PMMA's Role in Anti-Reflective Coating Technology

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA in AR Coatings: Background and Objectives

Anti-reflective (AR) coatings have become an integral part of modern optical systems, enhancing light transmission and reducing unwanted reflections. Poly(methyl methacrylate) (PMMA), a versatile synthetic polymer, has emerged as a key player in this technology. The evolution of PMMA's role in AR coatings can be traced back to the mid-20th century when researchers began exploring its potential in optical applications.

Initially, PMMA was primarily used as a substrate material for AR coatings due to its excellent optical clarity and ease of processing. However, as the demand for more efficient and durable AR coatings grew, scientists began investigating PMMA's potential as an active component in the coating itself. This shift in focus marked a significant turning point in the development of AR coating technology.

The primary objective of incorporating PMMA into AR coatings is to achieve a balance between optical performance and mechanical durability. Traditional inorganic AR coatings, while effective, often suffer from poor adhesion and susceptibility to environmental damage. PMMA, with its unique combination of optical and mechanical properties, offers a promising solution to these challenges.

One of the key trends in PMMA-based AR coating technology is the development of nanostructured surfaces. By creating nanoscale patterns on PMMA surfaces, researchers have been able to mimic the anti-reflective properties found in nature, such as moth eyes. This biomimetic approach has led to significant improvements in coating efficiency and broadband performance.

Another important trend is the exploration of PMMA copolymers and blends. By modifying the chemical structure of PMMA or combining it with other polymers, researchers aim to fine-tune its refractive index and enhance its compatibility with other coating materials. This approach has opened up new possibilities for creating multi-layer AR coatings with superior performance characteristics.

The integration of PMMA into AR coating technology also aligns with the growing emphasis on sustainability in materials science. As a thermoplastic, PMMA offers the potential for recyclability and reduced environmental impact compared to some traditional coating materials. This aspect is becoming increasingly important as industries seek to adopt more eco-friendly manufacturing processes.

Looking ahead, the objectives for PMMA in AR coating technology are multifaceted. Researchers are striving to develop coatings that offer broader spectral coverage, improved durability under harsh environmental conditions, and enhanced scratch resistance. Additionally, there is a push towards creating AR coatings that can be applied through more efficient and cost-effective processes, potentially revolutionizing large-scale production methods.

Initially, PMMA was primarily used as a substrate material for AR coatings due to its excellent optical clarity and ease of processing. However, as the demand for more efficient and durable AR coatings grew, scientists began investigating PMMA's potential as an active component in the coating itself. This shift in focus marked a significant turning point in the development of AR coating technology.

The primary objective of incorporating PMMA into AR coatings is to achieve a balance between optical performance and mechanical durability. Traditional inorganic AR coatings, while effective, often suffer from poor adhesion and susceptibility to environmental damage. PMMA, with its unique combination of optical and mechanical properties, offers a promising solution to these challenges.

One of the key trends in PMMA-based AR coating technology is the development of nanostructured surfaces. By creating nanoscale patterns on PMMA surfaces, researchers have been able to mimic the anti-reflective properties found in nature, such as moth eyes. This biomimetic approach has led to significant improvements in coating efficiency and broadband performance.

Another important trend is the exploration of PMMA copolymers and blends. By modifying the chemical structure of PMMA or combining it with other polymers, researchers aim to fine-tune its refractive index and enhance its compatibility with other coating materials. This approach has opened up new possibilities for creating multi-layer AR coatings with superior performance characteristics.

The integration of PMMA into AR coating technology also aligns with the growing emphasis on sustainability in materials science. As a thermoplastic, PMMA offers the potential for recyclability and reduced environmental impact compared to some traditional coating materials. This aspect is becoming increasingly important as industries seek to adopt more eco-friendly manufacturing processes.

Looking ahead, the objectives for PMMA in AR coating technology are multifaceted. Researchers are striving to develop coatings that offer broader spectral coverage, improved durability under harsh environmental conditions, and enhanced scratch resistance. Additionally, there is a push towards creating AR coatings that can be applied through more efficient and cost-effective processes, potentially revolutionizing large-scale production methods.

Market Analysis for AR Coatings

The global market for anti-reflective (AR) coatings has been experiencing significant growth, driven by increasing demand across various industries. The AR coating market is projected to expand at a robust rate in the coming years, with key applications in consumer electronics, solar panels, eyewear, automotive displays, and architectural glass.

