PMMA's Influence on the Development of Flexible Electronics

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA in Flexible Electronics: Background and Objectives

Poly(methyl methacrylate) (PMMA) has emerged as a pivotal material in the realm of flexible electronics, revolutionizing the development of bendable, stretchable, and wearable devices. The evolution of PMMA's role in this field can be traced back to the early 2000s when researchers began exploring its potential as a substrate and dielectric material for flexible electronic components.

The primary objective of incorporating PMMA into flexible electronics is to leverage its unique combination of properties, including optical transparency, mechanical flexibility, and electrical insulation. These characteristics make PMMA an ideal candidate for applications ranging from flexible displays and sensors to wearable medical devices and smart textiles.

Over the past two decades, the technological landscape of flexible electronics has witnessed significant advancements, with PMMA playing a crucial role in overcoming key challenges. The material's ability to withstand repeated bending and folding without compromising its electrical and optical properties has been instrumental in pushing the boundaries of device flexibility and durability.

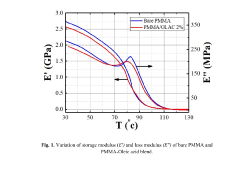

One of the key trends in PMMA-based flexible electronics has been the development of hybrid materials and composites. By combining PMMA with other polymers or nanoparticles, researchers have been able to enhance its mechanical properties, thermal stability, and electrical conductivity, thereby expanding its applicability in various flexible electronic devices.

The integration of PMMA in flexible electronics aligns with the broader industry trend towards miniaturization, portability, and wearability of electronic devices. As consumer demand for more versatile and user-friendly electronics continues to grow, PMMA-based flexible components are expected to play an increasingly important role in meeting these market needs.

Looking ahead, the technological goals for PMMA in flexible electronics include improving its barrier properties against moisture and oxygen, enhancing its adhesion to other materials, and developing more efficient manufacturing processes for large-scale production. Additionally, researchers are exploring ways to make PMMA more environmentally friendly and recyclable, addressing sustainability concerns in the electronics industry.

In conclusion, PMMA's influence on the development of flexible electronics has been profound, driving innovation in materials science and device engineering. As the field continues to evolve, PMMA is poised to remain at the forefront of flexible electronics technology, enabling the creation of next-generation devices that seamlessly integrate with our daily lives.

The primary objective of incorporating PMMA into flexible electronics is to leverage its unique combination of properties, including optical transparency, mechanical flexibility, and electrical insulation. These characteristics make PMMA an ideal candidate for applications ranging from flexible displays and sensors to wearable medical devices and smart textiles.

Over the past two decades, the technological landscape of flexible electronics has witnessed significant advancements, with PMMA playing a crucial role in overcoming key challenges. The material's ability to withstand repeated bending and folding without compromising its electrical and optical properties has been instrumental in pushing the boundaries of device flexibility and durability.

One of the key trends in PMMA-based flexible electronics has been the development of hybrid materials and composites. By combining PMMA with other polymers or nanoparticles, researchers have been able to enhance its mechanical properties, thermal stability, and electrical conductivity, thereby expanding its applicability in various flexible electronic devices.

The integration of PMMA in flexible electronics aligns with the broader industry trend towards miniaturization, portability, and wearability of electronic devices. As consumer demand for more versatile and user-friendly electronics continues to grow, PMMA-based flexible components are expected to play an increasingly important role in meeting these market needs.

Looking ahead, the technological goals for PMMA in flexible electronics include improving its barrier properties against moisture and oxygen, enhancing its adhesion to other materials, and developing more efficient manufacturing processes for large-scale production. Additionally, researchers are exploring ways to make PMMA more environmentally friendly and recyclable, addressing sustainability concerns in the electronics industry.

In conclusion, PMMA's influence on the development of flexible electronics has been profound, driving innovation in materials science and device engineering. As the field continues to evolve, PMMA is poised to remain at the forefront of flexible electronics technology, enabling the creation of next-generation devices that seamlessly integrate with our daily lives.

