How to Enhance UV Resistance in PMMA Products?

AUG 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA UV Resistance Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a versatile material in various industries for decades. Its exceptional optical clarity, weather resistance, and mechanical properties have made it a preferred choice for outdoor applications, automotive parts, and architectural elements. However, prolonged exposure to ultraviolet (UV) radiation remains a significant challenge, causing degradation of PMMA products over time.

The evolution of PMMA technology has been marked by continuous efforts to enhance its UV resistance. Initially developed in the 1930s, PMMA quickly gained popularity due to its transparency and durability. As its applications expanded, particularly in outdoor environments, the need for improved UV resistance became apparent. This led to a series of innovations in material science and polymer chemistry, aimed at mitigating the effects of UV radiation on PMMA products.

The primary objective of enhancing UV resistance in PMMA products is to extend their service life and maintain their optical and mechanical properties under prolonged sun exposure. This goal aligns with broader industry trends towards sustainability and cost-effectiveness, as improved UV resistance reduces the frequency of replacement and maintenance of PMMA-based products.

Recent technological advancements have focused on developing novel additives and modifying the polymer structure to enhance UV resistance. These efforts are driven by the increasing demand for high-performance materials in sectors such as construction, automotive, and renewable energy. The integration of nanotechnology and the exploration of bio-inspired solutions represent cutting-edge approaches in this field.

The global market for UV-resistant PMMA products is experiencing steady growth, fueled by expanding applications in emerging economies and the rising awareness of environmental sustainability. This market trend underscores the importance of continued research and development in UV resistance enhancement techniques.

As we look towards the future, the objectives for improving UV resistance in PMMA products are multifaceted. They include developing more efficient UV stabilizers, exploring new polymer blends, and investigating surface modification techniques. Additionally, there is a growing emphasis on creating environmentally friendly solutions that do not compromise the recyclability of PMMA materials.

In conclusion, the background of UV resistance in PMMA products reflects a journey of continuous innovation, driven by market demands and technological advancements. The current objectives focus on pushing the boundaries of material science to create more durable, sustainable, and high-performance PMMA products capable of withstanding the harsh effects of UV radiation.

The evolution of PMMA technology has been marked by continuous efforts to enhance its UV resistance. Initially developed in the 1930s, PMMA quickly gained popularity due to its transparency and durability. As its applications expanded, particularly in outdoor environments, the need for improved UV resistance became apparent. This led to a series of innovations in material science and polymer chemistry, aimed at mitigating the effects of UV radiation on PMMA products.

The primary objective of enhancing UV resistance in PMMA products is to extend their service life and maintain their optical and mechanical properties under prolonged sun exposure. This goal aligns with broader industry trends towards sustainability and cost-effectiveness, as improved UV resistance reduces the frequency of replacement and maintenance of PMMA-based products.

Recent technological advancements have focused on developing novel additives and modifying the polymer structure to enhance UV resistance. These efforts are driven by the increasing demand for high-performance materials in sectors such as construction, automotive, and renewable energy. The integration of nanotechnology and the exploration of bio-inspired solutions represent cutting-edge approaches in this field.

The global market for UV-resistant PMMA products is experiencing steady growth, fueled by expanding applications in emerging economies and the rising awareness of environmental sustainability. This market trend underscores the importance of continued research and development in UV resistance enhancement techniques.

As we look towards the future, the objectives for improving UV resistance in PMMA products are multifaceted. They include developing more efficient UV stabilizers, exploring new polymer blends, and investigating surface modification techniques. Additionally, there is a growing emphasis on creating environmentally friendly solutions that do not compromise the recyclability of PMMA materials.

In conclusion, the background of UV resistance in PMMA products reflects a journey of continuous innovation, driven by market demands and technological advancements. The current objectives focus on pushing the boundaries of material science to create more durable, sustainable, and high-performance PMMA products capable of withstanding the harsh effects of UV radiation.

Market Analysis for UV-Resistant PMMA Products

The market for UV-resistant PMMA products has been experiencing significant growth in recent years, driven by increasing demand across various industries. The global PMMA market size was valued at USD 4.2 billion in 2020 and is projected to reach USD 5.9 billion by 2028, with a compound annual growth rate (CAGR) of 4.3% during the forecast period. UV-resistant PMMA products are expected to capture a substantial portion of this market growth.

