How to Achieve Enhanced Optical Clarity in PMMA?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Optical Clarity Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries for decades due to its exceptional optical properties. The quest for enhanced optical clarity in PMMA has been driven by the ever-increasing demands of high-performance applications in fields such as optoelectronics, automotive, aerospace, and medical devices.

The evolution of PMMA's optical clarity can be traced back to its discovery in the 1930s. Initially valued for its transparency and weather resistance, PMMA quickly found applications in aircraft windows and optical lenses. As technology advanced, the need for materials with superior optical properties grew, pushing researchers and manufacturers to explore ways to improve PMMA's already impressive clarity.

Over the years, the focus has shifted from merely achieving transparency to enhancing specific optical characteristics such as light transmission, refractive index control, and minimization of optical distortions. This progression has been fueled by emerging technologies in fields like augmented reality, high-resolution displays, and advanced medical imaging, which require materials with exceptional optical performance.

The current technological landscape presents both challenges and opportunities in the pursuit of enhanced optical clarity in PMMA. Key areas of focus include reducing haze, improving light transmission across a broader spectrum, and maintaining optical properties under various environmental conditions. Additionally, there is a growing emphasis on developing PMMA formulations that can withstand high-energy radiation without compromising their optical clarity, a crucial factor in medical and scientific applications.

The objectives of enhancing optical clarity in PMMA are multifaceted. Primarily, there is a drive to achieve near-perfect transparency, with light transmission rates approaching 100% across the visible spectrum and extending into the UV and IR ranges. This goal is complemented by efforts to minimize optical phenomena that can detract from clarity, such as birefringence, chromatic aberration, and scattering.

Another critical objective is to maintain or even improve the material's mechanical properties while enhancing its optical characteristics. This balance is essential for applications where PMMA must serve both optical and structural functions, such as in automotive headlights or architectural glazing. Furthermore, there is a growing emphasis on developing environmentally sustainable methods for producing optically enhanced PMMA, aligning with global trends towards greener manufacturing processes.

As we look towards the future, the path to achieving enhanced optical clarity in PMMA is likely to involve interdisciplinary approaches, combining advances in polymer science, nanotechnology, and surface engineering. The ultimate goal is to create a new generation of PMMA materials that not only meet current optical performance standards but also anticipate and fulfill the requirements of emerging technologies in photonics, quantum computing, and beyond.

The evolution of PMMA's optical clarity can be traced back to its discovery in the 1930s. Initially valued for its transparency and weather resistance, PMMA quickly found applications in aircraft windows and optical lenses. As technology advanced, the need for materials with superior optical properties grew, pushing researchers and manufacturers to explore ways to improve PMMA's already impressive clarity.

Over the years, the focus has shifted from merely achieving transparency to enhancing specific optical characteristics such as light transmission, refractive index control, and minimization of optical distortions. This progression has been fueled by emerging technologies in fields like augmented reality, high-resolution displays, and advanced medical imaging, which require materials with exceptional optical performance.

The current technological landscape presents both challenges and opportunities in the pursuit of enhanced optical clarity in PMMA. Key areas of focus include reducing haze, improving light transmission across a broader spectrum, and maintaining optical properties under various environmental conditions. Additionally, there is a growing emphasis on developing PMMA formulations that can withstand high-energy radiation without compromising their optical clarity, a crucial factor in medical and scientific applications.

The objectives of enhancing optical clarity in PMMA are multifaceted. Primarily, there is a drive to achieve near-perfect transparency, with light transmission rates approaching 100% across the visible spectrum and extending into the UV and IR ranges. This goal is complemented by efforts to minimize optical phenomena that can detract from clarity, such as birefringence, chromatic aberration, and scattering.

Another critical objective is to maintain or even improve the material's mechanical properties while enhancing its optical characteristics. This balance is essential for applications where PMMA must serve both optical and structural functions, such as in automotive headlights or architectural glazing. Furthermore, there is a growing emphasis on developing environmentally sustainable methods for producing optically enhanced PMMA, aligning with global trends towards greener manufacturing processes.

As we look towards the future, the path to achieving enhanced optical clarity in PMMA is likely to involve interdisciplinary approaches, combining advances in polymer science, nanotechnology, and surface engineering. The ultimate goal is to create a new generation of PMMA materials that not only meet current optical performance standards but also anticipate and fulfill the requirements of emerging technologies in photonics, quantum computing, and beyond.