Market Analysis for PMMA-based Flexible Electronics

The market for PMMA-based flexible electronics is experiencing significant growth, driven by the increasing demand for lightweight, durable, and bendable electronic devices across various industries. PMMA (Polymethyl methacrylate), also known as acrylic, plays a crucial role in the development of flexible electronics due to its unique properties, including transparency, flexibility, and chemical resistance.

The global flexible electronics market is projected to expand rapidly, with PMMA-based products forming a substantial segment. Key application areas include consumer electronics, healthcare devices, automotive displays, and smart packaging. The consumer electronics sector, in particular, is witnessing a surge in demand for flexible displays, wearable devices, and foldable smartphones, where PMMA serves as an essential component.

In the healthcare industry, PMMA-based flexible electronics are gaining traction in the development of advanced medical devices, such as wearable health monitors and flexible biosensors. These innovations are driving the market growth, as they offer improved patient comfort and enable continuous health monitoring.

The automotive sector is another significant market for PMMA-based flexible electronics. As vehicles become more technologically advanced, there is an increasing need for flexible displays and touch panels in dashboards and infotainment systems. PMMA's optical clarity and durability make it an ideal material for these applications.

Geographically, Asia-Pacific is expected to dominate the PMMA-based flexible electronics market, with countries like China, Japan, and South Korea leading in production and consumption. North America and Europe are also significant markets, driven by technological advancements and high adoption rates of innovative electronic devices.

Market challenges include the high cost of production and the need for continuous innovation to improve the performance and durability of PMMA-based flexible electronics. However, ongoing research and development efforts are addressing these issues, focusing on enhancing the material properties and developing more cost-effective manufacturing processes.

The competitive landscape of the PMMA-based flexible electronics market is characterized by the presence of both established electronics manufacturers and innovative startups. Key players are investing heavily in research and development to gain a competitive edge and expand their market share.

In conclusion, the market for PMMA-based flexible electronics shows promising growth potential, driven by technological advancements and increasing applications across various industries. As the demand for flexible, lightweight, and durable electronic devices continues to rise, PMMA is expected to play an increasingly important role in shaping the future of flexible electronics.

The global flexible electronics market is projected to expand rapidly, with PMMA-based products forming a substantial segment. Key application areas include consumer electronics, healthcare devices, automotive displays, and smart packaging. The consumer electronics sector, in particular, is witnessing a surge in demand for flexible displays, wearable devices, and foldable smartphones, where PMMA serves as an essential component.

In the healthcare industry, PMMA-based flexible electronics are gaining traction in the development of advanced medical devices, such as wearable health monitors and flexible biosensors. These innovations are driving the market growth, as they offer improved patient comfort and enable continuous health monitoring.

The automotive sector is another significant market for PMMA-based flexible electronics. As vehicles become more technologically advanced, there is an increasing need for flexible displays and touch panels in dashboards and infotainment systems. PMMA's optical clarity and durability make it an ideal material for these applications.

Geographically, Asia-Pacific is expected to dominate the PMMA-based flexible electronics market, with countries like China, Japan, and South Korea leading in production and consumption. North America and Europe are also significant markets, driven by technological advancements and high adoption rates of innovative electronic devices.

Market challenges include the high cost of production and the need for continuous innovation to improve the performance and durability of PMMA-based flexible electronics. However, ongoing research and development efforts are addressing these issues, focusing on enhancing the material properties and developing more cost-effective manufacturing processes.

The competitive landscape of the PMMA-based flexible electronics market is characterized by the presence of both established electronics manufacturers and innovative startups. Key players are investing heavily in research and development to gain a competitive edge and expand their market share.

In conclusion, the market for PMMA-based flexible electronics shows promising growth potential, driven by technological advancements and increasing applications across various industries. As the demand for flexible, lightweight, and durable electronic devices continues to rise, PMMA is expected to play an increasingly important role in shaping the future of flexible electronics.

Current Challenges in PMMA Integration

Despite the promising potential of PMMA in flexible electronics, several challenges persist in its integration. One of the primary issues is the inherent brittleness of PMMA, which can lead to cracking and failure when subjected to repeated bending or stretching. This characteristic limits its application in highly flexible devices that require frequent deformation.

