How PMMA Enhances Surface Modifications in Industries?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Surface Modification Overview and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has emerged as a versatile material in various industries due to its unique properties and potential for surface modification. The evolution of PMMA surface modification techniques has significantly expanded its applications across multiple sectors, including optics, electronics, biomedical engineering, and automotive industries.

The primary objective of PMMA surface modification is to enhance its surface properties without altering its bulk characteristics. This process aims to improve adhesion, wettability, biocompatibility, and other surface-dependent properties, thereby extending the material's functionality and applicability. The development of advanced surface modification techniques has been driven by the increasing demand for high-performance materials in cutting-edge applications.

Over the years, researchers and industry professionals have explored various approaches to modify PMMA surfaces. These methods range from physical treatments, such as plasma and UV irradiation, to chemical modifications involving grafting and coating techniques. Each approach offers distinct advantages and addresses specific industrial needs, contributing to the overall advancement of PMMA-based technologies.

The technological progression in PMMA surface modification has been marked by several key milestones. Early techniques focused on simple physical treatments to alter surface roughness and energy. As research progressed, more sophisticated methods emerged, including plasma-induced grafting, layer-by-layer assembly, and nanoparticle incorporation. These advancements have significantly expanded the scope of PMMA applications, enabling its use in fields such as microfluidics, biosensors, and advanced optical devices.

Current research in PMMA surface modification is driven by the need for more sustainable, efficient, and precise modification techniques. Emerging trends include the development of environmentally friendly processes, the integration of smart and responsive surface modifications, and the exploration of hybrid approaches combining multiple modification methods. These innovations aim to address the evolving requirements of various industries while maintaining the core benefits of PMMA as a material.

The ongoing efforts in PMMA surface modification are expected to yield novel solutions for existing challenges and open up new possibilities for industrial applications. As technology continues to advance, the potential for PMMA to enhance surface modifications across diverse industries remains significant, promising continued innovation and improved material performance in the years to come.

The primary objective of PMMA surface modification is to enhance its surface properties without altering its bulk characteristics. This process aims to improve adhesion, wettability, biocompatibility, and other surface-dependent properties, thereby extending the material's functionality and applicability. The development of advanced surface modification techniques has been driven by the increasing demand for high-performance materials in cutting-edge applications.

Over the years, researchers and industry professionals have explored various approaches to modify PMMA surfaces. These methods range from physical treatments, such as plasma and UV irradiation, to chemical modifications involving grafting and coating techniques. Each approach offers distinct advantages and addresses specific industrial needs, contributing to the overall advancement of PMMA-based technologies.

The technological progression in PMMA surface modification has been marked by several key milestones. Early techniques focused on simple physical treatments to alter surface roughness and energy. As research progressed, more sophisticated methods emerged, including plasma-induced grafting, layer-by-layer assembly, and nanoparticle incorporation. These advancements have significantly expanded the scope of PMMA applications, enabling its use in fields such as microfluidics, biosensors, and advanced optical devices.

Current research in PMMA surface modification is driven by the need for more sustainable, efficient, and precise modification techniques. Emerging trends include the development of environmentally friendly processes, the integration of smart and responsive surface modifications, and the exploration of hybrid approaches combining multiple modification methods. These innovations aim to address the evolving requirements of various industries while maintaining the core benefits of PMMA as a material.

The ongoing efforts in PMMA surface modification are expected to yield novel solutions for existing challenges and open up new possibilities for industrial applications. As technology continues to advance, the potential for PMMA to enhance surface modifications across diverse industries remains significant, promising continued innovation and improved material performance in the years to come.

Industrial Demand for PMMA Surface Enhancements

The industrial demand for PMMA surface enhancements has been steadily growing across various sectors due to the material's unique properties and versatility. PMMA, or polymethyl methacrylate, is widely recognized for its optical clarity, weather resistance, and durability, making it an ideal candidate for surface modification applications in industries ranging from automotive to medical devices.

