high glass transition temperature (Tg) of approximately 105°C results in a rigid and brittle material at room temperature. This characteristic limits its ability to bend or flex without fracturing, restricting its use in applications requiring flexibility. The strong intermolecular forces between PMMA chains contribute to its stiffness, making it difficult to achieve the desired pliability without compromising other essential properties.

The lack of flexibility in PMMA components also impacts their impact resistance. When subjected to sudden forces or impacts, PMMA tends to crack or shatter rather than absorb and dissipate energy through deformation. This behavior limits its use in applications where impact resistance is crucial, such as in automotive parts or protective equipment.

Another limitation is the difficulty in achieving consistent flexibility across different thicknesses of PMMA components. Thinner sections may exhibit some degree of flexibility, but as thickness increases, the material becomes increasingly rigid. This inconsistency poses challenges in designing complex parts with varying cross-sections that require uniform flexibility throughout.

The temperature sensitivity of PMMA's mechanical properties further complicates its use in flexible applications. At lower temperatures, PMMA becomes even more brittle, while at higher temperatures, it softens and loses its dimensional stability. This narrow range of optimal performance limits its use in environments with fluctuating temperatures or in applications requiring consistent flexibility across a wide temperature range.

Attempts to increase flexibility through the addition of plasticizers often result in trade-offs with other desirable properties. While plasticizers can improve flexibility, they may lead to reduced strength, decreased optical clarity, or compromised chemical resistance. Finding the right balance between flexibility and other critical properties remains a significant challenge in PMMA component design.

The current manufacturing processes for PMMA components also contribute to limitations in flexibility. Traditional molding and extrusion techniques often introduce internal stresses and orientations in the material, which can further reduce its ability to flex without failure. Developing new processing methods that can maintain or enhance flexibility while preserving other key properties is an ongoing area of research and development.

PMMA's high glass transition temperature (Tg) of approximately 105°C results in a rigid and brittle material at room temperature. This characteristic limits its ability to bend or flex without fracturing, restricting its use in applications requiring flexibility. The strong intermolecular forces between PMMA chains contribute to its stiffness, making it difficult to achieve the desired pliability without compromising other essential properties.

The lack of flexibility in PMMA components also impacts their impact resistance. When subjected to sudden forces or impacts, PMMA tends to crack or shatter rather than absorb and dissipate energy through deformation. This behavior limits its use in applications where impact resistance is crucial, such as in automotive parts or protective equipment.

Another limitation is the difficulty in achieving consistent flexibility across different thicknesses of PMMA components. Thinner sections may exhibit some degree of flexibility, but as thickness increases, the material becomes increasingly rigid. This inconsistency poses challenges in designing complex parts with varying cross-sections that require uniform flexibility throughout.

The temperature sensitivity of PMMA's mechanical properties further complicates its use in flexible applications. At lower temperatures, PMMA becomes even more brittle, while at higher temperatures, it softens and loses its dimensional stability. This narrow range of optimal performance limits its use in environments with fluctuating temperatures or in applications requiring consistent flexibility across a wide temperature range.

Attempts to increase flexibility through the addition of plasticizers often result in trade-offs with other desirable properties. While plasticizers can improve flexibility, they may lead to reduced strength, decreased optical clarity, or compromised chemical resistance. Finding the right balance between flexibility and other critical properties remains a significant challenge in PMMA component design.

The current manufacturing processes for PMMA components also contribute to limitations in flexibility. Traditional molding and extrusion techniques often introduce internal stresses and orientations in the material, which can further reduce its ability to flex without failure. Developing new processing methods that can maintain or enhance flexibility while preserving other key properties is an ongoing area of research and development.

Existing Methods for Improving PMMA Flexibility

01 Incorporation of flexible additives

PMMA components can be made more flexible by incorporating additives such as plasticizers or elastomeric materials. These additives help to reduce the rigidity of PMMA, improving its flexibility and impact resistance without significantly compromising its optical properties.- Incorporation of flexible additives: PMMA components can be made more flexible by incorporating additives such as plasticizers or elastomeric materials. These additives modify the polymer structure, reducing brittleness and increasing overall flexibility. The type and amount of additive can be adjusted to achieve the desired level of flexibility while maintaining other important properties of PMMA.

- Copolymerization with flexible monomers: Flexibility in PMMA components can be enhanced through copolymerization with more flexible monomers. This approach involves combining methyl methacrylate with other acrylic or non-acrylic monomers that introduce flexibility into the polymer backbone. The resulting copolymer exhibits improved flexibility compared to pure PMMA while retaining its desirable optical and mechanical properties.