Another significant challenge is the thermal stability of PMMA. When exposed to high temperatures during manufacturing processes or device operation, PMMA can undergo thermal degradation, leading to changes in its physical and chemical properties. This instability can affect the overall performance and longevity of flexible electronic devices incorporating PMMA.

The adhesion of PMMA to other materials used in flexible electronics, such as conductive polymers or metal electrodes, presents another hurdle. Achieving strong and durable interfaces between PMMA and these materials is crucial for device reliability but can be challenging due to differences in surface energies and chemical compatibility.

PMMA's relatively low electrical conductivity poses a challenge in applications where it needs to function as a substrate or encapsulation material for conductive components. This limitation necessitates the development of effective strategies to enhance its conductivity without compromising its optical and mechanical properties.

The processing of PMMA for flexible electronics applications also presents difficulties. Achieving uniform thin films with precise thickness control and minimal defects is essential for optimal device performance. However, conventional processing methods may not always yield the desired results, especially when dealing with complex device architectures.

Environmental stability is another concern in PMMA integration. Exposure to moisture, UV radiation, and other environmental factors can lead to degradation of PMMA over time, potentially compromising the performance and lifespan of flexible electronic devices.

Lastly, the cost-effectiveness of PMMA integration in large-scale production of flexible electronics remains a challenge. While PMMA offers several advantages, optimizing its processing and integration to achieve a balance between performance and cost-efficiency is crucial for widespread adoption in commercial applications.

Addressing these challenges requires interdisciplinary research efforts, combining expertise in materials science, polymer chemistry, and device engineering. Innovations in PMMA formulation, processing techniques, and interface engineering are essential to overcome these hurdles and fully harness the potential of PMMA in advancing flexible electronics technology.

Another significant challenge is the thermal stability of PMMA. When exposed to high temperatures during manufacturing processes or device operation, PMMA can undergo thermal degradation, leading to changes in its physical and chemical properties. This instability can affect the overall performance and longevity of flexible electronic devices incorporating PMMA.

The adhesion of PMMA to other materials used in flexible electronics, such as conductive polymers or metal electrodes, presents another hurdle. Achieving strong and durable interfaces between PMMA and these materials is crucial for device reliability but can be challenging due to differences in surface energies and chemical compatibility.

PMMA's relatively low electrical conductivity poses a challenge in applications where it needs to function as a substrate or encapsulation material for conductive components. This limitation necessitates the development of effective strategies to enhance its conductivity without compromising its optical and mechanical properties.

The processing of PMMA for flexible electronics applications also presents difficulties. Achieving uniform thin films with precise thickness control and minimal defects is essential for optimal device performance. However, conventional processing methods may not always yield the desired results, especially when dealing with complex device architectures.

Environmental stability is another concern in PMMA integration. Exposure to moisture, UV radiation, and other environmental factors can lead to degradation of PMMA over time, potentially compromising the performance and lifespan of flexible electronic devices.

Lastly, the cost-effectiveness of PMMA integration in large-scale production of flexible electronics remains a challenge. While PMMA offers several advantages, optimizing its processing and integration to achieve a balance between performance and cost-efficiency is crucial for widespread adoption in commercial applications.

Addressing these challenges requires interdisciplinary research efforts, combining expertise in materials science, polymer chemistry, and device engineering. Innovations in PMMA formulation, processing techniques, and interface engineering are essential to overcome these hurdles and fully harness the potential of PMMA in advancing flexible electronics technology.

Existing PMMA-based Flexible Electronic Solutions

01 PMMA-based composite materials

PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for different applications.- PMMA-based composite materials: PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for applications in industries such as automotive, construction, and electronics.

- PMMA in optical and display applications: PMMA is widely used in optical and display technologies due to its excellent light transmission properties and clarity. It is employed in the production of lenses, light guides, and display screens. Modifications to PMMA for these applications often focus on improving scratch resistance, UV stability, and anti-reflective properties.