The automotive industry represents a key market for UV-resistant PMMA products, particularly in exterior applications such as headlights, taillights, and transparent body panels. The growing trend towards lightweight materials in vehicle manufacturing has further boosted the demand for PMMA products. Additionally, the construction sector has shown increased adoption of UV-resistant PMMA in applications like skylights, window glazing, and outdoor signage, driven by the material's durability and weather resistance properties.

The electronics and display industry has also emerged as a significant consumer of UV-resistant PMMA products. With the rising popularity of outdoor digital signage and electronic displays, there is a growing need for materials that can withstand prolonged exposure to sunlight while maintaining optical clarity. This trend is expected to continue as smart cities and digital advertising markets expand globally.

In the medical and healthcare sector, UV-resistant PMMA finds applications in laboratory equipment, medical devices, and protective screens. The ongoing COVID-19 pandemic has further accelerated the demand for transparent protective barriers, creating new opportunities for UV-resistant PMMA products in public spaces and healthcare facilities.

Geographically, Asia-Pacific is expected to be the fastest-growing market for UV-resistant PMMA products, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance applications in automotive and aerospace industries.

The market for UV-resistant PMMA products is characterized by intense competition among key players, including Evonik Industries, Mitsubishi Chemical Corporation, and Arkema Group. These companies are investing heavily in research and development to improve the UV resistance and overall performance of PMMA products, aiming to gain a competitive edge in the market.

The automotive industry represents a key market for UV-resistant PMMA products, particularly in exterior applications such as headlights, taillights, and transparent body panels. The growing trend towards lightweight materials in vehicle manufacturing has further boosted the demand for PMMA products. Additionally, the construction sector has shown increased adoption of UV-resistant PMMA in applications like skylights, window glazing, and outdoor signage, driven by the material's durability and weather resistance properties.

The electronics and display industry has also emerged as a significant consumer of UV-resistant PMMA products. With the rising popularity of outdoor digital signage and electronic displays, there is a growing need for materials that can withstand prolonged exposure to sunlight while maintaining optical clarity. This trend is expected to continue as smart cities and digital advertising markets expand globally.

In the medical and healthcare sector, UV-resistant PMMA finds applications in laboratory equipment, medical devices, and protective screens. The ongoing COVID-19 pandemic has further accelerated the demand for transparent protective barriers, creating new opportunities for UV-resistant PMMA products in public spaces and healthcare facilities.

Geographically, Asia-Pacific is expected to be the fastest-growing market for UV-resistant PMMA products, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance applications in automotive and aerospace industries.

The market for UV-resistant PMMA products is characterized by intense competition among key players, including Evonik Industries, Mitsubishi Chemical Corporation, and Arkema Group. These companies are investing heavily in research and development to improve the UV resistance and overall performance of PMMA products, aiming to gain a competitive edge in the market.

Current Challenges in PMMA UV Protection

PMMA (Poly(methyl methacrylate)) products face significant challenges in maintaining their UV resistance, which is crucial for their long-term performance and durability. One of the primary issues is the inherent susceptibility of PMMA to UV degradation. When exposed to UV radiation, PMMA undergoes photochemical reactions that lead to chain scission and oxidation, resulting in yellowing, embrittlement, and loss of mechanical properties.

The current UV protection methods for PMMA products have limitations in their effectiveness and longevity. UV absorbers and stabilizers, commonly used to enhance UV resistance, tend to migrate to the surface over time, reducing their protective capacity. This migration is accelerated by environmental factors such as heat and moisture, further compromising the long-term UV stability of PMMA products.

Another challenge lies in maintaining the optical clarity of PMMA while improving its UV resistance. Many UV protection additives can negatively impact the transparency and color of PMMA, which is often a critical property for its applications in automotive, construction, and optical industries. Balancing UV protection with optical clarity remains a significant hurdle for manufacturers.

The weathering resistance of PMMA products is also a concern, particularly in outdoor applications. While PMMA exhibits good resistance to many environmental factors, prolonged exposure to UV radiation, coupled with temperature fluctuations and moisture, can lead to surface crazing, micro-cracks, and eventual failure. Developing UV protection systems that can withstand these complex environmental conditions is a persistent challenge.