In the automotive industry, there is a significant demand for PMMA surface enhancements to improve the aesthetics and functionality of vehicle components. Manufacturers are increasingly using PMMA-based coatings and films to create scratch-resistant, anti-glare surfaces for instrument panels, touchscreens, and exterior lighting. This trend is driven by the need for lightweight materials that can withstand harsh environmental conditions while maintaining optical clarity.

The electronics sector has also shown a growing interest in PMMA surface modifications. With the rise of smart devices and touchscreens, there is a pressing need for durable, fingerprint-resistant surfaces that maintain high transparency. PMMA-based coatings are being developed to meet these requirements, offering improved scratch resistance and anti-smudge properties for smartphone and tablet displays.

In the medical field, PMMA surface enhancements are crucial for developing biocompatible implants and medical devices. The demand for antimicrobial surfaces in hospitals and healthcare facilities has led to the development of PMMA coatings with embedded antimicrobial agents. These coatings help reduce the risk of hospital-acquired infections and improve patient safety.

The construction industry has also recognized the benefits of PMMA surface modifications. There is a growing demand for weather-resistant, UV-stable coatings for exterior building materials. PMMA-based solutions are being used to enhance the durability and appearance of architectural elements, such as facades, windows, and signage, extending their lifespan and reducing maintenance costs.

The aerospace sector is another area where PMMA surface enhancements are in high demand. Aircraft manufacturers are seeking lightweight, impact-resistant materials for cabin windows and cockpit displays. PMMA-based coatings and laminates are being developed to meet stringent safety standards while providing excellent optical clarity and scratch resistance.

As sustainability becomes a key focus across industries, there is an increasing demand for eco-friendly PMMA surface modifications. Manufacturers are exploring bio-based PMMA alternatives and developing recyclable coating solutions to meet environmental regulations and consumer preferences for sustainable products.

The global market for PMMA surface enhancements is expected to continue its growth trajectory, driven by technological advancements and expanding applications across various industries. As research and development efforts intensify, new PMMA-based surface modification techniques are likely to emerge, further expanding the material's potential and meeting evolving industrial demands.

In the automotive industry, there is a significant demand for PMMA surface enhancements to improve the aesthetics and functionality of vehicle components. Manufacturers are increasingly using PMMA-based coatings and films to create scratch-resistant, anti-glare surfaces for instrument panels, touchscreens, and exterior lighting. This trend is driven by the need for lightweight materials that can withstand harsh environmental conditions while maintaining optical clarity.

The electronics sector has also shown a growing interest in PMMA surface modifications. With the rise of smart devices and touchscreens, there is a pressing need for durable, fingerprint-resistant surfaces that maintain high transparency. PMMA-based coatings are being developed to meet these requirements, offering improved scratch resistance and anti-smudge properties for smartphone and tablet displays.

In the medical field, PMMA surface enhancements are crucial for developing biocompatible implants and medical devices. The demand for antimicrobial surfaces in hospitals and healthcare facilities has led to the development of PMMA coatings with embedded antimicrobial agents. These coatings help reduce the risk of hospital-acquired infections and improve patient safety.

The construction industry has also recognized the benefits of PMMA surface modifications. There is a growing demand for weather-resistant, UV-stable coatings for exterior building materials. PMMA-based solutions are being used to enhance the durability and appearance of architectural elements, such as facades, windows, and signage, extending their lifespan and reducing maintenance costs.

The aerospace sector is another area where PMMA surface enhancements are in high demand. Aircraft manufacturers are seeking lightweight, impact-resistant materials for cabin windows and cockpit displays. PMMA-based coatings and laminates are being developed to meet stringent safety standards while providing excellent optical clarity and scratch resistance.

As sustainability becomes a key focus across industries, there is an increasing demand for eco-friendly PMMA surface modifications. Manufacturers are exploring bio-based PMMA alternatives and developing recyclable coating solutions to meet environmental regulations and consumer preferences for sustainable products.

The global market for PMMA surface enhancements is expected to continue its growth trajectory, driven by technological advancements and expanding applications across various industries. As research and development efforts intensify, new PMMA-based surface modification techniques are likely to emerge, further expanding the material's potential and meeting evolving industrial demands.