- PMMA in medical and dental applications: PMMA finds extensive use in medical and dental fields due to its biocompatibility and moldability. It is used in the production of dental prosthetics, bone cements, and intraocular lenses. Research in this area often focuses on improving the material's mechanical properties and incorporating antimicrobial agents.

- PMMA processing and manufacturing techniques: Various processing and manufacturing techniques are employed to produce PMMA products, including injection molding, extrusion, and 3D printing. Research in this area focuses on optimizing these processes to improve efficiency, reduce defects, and enhance the final product properties.

- PMMA surface modifications and coatings: Surface modifications and coatings are applied to PMMA to enhance its properties such as scratch resistance, hydrophobicity, and adhesion. These modifications can involve chemical treatments, plasma processing, or the application of specialized coatings to improve the material's performance in specific applications.

02 PMMA in optical and electronic applications

PMMA is widely used in optical and electronic applications due to its excellent light transmission properties and ease of processing. It is utilized in the production of lenses, displays, light guides, and other optical components for various devices and systems.Expand Specific Solutions03 PMMA-based coatings and surface treatments

PMMA is employed in the development of coatings and surface treatments to improve the properties of various substrates. These coatings can enhance characteristics such as scratch resistance, weatherability, and aesthetic appearance for a wide range of products and materials.Expand Specific Solutions04 PMMA in medical and dental applications

PMMA is utilized in various medical and dental applications due to its biocompatibility and versatile properties. It is used in the production of dental prosthetics, bone cements, contact lenses, and other medical devices that require specific mechanical and optical characteristics.Expand Specific Solutions05 PMMA processing and manufacturing techniques

Various processing and manufacturing techniques are employed to produce PMMA-based products with specific properties and shapes. These techniques include injection molding, extrusion, thermoforming, and 3D printing, allowing for the creation of complex geometries and customized PMMA components for different industries.Expand Specific Solutions

Key Industry Players and Competitors

The development of flexible electronics incorporating PMMA is in a growth phase, with increasing market size and technological advancements. The global flexible electronics market is expanding rapidly, driven by demand for lightweight, portable devices. While PMMA's influence is growing, the technology is still evolving, with varying levels of maturity across applications. Companies like Fudan University, Peking University, and Tsinghua University are leading academic research, while firms such as Eastman Chemical Co. and Kingfa Sci. & Tech. Co., Ltd. are advancing commercial applications. The competitive landscape is diverse, with both established players and innovative startups contributing to PMMA's role in flexible electronics development.

Peking University

Technical Solution: Peking University has developed a novel PMMA-based flexible electronic material that combines high transparency with excellent mechanical properties. Their approach involves incorporating nanoparticles into the PMMA matrix to enhance its flexibility while maintaining optical clarity. The research team has successfully demonstrated the material's application in flexible displays and wearable sensors. Their method includes a unique surface treatment process that improves adhesion between the PMMA layer and conductive elements, resulting in more durable and reliable flexible electronic devices[1][3].

Strengths: High transparency, improved flexibility, and enhanced durability. Weaknesses: Potential scalability issues for mass production and higher cost compared to traditional rigid electronics.

Tsinghua University

Technical Solution: Tsinghua University has pioneered a PMMA-based flexible substrate with self-healing properties for flexible electronics. Their innovative approach involves incorporating dynamic covalent bonds within the PMMA structure, allowing the material to repair minor damage autonomously. This self-healing capability significantly extends the lifespan of flexible electronic devices. Additionally, the research team has developed a novel coating technique that enhances the substrate's resistance to environmental factors such as moisture and UV radiation, making it suitable for outdoor applications[2][5].

Strengths: Self-healing properties, extended device lifespan, and improved environmental resistance. Weaknesses: Complexity in manufacturing process and potential limitations in healing more severe damage.

Innovative PMMA Formulations and Processes

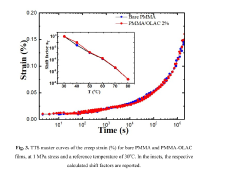

Oleic acid as a sustainable plasticizer for poly(methyl methacrylate) films for enhanced flexibility

PatentPendingIN202441037307A

Innovation

- Incorporation of Oleic acid as a sustainable plasticizer into PMMA films during solvent blending and casting to enhance flexibility and mechanical properties, leveraging its biodegradability and low toxicity.