Market Analysis for High-Clarity PMMA Applications

The market for high-clarity PMMA applications has been experiencing significant growth in recent years, driven by increasing demand across various industries. The optical clarity of PMMA, also known as acrylic, makes it an ideal material for applications requiring transparency and light transmission. Key sectors driving this market include automotive, electronics, construction, and medical devices.

In the automotive industry, high-clarity PMMA is increasingly used for headlamp lenses, instrument panels, and interior lighting. The trend towards advanced lighting systems and larger displays in vehicles has boosted the demand for optically clear PMMA. The electronics sector utilizes PMMA in smartphone screens, tablet displays, and LED lighting applications, where optical clarity is crucial for user experience and product performance.

The construction industry has seen a rise in the use of high-clarity PMMA for architectural glazing, skylights, and decorative elements. Its lightweight nature, combined with excellent optical properties, makes it an attractive alternative to glass in many applications. In the medical field, PMMA is used in various devices such as contact lenses, intraocular lenses, and diagnostic equipment, where optical clarity is paramount.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for high-clarity PMMA, driven by rapid industrialization and increasing consumer electronics production. North America and Europe remain significant markets, particularly in high-end applications requiring superior optical properties.

The global high-clarity PMMA market is characterized by intense competition among key players, with a focus on product innovation and technological advancements. Companies are investing in research and development to enhance the optical clarity of PMMA further, aiming to meet the evolving demands of various industries.

Challenges in the market include the need for consistent quality in large-scale production, cost pressures, and competition from alternative materials. However, the unique combination of optical clarity, durability, and versatility continues to position high-clarity PMMA as a preferred material in many applications.

Future growth in the market is expected to be driven by emerging applications in augmented reality (AR) and virtual reality (VR) devices, advanced automotive displays, and innovative architectural designs. The increasing focus on sustainability may also create opportunities for bio-based or recyclable high-clarity PMMA products, aligning with global environmental concerns.

In the automotive industry, high-clarity PMMA is increasingly used for headlamp lenses, instrument panels, and interior lighting. The trend towards advanced lighting systems and larger displays in vehicles has boosted the demand for optically clear PMMA. The electronics sector utilizes PMMA in smartphone screens, tablet displays, and LED lighting applications, where optical clarity is crucial for user experience and product performance.

The construction industry has seen a rise in the use of high-clarity PMMA for architectural glazing, skylights, and decorative elements. Its lightweight nature, combined with excellent optical properties, makes it an attractive alternative to glass in many applications. In the medical field, PMMA is used in various devices such as contact lenses, intraocular lenses, and diagnostic equipment, where optical clarity is paramount.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for high-clarity PMMA, driven by rapid industrialization and increasing consumer electronics production. North America and Europe remain significant markets, particularly in high-end applications requiring superior optical properties.

The global high-clarity PMMA market is characterized by intense competition among key players, with a focus on product innovation and technological advancements. Companies are investing in research and development to enhance the optical clarity of PMMA further, aiming to meet the evolving demands of various industries.

Challenges in the market include the need for consistent quality in large-scale production, cost pressures, and competition from alternative materials. However, the unique combination of optical clarity, durability, and versatility continues to position high-clarity PMMA as a preferred material in many applications.

Future growth in the market is expected to be driven by emerging applications in augmented reality (AR) and virtual reality (VR) devices, advanced automotive displays, and innovative architectural designs. The increasing focus on sustainability may also create opportunities for bio-based or recyclable high-clarity PMMA products, aligning with global environmental concerns.

Current PMMA Optical Clarity Challenges

Poly(methyl methacrylate) (PMMA), widely known as acrylic or plexiglass, is renowned for its exceptional optical clarity. However, achieving enhanced optical clarity in PMMA remains a significant challenge in various applications, particularly in high-performance optical devices and advanced display technologies.

One of the primary challenges in enhancing PMMA's optical clarity is the presence of residual impurities and contaminants in the polymer matrix. These impurities, which can include unreacted monomers, catalyst residues, and trace amounts of additives, can scatter light and reduce overall transparency. Even minute quantities of these contaminants can significantly impact the optical properties of PMMA, leading to reduced clarity and increased haze.

Another critical challenge is the formation of microvoids and inhomogeneities during the polymerization and processing of PMMA. These microscopic defects can arise from uneven polymerization rates, inadequate mixing, or rapid cooling during the manufacturing process. Such imperfections act as light-scattering centers, diminishing the material's optical clarity and potentially causing distortions in transmitted light.