In the consumer electronics sector, AR coatings are extensively used in smartphones, tablets, laptops, and televisions to enhance display visibility and reduce glare. As the demand for high-quality displays continues to rise, the market for AR coatings in this segment is expected to grow substantially. The automotive industry is another major driver, with AR coatings being increasingly incorporated into dashboard displays, heads-up displays, and windshields to improve visibility and safety.

The solar energy sector represents a significant opportunity for AR coating manufacturers. As the world shifts towards renewable energy sources, the demand for solar panels is increasing, and AR coatings play a crucial role in improving the efficiency of these panels by reducing light reflection and increasing light absorption.

In the eyewear industry, AR coatings are widely used to reduce glare and improve visual clarity in both prescription and non-prescription lenses. The growing awareness of eye health and the increasing prevalence of digital devices are driving the demand for AR-coated lenses.

Geographically, Asia-Pacific is expected to dominate the AR coating market, primarily due to the presence of major consumer electronics and solar panel manufacturers in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and increasing adoption in automotive and architectural applications.

The market is characterized by intense competition among key players, including Essilor, Carl Zeiss, Honeywell International, and PPG Industries. These companies are focusing on research and development to improve coating technologies and expand their product portfolios. Innovations in nanotechnology and the development of eco-friendly coating materials are expected to create new opportunities in the market.

Despite the positive outlook, the AR coating market faces challenges such as high production costs and the need for specialized equipment and skilled labor. However, ongoing technological advancements and increasing applications across various industries are expected to drive sustained growth in the coming years.

In the consumer electronics sector, AR coatings are extensively used in smartphones, tablets, laptops, and televisions to enhance display visibility and reduce glare. As the demand for high-quality displays continues to rise, the market for AR coatings in this segment is expected to grow substantially. The automotive industry is another major driver, with AR coatings being increasingly incorporated into dashboard displays, heads-up displays, and windshields to improve visibility and safety.

The solar energy sector represents a significant opportunity for AR coating manufacturers. As the world shifts towards renewable energy sources, the demand for solar panels is increasing, and AR coatings play a crucial role in improving the efficiency of these panels by reducing light reflection and increasing light absorption.

In the eyewear industry, AR coatings are widely used to reduce glare and improve visual clarity in both prescription and non-prescription lenses. The growing awareness of eye health and the increasing prevalence of digital devices are driving the demand for AR-coated lenses.

Geographically, Asia-Pacific is expected to dominate the AR coating market, primarily due to the presence of major consumer electronics and solar panel manufacturers in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and increasing adoption in automotive and architectural applications.

The market is characterized by intense competition among key players, including Essilor, Carl Zeiss, Honeywell International, and PPG Industries. These companies are focusing on research and development to improve coating technologies and expand their product portfolios. Innovations in nanotechnology and the development of eco-friendly coating materials are expected to create new opportunities in the market.

Despite the positive outlook, the AR coating market faces challenges such as high production costs and the need for specialized equipment and skilled labor. However, ongoing technological advancements and increasing applications across various industries are expected to drive sustained growth in the coming years.

PMMA AR Coating: Current State and Challenges

PMMA (Poly(methyl methacrylate)) has emerged as a crucial material in anti-reflective (AR) coating technology, offering significant advantages in optical applications. Currently, PMMA-based AR coatings are widely used in various industries, including electronics, automotive, and solar energy. The primary function of these coatings is to reduce light reflection and increase transmission, thereby enhancing the overall performance of optical devices.

The current state of PMMA AR coating technology showcases impressive advancements in terms of optical efficiency and durability. Modern PMMA AR coatings can achieve reflection reduction of up to 99.5% across a broad spectrum of wavelengths, significantly improving the performance of optical systems. Additionally, recent developments have led to the creation of multi-layer PMMA AR coatings that offer superior anti-reflective properties compared to single-layer alternatives.

Despite these achievements, the technology faces several challenges that hinder its widespread adoption and limit its potential applications. One of the primary concerns is the long-term stability of PMMA AR coatings, particularly in harsh environmental conditions. Exposure to UV radiation, high temperatures, and humidity can lead to degradation of the coating, reducing its effectiveness over time. This issue is particularly problematic in outdoor applications, such as solar panels and automotive displays.

Another significant challenge is the difficulty in achieving uniform coating thickness across large surface areas. Inconsistencies in coating thickness can result in variations in optical performance, leading to reduced overall efficiency. This challenge becomes more pronounced as the size of the substrate increases, making it particularly relevant for large-scale applications in the solar energy sector.

