PMMA Integration in Novel Sensor Technologies

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Sensor Tech Evolution

The integration of Poly(methyl methacrylate) (PMMA) in sensor technologies has undergone significant evolution over the past decades. Initially, PMMA was primarily used as a structural material in optical sensors due to its excellent transparency and durability. However, as sensor technologies advanced, researchers began to explore PMMA's potential beyond its mechanical properties.

In the early 2000s, PMMA started gaining attention for its ability to be functionalized with various chemical groups, opening up new possibilities in chemical and biological sensing. This led to the development of PMMA-based fluorescent sensors, where the polymer matrix served as a host for fluorescent dyes or nanoparticles. These sensors found applications in environmental monitoring and medical diagnostics.

The mid-2000s saw a surge in PMMA-based microfluidic devices for sensing applications. PMMA's ease of fabrication through techniques like hot embossing and injection molding made it an ideal material for creating complex microfluidic structures. These devices integrated multiple sensing elements, enabling lab-on-a-chip applications for point-of-care diagnostics.

As nanotechnology progressed, PMMA became a crucial component in nanocomposite sensors. By incorporating nanoparticles or nanostructures into PMMA matrices, researchers created sensors with enhanced sensitivity and selectivity. This approach led to the development of novel gas sensors, biosensors, and pressure sensors with improved performance characteristics.

The late 2010s marked a significant shift towards PMMA-based flexible and wearable sensors. Leveraging PMMA's flexibility and biocompatibility, researchers developed thin-film sensors that could conform to curved surfaces, opening up new possibilities in wearable health monitoring devices and smart textiles.

Recent advancements have focused on integrating PMMA with other emerging materials and technologies. For instance, the combination of PMMA with graphene or carbon nanotubes has resulted in highly sensitive and responsive sensors for various applications, including strain sensing and gas detection. Additionally, the incorporation of stimuli-responsive elements into PMMA matrices has led to the development of smart sensors capable of adapting to environmental changes.

Looking forward, the evolution of PMMA in sensor technologies is expected to continue, with increasing focus on sustainability and multifunctionality. Research is underway to develop biodegradable PMMA variants for eco-friendly sensor applications. Furthermore, the integration of PMMA with artificial intelligence and Internet of Things (IoT) technologies promises to create more intelligent and interconnected sensing systems, paving the way for advanced environmental monitoring, healthcare diagnostics, and industrial process control.

In the early 2000s, PMMA started gaining attention for its ability to be functionalized with various chemical groups, opening up new possibilities in chemical and biological sensing. This led to the development of PMMA-based fluorescent sensors, where the polymer matrix served as a host for fluorescent dyes or nanoparticles. These sensors found applications in environmental monitoring and medical diagnostics.

The mid-2000s saw a surge in PMMA-based microfluidic devices for sensing applications. PMMA's ease of fabrication through techniques like hot embossing and injection molding made it an ideal material for creating complex microfluidic structures. These devices integrated multiple sensing elements, enabling lab-on-a-chip applications for point-of-care diagnostics.

As nanotechnology progressed, PMMA became a crucial component in nanocomposite sensors. By incorporating nanoparticles or nanostructures into PMMA matrices, researchers created sensors with enhanced sensitivity and selectivity. This approach led to the development of novel gas sensors, biosensors, and pressure sensors with improved performance characteristics.

The late 2010s marked a significant shift towards PMMA-based flexible and wearable sensors. Leveraging PMMA's flexibility and biocompatibility, researchers developed thin-film sensors that could conform to curved surfaces, opening up new possibilities in wearable health monitoring devices and smart textiles.

Recent advancements have focused on integrating PMMA with other emerging materials and technologies. For instance, the combination of PMMA with graphene or carbon nanotubes has resulted in highly sensitive and responsive sensors for various applications, including strain sensing and gas detection. Additionally, the incorporation of stimuli-responsive elements into PMMA matrices has led to the development of smart sensors capable of adapting to environmental changes.

Looking forward, the evolution of PMMA in sensor technologies is expected to continue, with increasing focus on sustainability and multifunctionality. Research is underway to develop biodegradable PMMA variants for eco-friendly sensor applications. Furthermore, the integration of PMMA with artificial intelligence and Internet of Things (IoT) technologies promises to create more intelligent and interconnected sensing systems, paving the way for advanced environmental monitoring, healthcare diagnostics, and industrial process control.

