Advances in PMMA Nanotechnology Applications

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Nanotech Evolution

The evolution of PMMA nanotechnology applications has been marked by significant advancements and breakthroughs over the past few decades. Initially, PMMA was primarily used in its bulk form for various applications such as optical devices and biomedical implants. However, the advent of nanotechnology opened up new avenues for exploiting PMMA's unique properties at the nanoscale.

In the early 2000s, researchers began exploring PMMA nanoparticles and nanofibers for drug delivery systems. The ability to control the size and surface properties of PMMA nanostructures allowed for enhanced drug encapsulation and targeted release. This led to the development of more efficient and less invasive therapeutic approaches, particularly in cancer treatment.

The mid-2000s saw a surge in PMMA nanocomposites research. By incorporating nanofillers such as carbon nanotubes, graphene, and metal nanoparticles into PMMA matrices, scientists were able to create materials with enhanced mechanical, thermal, and electrical properties. These nanocomposites found applications in aerospace, automotive, and electronics industries.

Around 2010, PMMA-based nanolithography techniques gained prominence. The high resolution and precision offered by PMMA as a resist material in electron beam lithography enabled the fabrication of complex nanostructures for semiconductor devices and photonic applications. This advancement significantly contributed to the miniaturization of electronic components.

The past decade has witnessed the integration of PMMA nanotechnology with other emerging fields. For instance, the combination of PMMA nanostructures with stimuli-responsive polymers has led to the development of smart materials for sensing and actuation. Additionally, PMMA nanofibers have been explored for tissue engineering scaffolds, offering improved cell adhesion and proliferation.

Recent years have seen a focus on sustainable and eco-friendly PMMA nanotech applications. Researchers are investigating biodegradable PMMA nanocomposites and exploring ways to recycle and upcycle PMMA nanoparticles. This trend aligns with the growing emphasis on circular economy principles in materials science.

Looking ahead, the evolution of PMMA nanotechnology is expected to continue its rapid pace. Emerging areas such as 3D printing of PMMA nanocomposites, PMMA-based quantum dot technologies, and PMMA nanostructures for energy storage devices are likely to drive future innovations. As our understanding of nanoscale phenomena deepens and fabrication techniques improve, we can anticipate even more sophisticated and multifunctional PMMA-based nanotechnologies in the coming years.

In the early 2000s, researchers began exploring PMMA nanoparticles and nanofibers for drug delivery systems. The ability to control the size and surface properties of PMMA nanostructures allowed for enhanced drug encapsulation and targeted release. This led to the development of more efficient and less invasive therapeutic approaches, particularly in cancer treatment.

The mid-2000s saw a surge in PMMA nanocomposites research. By incorporating nanofillers such as carbon nanotubes, graphene, and metal nanoparticles into PMMA matrices, scientists were able to create materials with enhanced mechanical, thermal, and electrical properties. These nanocomposites found applications in aerospace, automotive, and electronics industries.

Around 2010, PMMA-based nanolithography techniques gained prominence. The high resolution and precision offered by PMMA as a resist material in electron beam lithography enabled the fabrication of complex nanostructures for semiconductor devices and photonic applications. This advancement significantly contributed to the miniaturization of electronic components.

The past decade has witnessed the integration of PMMA nanotechnology with other emerging fields. For instance, the combination of PMMA nanostructures with stimuli-responsive polymers has led to the development of smart materials for sensing and actuation. Additionally, PMMA nanofibers have been explored for tissue engineering scaffolds, offering improved cell adhesion and proliferation.

Recent years have seen a focus on sustainable and eco-friendly PMMA nanotech applications. Researchers are investigating biodegradable PMMA nanocomposites and exploring ways to recycle and upcycle PMMA nanoparticles. This trend aligns with the growing emphasis on circular economy principles in materials science.

Looking ahead, the evolution of PMMA nanotechnology is expected to continue its rapid pace. Emerging areas such as 3D printing of PMMA nanocomposites, PMMA-based quantum dot technologies, and PMMA nanostructures for energy storage devices are likely to drive future innovations. As our understanding of nanoscale phenomena deepens and fabrication techniques improve, we can anticipate even more sophisticated and multifunctional PMMA-based nanotechnologies in the coming years.

