How to Achieve Repeatable Quality Control in PMMA Production?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA QC Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries since its development in the 1930s. Its unique properties, including optical clarity, weather resistance, and ease of fabrication, have made it indispensable in applications ranging from automotive and aerospace to medical devices and consumer electronics.

The evolution of PMMA production techniques has been driven by the increasing demand for higher quality and more consistent products. Initially, the focus was on improving the polymerization process to achieve better optical properties and mechanical strength. As manufacturing scales expanded, the emphasis shifted towards developing more efficient and controlled production methods, such as continuous bulk polymerization and suspension polymerization.

In recent years, the primary technological goal in PMMA production has been to achieve repeatable quality control. This objective is crucial for several reasons. Firstly, modern applications of PMMA, particularly in high-tech industries, require extremely tight tolerances and consistent performance. Secondly, the global market for PMMA is becoming increasingly competitive, with manufacturers seeking to differentiate themselves through superior quality and reliability.

The challenge of repeatable quality control in PMMA production is multifaceted. It involves maintaining consistent molecular weight distribution, minimizing residual monomer content, controlling optical properties, and ensuring uniform mechanical characteristics across production batches. These factors are influenced by numerous variables in the production process, including temperature, pressure, catalyst concentration, and polymerization time.

Advancements in process monitoring and control technologies have played a significant role in addressing these challenges. The integration of real-time analytics, such as in-line spectroscopy and advanced rheological measurements, has enabled more precise control over the polymerization process. Additionally, the application of statistical process control (SPC) and Six Sigma methodologies has helped manufacturers identify and mitigate sources of variability in their production lines.

Looking forward, the technological objectives for PMMA quality control are centered on further enhancing precision and repeatability while increasing production efficiency. This includes the development of more sophisticated predictive models for polymerization kinetics, the implementation of artificial intelligence and machine learning algorithms for process optimization, and the exploration of novel polymerization techniques that offer greater control over material properties.

The evolution of PMMA production techniques has been driven by the increasing demand for higher quality and more consistent products. Initially, the focus was on improving the polymerization process to achieve better optical properties and mechanical strength. As manufacturing scales expanded, the emphasis shifted towards developing more efficient and controlled production methods, such as continuous bulk polymerization and suspension polymerization.

In recent years, the primary technological goal in PMMA production has been to achieve repeatable quality control. This objective is crucial for several reasons. Firstly, modern applications of PMMA, particularly in high-tech industries, require extremely tight tolerances and consistent performance. Secondly, the global market for PMMA is becoming increasingly competitive, with manufacturers seeking to differentiate themselves through superior quality and reliability.

The challenge of repeatable quality control in PMMA production is multifaceted. It involves maintaining consistent molecular weight distribution, minimizing residual monomer content, controlling optical properties, and ensuring uniform mechanical characteristics across production batches. These factors are influenced by numerous variables in the production process, including temperature, pressure, catalyst concentration, and polymerization time.

Advancements in process monitoring and control technologies have played a significant role in addressing these challenges. The integration of real-time analytics, such as in-line spectroscopy and advanced rheological measurements, has enabled more precise control over the polymerization process. Additionally, the application of statistical process control (SPC) and Six Sigma methodologies has helped manufacturers identify and mitigate sources of variability in their production lines.

Looking forward, the technological objectives for PMMA quality control are centered on further enhancing precision and repeatability while increasing production efficiency. This includes the development of more sophisticated predictive models for polymerization kinetics, the implementation of artificial intelligence and machine learning algorithms for process optimization, and the exploration of novel polymerization techniques that offer greater control over material properties.

Market Demand for High-Quality PMMA

The market demand for high-quality Poly(methyl methacrylate) (PMMA) has been steadily increasing across various industries due to its exceptional optical clarity, weather resistance, and versatility. In the automotive sector, PMMA is increasingly used for lightweight, shatter-resistant windows and innovative lighting solutions, driven by the trend towards electric vehicles and enhanced safety features. The aerospace industry also shows growing demand for high-grade PMMA in aircraft windows and interior components, valuing its durability and low weight.

The electronics and display industry represents another significant market for premium PMMA. With the proliferation of smartphones, tablets, and large-format displays, manufacturers require PMMA with superior optical properties and scratch resistance. The medical field continues to expand its use of high-quality PMMA in applications such as bone cement, dental implants, and contact lenses, where biocompatibility and consistent performance are crucial.

