PMMA Innovations in Smart Window Technologies

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Smart Window Evolution and Objectives

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has been a staple in the construction and automotive industries for decades. However, its application in smart window technologies represents a significant evolution in its utility and potential. The journey of PMMA in smart windows began in the late 20th century when researchers started exploring its optical and thermal properties for energy-efficient building designs.

The primary objective of incorporating PMMA into smart window technologies is to enhance energy efficiency, improve occupant comfort, and reduce the environmental impact of buildings. PMMA's unique properties, including high transparency, low weight, and excellent weatherability, make it an ideal candidate for smart window applications. As the technology has progressed, the goals have expanded to include dynamic control of light transmission, heat regulation, and even energy generation.

In the early stages of development, PMMA was primarily used as a lightweight, shatter-resistant alternative to glass in traditional windows. The evolution towards smart window applications began with the integration of PMMA with other materials and technologies. For instance, the combination of PMMA with electrochromic materials allowed for the creation of windows that could change their opacity in response to electrical stimuli, offering a new level of control over light and heat transmission.

Another significant milestone in the evolution of PMMA smart windows was the development of thermochromic PMMA composites. These materials can change their optical properties in response to temperature fluctuations, providing passive climate control for buildings. This innovation aligned perfectly with the growing emphasis on sustainable architecture and energy-efficient building designs.

The objectives of PMMA innovations in smart window technologies have become increasingly ambitious over time. Current research focuses on developing multi-functional PMMA-based smart windows that can simultaneously regulate light, heat, and even generate electricity. For example, the integration of PMMA with quantum dots or luminescent solar concentrators aims to create windows that can harvest solar energy while maintaining transparency.

Looking ahead, the objectives for PMMA in smart window technologies include enhancing its durability, improving its compatibility with other smart materials, and increasing its overall performance in terms of energy efficiency and user comfort. Researchers are also exploring ways to make PMMA-based smart windows more cost-effective and easier to manufacture at scale, which is crucial for widespread adoption in both new construction and retrofitting applications.

In conclusion, the evolution of PMMA in smart window technologies represents a convergence of material science, energy efficiency, and architectural innovation. The ongoing research and development in this field aim to transform windows from passive building elements into active, intelligent components of sustainable and comfortable living spaces.

The primary objective of incorporating PMMA into smart window technologies is to enhance energy efficiency, improve occupant comfort, and reduce the environmental impact of buildings. PMMA's unique properties, including high transparency, low weight, and excellent weatherability, make it an ideal candidate for smart window applications. As the technology has progressed, the goals have expanded to include dynamic control of light transmission, heat regulation, and even energy generation.

In the early stages of development, PMMA was primarily used as a lightweight, shatter-resistant alternative to glass in traditional windows. The evolution towards smart window applications began with the integration of PMMA with other materials and technologies. For instance, the combination of PMMA with electrochromic materials allowed for the creation of windows that could change their opacity in response to electrical stimuli, offering a new level of control over light and heat transmission.

Another significant milestone in the evolution of PMMA smart windows was the development of thermochromic PMMA composites. These materials can change their optical properties in response to temperature fluctuations, providing passive climate control for buildings. This innovation aligned perfectly with the growing emphasis on sustainable architecture and energy-efficient building designs.

The objectives of PMMA innovations in smart window technologies have become increasingly ambitious over time. Current research focuses on developing multi-functional PMMA-based smart windows that can simultaneously regulate light, heat, and even generate electricity. For example, the integration of PMMA with quantum dots or luminescent solar concentrators aims to create windows that can harvest solar energy while maintaining transparency.

Looking ahead, the objectives for PMMA in smart window technologies include enhancing its durability, improving its compatibility with other smart materials, and increasing its overall performance in terms of energy efficiency and user comfort. Researchers are also exploring ways to make PMMA-based smart windows more cost-effective and easier to manufacture at scale, which is crucial for widespread adoption in both new construction and retrofitting applications.

In conclusion, the evolution of PMMA in smart window technologies represents a convergence of material science, energy efficiency, and architectural innovation. The ongoing research and development in this field aim to transform windows from passive building elements into active, intelligent components of sustainable and comfortable living spaces.