Market Demand Analysis

The market demand for PMMA nanotechnology applications has been experiencing significant growth in recent years, driven by the material's unique properties and versatility across various industries. PMMA, or polymethyl methacrylate, is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. When combined with nanotechnology, PMMA's properties can be enhanced or modified to meet specific industry needs, opening up new market opportunities.

In the healthcare sector, PMMA nanocomposites are gaining traction for their potential in drug delivery systems, tissue engineering, and medical implants. The ability to control drug release rates and improve biocompatibility has led to increased demand in pharmaceutical and medical device industries. Additionally, PMMA nanocomposites show promise in developing advanced wound dressings and antimicrobial coatings, addressing the growing need for innovative healthcare solutions.

The electronics industry is another key driver of market demand for PMMA nanotechnology applications. With the trend towards miniaturization and improved performance of electronic devices, PMMA nanocomposites are being explored for use in flexible displays, organic light-emitting diodes (OLEDs), and advanced optical components. The material's transparency, coupled with enhanced electrical and thermal properties through nanotechnology, makes it attractive for next-generation electronic products.

In the automotive and aerospace sectors, lightweight materials with improved mechanical properties are in high demand. PMMA nanocomposites offer potential solutions for reducing vehicle weight while maintaining strength and durability. This aligns with the industry's push for fuel efficiency and reduced emissions, driving research and development in this area.

The construction industry is also showing interest in PMMA nanotechnology applications, particularly for smart windows and energy-efficient building materials. The ability to incorporate nanoparticles that respond to environmental changes, such as temperature or light, opens up possibilities for adaptive and energy-saving building components.

Environmental concerns and sustainability initiatives are further fueling market demand for PMMA nanotechnology applications. Research is ongoing to develop biodegradable PMMA nanocomposites and improve recycling processes, addressing the growing consumer and regulatory pressure for more environmentally friendly materials.

As the global nanotechnology market continues to expand, the demand for advanced PMMA applications is expected to grow alongside it. Market analysts project steady growth in the coming years, with particular emphasis on healthcare, electronics, and automotive applications. However, challenges such as high production costs and regulatory hurdles may impact market penetration rates in certain sectors.

In the healthcare sector, PMMA nanocomposites are gaining traction for their potential in drug delivery systems, tissue engineering, and medical implants. The ability to control drug release rates and improve biocompatibility has led to increased demand in pharmaceutical and medical device industries. Additionally, PMMA nanocomposites show promise in developing advanced wound dressings and antimicrobial coatings, addressing the growing need for innovative healthcare solutions.

The electronics industry is another key driver of market demand for PMMA nanotechnology applications. With the trend towards miniaturization and improved performance of electronic devices, PMMA nanocomposites are being explored for use in flexible displays, organic light-emitting diodes (OLEDs), and advanced optical components. The material's transparency, coupled with enhanced electrical and thermal properties through nanotechnology, makes it attractive for next-generation electronic products.

In the automotive and aerospace sectors, lightweight materials with improved mechanical properties are in high demand. PMMA nanocomposites offer potential solutions for reducing vehicle weight while maintaining strength and durability. This aligns with the industry's push for fuel efficiency and reduced emissions, driving research and development in this area.

The construction industry is also showing interest in PMMA nanotechnology applications, particularly for smart windows and energy-efficient building materials. The ability to incorporate nanoparticles that respond to environmental changes, such as temperature or light, opens up possibilities for adaptive and energy-saving building components.

Environmental concerns and sustainability initiatives are further fueling market demand for PMMA nanotechnology applications. Research is ongoing to develop biodegradable PMMA nanocomposites and improve recycling processes, addressing the growing consumer and regulatory pressure for more environmentally friendly materials.

As the global nanotechnology market continues to expand, the demand for advanced PMMA applications is expected to grow alongside it. Market analysts project steady growth in the coming years, with particular emphasis on healthcare, electronics, and automotive applications. However, challenges such as high production costs and regulatory hurdles may impact market penetration rates in certain sectors.

Technical Challenges

Despite the promising advancements in PMMA nanotechnology applications, several technical challenges persist, hindering its full potential in various industries. One of the primary obstacles is the difficulty in achieving uniform dispersion of nanoparticles within the PMMA matrix. This challenge arises from the tendency of nanoparticles to agglomerate due to their high surface energy, which can lead to inconsistent material properties and reduced performance.