Market Demand Analysis

The integration of PMMA (Polymethyl Methacrylate) in novel sensor technologies has sparked significant market interest due to its unique properties and versatile applications. The global demand for advanced sensors incorporating PMMA is driven by several key factors, including the growing need for miniaturization, improved sensitivity, and cost-effective solutions across various industries.

In the healthcare sector, there is a rising demand for PMMA-based biosensors for rapid and accurate disease diagnosis, drug discovery, and personalized medicine. These sensors offer enhanced biocompatibility and optical clarity, making them ideal for point-of-care testing and lab-on-a-chip devices. The aging population and increasing prevalence of chronic diseases further amplify this demand, as healthcare providers seek more efficient and accessible diagnostic tools.

The environmental monitoring industry also shows a strong market pull for PMMA-integrated sensors. With growing concerns about air and water quality, there is a need for robust, portable, and highly sensitive sensors that can detect pollutants and contaminants at low concentrations. PMMA's resistance to weathering and chemical stability make it an excellent choice for outdoor and harsh environment applications.

In the automotive and aerospace sectors, the demand for lightweight, durable, and high-performance sensors is driving the adoption of PMMA-based solutions. These industries require sensors for various applications, including structural health monitoring, collision avoidance systems, and fuel efficiency optimization. The integration of PMMA in these sensors offers advantages in terms of weight reduction and improved optical properties.

The consumer electronics market presents another significant opportunity for PMMA-integrated sensors. With the proliferation of smartphones, wearables, and IoT devices, there is a growing need for compact, energy-efficient sensors that can measure various parameters such as temperature, humidity, and ambient light. PMMA's transparency and moldability make it an attractive material for these applications.

Industrial automation and smart manufacturing sectors are also contributing to the market demand for PMMA-based sensors. The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) requires advanced sensing technologies for process control, quality assurance, and predictive maintenance. PMMA-integrated sensors offer improved reliability and performance in these demanding industrial environments.

The market for PMMA-integrated sensors is expected to experience substantial growth in the coming years, driven by technological advancements and expanding application areas. However, challenges such as competition from alternative materials and the need for standardization in manufacturing processes may impact market dynamics. As research and development efforts continue to unlock new possibilities for PMMA in sensor technologies, the market is likely to see innovative products and solutions that address evolving industry needs and consumer preferences.

In the healthcare sector, there is a rising demand for PMMA-based biosensors for rapid and accurate disease diagnosis, drug discovery, and personalized medicine. These sensors offer enhanced biocompatibility and optical clarity, making them ideal for point-of-care testing and lab-on-a-chip devices. The aging population and increasing prevalence of chronic diseases further amplify this demand, as healthcare providers seek more efficient and accessible diagnostic tools.

The environmental monitoring industry also shows a strong market pull for PMMA-integrated sensors. With growing concerns about air and water quality, there is a need for robust, portable, and highly sensitive sensors that can detect pollutants and contaminants at low concentrations. PMMA's resistance to weathering and chemical stability make it an excellent choice for outdoor and harsh environment applications.

In the automotive and aerospace sectors, the demand for lightweight, durable, and high-performance sensors is driving the adoption of PMMA-based solutions. These industries require sensors for various applications, including structural health monitoring, collision avoidance systems, and fuel efficiency optimization. The integration of PMMA in these sensors offers advantages in terms of weight reduction and improved optical properties.

The consumer electronics market presents another significant opportunity for PMMA-integrated sensors. With the proliferation of smartphones, wearables, and IoT devices, there is a growing need for compact, energy-efficient sensors that can measure various parameters such as temperature, humidity, and ambient light. PMMA's transparency and moldability make it an attractive material for these applications.

Industrial automation and smart manufacturing sectors are also contributing to the market demand for PMMA-based sensors. The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) requires advanced sensing technologies for process control, quality assurance, and predictive maintenance. PMMA-integrated sensors offer improved reliability and performance in these demanding industrial environments.

The market for PMMA-integrated sensors is expected to experience substantial growth in the coming years, driven by technological advancements and expanding application areas. However, challenges such as competition from alternative materials and the need for standardization in manufacturing processes may impact market dynamics. As research and development efforts continue to unlock new possibilities for PMMA in sensor technologies, the market is likely to see innovative products and solutions that address evolving industry needs and consumer preferences.

PMMA Sensor Challenges

The integration of PMMA (Polymethyl methacrylate) in novel sensor technologies presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the material's inherent limitations in terms of thermal stability and chemical resistance. PMMA's relatively low glass transition temperature (around 105°C) restricts its use in high-temperature sensing applications, potentially limiting its versatility in industrial or harsh environment deployments.