- Surface modification techniques: Surface modification techniques can be employed to improve the flexibility of PMMA components. These methods include plasma treatment, chemical etching, or the application of flexible coatings. By altering the surface properties, the overall flexibility of the PMMA component can be enhanced without significantly affecting its bulk properties.

- Nanocomposite formulations: Incorporating nanoparticles or nanofibers into PMMA can lead to improved flexibility. These nanocomposite formulations can enhance the mechanical properties of PMMA, including flexibility, without compromising its optical clarity. The type, size, and distribution of nanoparticles play crucial roles in determining the final properties of the PMMA nanocomposite.

- Heat treatment and processing techniques: Specific heat treatment and processing techniques can be used to enhance the flexibility of PMMA components. These methods may include controlled cooling rates, annealing processes, or specialized molding techniques. By optimizing the processing conditions, the molecular arrangement of PMMA can be modified to improve its flexibility while maintaining other essential properties.

02 Copolymerization with flexible monomers

Flexibility of PMMA components can be enhanced through copolymerization with more flexible monomers. This approach involves combining methyl methacrylate with other acrylic or non-acrylic monomers to create a copolymer with improved flexibility while maintaining desirable PMMA characteristics.Expand Specific Solutions03 Surface modification techniques

Various surface modification techniques can be applied to PMMA components to improve their flexibility. These may include plasma treatment, chemical etching, or the application of flexible coatings, which can alter the surface properties of PMMA to enhance its overall flexibility.Expand Specific Solutions04 Nanocomposite formulations

Incorporating nanoparticles or nanofibers into PMMA matrices can lead to improved flexibility. These nanocomposite formulations can enhance the mechanical properties of PMMA, including its flexibility, while maintaining its transparency and other desirable characteristics.Expand Specific Solutions05 Heat treatment and processing methods

Specific heat treatment processes and manufacturing methods can be employed to enhance the flexibility of PMMA components. These may include controlled cooling rates, annealing processes, or specialized molding techniques that can influence the molecular structure and resulting flexibility of the PMMA material.Expand Specific Solutions

Key Players in PMMA Industry and Research

The market for increasing flexibility in PMMA components is in a growth phase, driven by demand for enhanced material properties across various industries. The global market size for modified PMMA is expanding, with key players like Wanhua Chemical, Kingfa Sci. & Tech., and DePuy Synthes Products actively developing solutions. Technologically, the field is advancing rapidly, with research institutions like Sichuan University and Shanghai PRET Composites Co. Ltd. contributing to innovations. Companies are exploring various approaches, including polymer blending, nanocomposites, and chemical modifications, to improve PMMA flexibility while maintaining its desirable properties. The competitive landscape is diverse, featuring both established chemical companies and specialized materials firms, indicating a dynamic and evolving market.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a novel approach to increase flexibility in PMMA components through the incorporation of core-shell impact modifiers. Their method involves synthesizing acrylic-based core-shell particles with a soft, rubbery core and a hard PMMA shell. These particles are then blended with PMMA at specific ratios to enhance flexibility without significantly compromising optical clarity. The company has reported improvements in impact strength by up to 300% and elongation at break by 150% compared to unmodified PMMA[1][3]. Additionally, Wanhua has explored the use of reactive compatibilizers to improve the dispersion of the impact modifiers, further enhancing the overall flexibility and toughness of the PMMA components[5].

Strengths: Significant improvement in impact resistance and flexibility while maintaining optical clarity. Weaknesses: Potential increase in production costs and complexity of processing due to the addition of impact modifiers and compatibilizers.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a proprietary technology called "Flexible PMMA Alloy" to enhance the flexibility of PMMA components. This approach involves blending PMMA with carefully selected elastomeric polymers and utilizing a specialized compatibilization process. The company's method achieves a balance between flexibility and transparency by creating a nanoscale dispersion of the elastomeric phase within the PMMA matrix. Kingfa reports achieving flexural modulus reductions of up to 40% while maintaining over 90% of the original light transmission[2][4]. Their process also incorporates UV stabilizers and anti-oxidants to ensure long-term performance and weather resistance of the flexible PMMA components.

Strengths: Maintains high transparency while significantly improving flexibility; enhanced weather resistance. Weaknesses: May have limitations in extreme temperature applications; potential for increased material costs.