Current PMMA Surface Modification Techniques

Poly(methyl methacrylate) (PMMA) surface modification techniques have evolved significantly in recent years, offering enhanced properties and expanded applications across various industries. The current landscape of PMMA surface modification encompasses a diverse range of methods, each tailored to specific industrial needs and desired surface characteristics.

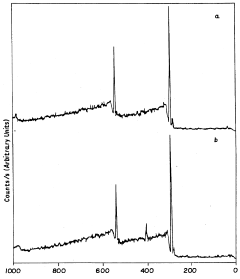

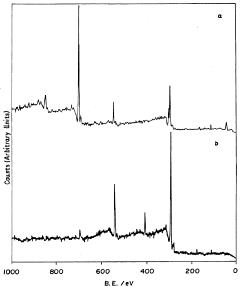

One of the most widely employed techniques is plasma treatment, which utilizes ionized gas to modify the PMMA surface. This method effectively increases surface energy, improves wettability, and enhances adhesion properties. Plasma treatment can be fine-tuned to achieve specific surface functionalities by adjusting parameters such as gas composition, power, and exposure time. It is particularly valuable in industries requiring improved bonding or printing on PMMA surfaces.

Chemical modification techniques have also gained prominence in PMMA surface treatment. These methods involve the use of various chemical agents to alter the surface properties of PMMA. Grafting of functional groups, such as carboxyl or amine groups, onto the PMMA surface is a common approach. This technique allows for tailored surface properties, including enhanced hydrophilicity or hydrophobicity, improved biocompatibility, and increased reactivity for further modifications.

UV-initiated surface modification has emerged as an efficient and environmentally friendly method for PMMA treatment. This technique utilizes ultraviolet light to initiate chemical reactions on the PMMA surface, often in the presence of specific monomers or photoinitiators. UV modification offers precise control over the treated area and can be used to create patterned surfaces, which is particularly useful in microfluidic and optical applications.

Physical surface modification techniques, such as mechanical abrasion and sandblasting, continue to be relevant in certain industrial applications. These methods alter the surface topography of PMMA, increasing roughness and surface area. While less sophisticated than some newer techniques, they remain effective for improving adhesion in applications like bonding and coating.

Nanoparticle incorporation has gained traction as an advanced PMMA surface modification technique. By embedding nanoparticles into the PMMA surface, properties such as hardness, scratch resistance, and even antimicrobial activity can be significantly enhanced. This method is particularly valuable in industries requiring high-performance PMMA materials, such as automotive and medical device manufacturing.

Laser surface modification has emerged as a precise and versatile technique for PMMA treatment. This method allows for highly localized surface alterations, creating intricate patterns or modifying specific areas without affecting the bulk properties of the material. Laser treatment can induce chemical changes, create micro- or nano-scale surface structures, and even selectively remove material, offering unprecedented control over surface properties.

In conclusion, the current landscape of PMMA surface modification techniques offers a diverse toolkit for industries to enhance and tailor PMMA properties. From traditional methods like mechanical abrasion to cutting-edge approaches such as plasma treatment and nanoparticle incorporation, these techniques continue to expand the applications and performance of PMMA across various sectors.

One of the most widely employed techniques is plasma treatment, which utilizes ionized gas to modify the PMMA surface. This method effectively increases surface energy, improves wettability, and enhances adhesion properties. Plasma treatment can be fine-tuned to achieve specific surface functionalities by adjusting parameters such as gas composition, power, and exposure time. It is particularly valuable in industries requiring improved bonding or printing on PMMA surfaces.

Chemical modification techniques have also gained prominence in PMMA surface treatment. These methods involve the use of various chemical agents to alter the surface properties of PMMA. Grafting of functional groups, such as carboxyl or amine groups, onto the PMMA surface is a common approach. This technique allows for tailored surface properties, including enhanced hydrophilicity or hydrophobicity, improved biocompatibility, and increased reactivity for further modifications.

UV-initiated surface modification has emerged as an efficient and environmentally friendly method for PMMA treatment. This technique utilizes ultraviolet light to initiate chemical reactions on the PMMA surface, often in the presence of specific monomers or photoinitiators. UV modification offers precise control over the treated area and can be used to create patterned surfaces, which is particularly useful in microfluidic and optical applications.