Another critical challenge lies in the optimization of PMMA's optical properties for sensor applications. While PMMA offers excellent transparency and light transmission characteristics, fine-tuning these properties for specific wavelengths or sensing mechanisms can be complex. This is particularly crucial in optical sensors where precise control over light propagation and interaction is essential for accurate measurements.

The long-term stability and durability of PMMA-based sensors pose additional concerns. Environmental factors such as UV radiation, humidity, and chemical exposure can lead to degradation of PMMA over time, potentially affecting sensor performance and reliability. Developing effective protective coatings or stabilization techniques without compromising the sensor's sensitivity remains a significant challenge.

Integration of PMMA with other materials and components in sensor fabrication presents its own set of difficulties. Ensuring strong adhesion between PMMA and other sensor elements, such as electrodes or other polymers, while maintaining the integrity of the sensing mechanism, requires careful material selection and process optimization. This challenge is particularly pronounced in the development of flexible or wearable sensors where PMMA must interface seamlessly with substrates of varying properties.

Miniaturization of PMMA-based sensors for applications in microfluidics and lab-on-a-chip devices introduces further complexities. Achieving precise micro- and nano-scale features in PMMA through techniques like hot embossing or injection molding while maintaining the material's sensing capabilities demands advanced manufacturing processes and quality control measures.

The biocompatibility of PMMA in biosensing applications, while generally favorable, still presents challenges in terms of surface functionalization and prevention of non-specific adsorption. Developing effective methods to modify PMMA surfaces for selective biomolecule attachment without altering the bulk properties of the material is crucial for advancing its use in medical and biological sensing applications.

Lastly, the cost-effective mass production of PMMA-based sensors remains a significant hurdle. Balancing the material's advantages with the need for economical large-scale manufacturing processes that maintain sensor quality and performance consistency is essential for widespread adoption in commercial applications.

Another critical challenge lies in the optimization of PMMA's optical properties for sensor applications. While PMMA offers excellent transparency and light transmission characteristics, fine-tuning these properties for specific wavelengths or sensing mechanisms can be complex. This is particularly crucial in optical sensors where precise control over light propagation and interaction is essential for accurate measurements.

The long-term stability and durability of PMMA-based sensors pose additional concerns. Environmental factors such as UV radiation, humidity, and chemical exposure can lead to degradation of PMMA over time, potentially affecting sensor performance and reliability. Developing effective protective coatings or stabilization techniques without compromising the sensor's sensitivity remains a significant challenge.

Integration of PMMA with other materials and components in sensor fabrication presents its own set of difficulties. Ensuring strong adhesion between PMMA and other sensor elements, such as electrodes or other polymers, while maintaining the integrity of the sensing mechanism, requires careful material selection and process optimization. This challenge is particularly pronounced in the development of flexible or wearable sensors where PMMA must interface seamlessly with substrates of varying properties.

Miniaturization of PMMA-based sensors for applications in microfluidics and lab-on-a-chip devices introduces further complexities. Achieving precise micro- and nano-scale features in PMMA through techniques like hot embossing or injection molding while maintaining the material's sensing capabilities demands advanced manufacturing processes and quality control measures.

The biocompatibility of PMMA in biosensing applications, while generally favorable, still presents challenges in terms of surface functionalization and prevention of non-specific adsorption. Developing effective methods to modify PMMA surfaces for selective biomolecule attachment without altering the bulk properties of the material is crucial for advancing its use in medical and biological sensing applications.

Lastly, the cost-effective mass production of PMMA-based sensors remains a significant hurdle. Balancing the material's advantages with the need for economical large-scale manufacturing processes that maintain sensor quality and performance consistency is essential for widespread adoption in commercial applications.

Current PMMA Solutions

01 PMMA synthesis and modification

Various methods for synthesizing and modifying PMMA are explored, including polymerization techniques, copolymerization with other monomers, and surface modifications to enhance specific properties such as thermal stability, impact resistance, or optical characteristics.- PMMA-based composite materials: PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for applications in industries such as automotive, construction, and electronics.

- PMMA in optical applications: PMMA is widely used in optical applications due to its excellent light transmission properties and ease of processing. It is utilized in the production of lenses, light guides, optical fibers, and display screens. Modifications to PMMA for optical purposes often focus on improving clarity, UV resistance, and scratch resistance.