The molecular weight distribution of PMMA also plays a crucial role in its optical properties. Achieving a narrow molecular weight distribution is essential for optimal optical clarity, as a broad distribution can lead to variations in refractive index throughout the material. This challenge is particularly pronounced in large-scale production, where maintaining consistent molecular weight distributions across batches can be difficult.

Surface quality is another significant factor affecting PMMA's optical clarity. Scratches, micro-cracks, and surface irregularities can dramatically reduce transparency and increase light scattering. Maintaining pristine surface quality during manufacturing, handling, and use remains a persistent challenge, especially in applications requiring large or complex PMMA components.

Thermal stability and resistance to environmental factors pose additional challenges to maintaining long-term optical clarity in PMMA. Exposure to UV radiation, temperature fluctuations, and humidity can lead to yellowing, crazing, and other forms of degradation that compromise optical performance over time. Developing PMMA formulations with enhanced resistance to these environmental factors without sacrificing initial optical clarity is an ongoing area of research and development.

Lastly, the trade-off between optical clarity and other desirable properties, such as impact resistance or heat deflection temperature, presents a significant challenge. Modifications to improve these mechanical or thermal properties often come at the cost of reduced optical clarity, necessitating careful balancing of material characteristics to meet specific application requirements.

One of the primary challenges in enhancing PMMA's optical clarity is the presence of residual impurities and contaminants in the polymer matrix. These impurities, which can include unreacted monomers, catalyst residues, and trace amounts of additives, can scatter light and reduce overall transparency. Even minute quantities of these contaminants can significantly impact the optical properties of PMMA, leading to reduced clarity and increased haze.

Another critical challenge is the formation of microvoids and inhomogeneities during the polymerization and processing of PMMA. These microscopic defects can arise from uneven polymerization rates, inadequate mixing, or rapid cooling during the manufacturing process. Such imperfections act as light-scattering centers, diminishing the material's optical clarity and potentially causing distortions in transmitted light.

The molecular weight distribution of PMMA also plays a crucial role in its optical properties. Achieving a narrow molecular weight distribution is essential for optimal optical clarity, as a broad distribution can lead to variations in refractive index throughout the material. This challenge is particularly pronounced in large-scale production, where maintaining consistent molecular weight distributions across batches can be difficult.

Surface quality is another significant factor affecting PMMA's optical clarity. Scratches, micro-cracks, and surface irregularities can dramatically reduce transparency and increase light scattering. Maintaining pristine surface quality during manufacturing, handling, and use remains a persistent challenge, especially in applications requiring large or complex PMMA components.

Thermal stability and resistance to environmental factors pose additional challenges to maintaining long-term optical clarity in PMMA. Exposure to UV radiation, temperature fluctuations, and humidity can lead to yellowing, crazing, and other forms of degradation that compromise optical performance over time. Developing PMMA formulations with enhanced resistance to these environmental factors without sacrificing initial optical clarity is an ongoing area of research and development.

Lastly, the trade-off between optical clarity and other desirable properties, such as impact resistance or heat deflection temperature, presents a significant challenge. Modifications to improve these mechanical or thermal properties often come at the cost of reduced optical clarity, necessitating careful balancing of material characteristics to meet specific application requirements.

Existing PMMA Clarity Improvement Techniques

01 Improving optical clarity of PMMA

Various methods are employed to enhance the optical clarity of PMMA, including the use of specific additives, optimizing polymerization conditions, and developing novel processing techniques. These approaches aim to reduce light scattering and increase transparency, making PMMA suitable for high-performance optical applications.- Improving optical clarity of PMMA: Various methods are employed to enhance the optical clarity of PMMA, including optimizing polymerization conditions, using high-purity monomers, and incorporating additives. These techniques aim to reduce light scattering and improve transparency, making PMMA suitable for optical applications.

- PMMA-based optical components: PMMA is widely used in the manufacture of optical components due to its excellent optical clarity. Applications include lenses, light guides, and optical fibers. The material's properties are optimized for specific optical requirements in various devices and systems.

- Surface treatment for enhanced clarity: Surface treatments are applied to PMMA to improve its optical clarity. These may include polishing, coating, or chemical treatments that reduce surface roughness and minimize light scattering, resulting in improved transparency and optical performance.