Smart Window Market Analysis

The smart window market has been experiencing significant growth in recent years, driven by increasing demand for energy-efficient building solutions and advancements in materials technology. The global smart window market size was valued at approximately $4.5 billion in 2020 and is projected to reach $8.9 billion by 2026, growing at a CAGR of 12.1% during the forecast period.

The market is primarily segmented into residential, commercial, and industrial applications. The commercial sector, including office buildings, hotels, and retail spaces, currently dominates the market share due to the higher adoption rate of smart window technologies in these environments. However, the residential segment is expected to witness the fastest growth in the coming years as homeowners become more aware of the energy-saving benefits and improved comfort offered by smart windows.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to stringent energy efficiency regulations and the presence of major smart window manufacturers. The Asia-Pacific region is anticipated to exhibit the highest growth rate, driven by rapid urbanization, increasing construction activities, and growing awareness of green building technologies in countries like China and India.

Key players in the smart window market include View Inc., Saint-Gobain, Gentex Corporation, and Sage Electrochromics (acquired by Saint-Gobain). These companies are investing heavily in research and development to improve the performance and reduce the cost of smart window technologies. Mergers, acquisitions, and strategic partnerships are common strategies employed by market leaders to strengthen their market position and expand their product portfolios.

The market is witnessing several trends that are shaping its growth trajectory. The integration of Internet of Things (IoT) technology with smart windows is enabling advanced control and automation features, enhancing user experience and energy management capabilities. Additionally, there is a growing focus on developing self-powered smart windows that can generate electricity, further improving their energy efficiency proposition.

Challenges facing the smart window market include high initial costs, which can be a barrier to adoption, especially in price-sensitive markets. The complexity of installation and maintenance of smart windows compared to traditional windows also poses challenges. However, ongoing technological advancements and economies of scale are expected to gradually address these issues, making smart windows more accessible to a broader range of consumers and applications.

The market is primarily segmented into residential, commercial, and industrial applications. The commercial sector, including office buildings, hotels, and retail spaces, currently dominates the market share due to the higher adoption rate of smart window technologies in these environments. However, the residential segment is expected to witness the fastest growth in the coming years as homeowners become more aware of the energy-saving benefits and improved comfort offered by smart windows.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to stringent energy efficiency regulations and the presence of major smart window manufacturers. The Asia-Pacific region is anticipated to exhibit the highest growth rate, driven by rapid urbanization, increasing construction activities, and growing awareness of green building technologies in countries like China and India.

Key players in the smart window market include View Inc., Saint-Gobain, Gentex Corporation, and Sage Electrochromics (acquired by Saint-Gobain). These companies are investing heavily in research and development to improve the performance and reduce the cost of smart window technologies. Mergers, acquisitions, and strategic partnerships are common strategies employed by market leaders to strengthen their market position and expand their product portfolios.

The market is witnessing several trends that are shaping its growth trajectory. The integration of Internet of Things (IoT) technology with smart windows is enabling advanced control and automation features, enhancing user experience and energy management capabilities. Additionally, there is a growing focus on developing self-powered smart windows that can generate electricity, further improving their energy efficiency proposition.

Challenges facing the smart window market include high initial costs, which can be a barrier to adoption, especially in price-sensitive markets. The complexity of installation and maintenance of smart windows compared to traditional windows also poses challenges. However, ongoing technological advancements and economies of scale are expected to gradually address these issues, making smart windows more accessible to a broader range of consumers and applications.

PMMA Challenges in Smart Windows

PMMA, or polymethyl methacrylate, has been widely used in smart window technologies due to its excellent optical properties and durability. However, its application in this field faces several significant challenges that need to be addressed for further advancement.

One of the primary challenges is the thermal stability of PMMA in smart window applications. While PMMA exhibits good transparency and weather resistance, it has a relatively low glass transition temperature compared to other materials used in smart windows. This can lead to deformation or degradation of the PMMA layer under prolonged exposure to high temperatures, potentially compromising the overall performance and longevity of the smart window system.

Another critical issue is the limited switching speed of PMMA-based smart windows. The response time for changing from transparent to opaque states, or vice versa, is often slower than desired for practical applications. This limitation can affect the user experience and energy efficiency of buildings equipped with such windows, as rapid adaptation to changing light conditions is crucial for optimal performance.