- PMMA in medical and dental applications: PMMA finds extensive use in medical and dental fields due to its biocompatibility and moldability. It is used in the production of dental prosthetics, bone cements, contact lenses, and intraocular lenses. Research in this area often focuses on improving biocompatibility, wear resistance, and antimicrobial properties.

- PMMA processing and manufacturing techniques: Various processing and manufacturing techniques are employed to produce PMMA products, including injection molding, extrusion, and 3D printing. Research in this area focuses on improving processing efficiency, reducing defects, and developing new manufacturing methods to expand PMMA's applications.

- PMMA surface modifications and coatings: Surface modifications and coatings are applied to PMMA to enhance its properties such as scratch resistance, hydrophobicity, and adhesion. These modifications can involve chemical treatments, plasma treatments, or the application of specialized coatings to improve the material's performance in specific applications.

02 PMMA composites and blends

Development of PMMA-based composites and blends with other materials to improve mechanical, thermal, or functional properties. This includes incorporation of nanoparticles, fibers, or other polymers to create materials with enhanced performance characteristics.Expand Specific Solutions03 PMMA in optical applications

Utilization of PMMA in various optical applications due to its excellent transparency and light transmission properties. This includes the development of PMMA-based optical fibers, lenses, light guides, and display components with improved optical performance.Expand Specific Solutions04 PMMA processing techniques

Advanced processing techniques for PMMA, including injection molding, extrusion, and 3D printing. These methods aim to improve the manufacturing efficiency, reduce defects, and enable the production of complex PMMA-based structures and components.Expand Specific Solutions05 PMMA in biomedical applications

Development of PMMA-based materials for various biomedical applications, including dental prosthetics, bone cements, and drug delivery systems. This involves modifying PMMA to improve biocompatibility, mechanical properties, and drug release characteristics for specific medical uses.Expand Specific Solutions

Key PMMA Sensor Players

The integration of PMMA in novel sensor technologies is in a nascent stage, with the market showing promising growth potential. The industry is transitioning from research to early commercialization, driven by advancements in materials science and miniaturization. Companies like Everspin Technologies and Kingfa Sci. & Tech. are at the forefront, leveraging their expertise in materials and sensor development. Academic institutions such as Southeast University and University College Cork are contributing significantly to R&D efforts. The technology's maturity varies across applications, with some areas like biomedical sensors showing more progress. As the field evolves, collaborations between industry leaders and research institutions are likely to accelerate innovation and market expansion.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced PMMA-based sensor technologies for various applications. Their approach integrates PMMA into novel sensor designs, particularly for gas and chemical detection. They have created a PMMA-based optical sensor platform that utilizes the material's transparency and stability for improved light transmission and signal detection[1]. The company has also explored PMMA nanocomposites with embedded nanoparticles to enhance sensitivity and selectivity in chemical sensing applications[2]. Honeywell's PMMA sensors feature miniaturized designs suitable for portable and wearable devices, offering real-time monitoring capabilities in industrial and environmental settings[3].

Strengths: High sensitivity and selectivity, miniaturization potential, and versatility across multiple sensing applications. Weaknesses: Potential limitations in extreme temperature environments and long-term stability issues in harsh chemical conditions.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has made significant strides in PMMA-based sensor technologies, particularly for radiation detection and environmental monitoring. Their approach involves developing PMMA scintillators and dosimeters with enhanced sensitivity and durability. CEA has created PMMA-based radiation sensors that incorporate novel dopants and nanoparticles to improve light yield and energy resolution in radiation detection applications[13]. They have also explored the use of PMMA in fiber optic sensors for distributed sensing of temperature and strain in harsh environments, such as nuclear facilities[14]. CEA's research extends to the development of PMMA-based chemical sensors for environmental pollutant detection, utilizing surface functionalization techniques to achieve high selectivity and sensitivity[15].

Strengths: Expertise in radiation detection and environmental sensing, potential for applications in high-risk environments, and integration with existing nuclear and environmental monitoring systems. Weaknesses: Specialized focus may limit broader commercial applications, and potential regulatory challenges in certain markets.

PMMA Sensor Innovations

Flame retardant and uv absorptive polymethylmethacrylate nanocomposites

PatentInactiveUS20050261413A1

Innovation

- A nanocomposite composition is developed by combining polymethylmethacrylate with functionalized montmorillonite clay, using an intercalation agent as a reaction product of a polyamine and an alkyl halide in a polar solvent, which improves thermal stability and flame retardancy, and is processed into transparent sheets using molding, casting, or extrusion.

