How PMMA is Reshaping Modern Display Technologies?

AUG 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA in Display Tech: Evolution and Objectives

Poly(methyl methacrylate), commonly known as PMMA, has emerged as a transformative material in modern display technologies. Its journey from a simple plastic to a crucial component in advanced displays reflects the rapid evolution of the industry. PMMA's unique properties, including exceptional optical clarity, light transmission, and durability, have positioned it at the forefront of display innovation.

The evolution of PMMA in display technologies can be traced back to the 1930s when it was first developed. Initially used in aircraft windshields and submarine periscopes due to its shatter-resistant properties, PMMA found its way into the consumer electronics market in the 1960s and 1970s. As televisions and computer monitors became more prevalent, PMMA's role in enhancing display quality became increasingly significant.

The advent of flat-panel displays in the 1990s marked a pivotal moment for PMMA in the display industry. Its ability to diffuse light evenly made it an ideal material for LCD backlights, improving brightness and reducing energy consumption. This period saw intensive research into optimizing PMMA's optical properties, leading to the development of specialized grades for display applications.

In the 2000s, the rise of LED technology further propelled PMMA's importance. Its excellent light-guiding properties made it essential for edge-lit LED displays, enabling thinner and more energy-efficient designs. Concurrently, advancements in PMMA formulation led to enhanced heat resistance and UV stability, addressing key challenges in outdoor and high-brightness display applications.

The current objectives for PMMA in display technologies are multifaceted. Researchers and manufacturers are focusing on developing PMMA variants with even higher light transmission and diffusion capabilities, aiming to improve display brightness and energy efficiency further. There's also a push towards creating PMMA formulations that can withstand higher temperatures, expanding its use in next-generation display technologies like OLED and MicroLED.

Another key objective is the integration of functional properties into PMMA for displays. This includes developing PMMA with built-in anti-glare, anti-reflective, and even self-healing properties. Such advancements could significantly enhance user experience and device longevity. Additionally, there's growing interest in exploring PMMA's potential in flexible and foldable display technologies, which could revolutionize the form factor of future devices.

The evolution of PMMA in display technologies can be traced back to the 1930s when it was first developed. Initially used in aircraft windshields and submarine periscopes due to its shatter-resistant properties, PMMA found its way into the consumer electronics market in the 1960s and 1970s. As televisions and computer monitors became more prevalent, PMMA's role in enhancing display quality became increasingly significant.

The advent of flat-panel displays in the 1990s marked a pivotal moment for PMMA in the display industry. Its ability to diffuse light evenly made it an ideal material for LCD backlights, improving brightness and reducing energy consumption. This period saw intensive research into optimizing PMMA's optical properties, leading to the development of specialized grades for display applications.

In the 2000s, the rise of LED technology further propelled PMMA's importance. Its excellent light-guiding properties made it essential for edge-lit LED displays, enabling thinner and more energy-efficient designs. Concurrently, advancements in PMMA formulation led to enhanced heat resistance and UV stability, addressing key challenges in outdoor and high-brightness display applications.

The current objectives for PMMA in display technologies are multifaceted. Researchers and manufacturers are focusing on developing PMMA variants with even higher light transmission and diffusion capabilities, aiming to improve display brightness and energy efficiency further. There's also a push towards creating PMMA formulations that can withstand higher temperatures, expanding its use in next-generation display technologies like OLED and MicroLED.

Another key objective is the integration of functional properties into PMMA for displays. This includes developing PMMA with built-in anti-glare, anti-reflective, and even self-healing properties. Such advancements could significantly enhance user experience and device longevity. Additionally, there's growing interest in exploring PMMA's potential in flexible and foldable display technologies, which could revolutionize the form factor of future devices.

Market Demand for PMMA-based Displays

The market demand for PMMA-based displays has been experiencing significant growth in recent years, driven by the material's unique properties and the evolving needs of the display industry. PMMA, or polymethyl methacrylate, has become increasingly popular in modern display technologies due to its excellent optical clarity, lightweight nature, and durability.