In the construction sector, there is an increasing preference for PMMA in architectural glazing, skylights, and decorative panels. This trend is fueled by the material's excellent light transmission, UV resistance, and design flexibility. The growing focus on energy-efficient buildings has also boosted demand for PMMA in solar panels and light guides.

The packaging industry is another key driver of high-quality PMMA demand. As consumers become more environmentally conscious, there's a shift towards recyclable and durable packaging materials. PMMA's clarity, chemical resistance, and recyclability make it an attractive option for premium product packaging in cosmetics, food, and beverages.

Emerging technologies like 3D printing and augmented reality displays are creating new avenues for high-performance PMMA. These applications require materials with precise optical properties and dimensional stability, further driving the need for superior quality control in PMMA production.

The global market for PMMA is projected to grow significantly in the coming years, with a particular emphasis on high-quality grades. This growth is underpinned by increasing urbanization, rising disposable incomes, and technological advancements across various end-use industries. As a result, manufacturers are under pressure to improve their production processes to meet the stringent quality requirements and maintain consistency across batches.

To address this growing demand, PMMA producers must focus on developing advanced quality control measures. This includes implementing real-time monitoring systems, enhancing process automation, and adopting cutting-edge analytical techniques to ensure consistent material properties. The ability to achieve repeatable quality control in PMMA production will be a key differentiator for manufacturers in this competitive landscape.

The electronics and display industry represents another significant market for premium PMMA. With the proliferation of smartphones, tablets, and large-format displays, manufacturers require PMMA with superior optical properties and scratch resistance. The medical field continues to expand its use of high-quality PMMA in applications such as bone cement, dental implants, and contact lenses, where biocompatibility and consistent performance are crucial.

In the construction sector, there is an increasing preference for PMMA in architectural glazing, skylights, and decorative panels. This trend is fueled by the material's excellent light transmission, UV resistance, and design flexibility. The growing focus on energy-efficient buildings has also boosted demand for PMMA in solar panels and light guides.

The packaging industry is another key driver of high-quality PMMA demand. As consumers become more environmentally conscious, there's a shift towards recyclable and durable packaging materials. PMMA's clarity, chemical resistance, and recyclability make it an attractive option for premium product packaging in cosmetics, food, and beverages.

Emerging technologies like 3D printing and augmented reality displays are creating new avenues for high-performance PMMA. These applications require materials with precise optical properties and dimensional stability, further driving the need for superior quality control in PMMA production.

The global market for PMMA is projected to grow significantly in the coming years, with a particular emphasis on high-quality grades. This growth is underpinned by increasing urbanization, rising disposable incomes, and technological advancements across various end-use industries. As a result, manufacturers are under pressure to improve their production processes to meet the stringent quality requirements and maintain consistency across batches.

To address this growing demand, PMMA producers must focus on developing advanced quality control measures. This includes implementing real-time monitoring systems, enhancing process automation, and adopting cutting-edge analytical techniques to ensure consistent material properties. The ability to achieve repeatable quality control in PMMA production will be a key differentiator for manufacturers in this competitive landscape.

PMMA Production Challenges

Poly(methyl methacrylate) (PMMA) production faces several significant challenges that impact the ability to achieve consistent quality control. One of the primary issues is the sensitivity of the polymerization process to environmental factors. Temperature fluctuations, even minor ones, can significantly affect the molecular weight distribution and overall properties of the final product. This sensitivity necessitates precise control systems and robust monitoring throughout the production process.

Another major challenge lies in the inherent variability of raw materials. The quality and composition of methyl methacrylate monomer can vary between batches or suppliers, leading to inconsistencies in the final PMMA product. Impurities in the monomer or other additives can act as chain transfer agents, altering the polymerization kinetics and resulting in unexpected changes in the polymer's properties.

The initiation step of PMMA polymerization presents its own set of challenges. Ensuring uniform initiation across the reaction mixture is crucial for producing PMMA with consistent molecular weight and polydispersity. Inadequate mixing or non-uniform distribution of initiators can lead to localized variations in reaction rates, resulting in heterogeneous product quality.

Control of the exothermic nature of PMMA polymerization is another significant hurdle. The heat generated during the reaction can cause temperature spikes, potentially leading to runaway reactions or degradation of the polymer. Efficient heat removal systems and careful reaction rate control are essential to maintain product quality and safety.

The presence of residual monomer in the final product is a persistent quality control issue in PMMA production. Incomplete conversion not only affects the mechanical and optical properties of the polymer but also raises safety concerns due to the potential release of unreacted monomer. Achieving high conversion rates while maintaining other desired properties requires a delicate balance of reaction conditions.