The adhesion of PMMA AR coatings to various substrates also presents a notable challenge. While PMMA exhibits good adhesion to many materials, certain substrates require additional surface treatments or primer layers to ensure proper bonding. This adds complexity to the manufacturing process and can increase production costs.

Furthermore, the development of PMMA AR coatings with enhanced mechanical properties remains an ongoing challenge. Current coatings are susceptible to scratching and abrasion, which can significantly impact their long-term performance. Improving the hardness and scratch resistance of PMMA AR coatings without compromising their optical properties is a key area of research and development.

In conclusion, while PMMA AR coating technology has made significant strides, addressing these challenges is crucial for its continued advancement and broader adoption across various industries. Ongoing research efforts are focused on developing novel formulations and manufacturing techniques to overcome these limitations and unlock the full potential of PMMA in anti-reflective coating applications.

The current state of PMMA AR coating technology showcases impressive advancements in terms of optical efficiency and durability. Modern PMMA AR coatings can achieve reflection reduction of up to 99.5% across a broad spectrum of wavelengths, significantly improving the performance of optical systems. Additionally, recent developments have led to the creation of multi-layer PMMA AR coatings that offer superior anti-reflective properties compared to single-layer alternatives.

Despite these achievements, the technology faces several challenges that hinder its widespread adoption and limit its potential applications. One of the primary concerns is the long-term stability of PMMA AR coatings, particularly in harsh environmental conditions. Exposure to UV radiation, high temperatures, and humidity can lead to degradation of the coating, reducing its effectiveness over time. This issue is particularly problematic in outdoor applications, such as solar panels and automotive displays.

Another significant challenge is the difficulty in achieving uniform coating thickness across large surface areas. Inconsistencies in coating thickness can result in variations in optical performance, leading to reduced overall efficiency. This challenge becomes more pronounced as the size of the substrate increases, making it particularly relevant for large-scale applications in the solar energy sector.

The adhesion of PMMA AR coatings to various substrates also presents a notable challenge. While PMMA exhibits good adhesion to many materials, certain substrates require additional surface treatments or primer layers to ensure proper bonding. This adds complexity to the manufacturing process and can increase production costs.

Furthermore, the development of PMMA AR coatings with enhanced mechanical properties remains an ongoing challenge. Current coatings are susceptible to scratching and abrasion, which can significantly impact their long-term performance. Improving the hardness and scratch resistance of PMMA AR coatings without compromising their optical properties is a key area of research and development.

In conclusion, while PMMA AR coating technology has made significant strides, addressing these challenges is crucial for its continued advancement and broader adoption across various industries. Ongoing research efforts are focused on developing novel formulations and manufacturing techniques to overcome these limitations and unlock the full potential of PMMA in anti-reflective coating applications.

Existing PMMA AR Coating Solutions

01 PMMA-based anti-reflective coatings

PMMA can be used as a base material for anti-reflective coatings. These coatings are typically applied to optical surfaces to reduce reflection and improve light transmission. The anti-reflective properties of PMMA-based coatings can be enhanced through various methods, such as incorporating nanoparticles or creating specific surface structures.- PMMA-based anti-reflective coatings: PMMA is used as a base material for anti-reflective coatings. These coatings are designed to reduce light reflection on various surfaces, improving optical performance and visibility. The anti-reflective properties are achieved by manipulating the refractive index and thickness of the PMMA layer, often in combination with other materials or surface treatments.

- Nanostructured PMMA for enhanced anti-reflective properties: Nanostructuring techniques are applied to PMMA to create surfaces with improved anti-reflective properties. This involves creating nanoscale patterns or textures on the PMMA surface, which can effectively reduce light reflection across a broad spectrum of wavelengths. These nanostructured PMMA surfaces find applications in optical devices, solar cells, and display technologies.

- PMMA blends and copolymers for anti-reflective applications: PMMA is blended with other polymers or copolymerized with different monomers to enhance its anti-reflective properties. These blends and copolymers can offer improved optical performance, durability, and processability compared to pure PMMA. The resulting materials are used in various applications, including optical lenses, displays, and protective coatings.

- Surface modification of PMMA for anti-reflective properties: Various surface modification techniques are applied to PMMA to enhance its anti-reflective properties. These methods include plasma treatment, chemical etching, and the application of functional coatings. Surface modification can alter the refractive index of the PMMA surface layer, creating an effective anti-reflective interface.