In the consumer electronics sector, PMMA-based displays are gaining traction, particularly in smartphones, tablets, and laptops. The material's high light transmission and low haze properties contribute to brighter, more vibrant displays, meeting the consumer demand for improved visual experiences. Additionally, PMMA's scratch-resistant characteristics address the need for more durable devices in everyday use.

The automotive industry represents another significant market for PMMA-based displays. As vehicles become more technologically advanced, there is a growing demand for larger, more sophisticated in-car displays. PMMA's ability to be molded into complex shapes while maintaining optical clarity makes it an ideal choice for curved dashboard displays and heads-up display systems. The material's lightweight nature also aligns with the automotive industry's push for fuel efficiency and reduced vehicle weight.

In the commercial and retail sectors, PMMA-based displays are finding applications in digital signage, interactive kiosks, and point-of-sale displays. The material's weather resistance and UV stability make it suitable for outdoor applications, expanding the potential market for digital advertising and information displays in various environments.

The healthcare industry is another area where PMMA-based displays are seeing increased demand. Medical imaging equipment, patient monitoring systems, and surgical displays benefit from PMMA's optical clarity and ability to be easily sterilized. As healthcare facilities continue to digitize and upgrade their equipment, the demand for high-quality, durable displays is expected to grow.

Market analysts project a compound annual growth rate (CAGR) for PMMA in display applications to be in the high single digits over the next five years. This growth is attributed to the expanding use of PMMA in emerging technologies such as augmented reality (AR) and virtual reality (VR) devices, where the material's optical properties and formability are particularly advantageous.

However, the market demand for PMMA-based displays is not without challenges. The increasing focus on sustainability and recyclability in consumer products may pose a potential barrier to growth. While PMMA is recyclable, the process is not as widespread or efficient as for some other materials. This has led to research and development efforts aimed at improving the recyclability of PMMA and exploring bio-based alternatives to meet the growing demand for more environmentally friendly display technologies.

In the consumer electronics sector, PMMA-based displays are gaining traction, particularly in smartphones, tablets, and laptops. The material's high light transmission and low haze properties contribute to brighter, more vibrant displays, meeting the consumer demand for improved visual experiences. Additionally, PMMA's scratch-resistant characteristics address the need for more durable devices in everyday use.

The automotive industry represents another significant market for PMMA-based displays. As vehicles become more technologically advanced, there is a growing demand for larger, more sophisticated in-car displays. PMMA's ability to be molded into complex shapes while maintaining optical clarity makes it an ideal choice for curved dashboard displays and heads-up display systems. The material's lightweight nature also aligns with the automotive industry's push for fuel efficiency and reduced vehicle weight.

In the commercial and retail sectors, PMMA-based displays are finding applications in digital signage, interactive kiosks, and point-of-sale displays. The material's weather resistance and UV stability make it suitable for outdoor applications, expanding the potential market for digital advertising and information displays in various environments.

The healthcare industry is another area where PMMA-based displays are seeing increased demand. Medical imaging equipment, patient monitoring systems, and surgical displays benefit from PMMA's optical clarity and ability to be easily sterilized. As healthcare facilities continue to digitize and upgrade their equipment, the demand for high-quality, durable displays is expected to grow.

Market analysts project a compound annual growth rate (CAGR) for PMMA in display applications to be in the high single digits over the next five years. This growth is attributed to the expanding use of PMMA in emerging technologies such as augmented reality (AR) and virtual reality (VR) devices, where the material's optical properties and formability are particularly advantageous.

However, the market demand for PMMA-based displays is not without challenges. The increasing focus on sustainability and recyclability in consumer products may pose a potential barrier to growth. While PMMA is recyclable, the process is not as widespread or efficient as for some other materials. This has led to research and development efforts aimed at improving the recyclability of PMMA and exploring bio-based alternatives to meet the growing demand for more environmentally friendly display technologies.

PMMA Display Tech: Current State and Challenges

PMMA (Polymethyl methacrylate) has emerged as a transformative material in modern display technologies, reshaping the landscape of visual interfaces. The current state of PMMA in display technologies is characterized by its widespread adoption across various applications, from smartphones and tablets to large-scale digital signage and automotive displays. Its popularity stems from its exceptional optical clarity, lightweight nature, and durability, making it an ideal choice for protective covers and light-guiding components in displays.