Scaling up PMMA production from laboratory to industrial scale introduces additional challenges. Maintaining uniform conditions throughout larger reaction vessels becomes more difficult, potentially leading to inconsistencies in product quality. The increased production volume also amplifies the impact of any process deviations, making robust quality control systems even more critical.

Post-polymerization processing steps, such as extrusion and molding, can introduce further variability in the final product. Thermal history during these processes can affect the polymer's properties, requiring careful control and monitoring to ensure consistency across different production runs.

Addressing these challenges requires a multifaceted approach, combining advanced process control technologies, rigorous quality assurance protocols, and continuous improvement initiatives. Implementing real-time monitoring systems, developing predictive models for process optimization, and enhancing the understanding of structure-property relationships in PMMA are key areas of focus for achieving repeatable quality control in PMMA production.

Another major challenge lies in the inherent variability of raw materials. The quality and composition of methyl methacrylate monomer can vary between batches or suppliers, leading to inconsistencies in the final PMMA product. Impurities in the monomer or other additives can act as chain transfer agents, altering the polymerization kinetics and resulting in unexpected changes in the polymer's properties.

The initiation step of PMMA polymerization presents its own set of challenges. Ensuring uniform initiation across the reaction mixture is crucial for producing PMMA with consistent molecular weight and polydispersity. Inadequate mixing or non-uniform distribution of initiators can lead to localized variations in reaction rates, resulting in heterogeneous product quality.

Control of the exothermic nature of PMMA polymerization is another significant hurdle. The heat generated during the reaction can cause temperature spikes, potentially leading to runaway reactions or degradation of the polymer. Efficient heat removal systems and careful reaction rate control are essential to maintain product quality and safety.

The presence of residual monomer in the final product is a persistent quality control issue in PMMA production. Incomplete conversion not only affects the mechanical and optical properties of the polymer but also raises safety concerns due to the potential release of unreacted monomer. Achieving high conversion rates while maintaining other desired properties requires a delicate balance of reaction conditions.

Scaling up PMMA production from laboratory to industrial scale introduces additional challenges. Maintaining uniform conditions throughout larger reaction vessels becomes more difficult, potentially leading to inconsistencies in product quality. The increased production volume also amplifies the impact of any process deviations, making robust quality control systems even more critical.

Post-polymerization processing steps, such as extrusion and molding, can introduce further variability in the final product. Thermal history during these processes can affect the polymer's properties, requiring careful control and monitoring to ensure consistency across different production runs.

Addressing these challenges requires a multifaceted approach, combining advanced process control technologies, rigorous quality assurance protocols, and continuous improvement initiatives. Implementing real-time monitoring systems, developing predictive models for process optimization, and enhancing the understanding of structure-property relationships in PMMA are key areas of focus for achieving repeatable quality control in PMMA production.

Current PMMA QC Methods

01 Testing methods for PMMA quality control

Various testing methods are employed to ensure the quality of PMMA. These include physical property tests, chemical composition analysis, and performance evaluations. Techniques such as spectroscopy, chromatography, and mechanical testing are used to assess parameters like molecular weight, purity, and mechanical strength.- Testing methods for PMMA quality control: Various testing methods are employed to ensure the quality of PMMA. These include physical property tests, chemical composition analysis, and optical performance evaluations. Specific techniques may involve spectroscopy, chromatography, and mechanical strength assessments to verify the material's conformity to required specifications.

- PMMA production process optimization: Optimizing the production process of PMMA is crucial for quality control. This involves careful control of polymerization conditions, including temperature, pressure, and catalyst concentrations. Advanced monitoring systems and process control algorithms are implemented to maintain consistency and reduce defects in the final product.

- Additives and modifications for enhanced PMMA properties: The incorporation of specific additives and modifications to PMMA can enhance its properties and quality. This may include the addition of stabilizers, impact modifiers, or surface treatments to improve characteristics such as weather resistance, impact strength, or optical clarity. Careful selection and integration of these additives are essential for maintaining overall quality.

- Quality control in PMMA sheet and film production: Specialized quality control measures are implemented in the production of PMMA sheets and films. This includes monitoring thickness uniformity, surface smoothness, and optical properties. Advanced inspection systems, such as laser scanners and high-resolution cameras, are used to detect defects and ensure consistent quality throughout the production process.

- Recycling and reprocessing of PMMA for quality maintenance: Recycling and reprocessing of PMMA are important aspects of quality control in sustainable manufacturing. Techniques are developed to maintain the quality of recycled PMMA, including purification processes, blending with virgin material, and re-polymerization methods. These approaches aim to ensure that recycled PMMA meets the same quality standards as newly produced material.