The integration of PMMA with other functional materials in smart window systems also presents challenges. Achieving seamless compatibility between PMMA and electrochromic materials, for instance, can be complex due to differences in chemical properties and adhesion characteristics. This can result in issues such as delamination or reduced durability of the multi-layer smart window structure over time.

Furthermore, the environmental impact of PMMA production and disposal remains a concern. While PMMA is recyclable, the process is not as straightforward as for some other materials used in smart windows. Developing more sustainable production methods and improving the recyclability of PMMA-based smart window components is crucial for meeting increasingly stringent environmental regulations and consumer demands for eco-friendly products.

The cost-effectiveness of PMMA in smart window applications is another challenge to be addressed. While PMMA offers several advantages, the overall cost of PMMA-based smart windows, including materials, manufacturing, and installation, needs to be competitive with alternative technologies to ensure widespread adoption in both residential and commercial markets.

Lastly, enhancing the durability and scratch resistance of PMMA surfaces in smart windows is an ongoing challenge. Although PMMA is known for its clarity and impact resistance, it is softer than glass and more prone to scratching. Improving the hardness and scratch resistance of PMMA layers without compromising their optical properties is essential for ensuring the long-term performance and aesthetics of smart windows in real-world applications.

One of the primary challenges is the thermal stability of PMMA in smart window applications. While PMMA exhibits good transparency and weather resistance, it has a relatively low glass transition temperature compared to other materials used in smart windows. This can lead to deformation or degradation of the PMMA layer under prolonged exposure to high temperatures, potentially compromising the overall performance and longevity of the smart window system.

Another critical issue is the limited switching speed of PMMA-based smart windows. The response time for changing from transparent to opaque states, or vice versa, is often slower than desired for practical applications. This limitation can affect the user experience and energy efficiency of buildings equipped with such windows, as rapid adaptation to changing light conditions is crucial for optimal performance.

The integration of PMMA with other functional materials in smart window systems also presents challenges. Achieving seamless compatibility between PMMA and electrochromic materials, for instance, can be complex due to differences in chemical properties and adhesion characteristics. This can result in issues such as delamination or reduced durability of the multi-layer smart window structure over time.

Furthermore, the environmental impact of PMMA production and disposal remains a concern. While PMMA is recyclable, the process is not as straightforward as for some other materials used in smart windows. Developing more sustainable production methods and improving the recyclability of PMMA-based smart window components is crucial for meeting increasingly stringent environmental regulations and consumer demands for eco-friendly products.

The cost-effectiveness of PMMA in smart window applications is another challenge to be addressed. While PMMA offers several advantages, the overall cost of PMMA-based smart windows, including materials, manufacturing, and installation, needs to be competitive with alternative technologies to ensure widespread adoption in both residential and commercial markets.

Lastly, enhancing the durability and scratch resistance of PMMA surfaces in smart windows is an ongoing challenge. Although PMMA is known for its clarity and impact resistance, it is softer than glass and more prone to scratching. Improving the hardness and scratch resistance of PMMA layers without compromising their optical properties is essential for ensuring the long-term performance and aesthetics of smart windows in real-world applications.

Current PMMA Smart Window Solutions

01 PMMA-based smart window compositions

Smart window technologies incorporating PMMA as a key component in the composition. These formulations may include various additives, such as electrochromic materials or liquid crystals, to achieve the desired optical switching properties. The PMMA serves as a transparent matrix or substrate for the active components.- PMMA-based smart window compositions: Smart window technologies incorporating PMMA as a key component in the composition. These formulations may include various additives, polymers, or nanoparticles to enhance the optical and switching properties of the smart windows.

- Electrochromic PMMA smart windows: Development of electrochromic smart windows using PMMA as a matrix or substrate. These windows can change their optical properties in response to an applied electric field, allowing for controllable light transmission and energy efficiency.

- Thermochromic PMMA smart windows: Smart window technologies that utilize PMMA in combination with thermochromic materials. These windows can change their transparency or color in response to temperature changes, providing automatic shading and energy-saving benefits.

- PMMA-based smart window films and coatings: Development of thin films or coatings incorporating PMMA for smart window applications. These films can be applied to existing windows to provide smart functionalities such as switchable transparency, UV protection, or energy efficiency.