- PMMA blends and composites for optical applications: PMMA is often blended with other polymers or materials to create composites with enhanced optical properties. These blends can offer improved clarity, durability, or specific optical characteristics tailored for particular applications.

- Optical clarity measurement and quality control: Techniques and instruments are developed for measuring and ensuring the optical clarity of PMMA products. These methods involve assessing light transmission, haze, and other optical parameters to maintain consistent quality in PMMA optical components.

02 PMMA-based optical components

PMMA is utilized in the fabrication of various optical components due to its excellent optical clarity. These components include lenses, light guides, displays, and optical fibers. The material's properties are optimized for specific applications to ensure high performance and durability in optical systems.Expand Specific Solutions03 Surface treatment for enhanced clarity

Surface treatments are applied to PMMA to improve its optical clarity and reduce reflections. These treatments may include anti-reflective coatings, plasma treatments, or chemical modifications of the surface. Such processes enhance light transmission and reduce glare, improving the overall optical performance of PMMA-based products.Expand Specific Solutions04 Nanocomposites for improved optical properties

PMMA nanocomposites are developed by incorporating nanoparticles or nanostructures into the polymer matrix. These nanocomposites can exhibit enhanced optical clarity, improved mechanical properties, and additional functionalities such as UV protection or self-cleaning capabilities, expanding the range of applications for PMMA in optical and optoelectronic devices.Expand Specific Solutions05 Optical clarity measurement and quality control

Advanced techniques and instruments are used to measure and evaluate the optical clarity of PMMA. These methods include spectrophotometry, haze measurement, and light transmission analysis. Quality control processes are implemented to ensure consistent optical clarity in PMMA production, meeting the stringent requirements of optical applications.Expand Specific Solutions

Key PMMA Manufacturers and Researchers

The market for enhanced optical clarity in PMMA is in a growth phase, driven by increasing demand in various industries such as electronics, automotive, and medical devices. The global PMMA market size is projected to reach significant value in the coming years, with optical grade PMMA being a key segment. Technological advancements are pushing the boundaries of optical clarity, with companies like BASF Corp., Röhm GmbH, and Covestro Deutschland AG leading the way in developing innovative solutions. These industry giants, along with emerging players like Wanhua Chemical Group and Kingfa Sci. & Tech., are investing heavily in R&D to improve PMMA's optical properties, indicating a competitive and dynamic market landscape.

BASF Corp.

Technical Solution: BASF has developed a novel approach to enhance optical clarity in PMMA through their proprietary Lumina® technology. This method involves the use of specially designed nanoparticles that are uniformly dispersed within the PMMA matrix. The nanoparticles are engineered to have a refractive index closely matching that of PMMA, which minimizes light scattering and improves overall transparency. Additionally, BASF has implemented a controlled polymerization process that reduces the formation of microvoids and impurities, further enhancing optical clarity. The company has reported a significant increase in light transmission, with values exceeding 92% in the visible spectrum for their enhanced PMMA products[1][3].

Strengths: Superior optical clarity, reduced haze, and improved durability. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Carl Zeiss SMT GmbH

Technical Solution: Carl Zeiss SMT GmbH has developed a precision optical grade PMMA with enhanced clarity for high-performance optical applications. Their approach combines ultra-pure monomer synthesis with a carefully controlled polymerization process that minimizes defects and ensures uniform molecular weight distribution. Zeiss has also implemented an advanced annealing technique that reduces residual stress in the material, further improving optical homogeneity. Additionally, they have developed a proprietary coating technology that enhances surface quality and reduces scatter. Their enhanced PMMA exhibits a refractive index uniformity of ±0.0001 and a light transmission of over 92% in the visible and near-UV spectrum[9][10].

Strengths: Exceptional optical homogeneity, low birefringence, and suitability for precision optics. Weaknesses: High production costs and limited to specialized applications.