02 PMMA production process optimization

Optimizing the production process is crucial for maintaining PMMA quality. This involves controlling polymerization conditions, such as temperature, pressure, and catalyst concentration. Advanced monitoring systems and process control algorithms are implemented to ensure consistent product quality throughout the manufacturing process.Expand Specific Solutions03 Additives and modifications for enhanced PMMA properties

Incorporating additives and modifying PMMA formulations can improve its properties and quality. This includes the use of stabilizers, impact modifiers, and other functional additives to enhance UV resistance, thermal stability, and mechanical properties. Careful selection and precise dosing of these additives are essential for maintaining overall quality.Expand Specific Solutions04 Surface treatment and coating techniques for PMMA

Surface treatments and coating techniques are applied to PMMA to improve its quality and performance. These processes can enhance scratch resistance, chemical resistance, and optical properties. Various methods such as plasma treatment, UV curing, and application of specialized coatings are used to achieve desired surface characteristics.Expand Specific Solutions05 Quality control equipment and automation

Advanced equipment and automation systems are utilized for PMMA quality control. This includes the use of in-line monitoring devices, automated inspection systems, and data analysis software. These tools enable real-time quality assessment, defect detection, and process optimization, ensuring consistent PMMA quality throughout production.Expand Specific Solutions

Key PMMA Manufacturers

The market for PMMA production quality control is in a mature stage, with established players and well-defined processes. The global PMMA market size is projected to reach $8.2 billion by 2027, growing at a CAGR of 6.1%. Technologically, the industry is advanced, with companies like Arkema, Röhm GmbH, and Trinseo Europe GmbH leading innovation. Chinese firms such as Sinopec and PetroChina are also significant players, leveraging their petrochemical expertise. Academic institutions like Fudan University and Harbin Institute of Technology contribute to R&D efforts, enhancing the technological landscape. The focus is shifting towards developing more efficient and sustainable production methods to meet increasing demand and environmental regulations.

Arkema France SA

Technical Solution: Arkema has developed a comprehensive approach to achieve repeatable quality control in PMMA production. Their method involves advanced polymerization techniques, including controlled radical polymerization (CRP) and suspension polymerization[1]. They utilize real-time monitoring systems with in-line spectroscopic analysis to ensure consistent molecular weight distribution and optical properties[2]. Arkema's process also incorporates automated feed control systems that adjust monomer and initiator ratios based on real-time data, maintaining optimal reaction conditions throughout the production cycle[3]. Additionally, they have implemented a stringent post-production quality assurance protocol, including advanced optical testing and mechanical property analysis, to ensure each batch meets their high-quality standards[4].

Strengths: Advanced polymerization techniques, real-time monitoring, and automated control systems ensure consistent quality. Weaknesses: The complex system may require significant initial investment and ongoing maintenance.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has implemented a multi-faceted approach to ensure repeatable quality control in PMMA production. Their strategy includes the use of advanced continuous flow reactors that allow for precise control of reaction parameters such as temperature, pressure, and residence time[5]. Sinopec has also developed proprietary catalysts that improve conversion rates and reduce impurities in the final product[6]. They employ a sophisticated online analysis system that continuously monitors key quality indicators throughout the production process, allowing for real-time adjustments[7]. Furthermore, Sinopec has implemented a comprehensive traceability system that tracks raw materials, process parameters, and quality data for each batch, enabling rapid identification and resolution of any quality issues[8].

Strengths: Advanced reactor technology, proprietary catalysts, and comprehensive traceability system. Weaknesses: May face challenges in adapting the system to different grades of PMMA or scaling up production.

Innovative QC Technologies

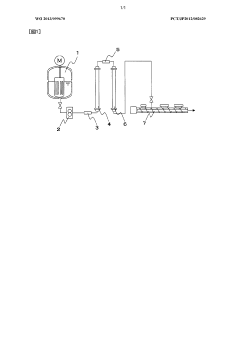

Method for manufacturing methacrylic polymer

PatentWO2013099670A1

Innovation

- A method involving continuous bulk polymerization using a complete mixing reactor and plug flow reactor, with specific conditions for adding radical polymerization initiators and controlling temperatures and half-lives to stabilize the polymerization process, ensuring high productivity and thermal decomposition resistance.