- PMMA smart windows with integrated sensors and controls: Smart window systems that combine PMMA-based materials with sensors, actuators, and control systems. These integrated systems can automatically adjust the window's properties based on environmental conditions or user preferences, enhancing energy efficiency and comfort.

02 Fabrication methods for PMMA smart windows

Techniques for manufacturing smart windows using PMMA, including processes such as solution casting, extrusion, or in-situ polymerization. These methods focus on achieving uniform thickness, optical clarity, and integration of smart materials within the PMMA matrix.Expand Specific Solutions03 PMMA-based smart window coatings

Development of coatings or films using PMMA for smart window applications. These coatings may be applied to existing glass surfaces or used as standalone films. The coatings incorporate active materials that respond to external stimuli to change optical properties.Expand Specific Solutions04 Integration of PMMA smart windows with energy systems

Approaches to combine PMMA-based smart window technologies with energy harvesting or management systems. This may include integration with photovoltaic cells, thermal management systems, or building automation to enhance energy efficiency and user comfort.Expand Specific Solutions05 Control systems for PMMA smart windows

Development of control mechanisms and systems for PMMA-based smart windows. This includes sensors, actuators, and software algorithms to manage the optical switching of the windows in response to environmental conditions or user preferences.Expand Specific Solutions

Smart Window Industry Leaders

The PMMA innovations in smart window technologies market is in a growth phase, with increasing demand driven by energy efficiency and sustainability trends. The market size is expanding, projected to reach several billion dollars by 2030. Technological maturity varies, with established players like DuPont and LG Chem leading in advanced PMMA formulations, while newer entrants like Nitto Denko and Röhm are developing novel applications. Companies such as Pilkington and SABIC are integrating PMMA into smart glass systems, while research institutions like Fuzhou University and Sichuan University are pushing boundaries in material science. The competitive landscape is diverse, with collaborations between industry and academia driving innovation in this rapidly evolving field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has made significant strides in PMMA innovations for smart window technologies. Their approach focuses on developing multi-layered PMMA films with embedded electrochromic materials. These films can change opacity when an electric current is applied, allowing for dynamic control of light transmission and heat gain[2]. DuPont's smart PMMA technology incorporates conductive nanoparticles that enable uniform electrical distribution across the window surface, resulting in faster and more even tinting[4]. The company has also developed a proprietary coating process that enhances the durability and longevity of their smart PMMA windows, addressing concerns about long-term performance in varying environmental conditions[6].

Strengths: Advanced electrochromic technology, improved durability, and seamless integration with existing window systems. Weaknesses: Higher production costs, complexity in manufacturing process, and potential issues with electrical components over time.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel PMMA-based smart window solution that combines the benefits of PMMA with advanced polymer-dispersed liquid crystal (PDLC) technology. Their approach involves sandwiching a PDLC layer between two PMMA sheets, creating a switchable privacy glass that can transition from transparent to opaque with the application of an electric field[7]. LG Chem's smart PMMA windows offer rapid switching times, typically less than 100 milliseconds, and can achieve up to 90% light transmittance in the transparent state[8]. The company has also incorporated UV-blocking additives into their PMMA formulation to enhance the longevity of the PDLC layer and improve overall energy efficiency[9].

Strengths: Fast switching times, high transparency in clear state, and enhanced UV protection. Weaknesses: Relatively high power consumption when in opaque state, potential for haze in transparent mode, and higher cost compared to traditional glazing solutions.

Key PMMA Innovations for Smart Windows

Flame retardant and uv absorptive polymethylmethacrylate nanocomposites

PatentInactiveUS20050261413A1

Innovation

- A nanocomposite composition is developed by combining polymethylmethacrylate with functionalized montmorillonite clay, using an intercalation agent as a reaction product of a polyamine and an alkyl halide in a polar solvent, which improves thermal stability and flame retardancy, and is processed into transparent sheets using molding, casting, or extrusion.