- PMMA-based multi-layer anti-reflective systems: Multi-layer anti-reflective systems incorporating PMMA are developed to achieve superior anti-reflective performance. These systems typically consist of alternating layers of PMMA and other materials with different refractive indices. The thickness and composition of each layer are carefully controlled to minimize reflection across a wide range of wavelengths and incident angles.

02 Nanostructured PMMA surfaces for anti-reflection

Creating nanostructures on PMMA surfaces can significantly improve its anti-reflective properties. These nanostructures can be fabricated through various techniques such as etching, nanoimprinting, or self-assembly processes. The resulting surface mimics the moth-eye effect, effectively reducing reflection across a wide range of wavelengths.Expand Specific Solutions03 PMMA blends and copolymers for enhanced anti-reflection

Blending PMMA with other polymers or creating copolymers can improve its anti-reflective properties. These modifications can alter the refractive index of the material or introduce specific functional groups that enhance light transmission and reduce reflection. Such blends and copolymers can be used in various optical applications.Expand Specific Solutions04 Multi-layer anti-reflective coatings incorporating PMMA

PMMA can be used as one of the layers in multi-layer anti-reflective coatings. These coatings typically consist of alternating layers of materials with different refractive indices. By carefully designing the thickness and composition of each layer, including PMMA layers, the overall anti-reflective performance can be optimized for specific wavelength ranges.Expand Specific Solutions05 Surface treatments for improving PMMA anti-reflective properties

Various surface treatments can be applied to PMMA to enhance its anti-reflective properties. These treatments may include plasma etching, chemical modifications, or the application of specialized coatings. Such treatments can alter the surface chemistry or create micro/nanostructures that effectively reduce reflection and improve light transmission.Expand Specific Solutions

Key Players in PMMA AR Coating Industry

The anti-reflective coating technology market, particularly PMMA's role within it, is in a growth phase characterized by increasing demand across various industries. The market size is expanding due to the rising adoption of anti-reflective coatings in consumer electronics, automotive, and optical applications. Technologically, the field is advancing rapidly, with companies like Röhm GmbH, DuPont de Nemours, Inc., and Mitsui Chemicals, Inc. leading innovation in PMMA-based anti-reflective solutions. These firms are developing more efficient and durable coatings, leveraging PMMA's optical properties and versatility. The competitive landscape is diverse, with both established chemical companies and specialized materials firms vying for market share through product differentiation and technological advancements.

Röhm GmbH

Technical Solution: Röhm GmbH has developed advanced PMMA-based anti-reflective coatings for optical applications. Their technology involves creating nanoporous PMMA structures that significantly reduce surface reflections. The company utilizes a sol-gel process to create these nanostructures, which can achieve reflection rates as low as 0.5% across a wide spectrum of light[1]. Röhm's coatings are particularly effective in improving the efficiency of solar panels and enhancing the clarity of display screens. The company has also developed a proprietary plasma etching technique to further refine the anti-reflective properties of their PMMA coatings, allowing for customization based on specific wavelength requirements[3].

Strengths: Highly effective anti-reflective properties, customizable for specific applications, and expertise in PMMA technology. Weaknesses: May be more expensive than traditional coatings, and the nanoporous structure could potentially be more susceptible to contamination or damage.

DuPont de Nemours, Inc.

Technical Solution: DuPont has innovated in the field of PMMA-based anti-reflective coatings by developing a multi-layer approach. Their technology combines PMMA with other materials to create a gradient refractive index structure. This multi-layer system can reduce reflections to less than 0.1% across visible and near-infrared wavelengths[2]. DuPont's coatings are particularly notable for their durability and resistance to environmental factors. The company has also developed a UV-curable PMMA formulation that allows for rapid, energy-efficient application of anti-reflective coatings in high-volume manufacturing processes[4].

Strengths: Exceptional anti-reflective performance, high durability, and efficient manufacturing process. Weaknesses: Complex multi-layer structure may increase production costs and potentially limit flexibility in some applications.

Core Innovations in PMMA AR Coating Technology

Coating agent for poly(methyl methacrylate) panel nano imprinting and methods of use

PatentActiveUS8252849B2

Innovation

- A UV curable resin coating agent with a refractive index similar to PMMA, comprising a photoinitiator, solvent-free additive for surface modification, and weather-resistant stabilizer, which enables nanopattern formation with improved transmittance, heat resistance, and scratch resistance, minimizing light reflection.