Another significant hurdle is the optimization of the interface between PMMA and nanoparticles. Achieving strong interfacial bonding is crucial for enhancing the mechanical and thermal properties of nanocomposites. However, the hydrophobic nature of PMMA often results in poor compatibility with many types of nanofillers, necessitating the development of effective surface modification techniques.

The scalability of PMMA nanocomposite production presents a formidable challenge. While laboratory-scale synthesis has shown promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and properties remains a significant technical barrier. This includes issues related to process control, quality assurance, and cost-effectiveness in large-scale production.

Thermal stability is another area of concern in PMMA nanotechnology applications. Although the incorporation of nanoparticles can improve thermal properties, achieving a balance between enhanced thermal resistance and maintaining other desirable characteristics of PMMA, such as optical clarity, is a complex task that requires further research and development.

The long-term stability and durability of PMMA nanocomposites in various environmental conditions pose additional challenges. Factors such as UV exposure, moisture, and temperature fluctuations can potentially degrade the material properties over time, necessitating the development of strategies to enhance the longevity and reliability of these advanced materials.

Furthermore, the characterization and quality control of PMMA nanocomposites present unique challenges. Developing standardized testing methods and protocols for assessing the distribution, orientation, and interactions of nanoparticles within the PMMA matrix is essential for ensuring consistent performance and facilitating widespread adoption of these materials.

Lastly, addressing environmental and health concerns associated with the production and use of PMMA nanocomposites is a critical challenge. This includes developing eco-friendly synthesis methods, ensuring the safe handling of nanomaterials during manufacturing, and assessing the potential long-term environmental impact of these advanced materials throughout their lifecycle.

Another significant hurdle is the optimization of the interface between PMMA and nanoparticles. Achieving strong interfacial bonding is crucial for enhancing the mechanical and thermal properties of nanocomposites. However, the hydrophobic nature of PMMA often results in poor compatibility with many types of nanofillers, necessitating the development of effective surface modification techniques.

The scalability of PMMA nanocomposite production presents a formidable challenge. While laboratory-scale synthesis has shown promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and properties remains a significant technical barrier. This includes issues related to process control, quality assurance, and cost-effectiveness in large-scale production.

Thermal stability is another area of concern in PMMA nanotechnology applications. Although the incorporation of nanoparticles can improve thermal properties, achieving a balance between enhanced thermal resistance and maintaining other desirable characteristics of PMMA, such as optical clarity, is a complex task that requires further research and development.

The long-term stability and durability of PMMA nanocomposites in various environmental conditions pose additional challenges. Factors such as UV exposure, moisture, and temperature fluctuations can potentially degrade the material properties over time, necessitating the development of strategies to enhance the longevity and reliability of these advanced materials.

Furthermore, the characterization and quality control of PMMA nanocomposites present unique challenges. Developing standardized testing methods and protocols for assessing the distribution, orientation, and interactions of nanoparticles within the PMMA matrix is essential for ensuring consistent performance and facilitating widespread adoption of these materials.

Lastly, addressing environmental and health concerns associated with the production and use of PMMA nanocomposites is a critical challenge. This includes developing eco-friendly synthesis methods, ensuring the safe handling of nanomaterials during manufacturing, and assessing the potential long-term environmental impact of these advanced materials throughout their lifecycle.

Current PMMA Solutions

01 PMMA-based composite materials

PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for different applications.- PMMA-based composite materials: PMMA is used as a base material in various composite formulations to enhance properties such as strength, durability, and thermal stability. These composites often incorporate other materials like nanoparticles, fibers, or other polymers to achieve specific characteristics for applications in industries such as automotive, construction, and electronics.

- PMMA in optical applications: PMMA is widely used in optical applications due to its excellent light transmission properties and ease of processing. It is utilized in the production of lenses, optical fibers, light guides, and display screens. Modifications to PMMA for optical purposes often focus on improving clarity, UV resistance, and scratch resistance.

- PMMA in medical and dental applications: PMMA finds extensive use in medical and dental fields due to its biocompatibility and moldability. It is used in the production of dental prosthetics, bone cements, contact lenses, and intraocular lenses. Research in this area often focuses on improving biocompatibility, wear resistance, and antimicrobial properties.