Cost-effectiveness is another critical issue in enhancing UV resistance in PMMA products. High-performance UV stabilizers and advanced protection methods often come with increased production costs, which can be prohibitive for large-scale applications. Finding economically viable solutions that provide long-lasting UV protection without significantly increasing product costs remains a key challenge for the industry.

Furthermore, there is a growing demand for environmentally friendly and sustainable UV protection methods. Traditional UV stabilizers and additives may have environmental concerns, and there is a push towards developing green alternatives that maintain effectiveness while reducing environmental impact. This shift presents both a challenge and an opportunity for innovation in PMMA UV protection.

Lastly, the varying requirements for UV resistance across different applications pose a challenge in developing universal solutions. PMMA products used in outdoor signage, for instance, have different UV protection needs compared to those used in medical devices or automotive components. Tailoring UV protection strategies to meet these diverse requirements while maintaining other essential properties of PMMA is an ongoing challenge for researchers and manufacturers in the field.

The current UV protection methods for PMMA products have limitations in their effectiveness and longevity. UV absorbers and stabilizers, commonly used to enhance UV resistance, tend to migrate to the surface over time, reducing their protective capacity. This migration is accelerated by environmental factors such as heat and moisture, further compromising the long-term UV stability of PMMA products.

Another challenge lies in maintaining the optical clarity of PMMA while improving its UV resistance. Many UV protection additives can negatively impact the transparency and color of PMMA, which is often a critical property for its applications in automotive, construction, and optical industries. Balancing UV protection with optical clarity remains a significant hurdle for manufacturers.

The weathering resistance of PMMA products is also a concern, particularly in outdoor applications. While PMMA exhibits good resistance to many environmental factors, prolonged exposure to UV radiation, coupled with temperature fluctuations and moisture, can lead to surface crazing, micro-cracks, and eventual failure. Developing UV protection systems that can withstand these complex environmental conditions is a persistent challenge.

Cost-effectiveness is another critical issue in enhancing UV resistance in PMMA products. High-performance UV stabilizers and advanced protection methods often come with increased production costs, which can be prohibitive for large-scale applications. Finding economically viable solutions that provide long-lasting UV protection without significantly increasing product costs remains a key challenge for the industry.

Furthermore, there is a growing demand for environmentally friendly and sustainable UV protection methods. Traditional UV stabilizers and additives may have environmental concerns, and there is a push towards developing green alternatives that maintain effectiveness while reducing environmental impact. This shift presents both a challenge and an opportunity for innovation in PMMA UV protection.

Lastly, the varying requirements for UV resistance across different applications pose a challenge in developing universal solutions. PMMA products used in outdoor signage, for instance, have different UV protection needs compared to those used in medical devices or automotive components. Tailoring UV protection strategies to meet these diverse requirements while maintaining other essential properties of PMMA is an ongoing challenge for researchers and manufacturers in the field.

Existing UV Protection Solutions for PMMA

01 UV stabilizers and absorbers for PMMA

Various UV stabilizers and absorbers can be incorporated into PMMA products to enhance their UV resistance. These additives work by absorbing or blocking harmful UV radiation, preventing degradation of the polymer structure. Common UV stabilizers include benzotriazoles, benzophenones, and hindered amine light stabilizers (HALS).- UV stabilizers and absorbers for PMMA: Various UV stabilizers and absorbers can be incorporated into PMMA products to enhance their UV resistance. These additives help to protect the polymer from degradation caused by UV radiation, extending the lifespan and maintaining the optical properties of PMMA products.

- Surface treatment techniques: Surface treatment methods can be applied to PMMA products to improve their UV resistance. These techniques may include coating with UV-resistant materials, plasma treatment, or chemical modification of the surface layer to enhance protection against UV radiation.

- Nanoparticle incorporation: The addition of nanoparticles, such as titanium dioxide or zinc oxide, to PMMA can significantly improve its UV resistance. These nanoparticles act as efficient UV blockers and can be dispersed throughout the polymer matrix to provide comprehensive protection.