One of the primary challenges facing PMMA in display technologies is the ongoing demand for thinner and more flexible displays. While PMMA offers excellent optical properties, its rigidity can limit its application in next-generation flexible and foldable displays. Researchers and manufacturers are actively exploring ways to enhance PMMA's flexibility without compromising its optical performance, a task that requires significant innovation in polymer science and materials engineering.

Another critical challenge is the need for improved scratch resistance. Although PMMA is more resistant to impact than glass, it is more susceptible to scratching, which can degrade display quality over time. Developing scratch-resistant coatings or modifying the PMMA structure to enhance its surface hardness without affecting its optical properties remains a key area of focus for many in the industry.

The integration of advanced functionalities into PMMA-based display components presents another frontier. There is growing interest in incorporating features such as anti-glare, anti-reflective, and self-healing properties directly into PMMA materials. These enhancements could significantly improve user experience and device longevity but require sophisticated material science solutions.

Environmental concerns also pose challenges for PMMA in display technologies. As sustainability becomes increasingly important, there is pressure to develop more eco-friendly production processes for PMMA and improve its recyclability. The industry is exploring bio-based alternatives and closed-loop recycling systems to address these environmental challenges.

Lastly, the push for higher resolution and more vibrant displays is driving research into enhancing PMMA's optical properties even further. This includes efforts to increase light transmission, reduce haze, and improve color accuracy. As display technologies continue to evolve, PMMA must keep pace with these advancements to maintain its position as a preferred material in the industry.

One of the primary challenges facing PMMA in display technologies is the ongoing demand for thinner and more flexible displays. While PMMA offers excellent optical properties, its rigidity can limit its application in next-generation flexible and foldable displays. Researchers and manufacturers are actively exploring ways to enhance PMMA's flexibility without compromising its optical performance, a task that requires significant innovation in polymer science and materials engineering.

Another critical challenge is the need for improved scratch resistance. Although PMMA is more resistant to impact than glass, it is more susceptible to scratching, which can degrade display quality over time. Developing scratch-resistant coatings or modifying the PMMA structure to enhance its surface hardness without affecting its optical properties remains a key area of focus for many in the industry.

The integration of advanced functionalities into PMMA-based display components presents another frontier. There is growing interest in incorporating features such as anti-glare, anti-reflective, and self-healing properties directly into PMMA materials. These enhancements could significantly improve user experience and device longevity but require sophisticated material science solutions.

Environmental concerns also pose challenges for PMMA in display technologies. As sustainability becomes increasingly important, there is pressure to develop more eco-friendly production processes for PMMA and improve its recyclability. The industry is exploring bio-based alternatives and closed-loop recycling systems to address these environmental challenges.

Lastly, the push for higher resolution and more vibrant displays is driving research into enhancing PMMA's optical properties even further. This includes efforts to increase light transmission, reduce haze, and improve color accuracy. As display technologies continue to evolve, PMMA must keep pace with these advancements to maintain its position as a preferred material in the industry.

Current PMMA-based Display Solutions

01 Composition and synthesis of PMMA

PMMA is a synthetic polymer of methyl methacrylate. Various methods and compositions are used to synthesize PMMA with specific properties, including different polymerization techniques and the incorporation of additives to enhance its characteristics.- PMMA composite materials: PMMA is often used in composite materials, combining it with other substances to enhance its properties or create new functionalities. These composites can include blends with other polymers, incorporation of nanoparticles, or the addition of various fillers to improve mechanical, thermal, or optical properties.

- PMMA in optical applications: PMMA is widely used in optical applications due to its excellent transparency and light transmission properties. It is utilized in the production of lenses, optical fibers, light guides, and other optical components. Modifications to PMMA can enhance its performance in specific optical applications.

- PMMA processing techniques: Various processing techniques are employed to shape and form PMMA into desired products. These can include injection molding, extrusion, thermoforming, and 3D printing. Each technique may require specific formulations or modifications to the PMMA to optimize its performance during processing and in the final product.

- Surface modification of PMMA: Surface modification techniques are applied to PMMA to alter its surface properties, such as hydrophobicity, adhesion, or biocompatibility. These modifications can involve chemical treatments, plasma processing, or the application of coatings to enhance the material's performance in specific applications.