Poly(methyl methacrylate) resin composition

PatentWO2019018219A1

Innovation

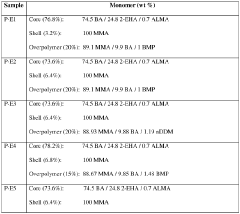

- A PMMA resin composition incorporating a methyl methacrylate polymer and a multistage acrylic impact modifier, comprising a core-shell polymer and an overpolymer, which improves impact strength while preserving gloss and melt flow.

PMMA Material Properties

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, is a versatile synthetic polymer with a unique combination of properties that make it particularly suitable for integration in novel sensor technologies. PMMA exhibits exceptional optical clarity, with a light transmittance of up to 92% in the visible spectrum, surpassing many other transparent polymers. This high transparency, coupled with its ability to be easily molded and shaped, makes PMMA an ideal material for optical sensors and light-guiding components in various sensing applications.

The mechanical properties of PMMA contribute significantly to its utility in sensor technologies. With a tensile strength ranging from 48 to 76 MPa and a flexural strength of 72 to 140 MPa, PMMA offers sufficient durability for many sensing applications while remaining lightweight, with a density of approximately 1.18 g/cm³. Its relatively low thermal conductivity (0.17-0.19 W/m·K) can be advantageous in thermal isolation scenarios, while its specific heat capacity of about 1.46 kJ/kg·K allows for stable performance across a range of temperatures.

PMMA's electrical properties are particularly relevant for certain sensor applications. It possesses excellent electrical insulation characteristics, with a dielectric strength of 15-30 kV/mm and a volume resistivity of 10^15 ohm·cm. These properties make PMMA suitable for use in capacitive sensors and as an insulating material in various electronic sensing devices.

The chemical resistance of PMMA is another critical factor in its integration into sensor technologies. While it exhibits good resistance to many common chemicals, including dilute acids and bases, it is vulnerable to certain organic solvents. This selective chemical resistance can be exploited in the design of chemical sensors or in protective coatings for other sensing elements.

PMMA's thermal properties are also noteworthy for sensor applications. With a glass transition temperature (Tg) of around 105°C and a maximum continuous service temperature of about 80-93°C, PMMA maintains its structural integrity and optical properties across a wide range of operating temperatures. This thermal stability ensures consistent sensor performance in various environmental conditions.

The surface properties of PMMA, including its relatively high surface energy and amenability to surface modifications, enhance its versatility in sensor design. These characteristics allow for the attachment of functional groups or sensing molecules, enabling the creation of biosensors and chemical sensors with high specificity and sensitivity.

In conclusion, the unique combination of optical, mechanical, electrical, chemical, and thermal properties of PMMA makes it an exceptionally versatile material for integration in novel sensor technologies. Its adaptability to various fabrication methods, including injection molding, extrusion, and 3D printing, further enhances its applicability across a wide range of sensing applications.

The mechanical properties of PMMA contribute significantly to its utility in sensor technologies. With a tensile strength ranging from 48 to 76 MPa and a flexural strength of 72 to 140 MPa, PMMA offers sufficient durability for many sensing applications while remaining lightweight, with a density of approximately 1.18 g/cm³. Its relatively low thermal conductivity (0.17-0.19 W/m·K) can be advantageous in thermal isolation scenarios, while its specific heat capacity of about 1.46 kJ/kg·K allows for stable performance across a range of temperatures.

PMMA's electrical properties are particularly relevant for certain sensor applications. It possesses excellent electrical insulation characteristics, with a dielectric strength of 15-30 kV/mm and a volume resistivity of 10^15 ohm·cm. These properties make PMMA suitable for use in capacitive sensors and as an insulating material in various electronic sensing devices.

The chemical resistance of PMMA is another critical factor in its integration into sensor technologies. While it exhibits good resistance to many common chemicals, including dilute acids and bases, it is vulnerable to certain organic solvents. This selective chemical resistance can be exploited in the design of chemical sensors or in protective coatings for other sensing elements.

PMMA's thermal properties are also noteworthy for sensor applications. With a glass transition temperature (Tg) of around 105°C and a maximum continuous service temperature of about 80-93°C, PMMA maintains its structural integrity and optical properties across a wide range of operating temperatures. This thermal stability ensures consistent sensor performance in various environmental conditions.

The surface properties of PMMA, including its relatively high surface energy and amenability to surface modifications, enhance its versatility in sensor design. These characteristics allow for the attachment of functional groups or sensing molecules, enabling the creation of biosensors and chemical sensors with high specificity and sensitivity.

