How to Develop PMMA Structures for Versatile Use?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Development Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a versatile material since its development in the 1930s. Its unique combination of optical clarity, durability, and ease of processing has made it a popular choice across various industries. The evolution of PMMA structures has been driven by the increasing demand for lightweight, transparent, and robust materials in applications ranging from automotive and aerospace to medical devices and consumer electronics.

The primary objective in developing PMMA structures for versatile use is to enhance its properties while maintaining its core advantages. This includes improving its mechanical strength, thermal stability, and chemical resistance without compromising its optical clarity and processability. Researchers and engineers are focusing on creating PMMA-based composites and nanostructures that can expand its application range and overcome some of its inherent limitations.

One of the key trends in PMMA development is the exploration of its potential in advanced manufacturing techniques, such as 3D printing and micro-fabrication. These technologies open up new possibilities for creating complex PMMA structures with precise geometries and tailored properties, which are particularly valuable in fields like biomedical engineering and microfluidics.

Another significant area of development is the modification of PMMA to enhance its functionality. This includes incorporating additives or creating copolymers to impart specific properties such as UV resistance, antimicrobial activity, or improved impact strength. These modifications aim to broaden PMMA's applicability in outdoor environments, healthcare settings, and high-stress applications.

The environmental aspect of PMMA development is also gaining prominence. With increasing focus on sustainability, efforts are being made to develop bio-based PMMA alternatives and improve recycling processes for PMMA products. This aligns with the global push towards more environmentally friendly materials and circular economy principles.

In the context of emerging technologies, PMMA is being explored for its potential in advanced optical applications. This includes the development of PMMA-based optical fibers, holographic materials, and photonic crystals. These applications leverage PMMA's excellent optical properties and processability to create innovative solutions in telecommunications, display technologies, and sensing devices.

The goal of developing versatile PMMA structures also extends to improving its compatibility with other materials. This involves research into surface modification techniques and the creation of PMMA-based hybrid materials that can interface seamlessly with metals, ceramics, or other polymers. Such developments are crucial for expanding PMMA's role in complex, multi-material systems and devices.

The primary objective in developing PMMA structures for versatile use is to enhance its properties while maintaining its core advantages. This includes improving its mechanical strength, thermal stability, and chemical resistance without compromising its optical clarity and processability. Researchers and engineers are focusing on creating PMMA-based composites and nanostructures that can expand its application range and overcome some of its inherent limitations.

One of the key trends in PMMA development is the exploration of its potential in advanced manufacturing techniques, such as 3D printing and micro-fabrication. These technologies open up new possibilities for creating complex PMMA structures with precise geometries and tailored properties, which are particularly valuable in fields like biomedical engineering and microfluidics.

Another significant area of development is the modification of PMMA to enhance its functionality. This includes incorporating additives or creating copolymers to impart specific properties such as UV resistance, antimicrobial activity, or improved impact strength. These modifications aim to broaden PMMA's applicability in outdoor environments, healthcare settings, and high-stress applications.

The environmental aspect of PMMA development is also gaining prominence. With increasing focus on sustainability, efforts are being made to develop bio-based PMMA alternatives and improve recycling processes for PMMA products. This aligns with the global push towards more environmentally friendly materials and circular economy principles.

In the context of emerging technologies, PMMA is being explored for its potential in advanced optical applications. This includes the development of PMMA-based optical fibers, holographic materials, and photonic crystals. These applications leverage PMMA's excellent optical properties and processability to create innovative solutions in telecommunications, display technologies, and sensing devices.

The goal of developing versatile PMMA structures also extends to improving its compatibility with other materials. This involves research into surface modification techniques and the creation of PMMA-based hybrid materials that can interface seamlessly with metals, ceramics, or other polymers. Such developments are crucial for expanding PMMA's role in complex, multi-material systems and devices.

Market Analysis for Versatile PMMA Structures

The market for versatile PMMA structures is experiencing significant growth, driven by the material's unique properties and diverse applications across multiple industries. PMMA, also known as acrylic or plexiglass, offers excellent optical clarity, weather resistance, and moldability, making it an attractive choice for various products and structures.