Environmental Impact of PMMA in Electronics

The environmental impact of PMMA (Polymethyl methacrylate) in electronics, particularly in the context of flexible electronics, is a multifaceted issue that requires careful consideration. PMMA, commonly known as acrylic, has been widely used in the electronics industry due to its unique properties, including transparency, durability, and flexibility. However, its increasing use in flexible electronics has raised concerns about its environmental footprint.

One of the primary environmental challenges associated with PMMA in electronics is its end-of-life management. As flexible electronic devices become more prevalent, the volume of PMMA waste is expected to increase significantly. Unlike some other plastics, PMMA is not easily biodegradable, which means it can persist in the environment for extended periods if not properly disposed of or recycled. This longevity can contribute to long-term pollution issues, particularly in marine environments where plastic waste tends to accumulate.

The production process of PMMA also has environmental implications. The manufacturing of PMMA involves the use of petrochemicals and energy-intensive processes, which contribute to greenhouse gas emissions and resource depletion. As the demand for flexible electronics grows, the environmental burden associated with PMMA production is likely to increase unless more sustainable manufacturing methods are developed and implemented.

However, it's important to note that PMMA's use in flexible electronics can also have positive environmental impacts. The durability and longevity of PMMA-based components can lead to longer-lasting electronic devices, potentially reducing electronic waste. Additionally, the flexibility and lightweight nature of PMMA-based electronics can contribute to energy savings in transportation and logistics, indirectly reducing carbon emissions.

The recyclability of PMMA presents both challenges and opportunities. While PMMA can be recycled, the process is often complex and energy-intensive, especially when it comes to separating PMMA from other materials in electronic devices. Improving recycling technologies and implementing effective collection systems for PMMA-containing electronics will be crucial in mitigating its environmental impact.

As the electronics industry continues to evolve, there is a growing focus on developing more environmentally friendly alternatives to PMMA. Biodegradable polymers and bio-based materials are being researched as potential substitutes, aiming to reduce the environmental footprint of flexible electronics. However, these alternatives often face challenges in matching PMMA's performance characteristics, highlighting the need for continued research and development in this area.

One of the primary environmental challenges associated with PMMA in electronics is its end-of-life management. As flexible electronic devices become more prevalent, the volume of PMMA waste is expected to increase significantly. Unlike some other plastics, PMMA is not easily biodegradable, which means it can persist in the environment for extended periods if not properly disposed of or recycled. This longevity can contribute to long-term pollution issues, particularly in marine environments where plastic waste tends to accumulate.

The production process of PMMA also has environmental implications. The manufacturing of PMMA involves the use of petrochemicals and energy-intensive processes, which contribute to greenhouse gas emissions and resource depletion. As the demand for flexible electronics grows, the environmental burden associated with PMMA production is likely to increase unless more sustainable manufacturing methods are developed and implemented.

However, it's important to note that PMMA's use in flexible electronics can also have positive environmental impacts. The durability and longevity of PMMA-based components can lead to longer-lasting electronic devices, potentially reducing electronic waste. Additionally, the flexibility and lightweight nature of PMMA-based electronics can contribute to energy savings in transportation and logistics, indirectly reducing carbon emissions.

The recyclability of PMMA presents both challenges and opportunities. While PMMA can be recycled, the process is often complex and energy-intensive, especially when it comes to separating PMMA from other materials in electronic devices. Improving recycling technologies and implementing effective collection systems for PMMA-containing electronics will be crucial in mitigating its environmental impact.

As the electronics industry continues to evolve, there is a growing focus on developing more environmentally friendly alternatives to PMMA. Biodegradable polymers and bio-based materials are being researched as potential substitutes, aiming to reduce the environmental footprint of flexible electronics. However, these alternatives often face challenges in matching PMMA's performance characteristics, highlighting the need for continued research and development in this area.