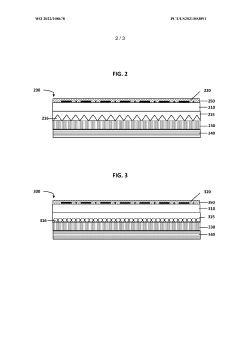

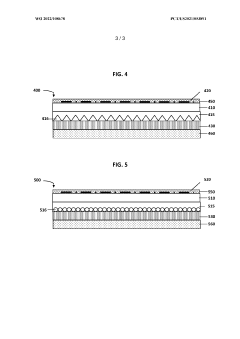

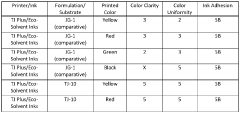

Printable films

PatentWO2022108678A1

Innovation

- A composition comprising PMMA and an acrylic copolymer with hard and soft segments, where the soft segments have a glass transition temperature less than 50°C, is used to enhance the print quality by improving ink adhesion and clarity, including the use of a pressure-sensitive adhesive and retroreflective elements in multilayer systems.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the development and adoption of smart window technologies, including those utilizing PMMA innovations. These regulations are designed to reduce energy consumption in buildings, which account for a significant portion of global energy use and greenhouse gas emissions.

In the United States, the Department of Energy (DOE) has established energy efficiency standards for windows and other building components. These standards are periodically updated to reflect advancements in technology and to drive further improvements in energy performance. For smart windows incorporating PMMA innovations, manufacturers must ensure compliance with these standards, which typically focus on metrics such as U-factor, Solar Heat Gain Coefficient (SHGC), and visible transmittance.

The European Union has implemented the Energy Performance of Buildings Directive (EPBD), which sets minimum energy performance requirements for new and existing buildings. This directive has led to the development of national building codes that often include specific requirements for windows and glazing systems. Smart windows utilizing PMMA technologies must meet or exceed these requirements to be eligible for use in construction projects across EU member states.

In Asia, countries like Japan and South Korea have also implemented stringent energy efficiency regulations for buildings. These regulations often include specific provisions for windows and glazing systems, driving the adoption of advanced technologies like smart windows with PMMA innovations.

The impact of these regulations on the smart window market has been significant. They have spurred innovation in PMMA-based technologies, encouraging manufacturers to develop products that not only meet but exceed regulatory requirements. This has led to the creation of smart windows with improved thermal insulation properties, better control over solar heat gain, and enhanced overall energy performance.

Furthermore, energy efficiency regulations have influenced the design and functionality of smart window control systems. Many jurisdictions now require automated shading or tinting mechanisms to optimize energy performance throughout the day. This has driven the development of sophisticated control algorithms and integration with building management systems, further enhancing the energy-saving potential of PMMA-based smart windows.

As regulations continue to evolve and become more stringent, the smart window industry is likely to see increased investment in research and development. This may lead to new PMMA formulations with enhanced optical and thermal properties, as well as improved manufacturing processes to reduce costs and increase market penetration.

In the United States, the Department of Energy (DOE) has established energy efficiency standards for windows and other building components. These standards are periodically updated to reflect advancements in technology and to drive further improvements in energy performance. For smart windows incorporating PMMA innovations, manufacturers must ensure compliance with these standards, which typically focus on metrics such as U-factor, Solar Heat Gain Coefficient (SHGC), and visible transmittance.

The European Union has implemented the Energy Performance of Buildings Directive (EPBD), which sets minimum energy performance requirements for new and existing buildings. This directive has led to the development of national building codes that often include specific requirements for windows and glazing systems. Smart windows utilizing PMMA technologies must meet or exceed these requirements to be eligible for use in construction projects across EU member states.

In Asia, countries like Japan and South Korea have also implemented stringent energy efficiency regulations for buildings. These regulations often include specific provisions for windows and glazing systems, driving the adoption of advanced technologies like smart windows with PMMA innovations.

The impact of these regulations on the smart window market has been significant. They have spurred innovation in PMMA-based technologies, encouraging manufacturers to develop products that not only meet but exceed regulatory requirements. This has led to the creation of smart windows with improved thermal insulation properties, better control over solar heat gain, and enhanced overall energy performance.

Furthermore, energy efficiency regulations have influenced the design and functionality of smart window control systems. Many jurisdictions now require automated shading or tinting mechanisms to optimize energy performance throughout the day. This has driven the development of sophisticated control algorithms and integration with building management systems, further enhancing the energy-saving potential of PMMA-based smart windows.