In the construction sector, PMMA structures are gaining popularity for architectural applications such as skylights, facades, and decorative elements. The material's lightweight nature and durability contribute to its increasing adoption in modern building designs. The automotive industry is another key market for PMMA structures, utilizing the material for lightweight components, headlight covers, and interior trim pieces to improve fuel efficiency and aesthetics.

The electronics and display industry represents a substantial market for PMMA structures, particularly in the production of screens, light guides, and optical components for devices ranging from smartphones to large-format displays. The material's excellent light transmission properties make it ideal for these applications, driving demand in the consumer electronics sector.

Medical and healthcare applications are emerging as a growing market for PMMA structures. The material's biocompatibility and ease of sterilization make it suitable for various medical devices, prosthetics, and laboratory equipment. As healthcare technology advances, the demand for specialized PMMA structures in this sector is expected to increase.

The packaging industry is also adopting PMMA structures for high-end cosmetic containers, food packaging, and luxury product displays. The material's clarity and ability to be molded into complex shapes provide opportunities for innovative packaging designs that enhance product presentation and consumer appeal.

Geographically, North America and Europe currently lead the market for versatile PMMA structures, owing to their advanced manufacturing capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to show the fastest growth in the coming years, driven by rapid industrialization, increasing consumer electronics production, and growing automotive manufacturing in countries like China, Japan, and South Korea.

Market analysts project a compound annual growth rate (CAGR) for the global PMMA market in the range of 5-7% over the next five years. This growth is attributed to the expanding applications of PMMA structures in emerging technologies such as augmented reality displays, advanced medical devices, and sustainable building materials.

In the construction sector, PMMA structures are gaining popularity for architectural applications such as skylights, facades, and decorative elements. The material's lightweight nature and durability contribute to its increasing adoption in modern building designs. The automotive industry is another key market for PMMA structures, utilizing the material for lightweight components, headlight covers, and interior trim pieces to improve fuel efficiency and aesthetics.

The electronics and display industry represents a substantial market for PMMA structures, particularly in the production of screens, light guides, and optical components for devices ranging from smartphones to large-format displays. The material's excellent light transmission properties make it ideal for these applications, driving demand in the consumer electronics sector.

Medical and healthcare applications are emerging as a growing market for PMMA structures. The material's biocompatibility and ease of sterilization make it suitable for various medical devices, prosthetics, and laboratory equipment. As healthcare technology advances, the demand for specialized PMMA structures in this sector is expected to increase.

The packaging industry is also adopting PMMA structures for high-end cosmetic containers, food packaging, and luxury product displays. The material's clarity and ability to be molded into complex shapes provide opportunities for innovative packaging designs that enhance product presentation and consumer appeal.

Geographically, North America and Europe currently lead the market for versatile PMMA structures, owing to their advanced manufacturing capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to show the fastest growth in the coming years, driven by rapid industrialization, increasing consumer electronics production, and growing automotive manufacturing in countries like China, Japan, and South Korea.

Market analysts project a compound annual growth rate (CAGR) for the global PMMA market in the range of 5-7% over the next five years. This growth is attributed to the expanding applications of PMMA structures in emerging technologies such as augmented reality displays, advanced medical devices, and sustainable building materials.

Current PMMA Technology Challenges

Despite the widespread use of PMMA (Poly(methyl methacrylate)) in various industries, several technological challenges persist in developing versatile PMMA structures. One of the primary obstacles is the material's inherent brittleness, which limits its application in high-impact or load-bearing scenarios. This characteristic makes it difficult to create PMMA structures that can withstand significant mechanical stress without fracturing.

Another challenge lies in the thermal stability of PMMA. While it possesses good heat resistance compared to some other thermoplastics, its relatively low glass transition temperature (around 105°C) restricts its use in high-temperature environments. This limitation poses difficulties in developing PMMA structures for applications that require exposure to elevated temperatures or thermal cycling.

The processing of PMMA for complex structures also presents challenges. Although PMMA can be easily molded and machined, creating intricate or large-scale structures with consistent properties throughout can be problematic. Issues such as internal stress buildup during processing and non-uniform cooling can lead to warping, cracking, or dimensional instability in the final product.