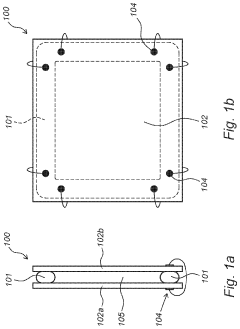

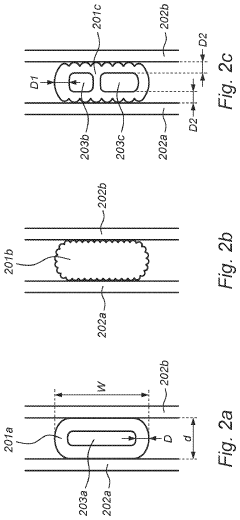

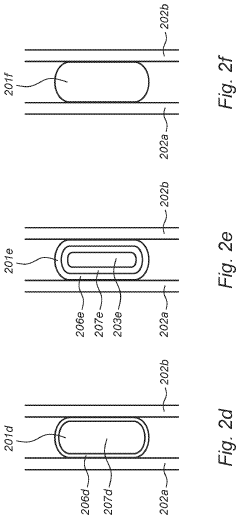

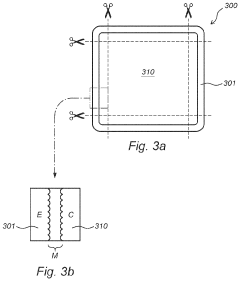

Method and Gasket for Producing a Polymethyl Methacrylate Plate

PatentPendingUS20240001594A1

Innovation

- A method utilizing a gasket made of hydrocarbon-based copolymers, which allows for easier separation and recycling of PMMA sheets by dissolving partially in the MMA liquid, enhancing the mechanical properties and enabling improved sealing during the polymerization process.

Regulatory Standards for PMMA

Regulatory standards play a crucial role in ensuring the quality and safety of PMMA production. In the United States, the Food and Drug Administration (FDA) oversees the regulation of PMMA used in medical applications, while the Environmental Protection Agency (EPA) regulates its production and use in other industries. The FDA has established specific guidelines for PMMA-based medical devices, including implants and intraocular lenses, under the 21 CFR Part 820 Quality System Regulation.

In the European Union, PMMA production must comply with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework aims to protect human health and the environment from the risks posed by chemicals. Manufacturers and importers of PMMA are required to register their substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, uses, and potential risks.

The International Organization for Standardization (ISO) has developed several standards relevant to PMMA production and quality control. ISO 13485 specifies requirements for a quality management system in medical device manufacturing, including PMMA-based products. ISO 14001 provides a framework for environmental management systems, which is particularly important for PMMA production due to its potential environmental impact.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates PMMA used in medical applications through the Pharmaceutical and Medical Device Act. This act sets forth requirements for manufacturing, quality control, and post-market surveillance of medical devices, including those made from PMMA.

China's National Medical Products Administration (NMPA) oversees the regulation of PMMA-based medical devices, while the Ministry of Ecology and Environment regulates its production and use in other industries. The NMPA has established specific guidelines for the registration and approval of medical devices, including those made from PMMA.

To achieve repeatable quality control in PMMA production, manufacturers must adhere to these regulatory standards and implement robust quality management systems. This includes establishing documented procedures for all aspects of production, from raw material sourcing to final product testing. Regular audits and inspections by regulatory bodies ensure ongoing compliance with these standards.

Furthermore, industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM), provide detailed specifications for PMMA properties and testing methods. Adherence to these standards helps ensure consistency and quality across different batches of PMMA production.

In the European Union, PMMA production must comply with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework aims to protect human health and the environment from the risks posed by chemicals. Manufacturers and importers of PMMA are required to register their substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, uses, and potential risks.

The International Organization for Standardization (ISO) has developed several standards relevant to PMMA production and quality control. ISO 13485 specifies requirements for a quality management system in medical device manufacturing, including PMMA-based products. ISO 14001 provides a framework for environmental management systems, which is particularly important for PMMA production due to its potential environmental impact.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates PMMA used in medical applications through the Pharmaceutical and Medical Device Act. This act sets forth requirements for manufacturing, quality control, and post-market surveillance of medical devices, including those made from PMMA.

China's National Medical Products Administration (NMPA) oversees the regulation of PMMA-based medical devices, while the Ministry of Ecology and Environment regulates its production and use in other industries. The NMPA has established specific guidelines for the registration and approval of medical devices, including those made from PMMA.