Innovative Approaches in PMMA Plasticization

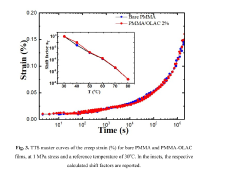

Oleic acid as a sustainable plasticizer for poly(methyl methacrylate) films for enhanced flexibility

PatentPendingIN202441037307A

Innovation

- Incorporation of Oleic acid as a sustainable plasticizer into PMMA films during solvent blending and casting to enhance flexibility and mechanical properties, leveraging its biodegradability and low toxicity.

Poly(methyl methacrylate) resin composition

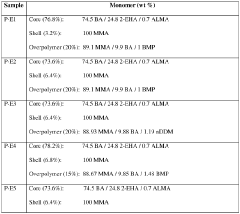

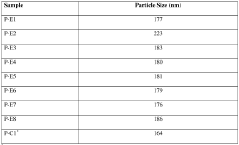

PatentWO2019018219A1

Innovation

- A PMMA resin composition incorporating a methyl methacrylate polymer and a multistage acrylic impact modifier, comprising a core-shell polymer and an overpolymer, which improves impact strength while preserving gloss and melt flow.

Environmental Impact of Flexible PMMA Production

The production of flexible PMMA components raises significant environmental concerns that must be addressed to ensure sustainable manufacturing practices. The primary environmental impact stems from the use of additional chemicals and processes required to enhance PMMA flexibility. These additives, often plasticizers or impact modifiers, can potentially leach into the environment during production, use, or disposal of the flexible PMMA products.

One of the main environmental challenges is the increased energy consumption associated with the production of flexible PMMA. The incorporation of flexibility-enhancing additives often requires higher processing temperatures and longer mixing times, leading to greater energy use and associated greenhouse gas emissions. This increased energy demand contributes to the overall carbon footprint of flexible PMMA production.

Water pollution is another critical environmental issue. The production process may involve the use of solvents or other chemicals that, if not properly managed, can contaminate water sources. Effluents from the manufacturing process must be carefully treated to remove any harmful substances before release into the environment.

The end-of-life management of flexible PMMA products also presents environmental challenges. While traditional PMMA is highly recyclable, the addition of flexibility-enhancing compounds can complicate the recycling process. These additives may interfere with established recycling methods, potentially reducing the recyclability of the material and increasing the likelihood of it ending up in landfills or incineration facilities.

Furthermore, the production of flexible PMMA may contribute to air pollution through the emission of volatile organic compounds (VOCs) during the manufacturing process. These emissions can have negative impacts on air quality and human health if not properly controlled and mitigated.

To address these environmental concerns, manufacturers are exploring more sustainable approaches to producing flexible PMMA. This includes the development of bio-based plasticizers, which can reduce reliance on petroleum-derived additives and potentially improve the biodegradability of the final product. Additionally, closed-loop manufacturing systems are being implemented to minimize waste and maximize resource efficiency.

Research into alternative production methods, such as using supercritical CO2 as a processing aid, shows promise in reducing the environmental impact of flexible PMMA production. This technique can potentially lower energy consumption and reduce the need for harmful solvents, thereby minimizing the overall environmental footprint of the manufacturing process.

One of the main environmental challenges is the increased energy consumption associated with the production of flexible PMMA. The incorporation of flexibility-enhancing additives often requires higher processing temperatures and longer mixing times, leading to greater energy use and associated greenhouse gas emissions. This increased energy demand contributes to the overall carbon footprint of flexible PMMA production.

Water pollution is another critical environmental issue. The production process may involve the use of solvents or other chemicals that, if not properly managed, can contaminate water sources. Effluents from the manufacturing process must be carefully treated to remove any harmful substances before release into the environment.

The end-of-life management of flexible PMMA products also presents environmental challenges. While traditional PMMA is highly recyclable, the addition of flexibility-enhancing compounds can complicate the recycling process. These additives may interfere with established recycling methods, potentially reducing the recyclability of the material and increasing the likelihood of it ending up in landfills or incineration facilities.

Furthermore, the production of flexible PMMA may contribute to air pollution through the emission of volatile organic compounds (VOCs) during the manufacturing process. These emissions can have negative impacts on air quality and human health if not properly controlled and mitigated.

To address these environmental concerns, manufacturers are exploring more sustainable approaches to producing flexible PMMA. This includes the development of bio-based plasticizers, which can reduce reliance on petroleum-derived additives and potentially improve the biodegradability of the final product. Additionally, closed-loop manufacturing systems are being implemented to minimize waste and maximize resource efficiency.