In conclusion, the unique combination of optical, mechanical, electrical, chemical, and thermal properties of PMMA makes it an exceptionally versatile material for integration in novel sensor technologies. Its adaptability to various fabrication methods, including injection molding, extrusion, and 3D printing, further enhances its applicability across a wide range of sensing applications.

PMMA Sensor Applications

PMMA (Poly(methyl methacrylate)) has emerged as a versatile material in the development of novel sensor technologies, offering unique properties that enhance sensor performance across various applications. The integration of PMMA in sensor designs has led to significant advancements in fields such as environmental monitoring, biomedical diagnostics, and industrial process control.

In environmental sensing, PMMA-based sensors have shown remarkable capabilities in detecting and measuring air and water pollutants. The material's transparency and resistance to weathering make it ideal for outdoor applications. PMMA-coated optical fibers, for instance, have been utilized in the creation of highly sensitive gas sensors capable of detecting trace amounts of volatile organic compounds (VOCs) in the atmosphere.

The biomedical sector has witnessed a surge in PMMA-integrated biosensors. These sensors leverage PMMA's biocompatibility and ease of surface modification to create platforms for detecting various biomolecules. Microfluidic devices incorporating PMMA have revolutionized point-of-care diagnostics, enabling rapid and accurate detection of disease markers, pathogens, and drug compounds in small sample volumes.

In industrial applications, PMMA-based sensors have found use in process monitoring and quality control. The material's resistance to many chemicals and its ability to be easily molded into complex shapes have facilitated the development of robust sensors for harsh industrial environments. For example, PMMA-based pressure sensors have been employed in manufacturing processes to ensure precise control and optimization of production parameters.

The integration of PMMA in optical sensor technologies has been particularly noteworthy. PMMA optical waveguides and resonators have been developed for applications in telecommunications and spectroscopy. These components offer advantages such as low optical loss, high flexibility, and cost-effectiveness compared to traditional glass-based alternatives.

Furthermore, PMMA's compatibility with various fabrication techniques, including 3D printing and soft lithography, has enabled the rapid prototyping and customization of sensor designs. This flexibility has accelerated innovation in sensor development, allowing researchers and engineers to quickly iterate and optimize sensor configurations for specific applications.

As sensor miniaturization continues to be a driving force in technology development, PMMA's role in micro- and nano-scale sensor fabrication has become increasingly important. The material's amenability to nanoimprint lithography and other advanced patterning techniques has facilitated the creation of highly sensitive and selective sensor arrays on a single chip.

In environmental sensing, PMMA-based sensors have shown remarkable capabilities in detecting and measuring air and water pollutants. The material's transparency and resistance to weathering make it ideal for outdoor applications. PMMA-coated optical fibers, for instance, have been utilized in the creation of highly sensitive gas sensors capable of detecting trace amounts of volatile organic compounds (VOCs) in the atmosphere.

The biomedical sector has witnessed a surge in PMMA-integrated biosensors. These sensors leverage PMMA's biocompatibility and ease of surface modification to create platforms for detecting various biomolecules. Microfluidic devices incorporating PMMA have revolutionized point-of-care diagnostics, enabling rapid and accurate detection of disease markers, pathogens, and drug compounds in small sample volumes.

In industrial applications, PMMA-based sensors have found use in process monitoring and quality control. The material's resistance to many chemicals and its ability to be easily molded into complex shapes have facilitated the development of robust sensors for harsh industrial environments. For example, PMMA-based pressure sensors have been employed in manufacturing processes to ensure precise control and optimization of production parameters.

The integration of PMMA in optical sensor technologies has been particularly noteworthy. PMMA optical waveguides and resonators have been developed for applications in telecommunications and spectroscopy. These components offer advantages such as low optical loss, high flexibility, and cost-effectiveness compared to traditional glass-based alternatives.

Furthermore, PMMA's compatibility with various fabrication techniques, including 3D printing and soft lithography, has enabled the rapid prototyping and customization of sensor designs. This flexibility has accelerated innovation in sensor development, allowing researchers and engineers to quickly iterate and optimize sensor configurations for specific applications.

As sensor miniaturization continues to be a driving force in technology development, PMMA's role in micro- and nano-scale sensor fabrication has become increasingly important. The material's amenability to nanoimprint lithography and other advanced patterning techniques has facilitated the creation of highly sensitive and selective sensor arrays on a single chip.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!