Physical surface modification techniques, such as mechanical abrasion and sandblasting, continue to be relevant in certain industrial applications. These methods alter the surface topography of PMMA, increasing roughness and surface area. While less sophisticated than some newer techniques, they remain effective for improving adhesion in applications like bonding and coating.

Nanoparticle incorporation has gained traction as an advanced PMMA surface modification technique. By embedding nanoparticles into the PMMA surface, properties such as hardness, scratch resistance, and even antimicrobial activity can be significantly enhanced. This method is particularly valuable in industries requiring high-performance PMMA materials, such as automotive and medical device manufacturing.

Laser surface modification has emerged as a precise and versatile technique for PMMA treatment. This method allows for highly localized surface alterations, creating intricate patterns or modifying specific areas without affecting the bulk properties of the material. Laser treatment can induce chemical changes, create micro- or nano-scale surface structures, and even selectively remove material, offering unprecedented control over surface properties.

In conclusion, the current landscape of PMMA surface modification techniques offers a diverse toolkit for industries to enhance and tailor PMMA properties. From traditional methods like mechanical abrasion to cutting-edge approaches such as plasma treatment and nanoparticle incorporation, these techniques continue to expand the applications and performance of PMMA across various sectors.

Existing PMMA Surface Enhancement Solutions

01 Plasma treatment for PMMA surface modification

Plasma treatment is used to modify the surface of PMMA, improving its properties such as adhesion, wettability, and biocompatibility. This method can introduce functional groups, increase surface energy, and create nanoscale roughness on the PMMA surface without altering its bulk properties.- Plasma treatment for PMMA surface modification: Plasma treatment is used to modify the surface of PMMA, improving its properties such as adhesion, wettability, and biocompatibility. This method can introduce functional groups, increase surface energy, and create nanoscale roughness on the PMMA surface without altering its bulk properties.

- Chemical grafting for PMMA surface functionalization: Chemical grafting techniques are employed to attach specific functional groups or polymer chains onto the PMMA surface. This method allows for tailored surface properties, such as improved hydrophilicity, antibacterial properties, or specific molecular recognition capabilities.

- UV-induced surface modification of PMMA: UV irradiation is used to modify the PMMA surface, often in combination with photoinitiators or photosensitizers. This technique can induce crosslinking, grafting, or degradation of the surface layer, leading to changes in surface chemistry and topography.

- Nanoparticle incorporation for enhanced PMMA properties: Nanoparticles are incorporated into the PMMA surface to enhance its properties such as mechanical strength, thermal stability, or optical characteristics. This can be achieved through various methods including in-situ polymerization, melt blending, or surface coating techniques.

- Biomolecule immobilization on PMMA surfaces: Techniques for immobilizing biomolecules such as proteins, enzymes, or DNA on PMMA surfaces are developed for biomedical and biosensing applications. This often involves creating reactive sites on the PMMA surface followed by covalent attachment or physical adsorption of the biomolecules.

02 Chemical grafting for PMMA surface functionalization

Chemical grafting techniques are employed to attach specific functional groups or polymer chains onto the PMMA surface. This method allows for tailored surface properties, such as improved hydrophilicity, antibacterial properties, or specific molecular recognition capabilities.Expand Specific Solutions03 UV-induced surface modification of PMMA

UV irradiation is used to modify the PMMA surface, often in combination with photoinitiators or photosensitizers. This technique can induce crosslinking, grafting, or degradation of the surface layer, leading to changes in surface chemistry and topography.Expand Specific Solutions04 Nanoparticle incorporation for enhanced PMMA properties

Nanoparticles are incorporated into the PMMA surface or bulk material to enhance specific properties such as mechanical strength, thermal stability, or optical characteristics. This can be achieved through various methods including melt blending, in-situ polymerization, or surface deposition.Expand Specific Solutions05 Biomolecule immobilization on PMMA surfaces

Techniques for immobilizing biomolecules such as proteins, enzymes, or DNA on PMMA surfaces are developed for applications in biosensors, biomedical devices, and diagnostic platforms. This often involves creating reactive sites on the PMMA surface followed by covalent attachment or physical adsorption of the biomolecules.Expand Specific Solutions