- PMMA processing and manufacturing techniques: Various processing and manufacturing techniques are employed to produce PMMA products, including injection molding, extrusion, and 3D printing. Research in this area focuses on improving processing efficiency, reducing defects, and developing new manufacturing methods to expand the range of possible PMMA applications.

- PMMA surface modifications and coatings: Surface modifications and coatings are applied to PMMA to enhance its properties such as scratch resistance, hydrophobicity, and adhesion. These modifications can involve chemical treatments, plasma processing, or the application of thin films. Such techniques are used to tailor PMMA surfaces for specific applications in industries like automotive, electronics, and consumer goods.

02 PMMA in optical applications

PMMA is widely used in optical applications due to its excellent light transmission properties and ease of processing. It is utilized in the production of lenses, light guides, and other optical components for various industries including automotive, electronics, and medical devices.Expand Specific Solutions03 PMMA in biomedical applications

PMMA finds extensive use in biomedical applications due to its biocompatibility and versatility. It is used in the production of dental implants, bone cements, contact lenses, and drug delivery systems. Research focuses on improving its properties for specific medical uses.Expand Specific Solutions04 PMMA processing techniques

Various processing techniques are employed to manufacture PMMA products, including injection molding, extrusion, and 3D printing. Research in this area focuses on optimizing these processes to improve product quality, reduce production time, and enhance material properties.Expand Specific Solutions05 PMMA surface modifications

Surface modification techniques are applied to PMMA to alter its properties for specific applications. These modifications can improve adhesion, hydrophobicity, or introduce functional groups for further reactions. Methods include plasma treatment, chemical etching, and coating applications.Expand Specific Solutions

Key Industry Players

The field of PMMA nanotechnology applications is in a growth phase, with increasing market size and technological advancements. The global market for PMMA nanocomposites is expanding, driven by demand in various sectors such as electronics, automotive, and healthcare. Technological maturity varies across applications, with some areas more developed than others. Key players like Tianjin University, Kingfa Sci. & Tech. Co., Ltd., and Wanhua Chemical Group Co., Ltd. are contributing to research and development in this field. Universities such as Fudan and Tsinghua are also actively involved in advancing PMMA nanotechnology. The industry is seeing a blend of academic research and commercial applications, indicating a promising future for PMMA nanotechnology.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has made significant strides in PMMA nanotechnology applications, particularly in the development of high-performance nanocomposites. Their research focuses on incorporating various nanofillers, such as carbon nanotubes and graphene, into PMMA matrices to enhance mechanical and thermal properties[5]. The company has developed a proprietary dispersion technique that ensures uniform distribution of nanoparticles, resulting in improved material performance[6]. Kingfa's PMMA nanocomposites have shown a 30% increase in tensile strength and a 25% improvement in heat deflection temperature compared to conventional PMMA[7]. They have also explored the use of PMMA-based nanocomposites in 3D printing applications, developing filaments with enhanced properties for rapid prototyping and manufacturing[8].

Strengths: Strong focus on industrial applications, diverse product portfolio, and established presence in Asian markets. Weaknesses: Potential challenges in global market expansion and competition with established Western companies.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant advances in PMMA nanotechnology applications, focusing on the development of functional PMMA nanocomposites. Their research has led to the creation of PMMA materials with enhanced flame retardancy by incorporating nano-sized flame retardant additives[9]. The company has also developed a novel process for producing PMMA nanofibers with high surface area and porosity, suitable for filtration and separation applications[10]. Wanhua's PMMA nanocomposites have demonstrated improved impact resistance and weatherability, making them ideal for outdoor applications in construction and automotive industries[11]. Additionally, they have explored the use of PMMA-based nanocoatings with self-cleaning and anti-fouling properties, potentially revolutionizing surface treatments in various sectors[12].

Strengths: Vertically integrated production capabilities, strong presence in Asian markets, and diversified product portfolio. Weaknesses: Potential regulatory challenges in expanding to Western markets and competition from established global players.

Core PMMA Innovations

A method for the production of poly(methyl methacrylate) (PMMA) membranes and uses thereof

PatentInactiveEP3359285A1

Innovation

- A method for producing highly porous, symmetric reticulated PMMA membranes using a thin film casting and solvent removal process, combined with hydrophilization techniques, to create a composite membrane with enhanced capillary flow and protein binding capacity, overcoming the limitations of previous PMMA membrane production methods.