Surface modification of PMMA structures remains a significant challenge. While PMMA has excellent optical properties, its surface is prone to scratching and can be difficult to functionalize for specific applications. Developing durable, scratch-resistant surfaces or incorporating functional groups for enhanced properties (such as hydrophobicity or antimicrobial activity) without compromising the bulk material properties is an ongoing area of research.

The recyclability and environmental impact of PMMA structures also pose challenges. Although PMMA is theoretically recyclable, the process is not as straightforward as with some other plastics. Developing efficient recycling methods and creating PMMA structures that are easily recyclable without loss of properties is crucial for sustainable use.

Addressing the limitations in PMMA's chemical resistance is another technological hurdle. While PMMA exhibits good resistance to many chemicals, it is vulnerable to certain organic solvents and strong acids. This susceptibility restricts its use in chemically harsh environments and necessitates the development of more resistant PMMA formulations or protective coatings.

Lastly, the challenge of enhancing the multifunctionality of PMMA structures persists. As applications demand materials with multiple properties (e.g., optical clarity, mechanical strength, and electrical conductivity), developing PMMA composites or hybrid structures that maintain the desirable properties of PMMA while incorporating additional functionalities remains a complex task for researchers and engineers.

Another challenge lies in the thermal stability of PMMA. While it possesses good heat resistance compared to some other thermoplastics, its relatively low glass transition temperature (around 105°C) restricts its use in high-temperature environments. This limitation poses difficulties in developing PMMA structures for applications that require exposure to elevated temperatures or thermal cycling.

The processing of PMMA for complex structures also presents challenges. Although PMMA can be easily molded and machined, creating intricate or large-scale structures with consistent properties throughout can be problematic. Issues such as internal stress buildup during processing and non-uniform cooling can lead to warping, cracking, or dimensional instability in the final product.

Surface modification of PMMA structures remains a significant challenge. While PMMA has excellent optical properties, its surface is prone to scratching and can be difficult to functionalize for specific applications. Developing durable, scratch-resistant surfaces or incorporating functional groups for enhanced properties (such as hydrophobicity or antimicrobial activity) without compromising the bulk material properties is an ongoing area of research.

The recyclability and environmental impact of PMMA structures also pose challenges. Although PMMA is theoretically recyclable, the process is not as straightforward as with some other plastics. Developing efficient recycling methods and creating PMMA structures that are easily recyclable without loss of properties is crucial for sustainable use.

Addressing the limitations in PMMA's chemical resistance is another technological hurdle. While PMMA exhibits good resistance to many chemicals, it is vulnerable to certain organic solvents and strong acids. This susceptibility restricts its use in chemically harsh environments and necessitates the development of more resistant PMMA formulations or protective coatings.

Lastly, the challenge of enhancing the multifunctionality of PMMA structures persists. As applications demand materials with multiple properties (e.g., optical clarity, mechanical strength, and electrical conductivity), developing PMMA composites or hybrid structures that maintain the desirable properties of PMMA while incorporating additional functionalities remains a complex task for researchers and engineers.

Current PMMA Structure Solutions

01 PMMA-based optical structures

PMMA is used to create various optical structures due to its excellent light transmission properties. These structures include lenses, waveguides, and optical fibers. The material's versatility allows for the fabrication of complex optical components with high precision and performance.- PMMA-based optical structures: PMMA is used to create various optical structures due to its excellent light transmission properties. These structures include lenses, waveguides, and optical fibers. The material's versatility allows for the fabrication of complex optical components with high precision and performance.

- PMMA nanostructures and microstructures: Advanced fabrication techniques are employed to create PMMA nanostructures and microstructures. These include nanoparticles, nanofibers, and micropatterned surfaces. Such structures have applications in fields like drug delivery, tissue engineering, and surface modification.

- PMMA-based composite materials: PMMA is combined with other materials to form composite structures with enhanced properties. These composites may incorporate nanoparticles, fibers, or other polymers to improve mechanical strength, thermal stability, or introduce new functionalities.