Key Players in PMMA Surface Modification Industry

The PMMA surface modification technology market is in a growth phase, driven by increasing demand across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, PMMA surface modification is advancing rapidly, with key players like DuPont, LG Chem, and Evonik leading innovation. These companies are developing sophisticated techniques to enhance PMMA's properties, such as improved adhesion, durability, and functionality. The technology's maturity varies across applications, with some sectors seeing more advanced implementations than others. Emerging players like Wanhua Chemical and Shanghai Kumho Sunny Plastics are also contributing to the field's development, particularly in Asian markets.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of surface modification technologies for PMMA and other polymers. Their approach includes the use of plasma treatment and chemical grafting to enhance surface properties. DuPont's plasma treatment process creates nanoscale surface roughness and introduces polar groups, improving adhesion and wettability[3]. They have also developed a proprietary chemical grafting technique that allows for the attachment of functional molecules to PMMA surfaces, enabling customization of surface properties such as hydrophobicity, conductivity, and biocompatibility[4]. DuPont's research extends to the development of nanocomposite coatings that can be applied to PMMA surfaces to impart additional functionalities like scratch resistance and UV protection.

Strengths: Broad expertise across multiple polymer types; advanced R&D capabilities. Weaknesses: Solutions may be more generalized and not PMMA-specific; potentially higher costs due to extensive R&D investments.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative surface modification techniques for PMMA, focusing on enhancing its properties for various industrial applications. Their approach includes a combination of physical and chemical treatments. LG Chem utilizes a controlled oxidation process to introduce specific functional groups onto the PMMA surface, improving its adhesion properties and compatibility with other materials[5]. They have also developed a proprietary coating technology that incorporates nanoparticles to enhance scratch resistance and UV stability of PMMA surfaces[6]. LG Chem's research extends to the development of self-healing coatings for PMMA, which can repair minor scratches and maintain optical clarity over time.

Strengths: Strong focus on practical industrial applications; integration of nanotechnology in surface treatments. Weaknesses: May have less historical expertise in PMMA compared to some competitors; potential regional limitations in global market reach.

Innovative PMMA Surface Modification Technologies

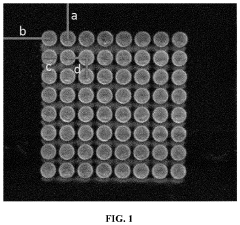

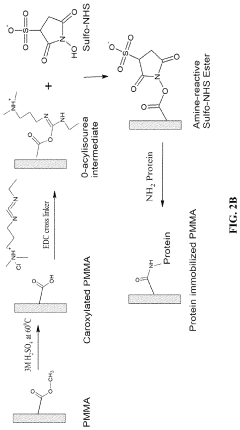

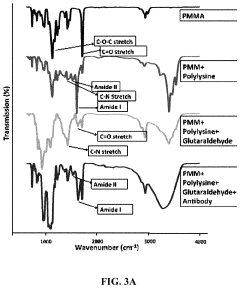

Sensitive ELISA for disease diagnosis on surface modified poly(methyl methacrylate) (PMMA) microfluidic microplates

PatentActiveUS11014088B2

Innovation

- A poly(methyl methacrylate) (PMMA) microfluidic microplate with a surface modified using poly-lysine or carboxylation for covalent binding of proteins, allowing for rapid and ultrasensitive detection of disease biomarkers with reduced reagent consumption and no need for expensive equipment, achieving detection limits 10-fold more sensitive than commercial ELISA kits.

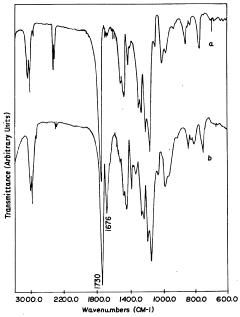

Surface modification of plastic optical fibers

PatentInactiveUS5236667A

Innovation

- The chemical modification of PMMA cladding on optical fibers using N-lithio ethylene diamine as an aminolyzing agent at room temperature, allowing for the introduction of amino groups and subsequent binding of pH-sensitive dyes with isothiocyanate functionality, ensuring the reaction occurs on the surface without damaging the fiber.