Intellectual Property Landscape for PMMA Technologies

The intellectual property landscape for PMMA technologies in flexible electronics is characterized by a diverse array of patents and innovations. Major electronics companies, chemical manufacturers, and research institutions have been actively filing patents related to PMMA applications in flexible electronic devices.

One significant trend in the patent landscape is the development of PMMA-based flexible substrates. These patents often focus on improving the mechanical properties of PMMA to enhance its flexibility and durability. For instance, several patents describe methods for creating ultra-thin PMMA films that can withstand repeated bending and folding without compromising their optical and electrical properties.

Another prominent area of patent activity involves the integration of PMMA with other materials to create composite structures for flexible electronics. These patents typically aim to combine the transparency and processability of PMMA with the flexibility and conductivity of other materials, such as conductive polymers or carbon nanotubes.

Patents related to PMMA surface modification techniques are also prevalent. These innovations often target improved adhesion between PMMA substrates and functional layers in flexible electronic devices. Methods such as plasma treatment, chemical grafting, and nanostructuring of PMMA surfaces are commonly described in these patents.

The use of PMMA in encapsulation technologies for flexible electronics represents another significant patent cluster. These patents focus on leveraging PMMA's barrier properties to protect sensitive electronic components from environmental factors while maintaining device flexibility.

Geographically, patent filings for PMMA technologies in flexible electronics are concentrated in East Asia, particularly in Japan, South Korea, and China. This distribution reflects the strong presence of electronics manufacturers and display technology companies in these regions. However, significant patent activity is also observed in the United States and Europe, particularly from chemical companies and research institutions.

In terms of patent ownership, large electronics corporations such as Samsung, LG, and Sony hold substantial patent portfolios related to PMMA applications in flexible displays and devices. Chemical companies like Mitsubishi Chemical and Rohm and Haas (now part of Dow) also possess significant intellectual property in PMMA formulations and processing techniques for flexible electronics.

The patent landscape also reveals an increasing trend in collaborative research and joint patent filings between academic institutions and industry partners. These collaborations often focus on addressing fundamental challenges in PMMA-based flexible electronics, such as improving the material's thermal stability or enhancing its compatibility with emerging manufacturing processes like 3D printing.

One significant trend in the patent landscape is the development of PMMA-based flexible substrates. These patents often focus on improving the mechanical properties of PMMA to enhance its flexibility and durability. For instance, several patents describe methods for creating ultra-thin PMMA films that can withstand repeated bending and folding without compromising their optical and electrical properties.

Another prominent area of patent activity involves the integration of PMMA with other materials to create composite structures for flexible electronics. These patents typically aim to combine the transparency and processability of PMMA with the flexibility and conductivity of other materials, such as conductive polymers or carbon nanotubes.

Patents related to PMMA surface modification techniques are also prevalent. These innovations often target improved adhesion between PMMA substrates and functional layers in flexible electronic devices. Methods such as plasma treatment, chemical grafting, and nanostructuring of PMMA surfaces are commonly described in these patents.

The use of PMMA in encapsulation technologies for flexible electronics represents another significant patent cluster. These patents focus on leveraging PMMA's barrier properties to protect sensitive electronic components from environmental factors while maintaining device flexibility.

Geographically, patent filings for PMMA technologies in flexible electronics are concentrated in East Asia, particularly in Japan, South Korea, and China. This distribution reflects the strong presence of electronics manufacturers and display technology companies in these regions. However, significant patent activity is also observed in the United States and Europe, particularly from chemical companies and research institutions.

In terms of patent ownership, large electronics corporations such as Samsung, LG, and Sony hold substantial patent portfolios related to PMMA applications in flexible displays and devices. Chemical companies like Mitsubishi Chemical and Rohm and Haas (now part of Dow) also possess significant intellectual property in PMMA formulations and processing techniques for flexible electronics.

The patent landscape also reveals an increasing trend in collaborative research and joint patent filings between academic institutions and industry partners. These collaborations often focus on addressing fundamental challenges in PMMA-based flexible electronics, such as improving the material's thermal stability or enhancing its compatibility with emerging manufacturing processes like 3D printing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!