- PMMA surface modifications: Various techniques are used to modify PMMA surfaces, including plasma treatment, chemical etching, and grafting. These modifications can alter surface properties such as wettability, adhesion, and biocompatibility, expanding the material's applications in areas like biomedical devices and coatings.

- PMMA-based membranes and films: PMMA is utilized to create thin films and membranes with specific properties. These structures find applications in areas such as filtration, gas separation, and protective coatings. The fabrication methods allow for control over porosity, thickness, and surface characteristics.

02 PMMA nanostructures and microstructures

Advanced fabrication techniques are employed to create PMMA nanostructures and microstructures. These include nanoparticles, nanofibers, and micropatterned surfaces. Such structures find applications in fields like drug delivery, tissue engineering, and surface modification.Expand Specific Solutions03 PMMA-based composite materials

PMMA is combined with other materials to form composite structures with enhanced properties. These composites may incorporate nanoparticles, fibers, or other polymers to improve mechanical strength, thermal stability, or introduce new functionalities like conductivity or biocompatibility.Expand Specific Solutions04 PMMA surface modifications and coatings

Various techniques are used to modify PMMA surfaces or apply coatings to PMMA structures. These modifications can enhance properties such as scratch resistance, hydrophobicity, or biocompatibility. Methods include plasma treatment, chemical grafting, and thin film deposition.Expand Specific Solutions05 PMMA-based 3D printing and additive manufacturing

PMMA is utilized in 3D printing and additive manufacturing processes to create complex three-dimensional structures. This includes the development of PMMA-based printing materials, optimization of printing parameters, and post-processing techniques to enhance the properties of printed structures.Expand Specific Solutions

Key PMMA Industry Players

The development of PMMA structures for versatile use is in a mature stage, with a significant market presence and ongoing research for advanced applications. The global PMMA market size is substantial, driven by diverse industrial applications. Technologically, PMMA production is well-established, with companies like China Petroleum & Chemical Corp. and Kingfa Sci. & Tech. Co., Ltd. leading in large-scale manufacturing. However, innovation continues, particularly in areas of improved properties and sustainability. Research institutions such as Fudan University and the Institute of Process Engineering, CAS, are actively contributing to advancements in PMMA technology, focusing on enhancing versatility and exploring new applications across various sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced PMMA structures through a proprietary polymerization process. Their method involves controlled radical polymerization using specific initiators and chain transfer agents, resulting in PMMA with tailored molecular weight and narrow polydispersity[1]. This allows for precise control over the material's properties, such as optical clarity, impact resistance, and thermal stability. Sinopec's PMMA structures incorporate nano-scale reinforcements, enhancing mechanical strength and durability[3]. The company has also implemented a continuous production process, improving efficiency and reducing production costs[5].

Strengths: High-quality PMMA with customizable properties, improved mechanical performance, and cost-effective production. Weaknesses: Potential limitations in extreme temperature applications and chemical resistance compared to some specialized polymers.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has pioneered a novel approach to PMMA structure development, focusing on enhancing versatility through multi-functional additives and copolymerization techniques. Their process involves incorporating specially designed nanoparticles that improve both impact resistance and flame retardancy without compromising optical clarity[2]. Kingfa's PMMA structures feature a unique core-shell architecture, where the core provides strength and the shell offers tailored surface properties[4]. This allows for a wide range of applications, from automotive parts to medical devices. The company has also developed a proprietary extrusion process that enables the production of complex PMMA profiles with consistent quality and reduced internal stress[6].

Strengths: Highly versatile PMMA structures suitable for diverse applications, improved impact resistance and flame retardancy. Weaknesses: Potentially higher production costs due to specialized additives and processing techniques.

Innovative PMMA Technologies

A method for the production of poly(methyl methacrylate) (PMMA) membranes and uses thereof

PatentInactiveEP3359285A1

Innovation

- A method for producing highly porous, symmetric reticulated PMMA membranes using a thin film casting and solvent removal process, combined with hydrophilization techniques, to create a composite membrane with enhanced capillary flow and protein binding capacity, overcoming the limitations of previous PMMA membrane production methods.