Research into alternative production methods, such as using supercritical CO2 as a processing aid, shows promise in reducing the environmental impact of flexible PMMA production. This technique can potentially lower energy consumption and reduce the need for harmful solvents, thereby minimizing the overall environmental footprint of the manufacturing process.

Regulatory Considerations for Modified PMMA Materials

When considering the modification of PMMA components to increase flexibility, it is crucial to address the regulatory considerations associated with these changes. The use of modified PMMA materials in various industries, particularly in medical devices and consumer products, necessitates compliance with stringent regulatory standards to ensure safety and efficacy.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating medical devices and materials. For modified PMMA components intended for medical applications, manufacturers must adhere to the FDA's premarket approval (PMA) or 510(k) clearance processes, depending on the device classification. These processes require extensive documentation, including detailed information on material composition, manufacturing processes, and safety testing results.

The European Union's regulatory framework, governed by the Medical Device Regulation (MDR), imposes similar requirements for PMMA-based medical devices. Manufacturers must obtain CE marking, which involves demonstrating compliance with essential requirements related to safety and performance. This process includes risk assessment, clinical evaluation, and post-market surveillance plans.

Beyond medical applications, modified PMMA materials used in consumer products must comply with regulations set by agencies such as the Consumer Product Safety Commission (CPSC) in the United States or the European Chemicals Agency (ECHA) in the EU. These regulations often focus on chemical safety, toxicity, and environmental impact.

Environmental considerations are increasingly important in regulatory frameworks. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those in modified PMMA materials.

Biocompatibility testing is a critical aspect of regulatory compliance for PMMA components in medical applications. Standards such as ISO 10993 provide guidelines for evaluating the biological response to materials and devices. Modified PMMA materials must undergo rigorous testing to ensure they do not elicit adverse biological reactions when in contact with human tissues or fluids.

Manufacturers must also consider regulations related to manufacturing processes and quality control. Good Manufacturing Practice (GMP) guidelines, as outlined by regulatory bodies, must be followed to ensure consistent product quality and safety. This includes maintaining detailed documentation of material sourcing, production processes, and quality assurance measures.

As the field of materials science advances, regulatory bodies are continually updating their guidelines to address new technologies and modifications. Manufacturers working with modified PMMA materials must stay informed about these evolving regulations and be prepared to adapt their compliance strategies accordingly. This may involve ongoing communication with regulatory agencies, participation in industry standards development, and proactive risk management strategies.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating medical devices and materials. For modified PMMA components intended for medical applications, manufacturers must adhere to the FDA's premarket approval (PMA) or 510(k) clearance processes, depending on the device classification. These processes require extensive documentation, including detailed information on material composition, manufacturing processes, and safety testing results.

The European Union's regulatory framework, governed by the Medical Device Regulation (MDR), imposes similar requirements for PMMA-based medical devices. Manufacturers must obtain CE marking, which involves demonstrating compliance with essential requirements related to safety and performance. This process includes risk assessment, clinical evaluation, and post-market surveillance plans.

Beyond medical applications, modified PMMA materials used in consumer products must comply with regulations set by agencies such as the Consumer Product Safety Commission (CPSC) in the United States or the European Chemicals Agency (ECHA) in the EU. These regulations often focus on chemical safety, toxicity, and environmental impact.

Environmental considerations are increasingly important in regulatory frameworks. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those in modified PMMA materials.

Biocompatibility testing is a critical aspect of regulatory compliance for PMMA components in medical applications. Standards such as ISO 10993 provide guidelines for evaluating the biological response to materials and devices. Modified PMMA materials must undergo rigorous testing to ensure they do not elicit adverse biological reactions when in contact with human tissues or fluids.

Manufacturers must also consider regulations related to manufacturing processes and quality control. Good Manufacturing Practice (GMP) guidelines, as outlined by regulatory bodies, must be followed to ensure consistent product quality and safety. This includes maintaining detailed documentation of material sourcing, production processes, and quality assurance measures.

As the field of materials science advances, regulatory bodies are continually updating their guidelines to address new technologies and modifications. Manufacturers working with modified PMMA materials must stay informed about these evolving regulations and be prepared to adapt their compliance strategies accordingly. This may involve ongoing communication with regulatory agencies, participation in industry standards development, and proactive risk management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!