- PMMA in biomedical applications: PMMA finds extensive use in biomedical applications due to its biocompatibility and versatility. It is used in dental prosthetics, bone cements, intraocular lenses, and drug delivery systems. Modifications to PMMA can enhance its properties for specific medical uses, such as improving its antimicrobial properties or drug release characteristics.

02 Applications of PMMA in optical devices

PMMA is widely used in optical applications due to its transparency and light transmission properties. It is utilized in the production of lenses, optical fibers, and other optical components, often with specific modifications to enhance its performance in these applications.Expand Specific Solutions03 PMMA in biomedical applications

PMMA finds extensive use in biomedical fields, particularly in orthopedic and dental applications. It is used for bone cements, dental prosthetics, and other medical devices due to its biocompatibility and mechanical properties.Expand Specific Solutions04 Surface modification of PMMA

Various techniques are employed to modify the surface properties of PMMA, including plasma treatment, chemical etching, and coating applications. These modifications aim to improve adhesion, wettability, or introduce specific functionalities to the PMMA surface.Expand Specific Solutions05 PMMA composites and blends

PMMA is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or introduce new functionalities to the resulting material.Expand Specific Solutions

Key Players in PMMA Display Industry

The PMMA (polymethyl methacrylate) market in display technologies is in a growth phase, driven by increasing demand for high-performance optical materials. The global market size is expanding, with key players like Merck Patent GmbH, DuPont de Nemours, and LG Chem Ltd. leading innovation. These companies are investing heavily in R&D to improve PMMA's optical properties, durability, and cost-effectiveness. The technology is maturing rapidly, with advancements in light transmission, impact resistance, and thermal stability. Emerging players like Kingfa Sci. & Tech. and Corning, Inc. are also contributing to the competitive landscape, focusing on specialized PMMA formulations for next-generation displays.

Merck Patent GmbH

Technical Solution: Merck has developed advanced PMMA formulations for display technologies, focusing on enhancing optical properties and durability. Their PMMA-based light guide plates (LGPs) for LCD displays offer improved light transmission and uniformity[1]. They have also introduced PMMA nanocomposites with enhanced thermal stability and scratch resistance for OLED display covers[2]. Merck's research extends to PMMA-based quantum dot films, which significantly improve color gamut and energy efficiency in displays[3]. Their patented PMMA microstructures for AR/VR devices provide better light management and reduced ghosting effects[4].

Strengths: High-quality optical properties, advanced nanocomposite technology, and diverse applications in various display types. Weaknesses: Potentially higher production costs and complexity in manufacturing specialized formulations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered PMMA-based solutions for modern display technologies, focusing on durability and optical performance. Their PMMA formulations include impact-modified grades that offer enhanced drop resistance for mobile device displays[5]. DuPont has also developed PMMA-based optical films with advanced light diffusion properties, improving viewing angles and reducing glare in large-format displays[6]. Their research extends to PMMA-based barrier films for flexible OLED displays, providing excellent moisture and oxygen barrier properties while maintaining transparency[7]. Additionally, DuPont has introduced PMMA blends with other polymers to create hybrid materials that combine the optical clarity of PMMA with improved thermal and mechanical properties[8].

Strengths: Strong focus on durability and optical performance, innovative hybrid materials, and solutions for flexible displays. Weaknesses: May face challenges in cost-effectiveness for mass-market applications.

Core Innovations in PMMA Display Technology

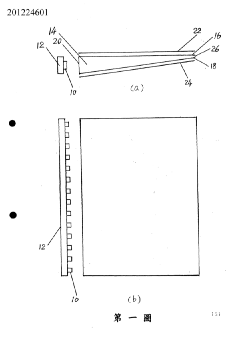

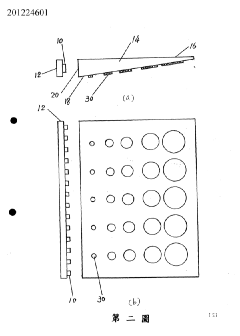

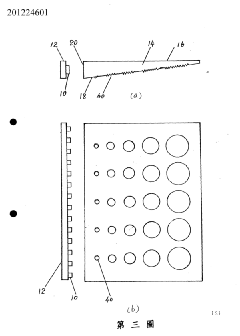

Light guide plate and liquid crystal display backlight module using the same

PatentInactiveTW201224601A

Innovation

- Utilizing a casting polymerization process with MMA as raw material to manufacture wedge-shaped PMMA light guide plates for large-size TV LCD applications.