- Copolymerization with UV-resistant monomers: PMMA can be copolymerized with other monomers that inherently possess UV-resistant properties. This approach allows for the creation of a polymer with enhanced UV stability built into its molecular structure, providing long-lasting protection against UV degradation.

- Multi-layer PMMA structures: Developing multi-layer PMMA structures where one or more layers contain UV-resistant additives or are specifically designed to block UV radiation can improve the overall UV resistance of the product. This approach allows for the optimization of UV protection while maintaining other desired properties in different layers.

02 Surface treatment and coatings

Applying specialized surface treatments or coatings to PMMA products can significantly improve their UV resistance. These treatments may include UV-resistant lacquers, hard coatings, or nanoparticle-based coatings that provide a protective layer against UV radiation and environmental factors.Expand Specific Solutions03 Copolymerization and blending

Improving UV resistance of PMMA products can be achieved through copolymerization with other UV-resistant monomers or blending with other polymers. This approach modifies the chemical structure of the material, making it inherently more resistant to UV degradation.Expand Specific Solutions04 Nanocomposite PMMA materials

Incorporating nanoparticles or nanofillers into PMMA can enhance its UV resistance. Materials such as titanium dioxide, zinc oxide, or carbon nanotubes can be dispersed within the PMMA matrix, providing improved UV absorption and scattering properties.Expand Specific Solutions05 Modified PMMA formulations

Developing modified PMMA formulations with enhanced UV resistance properties is another approach. This may involve adjusting the molecular weight distribution, incorporating specific functional groups, or using specialized polymerization techniques to create PMMA variants with improved UV stability.Expand Specific Solutions

Key Players in UV-Resistant PMMA Industry

The UV resistance enhancement in PMMA products market is in a growth phase, driven by increasing demand for durable outdoor materials. The global market size for UV-resistant PMMA is expanding, with projections indicating steady growth in the coming years. Technologically, the field is advancing rapidly, with companies like Röhm GmbH, Wanhua Chemical Group, and Kingfa Sci. & Tech. leading innovation. These firms are developing advanced UV stabilizers and coating technologies, pushing the boundaries of PMMA's UV resistance capabilities. Emerging players such as Ningbo Exciton Technology and Shanghai PRET Composites are also contributing to the competitive landscape, focusing on specialized applications and novel formulations to improve UV stability in PMMA products.

Röhm GmbH

Technical Solution: Röhm GmbH has developed PLEXIGLAS® Resist AG 100, a PMMA grade with enhanced UV resistance. This material incorporates specially designed UV absorbers and light stabilizers into the PMMA matrix. The proprietary technology involves a co-extrusion process where a thin, highly UV-resistant layer is applied to the surface of the PMMA sheet[1]. This layer acts as a protective shield, absorbing harmful UV radiation before it can penetrate the bulk material. Additionally, Röhm has implemented a cross-linking technique that enhances the overall stability of the polymer structure, further improving its resistance to UV degradation[2].

Strengths: Excellent UV resistance, maintains optical clarity, suitable for outdoor applications. Weaknesses: Higher production costs, potential limitations in thermoforming processes due to the protective layer.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a novel UV-resistant PMMA formulation using a combination of hindered amine light stabilizers (HALS) and UV absorbers. Their approach involves grafting these additives onto the PMMA backbone, ensuring a more uniform distribution and preventing migration of the stabilizers over time[3]. The company has also introduced a proprietary nanocomposite technology, incorporating inorganic nanoparticles such as cerium oxide into the PMMA matrix. These nanoparticles act as efficient UV blockers while maintaining the transparency of the material[4]. Wanhua's research has shown that this combination can extend the service life of PMMA products by up to 50% in high UV exposure environments.

Strengths: Long-lasting UV protection, improved mechanical properties due to nanocomposite structure. Weaknesses: Potential increase in production complexity, possible color shifts in certain applications.