Environmental Impact of PMMA Surface Treatments

The environmental impact of PMMA surface treatments is a critical consideration in industrial applications. These treatments, while enhancing material properties, can have both positive and negative effects on the environment.

PMMA surface modifications often involve chemical processes that may release volatile organic compounds (VOCs) into the atmosphere. These emissions can contribute to air pollution and potentially harm human health and ecosystems. However, advancements in treatment technologies have led to the development of low-VOC and water-based solutions, significantly reducing environmental risks.

Water consumption is another environmental concern associated with PMMA surface treatments. Traditional methods may require substantial amounts of water for cleaning and processing. To address this issue, industries are increasingly adopting water-efficient techniques and closed-loop systems that recycle and reuse water, minimizing overall consumption and wastewater generation.

The disposal of waste materials from PMMA surface treatments poses challenges for environmental management. Chemical residues and byproducts can contaminate soil and water if not properly handled. To mitigate these risks, many facilities have implemented comprehensive waste management protocols, including on-site treatment, recycling, and safe disposal practices.

Energy consumption during PMMA surface modification processes is an additional environmental factor. High-energy treatments, such as plasma or UV curing, can contribute to increased carbon footprints. However, ongoing research focuses on developing energy-efficient alternatives and optimizing existing processes to reduce overall energy requirements.

The durability and longevity of PMMA products enhanced through surface treatments can have positive environmental implications. Improved resistance to weathering, chemicals, and mechanical stress extends product lifespans, potentially reducing the need for replacements and minimizing waste generation over time.

Recycling of PMMA materials after surface treatment presents both opportunities and challenges. While PMMA itself is recyclable, certain surface modifications may complicate the recycling process. Efforts are underway to develop surface treatments that maintain recyclability without compromising performance, aligning with circular economy principles.

As industries strive for sustainability, the environmental impact of PMMA surface treatments is driving innovation in green chemistry and eco-friendly processing methods. This includes the exploration of bio-based alternatives, solvent-free technologies, and the integration of life cycle assessments in treatment selection and optimization.

PMMA surface modifications often involve chemical processes that may release volatile organic compounds (VOCs) into the atmosphere. These emissions can contribute to air pollution and potentially harm human health and ecosystems. However, advancements in treatment technologies have led to the development of low-VOC and water-based solutions, significantly reducing environmental risks.

Water consumption is another environmental concern associated with PMMA surface treatments. Traditional methods may require substantial amounts of water for cleaning and processing. To address this issue, industries are increasingly adopting water-efficient techniques and closed-loop systems that recycle and reuse water, minimizing overall consumption and wastewater generation.

The disposal of waste materials from PMMA surface treatments poses challenges for environmental management. Chemical residues and byproducts can contaminate soil and water if not properly handled. To mitigate these risks, many facilities have implemented comprehensive waste management protocols, including on-site treatment, recycling, and safe disposal practices.

Energy consumption during PMMA surface modification processes is an additional environmental factor. High-energy treatments, such as plasma or UV curing, can contribute to increased carbon footprints. However, ongoing research focuses on developing energy-efficient alternatives and optimizing existing processes to reduce overall energy requirements.

The durability and longevity of PMMA products enhanced through surface treatments can have positive environmental implications. Improved resistance to weathering, chemicals, and mechanical stress extends product lifespans, potentially reducing the need for replacements and minimizing waste generation over time.

Recycling of PMMA materials after surface treatment presents both opportunities and challenges. While PMMA itself is recyclable, certain surface modifications may complicate the recycling process. Efforts are underway to develop surface treatments that maintain recyclability without compromising performance, aligning with circular economy principles.

As industries strive for sustainability, the environmental impact of PMMA surface treatments is driving innovation in green chemistry and eco-friendly processing methods. This includes the exploration of bio-based alternatives, solvent-free technologies, and the integration of life cycle assessments in treatment selection and optimization.