- Integrating multiple components (LEDs, reflector, diffuser, and wedge-shaped light guide plate) into a single backlight module design for LCD displays.

- Applying the wedge-shaped design to the PMMA light guide plate to enhance light distribution and efficiency in large-size TV displays.

Method for producing an impact-resistant polymethylmethacrylate, and corresponding polymethylmethacrylate (PMMA)

PatentInactiveEP1470169A1

Innovation

- A process involving dissolving impact modifiers in methyl methacrylate (MMA) or polymerized MMA, followed by polymerization in a chamber, using a formulation with stabilizers and additives, to produce a cast plastic molding with enhanced impact strength without interpenetrating networks or complicated isolation steps.

Environmental Impact of PMMA in Displays

The environmental impact of PMMA (Polymethyl methacrylate) in display technologies is a crucial consideration as the material gains prominence in modern screens. PMMA offers several advantages in terms of optical clarity and durability, but its production and disposal processes raise important environmental concerns.

PMMA production involves the polymerization of methyl methacrylate, a process that requires significant energy input and generates greenhouse gas emissions. The manufacturing process also utilizes potentially harmful chemicals, including acetone and methanol, which can contribute to air and water pollution if not properly managed.

However, PMMA's durability and longevity in display applications can offset some of these initial environmental costs. PMMA screens typically have a longer lifespan compared to other materials, reducing the frequency of replacement and, consequently, the overall environmental impact over time.

One of the most significant environmental challenges associated with PMMA in displays is its end-of-life management. While PMMA is theoretically recyclable, the complex nature of modern display devices often makes separation and recycling of PMMA components difficult. This can lead to increased e-waste, as many PMMA-containing displays end up in landfills or incinerators.

Efforts are being made to address these environmental concerns. Some manufacturers are exploring more sustainable production methods for PMMA, including the use of renewable resources and energy-efficient processes. Additionally, research is ongoing to develop more effective recycling techniques for PMMA in electronic devices.

The use of PMMA in displays also has indirect environmental implications. Its lightweight nature can contribute to reduced transportation emissions for finished products. Furthermore, the material's excellent light transmission properties can lead to more energy-efficient displays, potentially reducing power consumption and associated carbon emissions during the use phase.

As the demand for display technologies continues to grow, balancing the benefits of PMMA with its environmental impact remains a key challenge for the industry. Future developments in green chemistry, circular economy principles, and advanced recycling technologies will be crucial in mitigating the environmental footprint of PMMA in modern display technologies.

PMMA production involves the polymerization of methyl methacrylate, a process that requires significant energy input and generates greenhouse gas emissions. The manufacturing process also utilizes potentially harmful chemicals, including acetone and methanol, which can contribute to air and water pollution if not properly managed.

However, PMMA's durability and longevity in display applications can offset some of these initial environmental costs. PMMA screens typically have a longer lifespan compared to other materials, reducing the frequency of replacement and, consequently, the overall environmental impact over time.

One of the most significant environmental challenges associated with PMMA in displays is its end-of-life management. While PMMA is theoretically recyclable, the complex nature of modern display devices often makes separation and recycling of PMMA components difficult. This can lead to increased e-waste, as many PMMA-containing displays end up in landfills or incinerators.

Efforts are being made to address these environmental concerns. Some manufacturers are exploring more sustainable production methods for PMMA, including the use of renewable resources and energy-efficient processes. Additionally, research is ongoing to develop more effective recycling techniques for PMMA in electronic devices.

The use of PMMA in displays also has indirect environmental implications. Its lightweight nature can contribute to reduced transportation emissions for finished products. Furthermore, the material's excellent light transmission properties can lead to more energy-efficient displays, potentially reducing power consumption and associated carbon emissions during the use phase.