Poly(methyl methacrylate) resin composition

PatentWO2019018219A1

Innovation

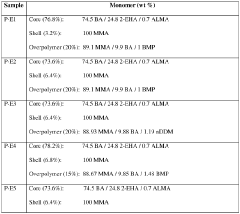

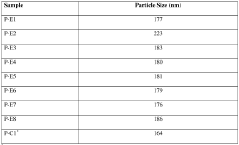

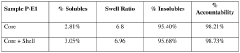

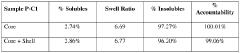

- A PMMA resin composition incorporating a methyl methacrylate polymer and a multistage acrylic impact modifier, comprising a core-shell polymer and an overpolymer, which improves impact strength while preserving gloss and melt flow.

Environmental Impact of PMMA AR Coatings

The environmental impact of PMMA (Poly(methyl methacrylate)) anti-reflective (AR) coatings is a crucial consideration in the development and application of this technology. PMMA AR coatings have gained popularity due to their excellent optical properties and durability, but their environmental implications must be carefully evaluated.

One of the primary environmental concerns associated with PMMA AR coatings is the production process. The synthesis of PMMA involves the use of petrochemical-based raw materials, which contributes to the depletion of non-renewable resources. Additionally, the manufacturing process may release volatile organic compounds (VOCs) and other potentially harmful emissions into the atmosphere, contributing to air pollution and potentially affecting local ecosystems.

The disposal of PMMA AR coatings at the end of their lifecycle presents another environmental challenge. While PMMA is theoretically recyclable, the presence of additional compounds in AR coatings can complicate the recycling process. Improper disposal may lead to the accumulation of these materials in landfills, where they can persist for extended periods due to their slow degradation rates.

However, it is important to note that PMMA AR coatings also offer some environmental benefits. By improving the efficiency of optical devices, these coatings can contribute to energy savings in various applications. For instance, in solar panels, PMMA AR coatings can enhance light transmission, leading to improved energy conversion efficiency and potentially reducing the overall carbon footprint of solar energy systems.

The durability of PMMA AR coatings is another factor that impacts their environmental profile. Their resistance to weathering and degradation means that they require less frequent replacement compared to some alternative materials. This longevity can reduce waste generation and the need for frequent reapplication, which in turn minimizes the environmental impact associated with production and disposal cycles.

Recent research has focused on developing more environmentally friendly PMMA AR coatings. This includes exploring bio-based alternatives to traditional petrochemical-derived PMMA, as well as investigating methods to enhance the recyclability of these coatings. Some studies have also examined the potential for incorporating nanoparticles or other additives to improve the coatings' performance while minimizing environmental impact.

As environmental regulations become more stringent, manufacturers are increasingly required to consider the entire lifecycle of PMMA AR coatings, from raw material extraction to end-of-life disposal. This holistic approach is driving innovations in green chemistry and sustainable manufacturing practices within the industry, aiming to reduce the overall environmental footprint of these coatings.

One of the primary environmental concerns associated with PMMA AR coatings is the production process. The synthesis of PMMA involves the use of petrochemical-based raw materials, which contributes to the depletion of non-renewable resources. Additionally, the manufacturing process may release volatile organic compounds (VOCs) and other potentially harmful emissions into the atmosphere, contributing to air pollution and potentially affecting local ecosystems.

The disposal of PMMA AR coatings at the end of their lifecycle presents another environmental challenge. While PMMA is theoretically recyclable, the presence of additional compounds in AR coatings can complicate the recycling process. Improper disposal may lead to the accumulation of these materials in landfills, where they can persist for extended periods due to their slow degradation rates.

However, it is important to note that PMMA AR coatings also offer some environmental benefits. By improving the efficiency of optical devices, these coatings can contribute to energy savings in various applications. For instance, in solar panels, PMMA AR coatings can enhance light transmission, leading to improved energy conversion efficiency and potentially reducing the overall carbon footprint of solar energy systems.

The durability of PMMA AR coatings is another factor that impacts their environmental profile. Their resistance to weathering and degradation means that they require less frequent replacement compared to some alternative materials. This longevity can reduce waste generation and the need for frequent reapplication, which in turn minimizes the environmental impact associated with production and disposal cycles.

Recent research has focused on developing more environmentally friendly PMMA AR coatings. This includes exploring bio-based alternatives to traditional petrochemical-derived PMMA, as well as investigating methods to enhance the recyclability of these coatings. Some studies have also examined the potential for incorporating nanoparticles or other additives to improve the coatings' performance while minimizing environmental impact.