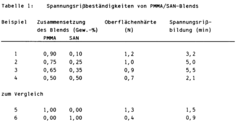

Thermoplastic, transparent moulding masses based on PMMA having increased stress-cracking resistance

PatentInactiveEP0508173A1

Innovation

- Blends of PMMA with styrene-acrylonitrile copolymers (SAN) are developed, with a high PMMA content and a specific range of SAN, along with a polymeric processing aid, to enhance stress crack resistance while maintaining surface hardness and flowability.

Environmental Impact of PMMA

The environmental impact of PMMA (Poly(methyl methacrylate)) is a crucial consideration in developing versatile structures. PMMA, commonly known as acrylic or plexiglass, has both positive and negative effects on the environment throughout its lifecycle.

PMMA production involves the polymerization of methyl methacrylate, which requires significant energy input and petrochemical resources. This process contributes to greenhouse gas emissions and the depletion of fossil fuel reserves. However, compared to some other plastics, PMMA production generally has a lower environmental footprint due to its relatively simple manufacturing process.

One of the primary environmental advantages of PMMA is its durability and longevity. PMMA structures can last for decades, reducing the need for frequent replacements and minimizing waste generation. Additionally, PMMA is 100% recyclable, allowing for the recovery and reuse of the material at the end of its life cycle. This recyclability helps to conserve resources and reduce the overall environmental impact.

PMMA's lightweight nature contributes to reduced transportation-related emissions when compared to heavier materials like glass. This characteristic is particularly beneficial in applications such as automotive and aerospace industries, where weight reduction leads to improved fuel efficiency and lower carbon emissions during the use phase.

However, the disposal of PMMA products can pose environmental challenges. While recyclable, PMMA is not biodegradable, meaning that improperly disposed items can persist in the environment for extended periods. This persistence can contribute to plastic pollution in terrestrial and aquatic ecosystems if not managed correctly.

The production of PMMA involves the use of potentially hazardous chemicals, including methyl methacrylate monomer and various additives. Proper handling and disposal of these substances are essential to prevent environmental contamination and protect human health. Stringent regulations and industry best practices help mitigate these risks.

In terms of energy efficiency, PMMA's excellent optical properties and thermal insulation capabilities can contribute to reduced energy consumption in buildings when used in windows, skylights, or other architectural applications. This indirect environmental benefit can be significant over the lifetime of a structure.

As the demand for sustainable materials grows, research into bio-based alternatives to traditional PMMA is gaining momentum. These efforts aim to reduce reliance on petrochemical feedstocks and further improve the environmental profile of PMMA-like materials.

PMMA production involves the polymerization of methyl methacrylate, which requires significant energy input and petrochemical resources. This process contributes to greenhouse gas emissions and the depletion of fossil fuel reserves. However, compared to some other plastics, PMMA production generally has a lower environmental footprint due to its relatively simple manufacturing process.

One of the primary environmental advantages of PMMA is its durability and longevity. PMMA structures can last for decades, reducing the need for frequent replacements and minimizing waste generation. Additionally, PMMA is 100% recyclable, allowing for the recovery and reuse of the material at the end of its life cycle. This recyclability helps to conserve resources and reduce the overall environmental impact.

PMMA's lightweight nature contributes to reduced transportation-related emissions when compared to heavier materials like glass. This characteristic is particularly beneficial in applications such as automotive and aerospace industries, where weight reduction leads to improved fuel efficiency and lower carbon emissions during the use phase.

However, the disposal of PMMA products can pose environmental challenges. While recyclable, PMMA is not biodegradable, meaning that improperly disposed items can persist in the environment for extended periods. This persistence can contribute to plastic pollution in terrestrial and aquatic ecosystems if not managed correctly.

The production of PMMA involves the use of potentially hazardous chemicals, including methyl methacrylate monomer and various additives. Proper handling and disposal of these substances are essential to prevent environmental contamination and protect human health. Stringent regulations and industry best practices help mitigate these risks.

In terms of energy efficiency, PMMA's excellent optical properties and thermal insulation capabilities can contribute to reduced energy consumption in buildings when used in windows, skylights, or other architectural applications. This indirect environmental benefit can be significant over the lifetime of a structure.