As the demand for display technologies continues to grow, balancing the benefits of PMMA with its environmental impact remains a key challenge for the industry. Future developments in green chemistry, circular economy principles, and advanced recycling technologies will be crucial in mitigating the environmental footprint of PMMA in modern display technologies.

PMMA Display Manufacturing Processes

PMMA (Polymethyl Methacrylate) has become a crucial material in modern display manufacturing processes, revolutionizing the industry with its unique properties and versatile applications. The manufacturing process of PMMA-based displays involves several key steps, each contributing to the final product's quality and performance.

The process typically begins with the polymerization of methyl methacrylate monomers to form PMMA. This can be achieved through various methods, including bulk polymerization, solution polymerization, or suspension polymerization. The choice of method depends on the desired properties of the final product and the specific application requirements.

Once the PMMA is synthesized, it undergoes a series of processing steps to prepare it for display manufacturing. This often includes extrusion or casting to form sheets or films of the desired thickness and dimensions. The PMMA sheets are then subjected to precise cutting and shaping techniques to fit the specific display requirements.

Surface treatment is a critical step in the manufacturing process. PMMA surfaces are often treated to enhance their optical properties, improve adhesion for subsequent layers, or add functional coatings. This may involve techniques such as plasma treatment, chemical etching, or the application of specialized coatings to achieve desired characteristics like anti-glare or scratch-resistant properties.

The integration of PMMA into display assemblies is a complex process that requires precision and careful handling. PMMA components are often used as light guide plates in LCD displays or as protective covers for various display technologies. The material's high optical clarity and ability to be molded into complex shapes make it ideal for these applications.

In recent years, advancements in PMMA manufacturing have led to the development of enhanced formulations with improved thermal stability, impact resistance, and optical properties. These innovations have expanded the use of PMMA in high-performance display applications, including automotive displays and large-format outdoor signage.

The final stages of PMMA display manufacturing often involve quality control measures to ensure the consistency and performance of the finished products. This includes optical testing, durability assessments, and environmental stress testing to verify that the PMMA components meet the rigorous standards required for modern display technologies.

As display technologies continue to evolve, PMMA manufacturing processes are adapting to meet new challenges. This includes the development of thinner, more flexible PMMA films for use in emerging flexible display technologies, as well as the integration of PMMA with other advanced materials to create hybrid display solutions with enhanced functionality.

The process typically begins with the polymerization of methyl methacrylate monomers to form PMMA. This can be achieved through various methods, including bulk polymerization, solution polymerization, or suspension polymerization. The choice of method depends on the desired properties of the final product and the specific application requirements.

Once the PMMA is synthesized, it undergoes a series of processing steps to prepare it for display manufacturing. This often includes extrusion or casting to form sheets or films of the desired thickness and dimensions. The PMMA sheets are then subjected to precise cutting and shaping techniques to fit the specific display requirements.

Surface treatment is a critical step in the manufacturing process. PMMA surfaces are often treated to enhance their optical properties, improve adhesion for subsequent layers, or add functional coatings. This may involve techniques such as plasma treatment, chemical etching, or the application of specialized coatings to achieve desired characteristics like anti-glare or scratch-resistant properties.

The integration of PMMA into display assemblies is a complex process that requires precision and careful handling. PMMA components are often used as light guide plates in LCD displays or as protective covers for various display technologies. The material's high optical clarity and ability to be molded into complex shapes make it ideal for these applications.

In recent years, advancements in PMMA manufacturing have led to the development of enhanced formulations with improved thermal stability, impact resistance, and optical properties. These innovations have expanded the use of PMMA in high-performance display applications, including automotive displays and large-format outdoor signage.

The final stages of PMMA display manufacturing often involve quality control measures to ensure the consistency and performance of the finished products. This includes optical testing, durability assessments, and environmental stress testing to verify that the PMMA components meet the rigorous standards required for modern display technologies.

As display technologies continue to evolve, PMMA manufacturing processes are adapting to meet new challenges. This includes the development of thinner, more flexible PMMA films for use in emerging flexible display technologies, as well as the integration of PMMA with other advanced materials to create hybrid display solutions with enhanced functionality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!