Innovative UV Resistance Mechanisms for PMMA

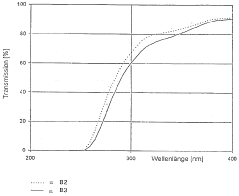

Use of reductive inorganic phosphorous compounds to increase UV transmissibility of moulded bodies made of polymethylmethacrylate moulding material as a suitable solar material

PatentWO1999025764A1

Innovation

- Incorporating reducing inorganic phosphorus compounds, such as phosphinic acid and phosphonic acid salts, into PMMA molding compounds before thermoplastic processing to increase UV permeability without altering the Vicat softening point or introducing technical difficulties.

Use of reductive inorganic phosphorous compounds to increase UV transmissibility of moulded bodies made of polymethylmethacrylate moulding material as a suitable solar material

PatentInactiveEP0953010A1

Innovation

- Incorporating reducing inorganic phosphorus compounds, such as phosphinic acid and phosphonic acid salts, into PMMA molding compounds during thermoplastic processing to increase UV transmission in the 260-400 nm range, specifically using sodium hypophosphite in small doses (0.001-0.1% by weight) with sterically hindered amines (HALS) to enhance UV stability.

Environmental Impact of UV-Resistant PMMA

The environmental impact of UV-resistant PMMA products is a critical consideration in their development and application. While enhancing UV resistance in PMMA offers numerous benefits, it also presents potential environmental challenges that must be carefully evaluated.

One of the primary environmental concerns associated with UV-resistant PMMA is the use of additives and stabilizers. These compounds, often including UV absorbers and hindered amine light stabilizers (HALS), can potentially leach into the environment over time. The long-term effects of these chemicals on ecosystems and wildlife are not fully understood, necessitating ongoing research and monitoring.

The production process of UV-resistant PMMA may also contribute to increased energy consumption and greenhouse gas emissions. The incorporation of UV-resistant additives often requires additional processing steps, which can lead to higher energy demands in manufacturing. This increased energy usage translates to a larger carbon footprint, potentially offsetting some of the environmental benefits gained from the extended lifespan of UV-resistant PMMA products.

However, the enhanced durability of UV-resistant PMMA products can have positive environmental implications. By extending the service life of PMMA-based products, the need for frequent replacements is reduced. This longevity can lead to decreased overall material consumption and waste generation, aligning with principles of sustainability and resource conservation.

The end-of-life management of UV-resistant PMMA products is another crucial environmental consideration. While PMMA is generally recyclable, the presence of UV-resistant additives may complicate the recycling process. Some additives can interfere with traditional recycling methods, potentially reducing the recyclability of the material or requiring specialized recycling techniques. This challenge underscores the importance of developing recycling technologies that can effectively handle UV-resistant PMMA.

Furthermore, the improved weatherability of UV-resistant PMMA can contribute to reduced microplastic pollution. As these products are less prone to degradation and fragmentation when exposed to sunlight, they are less likely to break down into harmful microplastics that can contaminate water bodies and ecosystems.

In conclusion, while UV-resistant PMMA offers significant benefits in terms of product longevity and performance, its environmental impact is multifaceted. Balancing the advantages of enhanced durability against the potential environmental risks associated with additives and production processes is crucial. Future research and development efforts should focus on minimizing negative environmental impacts while maximizing the sustainability benefits of UV-resistant PMMA products.

One of the primary environmental concerns associated with UV-resistant PMMA is the use of additives and stabilizers. These compounds, often including UV absorbers and hindered amine light stabilizers (HALS), can potentially leach into the environment over time. The long-term effects of these chemicals on ecosystems and wildlife are not fully understood, necessitating ongoing research and monitoring.

The production process of UV-resistant PMMA may also contribute to increased energy consumption and greenhouse gas emissions. The incorporation of UV-resistant additives often requires additional processing steps, which can lead to higher energy demands in manufacturing. This increased energy usage translates to a larger carbon footprint, potentially offsetting some of the environmental benefits gained from the extended lifespan of UV-resistant PMMA products.

However, the enhanced durability of UV-resistant PMMA products can have positive environmental implications. By extending the service life of PMMA-based products, the need for frequent replacements is reduced. This longevity can lead to decreased overall material consumption and waste generation, aligning with principles of sustainability and resource conservation.

The end-of-life management of UV-resistant PMMA products is another crucial environmental consideration. While PMMA is generally recyclable, the presence of UV-resistant additives may complicate the recycling process. Some additives can interfere with traditional recycling methods, potentially reducing the recyclability of the material or requiring specialized recycling techniques. This challenge underscores the importance of developing recycling technologies that can effectively handle UV-resistant PMMA.