As environmental regulations become more stringent, manufacturers are increasingly required to consider the entire lifecycle of PMMA AR coatings, from raw material extraction to end-of-life disposal. This holistic approach is driving innovations in green chemistry and sustainable manufacturing practices within the industry, aiming to reduce the overall environmental footprint of these coatings.

Optical Performance Metrics for PMMA AR Coatings

The optical performance of PMMA (Poly(methyl methacrylate)) anti-reflective (AR) coatings is crucial for their effectiveness in various applications. Key metrics used to evaluate these coatings include reflectance, transmittance, and refractive index.

Reflectance is a primary measure of an AR coating's effectiveness. For PMMA AR coatings, the goal is to minimize reflectance across the visible spectrum, typically aiming for less than 1% reflectance. This low reflectance ensures that more light passes through the coated surface rather than being reflected, enhancing optical clarity and reducing glare.

Transmittance, conversely, measures the amount of light that passes through the coated PMMA. High-quality AR coatings on PMMA can achieve transmittance values exceeding 99% in the visible spectrum. This high transmittance is essential for applications requiring maximum light throughput, such as optical lenses and display screens.

The refractive index of the AR coating layers is another critical metric. To achieve optimal anti-reflective properties, the coating's refractive index must be carefully matched to that of PMMA (approximately 1.49) and the surrounding medium (typically air, with a refractive index of 1). This matching is often achieved through multi-layer coatings with gradually changing refractive indices.

Spectral performance is also a key consideration. PMMA AR coatings are often designed to provide consistent anti-reflective properties across a specific wavelength range, which may vary depending on the application. For visible light applications, the coating should maintain its performance across the 400-700 nm range.

Durability metrics are equally important for PMMA AR coatings. These include adhesion strength, abrasion resistance, and chemical resistance. The coating must maintain its optical properties under various environmental conditions and over extended periods of use. Standard tests, such as the tape test for adhesion and the Taber abrasion test for wear resistance, are commonly used to evaluate these aspects.

Environmental stability is another crucial metric. PMMA AR coatings should maintain their optical performance under varying temperature and humidity conditions. Thermal cycling tests and humidity exposure tests are often employed to assess the coating's stability and longevity.

Uniformity of the coating is essential for consistent optical performance across the entire coated surface. This is typically measured using interferometry techniques, which can detect variations in coating thickness and refractive index across the substrate.

Finally, the angular dependence of the AR coating's performance is an important consideration, especially for applications involving non-normal light incidence. High-quality PMMA AR coatings should maintain their anti-reflective properties over a wide range of incident angles, typically up to 60 degrees from normal.

Reflectance is a primary measure of an AR coating's effectiveness. For PMMA AR coatings, the goal is to minimize reflectance across the visible spectrum, typically aiming for less than 1% reflectance. This low reflectance ensures that more light passes through the coated surface rather than being reflected, enhancing optical clarity and reducing glare.

Transmittance, conversely, measures the amount of light that passes through the coated PMMA. High-quality AR coatings on PMMA can achieve transmittance values exceeding 99% in the visible spectrum. This high transmittance is essential for applications requiring maximum light throughput, such as optical lenses and display screens.

The refractive index of the AR coating layers is another critical metric. To achieve optimal anti-reflective properties, the coating's refractive index must be carefully matched to that of PMMA (approximately 1.49) and the surrounding medium (typically air, with a refractive index of 1). This matching is often achieved through multi-layer coatings with gradually changing refractive indices.

Spectral performance is also a key consideration. PMMA AR coatings are often designed to provide consistent anti-reflective properties across a specific wavelength range, which may vary depending on the application. For visible light applications, the coating should maintain its performance across the 400-700 nm range.

Durability metrics are equally important for PMMA AR coatings. These include adhesion strength, abrasion resistance, and chemical resistance. The coating must maintain its optical properties under various environmental conditions and over extended periods of use. Standard tests, such as the tape test for adhesion and the Taber abrasion test for wear resistance, are commonly used to evaluate these aspects.

Environmental stability is another crucial metric. PMMA AR coatings should maintain their optical performance under varying temperature and humidity conditions. Thermal cycling tests and humidity exposure tests are often employed to assess the coating's stability and longevity.

Uniformity of the coating is essential for consistent optical performance across the entire coated surface. This is typically measured using interferometry techniques, which can detect variations in coating thickness and refractive index across the substrate.

Finally, the angular dependence of the AR coating's performance is an important consideration, especially for applications involving non-normal light incidence. High-quality PMMA AR coatings should maintain their anti-reflective properties over a wide range of incident angles, typically up to 60 degrees from normal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!