Breakthrough Technologies in PMMA Optics

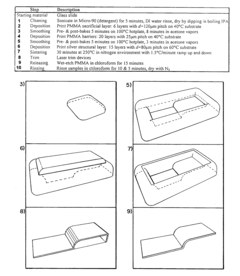

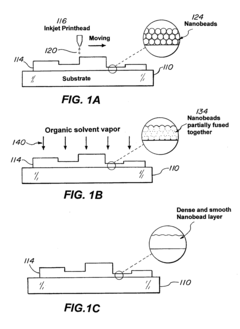

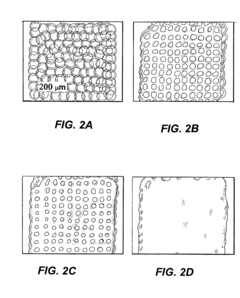

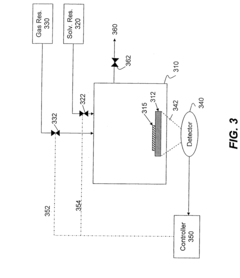

Method and apparatus for forming structures of polymer nanobeads

PatentActiveUS20110206839A1

Innovation

- A post-treatment process involving exposure to a solvent system that lowers the glass transition temperature of PMMA, allowing the polymer nanobeads to reflow and fuse at room temperature, creating a smooth and optically transparent film with improved surface morphology without altering the footprint, using an apparatus with a solvent reservoir and gas system to control the treatment.

PMMA binding peptides

PatentInactiveUS8206693B2

Innovation

- Identification of PMMA-binding peptides using mRNA-display, which provides a library of peptides with strong affinity for PMMA, allowing for the creation of peptide-based reagents that can bind to PMMA surfaces and couple benefit agents, either to the same surface or a different target surface, enhancing their delivery and durability.

Environmental Impact of PMMA Production

The production of Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has significant environmental implications that warrant careful consideration. The manufacturing process of PMMA involves the polymerization of methyl methacrylate (MMA) monomers, which requires substantial energy input and generates various emissions and waste products.

One of the primary environmental concerns associated with PMMA production is the release of volatile organic compounds (VOCs) during the polymerization process. These emissions can contribute to air pollution and potentially harm both human health and ecosystems if not properly managed. Additionally, the production of MMA monomers, a key ingredient in PMMA, often involves the use of acetone cyanohydrin, which is derived from fossil fuels and can pose environmental risks if not handled correctly.

Water consumption and wastewater generation are also significant factors in PMMA manufacturing. The cooling processes and cleaning operations involved in production can lead to substantial water usage and the potential release of contaminated wastewater. Proper treatment and recycling of this water are essential to minimize the environmental impact and conserve water resources.

Energy consumption is another critical aspect of PMMA production's environmental footprint. The polymerization process and subsequent molding or extrusion of PMMA products require considerable amounts of energy, often derived from fossil fuels. This contributes to greenhouse gas emissions and the overall carbon footprint of the material.

Waste management is a further environmental challenge in PMMA production. Off-spec products, trimmings, and other production waste need to be properly handled and, where possible, recycled to reduce the amount of material sent to landfills. The development of efficient recycling technologies for PMMA is crucial for improving its lifecycle sustainability.

Despite these environmental concerns, it is important to note that PMMA has several positive environmental attributes. Its durability and long lifespan can reduce the need for frequent replacements, potentially lowering overall resource consumption. Additionally, PMMA is 100% recyclable, and when properly collected and processed, it can be reused to create new products, thus reducing the demand for virgin materials.

Efforts to mitigate the environmental impact of PMMA production are ongoing. These include the development of more energy-efficient manufacturing processes, the use of renewable energy sources, improvements in emission control technologies, and the implementation of closed-loop water systems. Research into bio-based alternatives for MMA production is also underway, aiming to reduce reliance on fossil fuel-derived raw materials.

One of the primary environmental concerns associated with PMMA production is the release of volatile organic compounds (VOCs) during the polymerization process. These emissions can contribute to air pollution and potentially harm both human health and ecosystems if not properly managed. Additionally, the production of MMA monomers, a key ingredient in PMMA, often involves the use of acetone cyanohydrin, which is derived from fossil fuels and can pose environmental risks if not handled correctly.

Water consumption and wastewater generation are also significant factors in PMMA manufacturing. The cooling processes and cleaning operations involved in production can lead to substantial water usage and the potential release of contaminated wastewater. Proper treatment and recycling of this water are essential to minimize the environmental impact and conserve water resources.

Energy consumption is another critical aspect of PMMA production's environmental footprint. The polymerization process and subsequent molding or extrusion of PMMA products require considerable amounts of energy, often derived from fossil fuels. This contributes to greenhouse gas emissions and the overall carbon footprint of the material.

Waste management is a further environmental challenge in PMMA production. Off-spec products, trimmings, and other production waste need to be properly handled and, where possible, recycled to reduce the amount of material sent to landfills. The development of efficient recycling technologies for PMMA is crucial for improving its lifecycle sustainability.