Cost-Benefit Analysis of PMMA Surface Modifications

The cost-benefit analysis of PMMA surface modifications reveals a compelling case for its adoption across various industries. The initial investment in PMMA-based surface modification technologies can be significant, encompassing equipment, materials, and specialized training for personnel. However, the long-term benefits often outweigh these upfront costs, making it an economically viable solution for many applications.

One of the primary advantages of PMMA surface modifications is the enhanced durability and longevity of treated materials. This results in reduced maintenance and replacement costs over time, particularly in industries where material degradation is a significant concern. For instance, in automotive and aerospace sectors, PMMA-modified surfaces can extend the lifespan of components exposed to harsh environmental conditions, leading to substantial savings in the long run.

The improved surface properties achieved through PMMA modifications also contribute to increased product value and performance. In optical applications, PMMA treatments can enhance light transmission and reduce glare, resulting in higher-quality products that command premium prices. Similarly, in medical devices, PMMA-modified surfaces can improve biocompatibility and reduce the risk of infections, potentially lowering healthcare costs and improving patient outcomes.

Energy efficiency is another area where PMMA surface modifications offer significant benefits. In the construction industry, PMMA-treated windows and building materials can improve thermal insulation, leading to reduced heating and cooling costs. This energy-saving aspect not only provides economic benefits but also aligns with sustainability goals, potentially qualifying businesses for green incentives and improving their environmental profile.

However, it's important to consider the potential drawbacks. The complexity of PMMA surface modification processes may require specialized equipment and expertise, potentially increasing production time and costs. Additionally, the environmental impact of PMMA production and disposal must be factored into the overall cost-benefit analysis, as sustainable practices become increasingly important in industrial decision-making.

When evaluating the return on investment, industries must consider both tangible and intangible benefits. While quantifiable cost savings are evident in reduced maintenance and improved product performance, intangible benefits such as enhanced brand reputation and customer satisfaction can also significantly impact the overall value proposition of PMMA surface modifications.

In conclusion, the cost-benefit analysis of PMMA surface modifications generally favors their implementation across various industries. The initial investment is often justified by long-term savings, improved product quality, and enhanced performance. However, careful consideration of specific industry needs, regulatory requirements, and environmental factors is crucial in determining the optimal application of PMMA surface modification technologies.

One of the primary advantages of PMMA surface modifications is the enhanced durability and longevity of treated materials. This results in reduced maintenance and replacement costs over time, particularly in industries where material degradation is a significant concern. For instance, in automotive and aerospace sectors, PMMA-modified surfaces can extend the lifespan of components exposed to harsh environmental conditions, leading to substantial savings in the long run.

The improved surface properties achieved through PMMA modifications also contribute to increased product value and performance. In optical applications, PMMA treatments can enhance light transmission and reduce glare, resulting in higher-quality products that command premium prices. Similarly, in medical devices, PMMA-modified surfaces can improve biocompatibility and reduce the risk of infections, potentially lowering healthcare costs and improving patient outcomes.

Energy efficiency is another area where PMMA surface modifications offer significant benefits. In the construction industry, PMMA-treated windows and building materials can improve thermal insulation, leading to reduced heating and cooling costs. This energy-saving aspect not only provides economic benefits but also aligns with sustainability goals, potentially qualifying businesses for green incentives and improving their environmental profile.

However, it's important to consider the potential drawbacks. The complexity of PMMA surface modification processes may require specialized equipment and expertise, potentially increasing production time and costs. Additionally, the environmental impact of PMMA production and disposal must be factored into the overall cost-benefit analysis, as sustainable practices become increasingly important in industrial decision-making.

When evaluating the return on investment, industries must consider both tangible and intangible benefits. While quantifiable cost savings are evident in reduced maintenance and improved product performance, intangible benefits such as enhanced brand reputation and customer satisfaction can also significantly impact the overall value proposition of PMMA surface modifications.

In conclusion, the cost-benefit analysis of PMMA surface modifications generally favors their implementation across various industries. The initial investment is often justified by long-term savings, improved product quality, and enhanced performance. However, careful consideration of specific industry needs, regulatory requirements, and environmental factors is crucial in determining the optimal application of PMMA surface modification technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!