As the demand for sustainable materials grows, research into bio-based alternatives to traditional PMMA is gaining momentum. These efforts aim to reduce reliance on petrochemical feedstocks and further improve the environmental profile of PMMA-like materials.

PMMA Manufacturing Processes

PMMA manufacturing processes play a crucial role in developing versatile structures for various applications. The most common methods include injection molding, extrusion, and casting. Injection molding is widely used for producing complex shapes with high precision and efficiency. This process involves heating PMMA pellets until molten, then injecting the material into a mold under high pressure. Once cooled and solidified, the part is ejected, resulting in a finished product with excellent surface finish and dimensional accuracy.

Extrusion is another key manufacturing process for PMMA, particularly suitable for producing continuous profiles, sheets, and tubes. In this method, PMMA pellets are fed into a heated barrel, where they melt and are forced through a die of the desired cross-section. The extruded material is then cooled and cut to the required length. This process allows for the production of long, uniform structures with consistent properties along their length.

Casting is a versatile method for creating large, thick PMMA sheets or custom shapes. This process involves pouring liquid PMMA monomer into molds and allowing it to polymerize. Cell casting and continuous casting are two primary techniques within this category. Cell casting produces high-quality, optically clear PMMA sheets with excellent thickness uniformity, while continuous casting enables the production of long, continuous sheets with high productivity.

For more specialized applications, thermoforming can be employed to shape PMMA sheets into complex three-dimensional forms. This process involves heating the PMMA sheet until pliable, then forming it over a mold using vacuum or pressure. Thermoforming is particularly useful for creating large, lightweight structures with intricate contours.

Advanced manufacturing techniques such as CNC machining and laser cutting are often used for precision fabrication of PMMA components. These methods allow for the creation of highly detailed parts with tight tolerances, making them ideal for prototyping and small-scale production runs. Additionally, 3D printing technologies, particularly stereolithography (SLA) and digital light processing (DLP), are emerging as promising methods for producing complex PMMA structures with high resolution.

To develop PMMA structures for versatile use, it is essential to consider the specific requirements of the application and select the most appropriate manufacturing process. Factors such as part geometry, production volume, surface finish, and mechanical properties all influence the choice of manufacturing method. By leveraging the strengths of each process and combining them when necessary, it is possible to create a wide range of PMMA structures tailored to diverse applications across industries.

Extrusion is another key manufacturing process for PMMA, particularly suitable for producing continuous profiles, sheets, and tubes. In this method, PMMA pellets are fed into a heated barrel, where they melt and are forced through a die of the desired cross-section. The extruded material is then cooled and cut to the required length. This process allows for the production of long, uniform structures with consistent properties along their length.

Casting is a versatile method for creating large, thick PMMA sheets or custom shapes. This process involves pouring liquid PMMA monomer into molds and allowing it to polymerize. Cell casting and continuous casting are two primary techniques within this category. Cell casting produces high-quality, optically clear PMMA sheets with excellent thickness uniformity, while continuous casting enables the production of long, continuous sheets with high productivity.

For more specialized applications, thermoforming can be employed to shape PMMA sheets into complex three-dimensional forms. This process involves heating the PMMA sheet until pliable, then forming it over a mold using vacuum or pressure. Thermoforming is particularly useful for creating large, lightweight structures with intricate contours.

Advanced manufacturing techniques such as CNC machining and laser cutting are often used for precision fabrication of PMMA components. These methods allow for the creation of highly detailed parts with tight tolerances, making them ideal for prototyping and small-scale production runs. Additionally, 3D printing technologies, particularly stereolithography (SLA) and digital light processing (DLP), are emerging as promising methods for producing complex PMMA structures with high resolution.

To develop PMMA structures for versatile use, it is essential to consider the specific requirements of the application and select the most appropriate manufacturing process. Factors such as part geometry, production volume, surface finish, and mechanical properties all influence the choice of manufacturing method. By leveraging the strengths of each process and combining them when necessary, it is possible to create a wide range of PMMA structures tailored to diverse applications across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!