Despite these environmental concerns, it is important to note that PMMA has several positive environmental attributes. Its durability and long lifespan can reduce the need for frequent replacements, potentially lowering overall resource consumption. Additionally, PMMA is 100% recyclable, and when properly collected and processed, it can be reused to create new products, thus reducing the demand for virgin materials.

Efforts to mitigate the environmental impact of PMMA production are ongoing. These include the development of more energy-efficient manufacturing processes, the use of renewable energy sources, improvements in emission control technologies, and the implementation of closed-loop water systems. Research into bio-based alternatives for MMA production is also underway, aiming to reduce reliance on fossil fuel-derived raw materials.

Regulatory Standards for Optical-Grade PMMA

Regulatory standards for optical-grade PMMA play a crucial role in ensuring the quality and performance of this material in various applications. These standards are established by international organizations and national regulatory bodies to define the minimum requirements for optical clarity, mechanical properties, and safety of PMMA used in optical applications.

The International Organization for Standardization (ISO) has developed several standards specifically for optical-grade PMMA. ISO 7823-1 outlines the requirements for cast sheets of PMMA for optical applications, including specifications for light transmission, haze, and refractive index. This standard ensures that PMMA sheets meet the necessary optical properties for use in lenses, displays, and other optical components.

In the United States, the American Society for Testing and Materials (ASTM) has established ASTM D4802, which provides standard specifications for PMMA acrylic plastic sheets. This standard covers the optical, mechanical, and thermal properties of PMMA, including requirements for light transmission and haze. Additionally, the Food and Drug Administration (FDA) regulates the use of PMMA in medical devices and implants, ensuring its biocompatibility and safety for human use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to PMMA manufacturers and importers. This regulation ensures that PMMA products meet safety and environmental standards, including restrictions on hazardous substances and requirements for chemical safety assessments.

In Japan, the Japanese Industrial Standards (JIS) committee has established JIS K 6718, which specifies the testing methods and quality requirements for PMMA sheets. This standard covers optical properties such as light transmittance and haze, as well as mechanical and thermal properties.

Compliance with these regulatory standards is essential for manufacturers of optical-grade PMMA. It ensures that the material meets the necessary quality and performance criteria for use in various optical applications, from consumer electronics to medical devices. Manufacturers must conduct rigorous testing and quality control processes to meet these standards, often involving specialized equipment and procedures.

As technology advances and new applications for optical-grade PMMA emerge, regulatory standards continue to evolve. Ongoing research and development efforts focus on improving the optical clarity of PMMA while maintaining compliance with these standards. This includes exploring new manufacturing techniques, additives, and surface treatments that can enhance the material's optical properties without compromising its safety or regulatory compliance.

The International Organization for Standardization (ISO) has developed several standards specifically for optical-grade PMMA. ISO 7823-1 outlines the requirements for cast sheets of PMMA for optical applications, including specifications for light transmission, haze, and refractive index. This standard ensures that PMMA sheets meet the necessary optical properties for use in lenses, displays, and other optical components.

In the United States, the American Society for Testing and Materials (ASTM) has established ASTM D4802, which provides standard specifications for PMMA acrylic plastic sheets. This standard covers the optical, mechanical, and thermal properties of PMMA, including requirements for light transmission and haze. Additionally, the Food and Drug Administration (FDA) regulates the use of PMMA in medical devices and implants, ensuring its biocompatibility and safety for human use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to PMMA manufacturers and importers. This regulation ensures that PMMA products meet safety and environmental standards, including restrictions on hazardous substances and requirements for chemical safety assessments.

In Japan, the Japanese Industrial Standards (JIS) committee has established JIS K 6718, which specifies the testing methods and quality requirements for PMMA sheets. This standard covers optical properties such as light transmittance and haze, as well as mechanical and thermal properties.

Compliance with these regulatory standards is essential for manufacturers of optical-grade PMMA. It ensures that the material meets the necessary quality and performance criteria for use in various optical applications, from consumer electronics to medical devices. Manufacturers must conduct rigorous testing and quality control processes to meet these standards, often involving specialized equipment and procedures.

As technology advances and new applications for optical-grade PMMA emerge, regulatory standards continue to evolve. Ongoing research and development efforts focus on improving the optical clarity of PMMA while maintaining compliance with these standards. This includes exploring new manufacturing techniques, additives, and surface treatments that can enhance the material's optical properties without compromising its safety or regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!