To achieve repeatable quality control in PMMA production, manufacturers must adhere to these regulatory standards and implement robust quality management systems. This includes establishing documented procedures for all aspects of production, from raw material sourcing to final product testing. Regular audits and inspections by regulatory bodies ensure ongoing compliance with these standards.

Furthermore, industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM), provide detailed specifications for PMMA properties and testing methods. Adherence to these standards helps ensure consistency and quality across different batches of PMMA production.

Environmental Impact of PMMA QC

The environmental impact of quality control processes in PMMA production is a critical consideration for manufacturers and regulatory bodies alike. The production of Poly(methyl methacrylate) (PMMA) involves several stages, each with potential environmental implications. Quality control measures, while essential for ensuring product consistency and reliability, can contribute to these impacts if not managed properly.

One of the primary environmental concerns in PMMA quality control is the use of solvents and chemicals for testing and analysis. These substances, often volatile organic compounds (VOCs), can contribute to air pollution if not properly contained and disposed of. Manufacturers are increasingly adopting closed-loop systems and solvent recovery technologies to minimize emissions and reduce waste generation. Additionally, the implementation of non-destructive testing methods, such as spectroscopic techniques, can significantly reduce the need for chemical-based quality control processes.

Energy consumption is another significant factor in the environmental footprint of PMMA quality control. The operation of testing equipment, environmental chambers for accelerated aging tests, and other quality control machinery requires substantial power. To mitigate this impact, many facilities are investing in energy-efficient equipment and exploring renewable energy sources to power their quality control operations. Some manufacturers are also implementing smart energy management systems to optimize power usage during off-peak hours and reduce overall energy consumption.

Water usage and wastewater management are crucial aspects of PMMA quality control's environmental impact. Certain quality control processes, such as washing and rinsing of test samples, can consume significant amounts of water and generate contaminated wastewater. Advanced water treatment systems and water recycling technologies are being employed to minimize freshwater consumption and ensure that discharged water meets or exceeds environmental standards.

The disposal of waste materials generated during quality control processes presents another environmental challenge. This includes rejected PMMA samples, used test materials, and packaging waste. Implementing comprehensive recycling programs for PMMA scrap and other recyclable materials can significantly reduce the volume of waste sent to landfills. Some manufacturers are exploring innovative ways to repurpose quality control waste, such as using rejected PMMA samples as raw material for lower-grade products or as fuel in energy recovery systems.

As environmental regulations become more stringent, PMMA manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate and improve the environmental performance of their quality control processes. This holistic view allows companies to identify hotspots in their operations and implement targeted improvements. Furthermore, the integration of environmental management systems (EMS) into quality control procedures ensures that environmental considerations are systematically addressed throughout the production and testing processes.

One of the primary environmental concerns in PMMA quality control is the use of solvents and chemicals for testing and analysis. These substances, often volatile organic compounds (VOCs), can contribute to air pollution if not properly contained and disposed of. Manufacturers are increasingly adopting closed-loop systems and solvent recovery technologies to minimize emissions and reduce waste generation. Additionally, the implementation of non-destructive testing methods, such as spectroscopic techniques, can significantly reduce the need for chemical-based quality control processes.

Energy consumption is another significant factor in the environmental footprint of PMMA quality control. The operation of testing equipment, environmental chambers for accelerated aging tests, and other quality control machinery requires substantial power. To mitigate this impact, many facilities are investing in energy-efficient equipment and exploring renewable energy sources to power their quality control operations. Some manufacturers are also implementing smart energy management systems to optimize power usage during off-peak hours and reduce overall energy consumption.

Water usage and wastewater management are crucial aspects of PMMA quality control's environmental impact. Certain quality control processes, such as washing and rinsing of test samples, can consume significant amounts of water and generate contaminated wastewater. Advanced water treatment systems and water recycling technologies are being employed to minimize freshwater consumption and ensure that discharged water meets or exceeds environmental standards.

The disposal of waste materials generated during quality control processes presents another environmental challenge. This includes rejected PMMA samples, used test materials, and packaging waste. Implementing comprehensive recycling programs for PMMA scrap and other recyclable materials can significantly reduce the volume of waste sent to landfills. Some manufacturers are exploring innovative ways to repurpose quality control waste, such as using rejected PMMA samples as raw material for lower-grade products or as fuel in energy recovery systems.

As environmental regulations become more stringent, PMMA manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate and improve the environmental performance of their quality control processes. This holistic view allows companies to identify hotspots in their operations and implement targeted improvements. Furthermore, the integration of environmental management systems (EMS) into quality control procedures ensures that environmental considerations are systematically addressed throughout the production and testing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!