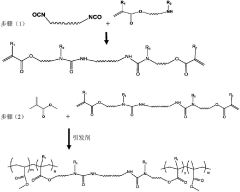

Preparation method of partially crosslinked PMMA (polymethyl methacrylate) and composite material thereof

PatentActiveCN115785328A

Innovation

- Using the preparation method of partially cross-linked PMMA, an intermediate product is generated through the polyurea reaction of diisocyanate and hindered amine acrylate, and then undergoes free radical copolymerization with MMA monomer to form partially cross-linked PMMA, thereby enhancing the cross-linking degree of its molecular chain. , thereby improving tensile strength and toughness.

Environmental Impact

The environmental impact of PMMA nanotechnology applications is a critical aspect that requires thorough examination. As PMMA nanocomposites gain traction in various industries, their potential effects on ecosystems and human health become increasingly important. One significant advantage of PMMA nanocomposites is their potential to reduce environmental pollution. These materials often exhibit enhanced durability and resistance to degradation, which can lead to longer product lifespans and reduced waste generation.

However, the production and disposal of PMMA nanocomposites also raise concerns. The manufacturing process may involve the use of potentially harmful chemicals and energy-intensive procedures. This could contribute to increased carbon emissions and resource depletion if not managed properly. Additionally, the release of nanoparticles during the production, use, or disposal of PMMA nanocomposites poses potential risks to aquatic and terrestrial ecosystems.

The fate of PMMA nanoparticles in the environment is an area of ongoing research. Studies have shown that these particles can persist in water and soil, potentially accumulating in living organisms. While PMMA is generally considered non-toxic, the long-term effects of nano-sized PMMA particles on ecosystems and food chains are not yet fully understood. This uncertainty underscores the need for comprehensive life cycle assessments and risk evaluations.

Efforts to mitigate the environmental impact of PMMA nanotechnology applications are underway. Researchers are exploring green synthesis methods that utilize renewable resources and reduce the use of harmful solvents. Biodegradable PMMA nanocomposites are also being developed, which could significantly reduce the environmental burden associated with disposal. Furthermore, advancements in recycling technologies for PMMA nanocomposites are being pursued to promote a circular economy approach.

The regulatory landscape surrounding PMMA nanotechnology is evolving to address potential environmental risks. Governments and international organizations are working to establish guidelines for the safe production, use, and disposal of nanomaterials, including PMMA nanocomposites. These regulations aim to strike a balance between fostering innovation and protecting the environment.

As PMMA nanotechnology continues to advance, it is crucial to prioritize sustainable practices throughout the entire product lifecycle. This includes optimizing production processes, implementing effective waste management strategies, and investing in research to better understand and mitigate potential environmental impacts. By addressing these challenges, the benefits of PMMA nanotechnology can be realized while minimizing negative environmental consequences.

However, the production and disposal of PMMA nanocomposites also raise concerns. The manufacturing process may involve the use of potentially harmful chemicals and energy-intensive procedures. This could contribute to increased carbon emissions and resource depletion if not managed properly. Additionally, the release of nanoparticles during the production, use, or disposal of PMMA nanocomposites poses potential risks to aquatic and terrestrial ecosystems.

The fate of PMMA nanoparticles in the environment is an area of ongoing research. Studies have shown that these particles can persist in water and soil, potentially accumulating in living organisms. While PMMA is generally considered non-toxic, the long-term effects of nano-sized PMMA particles on ecosystems and food chains are not yet fully understood. This uncertainty underscores the need for comprehensive life cycle assessments and risk evaluations.

Efforts to mitigate the environmental impact of PMMA nanotechnology applications are underway. Researchers are exploring green synthesis methods that utilize renewable resources and reduce the use of harmful solvents. Biodegradable PMMA nanocomposites are also being developed, which could significantly reduce the environmental burden associated with disposal. Furthermore, advancements in recycling technologies for PMMA nanocomposites are being pursued to promote a circular economy approach.

The regulatory landscape surrounding PMMA nanotechnology is evolving to address potential environmental risks. Governments and international organizations are working to establish guidelines for the safe production, use, and disposal of nanomaterials, including PMMA nanocomposites. These regulations aim to strike a balance between fostering innovation and protecting the environment.