As regulations continue to evolve and become more stringent, the smart window industry is likely to see increased investment in research and development. This may lead to new PMMA formulations with enhanced optical and thermal properties, as well as improved manufacturing processes to reduce costs and increase market penetration.

PMMA Recycling and Sustainability

PMMA recycling and sustainability have become increasingly important in the context of smart window technologies. As the demand for smart windows grows, so does the need for sustainable practices in the production and disposal of PMMA-based components. The recycling of PMMA offers significant environmental benefits, including reduced energy consumption and greenhouse gas emissions compared to the production of virgin PMMA.

One of the primary methods for recycling PMMA is mechanical recycling, which involves grinding used PMMA into small particles and reprocessing them into new products. This method is particularly effective for PMMA used in smart windows, as the material often remains in large, easily recoverable pieces. However, the challenge lies in maintaining the optical and mechanical properties of recycled PMMA, which are crucial for smart window applications.

Chemical recycling presents another promising avenue for PMMA sustainability. This process breaks down PMMA into its monomer components, which can then be repolymerized to create new PMMA with properties similar to virgin material. While more energy-intensive than mechanical recycling, chemical recycling offers the advantage of producing higher-quality recycled PMMA, potentially suitable for use in smart windows.

The integration of recycled PMMA into smart window production faces several challenges. These include ensuring consistent quality, meeting stringent optical requirements, and addressing potential discoloration or degradation over time. Innovations in recycling technologies, such as advanced sorting and purification methods, are helping to overcome these obstacles.

Sustainability efforts in PMMA smart windows extend beyond recycling. Manufacturers are exploring bio-based alternatives to traditional petroleum-derived PMMA, aiming to reduce the carbon footprint of smart window production. Additionally, efforts to improve the durability and lifespan of PMMA-based smart windows contribute to sustainability by reducing the frequency of replacement and disposal.

The development of closed-loop systems for PMMA in smart windows is gaining traction. These systems aim to recover and recycle PMMA from end-of-life smart windows, reintegrating the material into new production cycles. Such approaches not only reduce waste but also create a more sustainable supply chain for PMMA in the smart window industry.

As regulations around plastic waste and circular economy principles become more stringent, the importance of PMMA recycling and sustainability in smart window technologies is likely to increase. This trend is driving research into more efficient recycling processes, improved material recovery techniques, and the development of smart windows designed with end-of-life considerations in mind.

One of the primary methods for recycling PMMA is mechanical recycling, which involves grinding used PMMA into small particles and reprocessing them into new products. This method is particularly effective for PMMA used in smart windows, as the material often remains in large, easily recoverable pieces. However, the challenge lies in maintaining the optical and mechanical properties of recycled PMMA, which are crucial for smart window applications.

Chemical recycling presents another promising avenue for PMMA sustainability. This process breaks down PMMA into its monomer components, which can then be repolymerized to create new PMMA with properties similar to virgin material. While more energy-intensive than mechanical recycling, chemical recycling offers the advantage of producing higher-quality recycled PMMA, potentially suitable for use in smart windows.

The integration of recycled PMMA into smart window production faces several challenges. These include ensuring consistent quality, meeting stringent optical requirements, and addressing potential discoloration or degradation over time. Innovations in recycling technologies, such as advanced sorting and purification methods, are helping to overcome these obstacles.

Sustainability efforts in PMMA smart windows extend beyond recycling. Manufacturers are exploring bio-based alternatives to traditional petroleum-derived PMMA, aiming to reduce the carbon footprint of smart window production. Additionally, efforts to improve the durability and lifespan of PMMA-based smart windows contribute to sustainability by reducing the frequency of replacement and disposal.

The development of closed-loop systems for PMMA in smart windows is gaining traction. These systems aim to recover and recycle PMMA from end-of-life smart windows, reintegrating the material into new production cycles. Such approaches not only reduce waste but also create a more sustainable supply chain for PMMA in the smart window industry.

As regulations around plastic waste and circular economy principles become more stringent, the importance of PMMA recycling and sustainability in smart window technologies is likely to increase. This trend is driving research into more efficient recycling processes, improved material recovery techniques, and the development of smart windows designed with end-of-life considerations in mind.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!