Furthermore, the improved weatherability of UV-resistant PMMA can contribute to reduced microplastic pollution. As these products are less prone to degradation and fragmentation when exposed to sunlight, they are less likely to break down into harmful microplastics that can contaminate water bodies and ecosystems.

In conclusion, while UV-resistant PMMA offers significant benefits in terms of product longevity and performance, its environmental impact is multifaceted. Balancing the advantages of enhanced durability against the potential environmental risks associated with additives and production processes is crucial. Future research and development efforts should focus on minimizing negative environmental impacts while maximizing the sustainability benefits of UV-resistant PMMA products.

Cost-Benefit Analysis of Enhanced UV Resistance

Enhancing UV resistance in PMMA products involves a careful consideration of costs and benefits. The initial investment in UV-resistant additives or coatings can be substantial, often increasing the production cost by 10-15%. However, this upfront expense must be weighed against the long-term benefits of improved product durability and customer satisfaction.

The primary benefit of enhanced UV resistance is the extended lifespan of PMMA products. Untreated PMMA may show signs of degradation within 2-3 years of outdoor exposure, while UV-resistant PMMA can maintain its optical and mechanical properties for 5-10 years or more. This longevity translates to reduced replacement costs for end-users and fewer warranty claims for manufacturers, potentially saving 20-30% in long-term expenses.

Improved UV resistance also opens up new market opportunities. PMMA products with enhanced weatherability can compete in outdoor applications previously dominated by more expensive materials like polycarbonate. This market expansion can lead to increased sales volumes, potentially offsetting the higher production costs within 2-3 years.

Customer perception is another crucial factor. UV-resistant PMMA products are often perceived as higher quality, allowing manufacturers to command premium prices. This price differentiation can result in profit margins 5-8% higher than standard PMMA products, further justifying the initial investment in UV-resistant technologies.

However, the cost-benefit analysis must also consider potential drawbacks. Some UV-resistant additives may slightly alter the optical properties of PMMA, which could be unacceptable for certain high-precision applications. Additionally, the environmental impact of these additives should be evaluated, as some may pose challenges in recycling processes.

In conclusion, while the upfront costs of enhancing UV resistance in PMMA products are significant, the long-term benefits in terms of product longevity, market expansion, and customer satisfaction generally outweigh these initial expenses. Companies investing in UV-resistant PMMA technologies can expect to see a positive return on investment within 3-5 years, provided they effectively leverage the improved product characteristics in their marketing and pricing strategies.

The primary benefit of enhanced UV resistance is the extended lifespan of PMMA products. Untreated PMMA may show signs of degradation within 2-3 years of outdoor exposure, while UV-resistant PMMA can maintain its optical and mechanical properties for 5-10 years or more. This longevity translates to reduced replacement costs for end-users and fewer warranty claims for manufacturers, potentially saving 20-30% in long-term expenses.

Improved UV resistance also opens up new market opportunities. PMMA products with enhanced weatherability can compete in outdoor applications previously dominated by more expensive materials like polycarbonate. This market expansion can lead to increased sales volumes, potentially offsetting the higher production costs within 2-3 years.

Customer perception is another crucial factor. UV-resistant PMMA products are often perceived as higher quality, allowing manufacturers to command premium prices. This price differentiation can result in profit margins 5-8% higher than standard PMMA products, further justifying the initial investment in UV-resistant technologies.

However, the cost-benefit analysis must also consider potential drawbacks. Some UV-resistant additives may slightly alter the optical properties of PMMA, which could be unacceptable for certain high-precision applications. Additionally, the environmental impact of these additives should be evaluated, as some may pose challenges in recycling processes.

In conclusion, while the upfront costs of enhancing UV resistance in PMMA products are significant, the long-term benefits in terms of product longevity, market expansion, and customer satisfaction generally outweigh these initial expenses. Companies investing in UV-resistant PMMA technologies can expect to see a positive return on investment within 3-5 years, provided they effectively leverage the improved product characteristics in their marketing and pricing strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!