As PMMA nanotechnology continues to advance, it is crucial to prioritize sustainable practices throughout the entire product lifecycle. This includes optimizing production processes, implementing effective waste management strategies, and investing in research to better understand and mitigate potential environmental impacts. By addressing these challenges, the benefits of PMMA nanotechnology can be realized while minimizing negative environmental consequences.

Regulatory Framework

The regulatory framework surrounding PMMA nanotechnology applications is complex and evolving, reflecting the rapid advancements in this field. Governments and international organizations are working to establish guidelines and standards to ensure the safe development and use of PMMA-based nanomaterials.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PMMA nanotechnology applications, particularly in medical devices and drug delivery systems. The FDA has issued guidance documents on the use of nanotechnology in FDA-regulated products, emphasizing the need for thorough safety assessments and characterization of nanomaterials.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to nanomaterials, including PMMA-based nanoparticles. Under REACH, manufacturers and importers are required to register substances produced or imported in quantities of one tonne or more per year, providing detailed information on their properties and potential risks.

Japan has established the "Guidelines for Ensuring the Safety of Nanomaterials" through its Ministry of Health, Labour and Welfare. These guidelines provide a framework for risk assessment and management of nanomaterials, including those based on PMMA, in various applications.

International organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) have been actively developing guidelines and standards for nanotechnology. The OECD's Working Party on Manufactured Nanomaterials (WPMN) has published numerous reports and guidance documents on the safety assessment of nanomaterials, including those relevant to PMMA applications.

Regulatory challenges persist in the field of PMMA nanotechnology. One key issue is the lack of standardized testing methods for assessing the safety and environmental impact of PMMA nanoparticles. Efforts are underway to develop and validate such methods, but progress has been slow due to the complexity of nanomaterial behavior in different environments.

Another challenge is the need for specific regulations addressing the unique properties of nanomaterials. Many existing regulations were not designed with nanotechnology in mind, leading to potential gaps in oversight. Regulatory bodies are working to adapt existing frameworks and develop new ones to address these challenges.

As PMMA nanotechnology applications continue to advance, it is likely that regulatory frameworks will evolve to keep pace. This may include the development of more specific guidelines for different applications, such as medical devices, drug delivery systems, and environmental remediation technologies. Stakeholders in the field must stay informed about these regulatory developments to ensure compliance and responsible innovation in PMMA nanotechnology applications.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PMMA nanotechnology applications, particularly in medical devices and drug delivery systems. The FDA has issued guidance documents on the use of nanotechnology in FDA-regulated products, emphasizing the need for thorough safety assessments and characterization of nanomaterials.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to nanomaterials, including PMMA-based nanoparticles. Under REACH, manufacturers and importers are required to register substances produced or imported in quantities of one tonne or more per year, providing detailed information on their properties and potential risks.

Japan has established the "Guidelines for Ensuring the Safety of Nanomaterials" through its Ministry of Health, Labour and Welfare. These guidelines provide a framework for risk assessment and management of nanomaterials, including those based on PMMA, in various applications.

International organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) have been actively developing guidelines and standards for nanotechnology. The OECD's Working Party on Manufactured Nanomaterials (WPMN) has published numerous reports and guidance documents on the safety assessment of nanomaterials, including those relevant to PMMA applications.

Regulatory challenges persist in the field of PMMA nanotechnology. One key issue is the lack of standardized testing methods for assessing the safety and environmental impact of PMMA nanoparticles. Efforts are underway to develop and validate such methods, but progress has been slow due to the complexity of nanomaterial behavior in different environments.

Another challenge is the need for specific regulations addressing the unique properties of nanomaterials. Many existing regulations were not designed with nanotechnology in mind, leading to potential gaps in oversight. Regulatory bodies are working to adapt existing frameworks and develop new ones to address these challenges.

As PMMA nanotechnology applications continue to advance, it is likely that regulatory frameworks will evolve to keep pace. This may include the development of more specific guidelines for different applications, such as medical devices, drug delivery systems, and environmental remediation technologies. Stakeholders in the field must stay informed about these regulatory developments to ensure compliance and responsible innovation in PMMA nanotechnology applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!